Method for scanning sheet-type work material and cutting pattern pieces therefrom

A technology for processing materials and patterns, applied in the field of cutting pattern blocks for processing materials, can solve problems such as time-consuming and time lag, and achieve the effect of minimizing the number of personnel and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

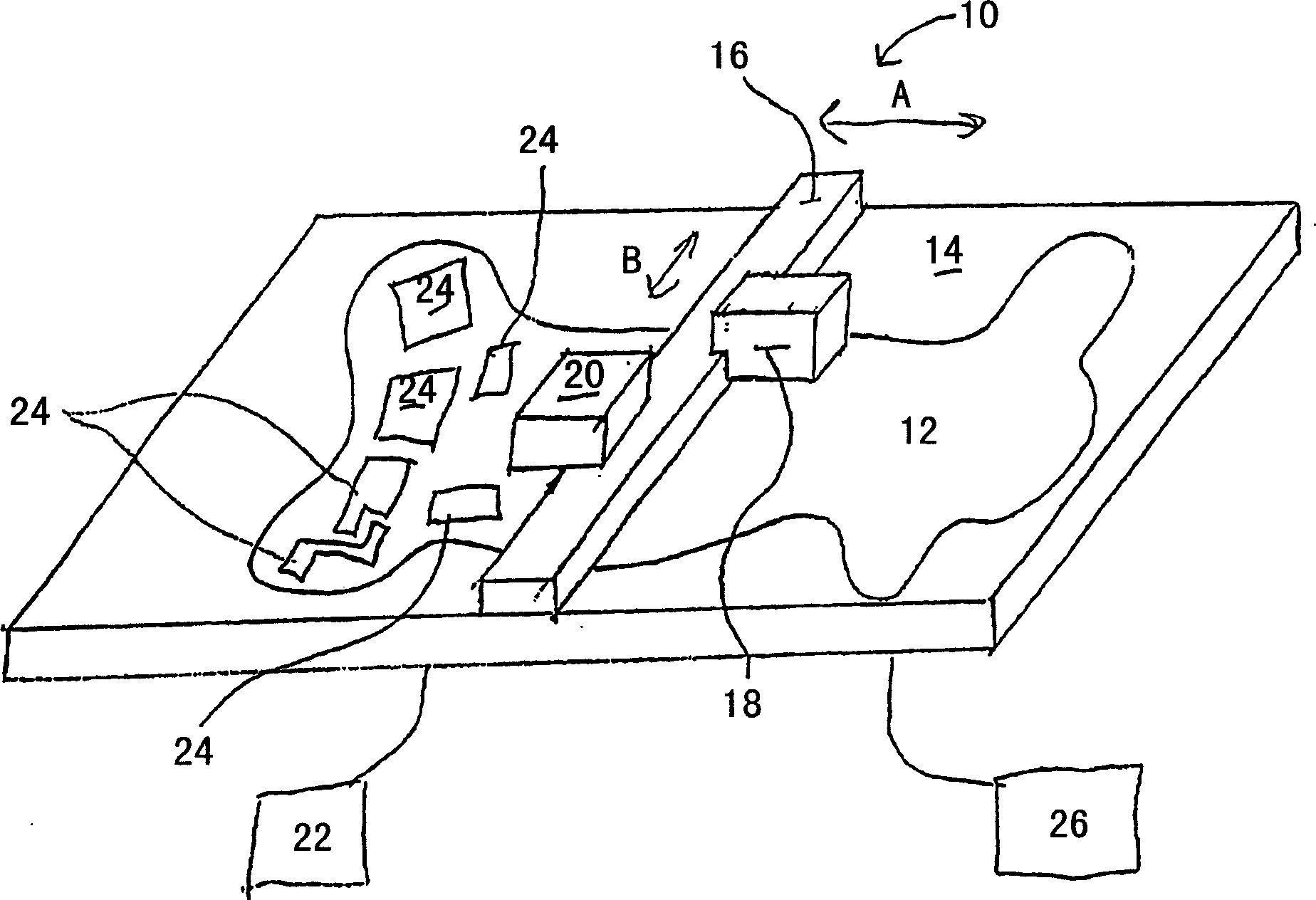

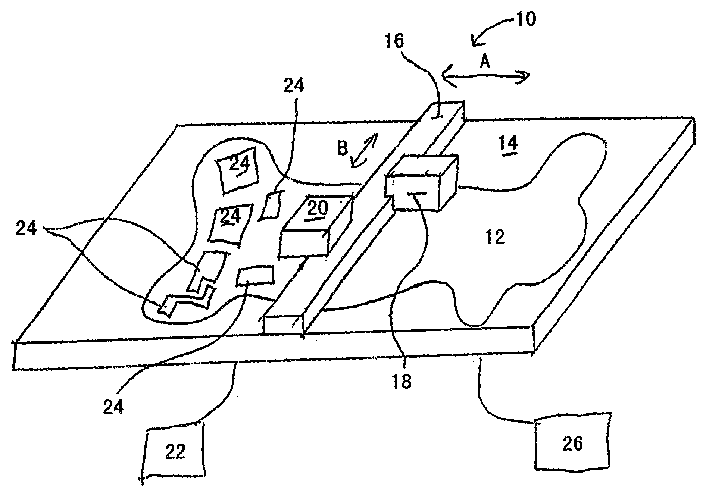

[0011] Such as figure 1 A scanning and cutting station, generally designated 10 throughout, is shown having a layer of sheet-like work material, in the illustrated embodiment leather 12 , resting on a support surface 14 . The scanning and cutting table 10 includes a carriage 16 mounted for longitudinally moving the cutting table back and forth along a first coordinate direction indicated by the arrow marked "A". The scanning head 18 is connected to the carriage 16 for moving back and forth along said carriage in a second coordinate direction indicated by the arrow indicated by "B". The second coordinate direction is substantially perpendicular to the first coordinate direction. Scanning head 18 includes suitable scanning means, such as but not limited to a camera, for scanning the surface of hide 12 to determine hide parameters and the location of any imperfections in the hide's surface. While leather has been shown and described, the invention is not so limited and other ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com