Cutting method of leather materials and skiving machine for implementing same

A cutting method and skin cutting technology, which can be applied in the directions of small raw hide/big raw hide/leather/fur mechanical treatment, leather punching/punching/cutting, small raw hide/big raw hide/leather/fur treatment, etc., which can solve the problems that cannot be formed Personalized requirements and quick response to the market, soft leather is difficult to lay flat, difficult to ensure cutting accuracy and other issues, to achieve the effect of novel structure, smooth feeding, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

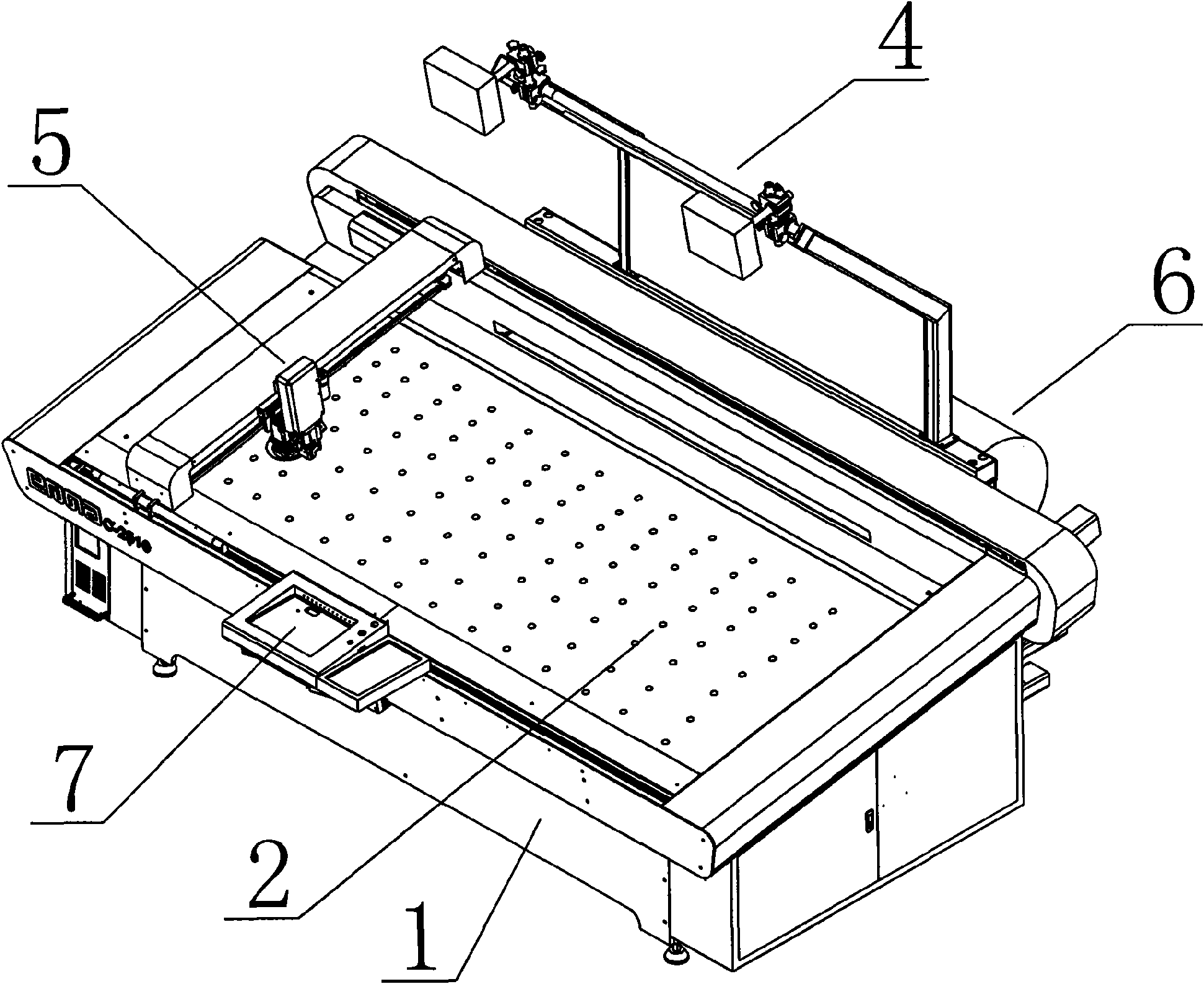

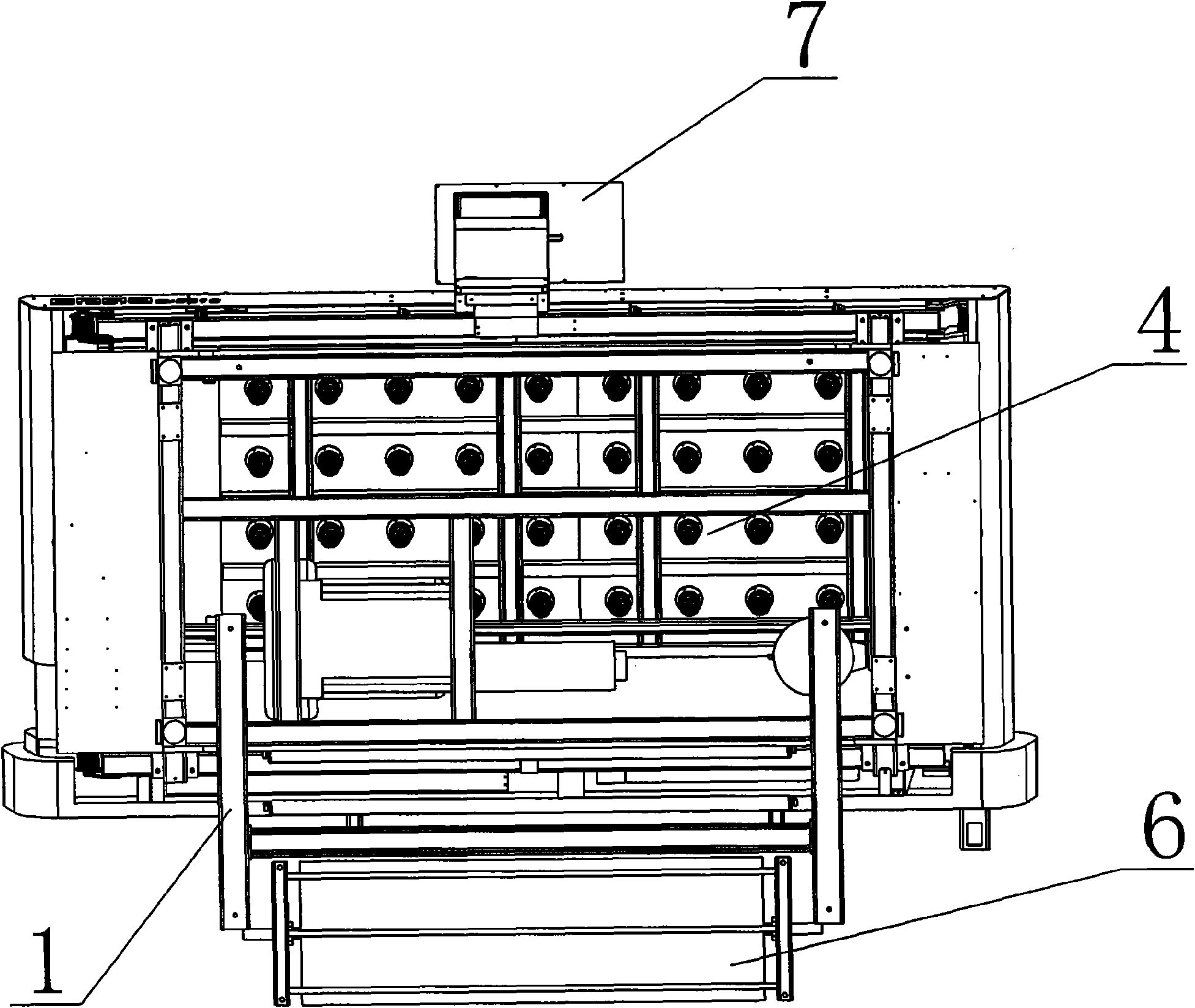

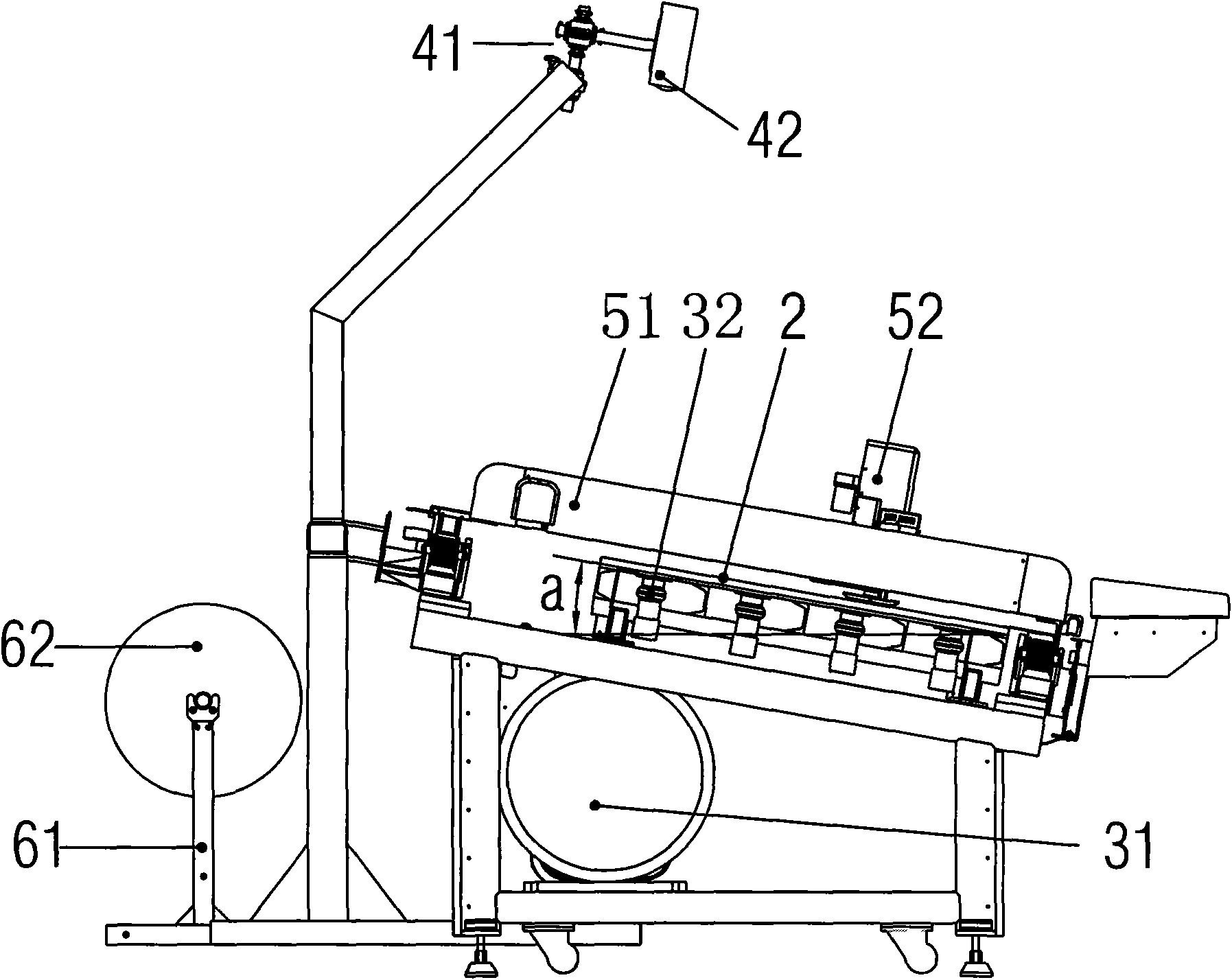

[0039] Example: see figure 1 , figure 2 and image 3 , a kind of leather material cutting method that the embodiment of the present invention provides, it comprises a frame 1 and a workbench 2 that is arranged on this frame 1, and it comprises the following steps:

[0040](1) An adsorption device 3 is arranged at the bottom of the workbench 2 to realize the adsorption and positioning of the leather to be cut on the workbench 2. The adsorption device 3 includes a vacuum pump 31, a blower assembly 32 and can be opened or closed. The solenoid valve of the air path between the vacuum pump 31 and the blower assembly 32 is controlled to realize the working or non-working state of the blower assembly 32;

[0041] The workbench 2 is divided into an auxiliary work area and an adsorption work area; the auxiliary work area is made of a MDF, and the adsorption work area is made of two adsorption flat plates and an anaerobic adhesive for galvanized punching mesh panels. It is bonded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com