Rapid and precise coating mechanism

A laminating mechanism and precise technology, applied in the directions of automatic packaging control, external support, transportation and packaging, etc., can solve problems such as damage to lamination efficiency, and achieve the effect of fast lamination, high efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

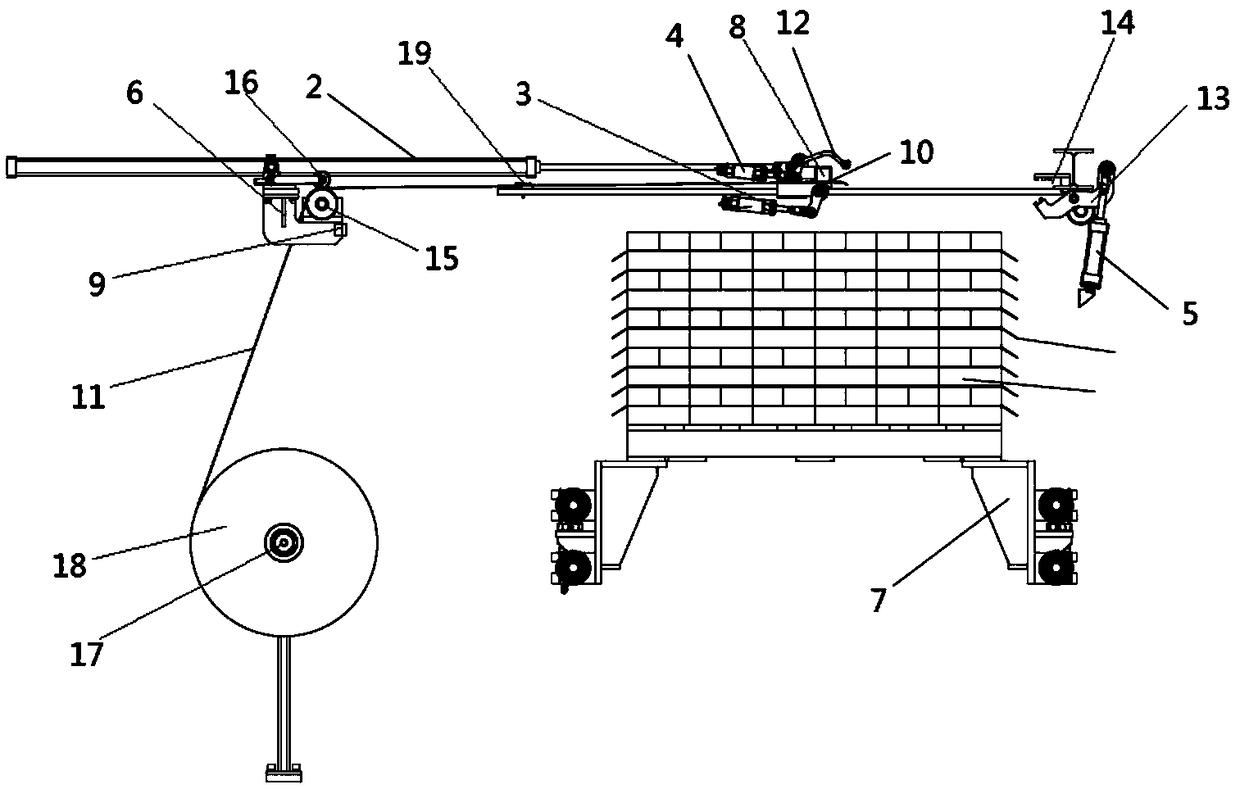

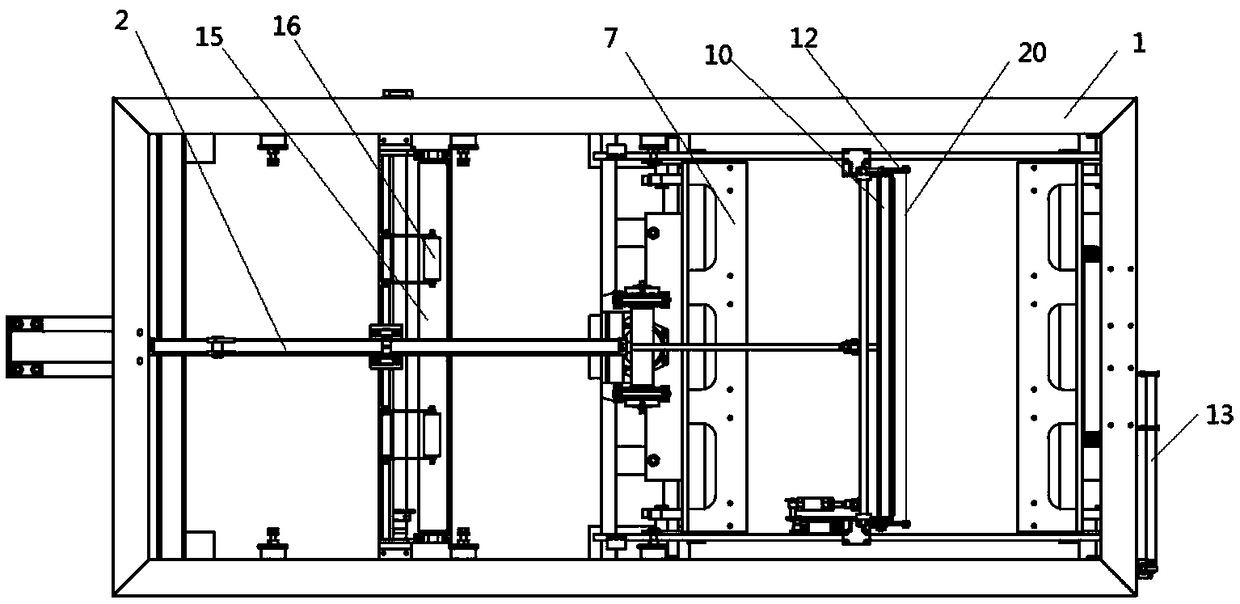

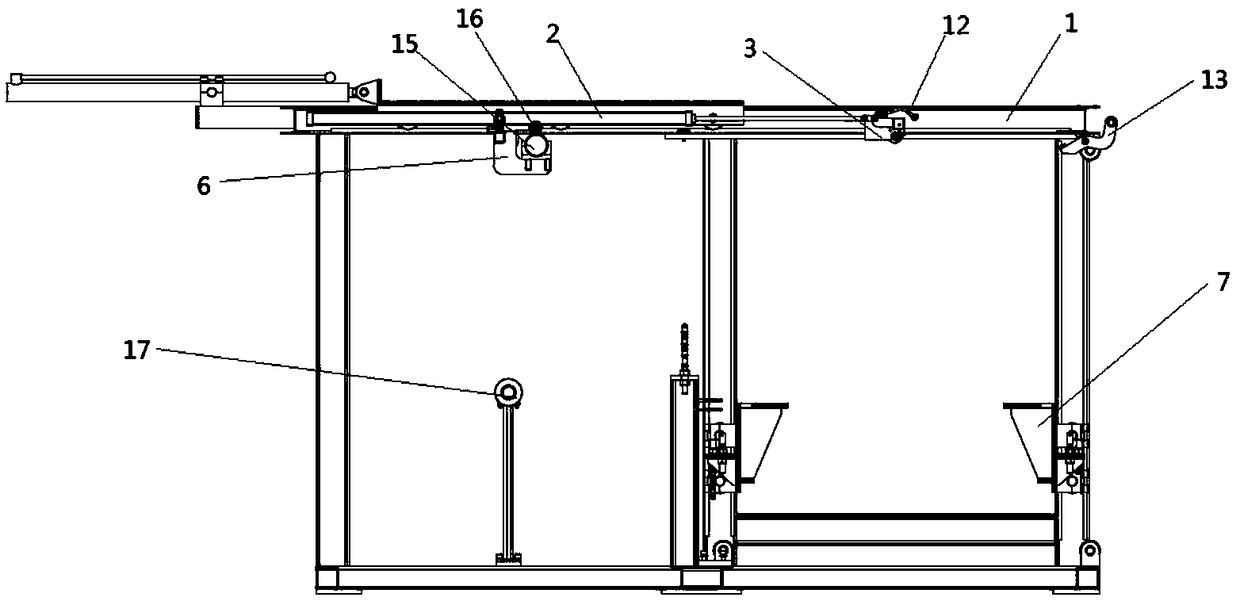

[0027] Such as Figure 1~4 As shown, the fast and precise lamination mechanism includes a frame 1, a film transfer component 2, a film feeding and holding film component 3, a cutting film component 4, a film holding component 5, a film guiding component 6, a brick lifting component 7, a transmission Film sensor 8, brick lifting sensor 9; said film passing assembly 2 is an air cylinder or a hydraulic cylinder, and said film passing assembly 2 is distributed in the middle part above the frame 1; said film sending and holding film assembly 3 includes a transmission device and a clamping Device 10, the width of the clamping device 10 is greater than the width of the film 11, which can prevent the film from falling during h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com