Efficient cutting device for leather production

An efficient and cutting technology, applied in the cutting field, can solve the problems of leather displacement and affecting the quality of cutting, and achieve the effect of avoiding displacement, improving cutting quality and wide applicability.

Inactive Publication Date: 2018-08-17

YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to solve the problem that the cutting device in the prior art generally does not have a clamping device and directly cuts the leather, which easily causes the displacement of the leather and thus affects the quality of the cutting. cutting device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

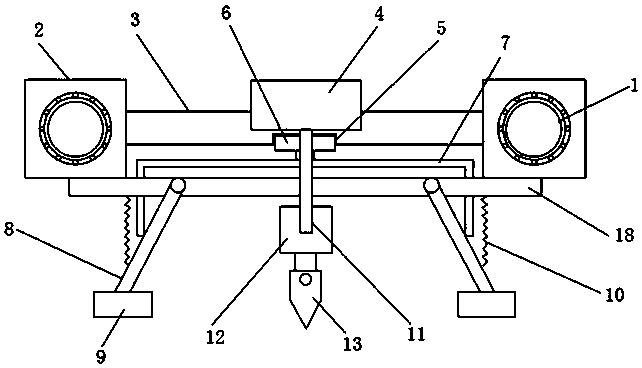

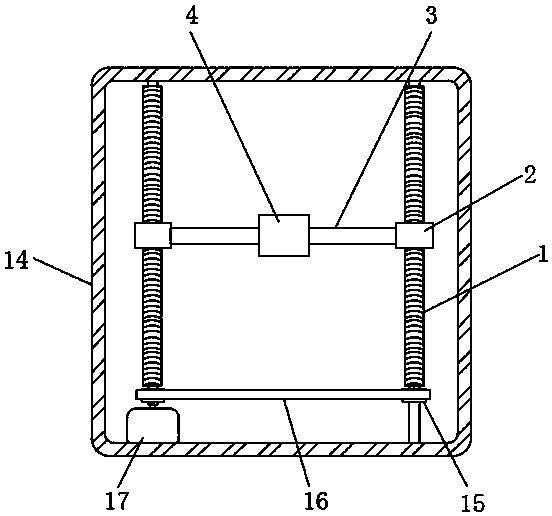

The invention discloses an efficient cutting device for leather production. The device comprises two parallel screws, the outer walls of the two screws are sleeved with ball nuts, the outer walls of the ball nuts are sleeved with moving blocks, a linear guide rail is jointly connected between the side walls of opposite sides of the two moving blocks, and comprises a guide rail body and a sliding block arranged on the outer wall of the guide rail body in a sleeving manner, a mounting opening is formed in the lower side wall of the guide rail body, a first air cylinder is arranged in the mounting opening, the drive end of the first air cylinder is connected with a U-shaped plate, the lower side walls of the two moving blocks are jointly connected with a connecting plate, and two rotating rods are rotatably connected with the lower side wall of the connecting plate. Leather can be clamped and then tailored through a pressing block, leather displacing during tailoring can be avoided, cutting quality is improved, meanwhile, through moving of the moving blocks and the sliding blocks, the leather with the proper length and width can be tailored, the adaptation is wider, the structure issimple, and the device is convenient and practical.

Description

technical field [0001] The invention relates to the technical field of cutting, in particular to a high-efficiency cutting device for leather production. Background technique [0002] The cutting device refers to a cutting machine that uses cutting to cut clothing fabrics. It is generally composed of a cutting bed, a metal liner, a cutting head, a transmission positioning device, a horizontal guide rail, a longitudinal guide rail and a cutter. The cutting device in the prior art is generally not equipped with a clamping device, and directly cuts the leather, which easily causes displacement of the leather, thereby affecting the quality of cutting. Contents of the invention [0003] The purpose of the present invention is to solve the problem that the cutting device in the prior art generally does not have a clamping device and directly cuts the leather, which easily causes the displacement of the leather and thus affects the quality of the cutting. Cutting device. [00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C14B5/00C14B17/06

CPCC14B5/00C14B17/06

Inventor 花金年

Owner YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com