Workbench for garment processing

A technology of workbench and processing platform, which is applied in the field of garment processing, can solve problems such as inaccurate cutting, lack of measurement, and inconvenient marking of cloth size, and achieve the effect of promoting improvement and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

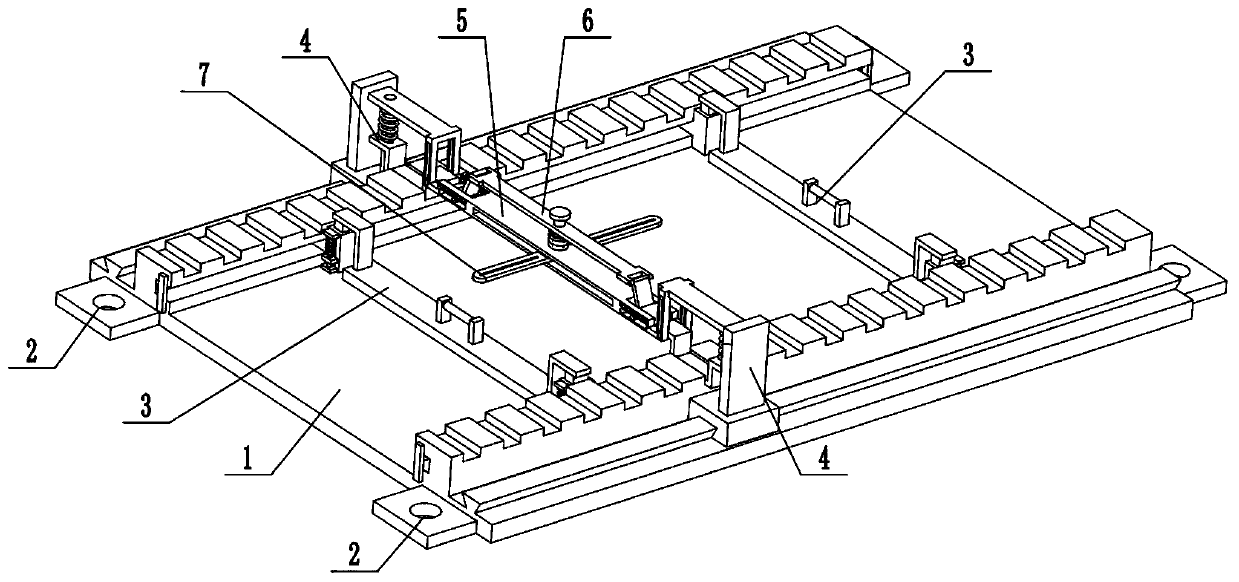

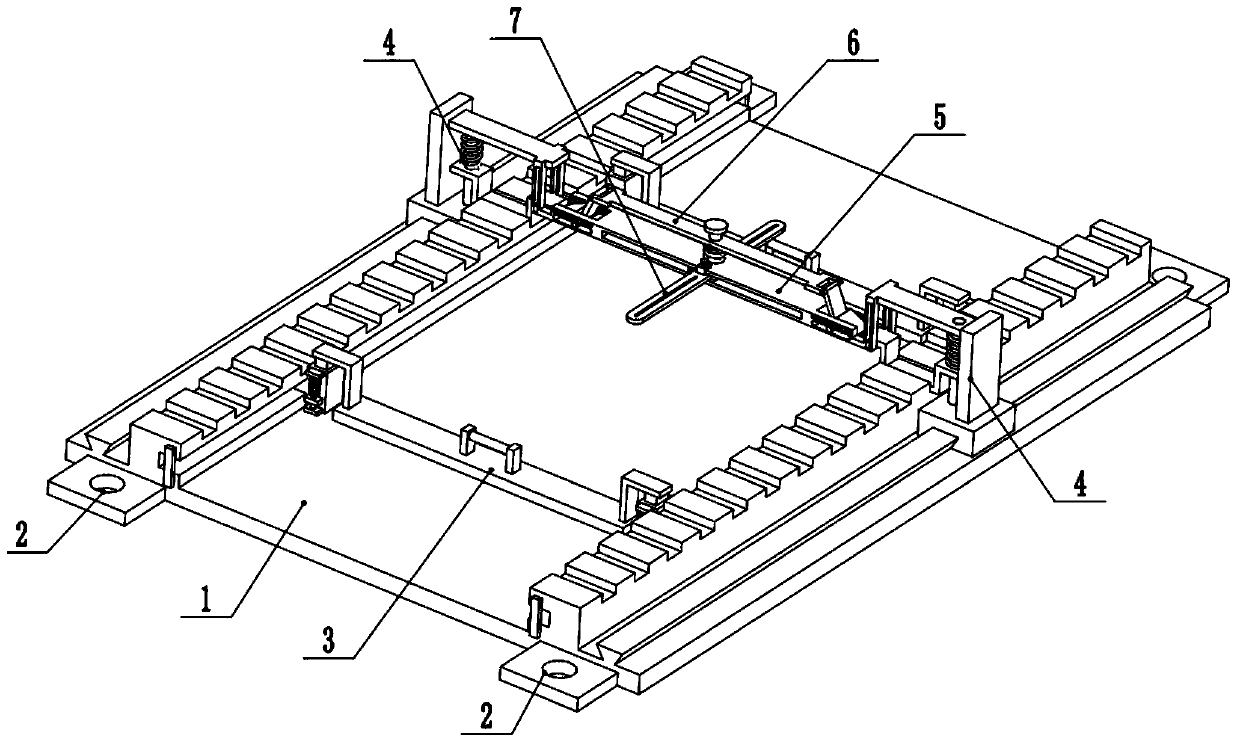

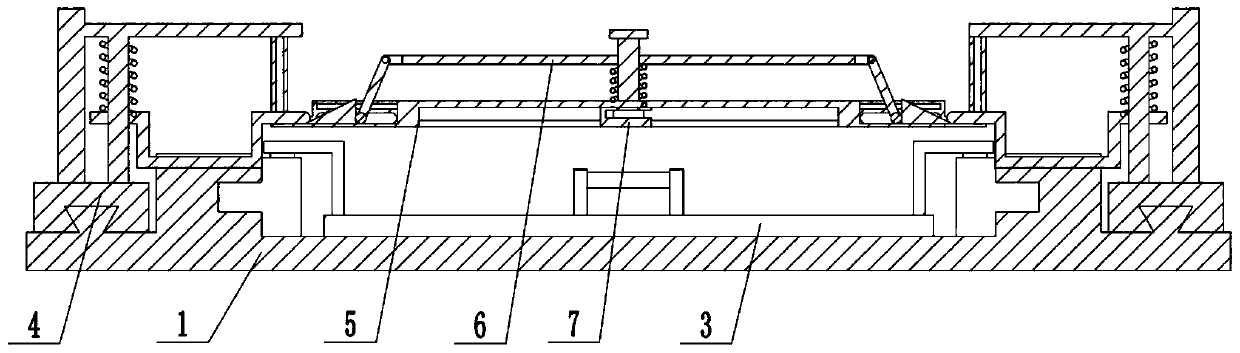

[0037] Combine below Figure 1-18 Describe this embodiment, a workbench for garment processing, including a processing platform assembly 1, a fixing seat 2, a smoothing and pressing cloth assembly 3, a positioning slide assembly 4, a vertical scale assembly 5, a vertical measurement adjustment assembly 6 and a horizontal There are two scale components 7, the described flattening and pressing cloth assembly 3 are provided with two, and the two flattening and pressing cloth assemblies 3 are symmetrically slidably connected to the left and right ends of the processing platform assembly 1, and there are two positioning slide assembly 4, The two positioning slide assemblies 4 are symmetrically slidably connected to the front and rear ends of the processing platform assembly 1, the vertical scale assembly 5 is fixedly connected between the two positioning slide assemblies 4, and the two ends of the vertical scale assembly 5 lean against the The inner sides of the two positioning sli...

specific Embodiment approach 2

[0038] Combine below Figure 1-18 To illustrate this embodiment, the workbench for garment processing also includes a fixed seat 2, and the four corners of the processing platform assembly 1 are respectively fixedly connected with a fixed seat 2, and the four fixed seats 2 are all provided with penetrating fixed seats. through hole. Fixing parts such as bolts and screws can be used to pass through the fixing through holes on the four fixing seats 2, so that the processing platform assembly 1 can be fixed at the corresponding position.

specific Embodiment approach 3

[0039] Combine below Figure 1-18 To illustrate this embodiment, the processing platform assembly 1 includes a processing platform body 1-1, a trapezoidal slide rail 1-2, a positioning seat 1-3, a positioning groove 1-4, an inner slide groove 1-5 and a limiting plate 1 -6; The four corners of the processing platform body 1-1 are respectively fixedly connected with a fixed seat 2, and the front and rear ends of the processing platform body 1-1 are respectively fixedly connected with a positioning seat 1-3, and two positioning seats 1-3 A plurality of positioning grooves 1-4 are uniformly arranged respectively, and an inner chute 1-5 is respectively arranged on the inner side surfaces of the two positioning seats 1-3; the outer ends of the front and rear ends of the processing platform body 1-1 are fixedly connected with one The trapezoidal slide rail 1-2; the left and right ends of the positioning seat 1-3 are respectively fixedly connected with a limiting plate 1-6, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com