Novel leather high speed cutting machine and cutting method

A cutting method and cutting machine technology, which are applied to leather punching/punching/cutting, small raw hides/large raw hides/leather/fur mechanical processing, small raw hides/large raw hides/leather/fur processing, etc., to save processing steps , Guaranteed quality, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

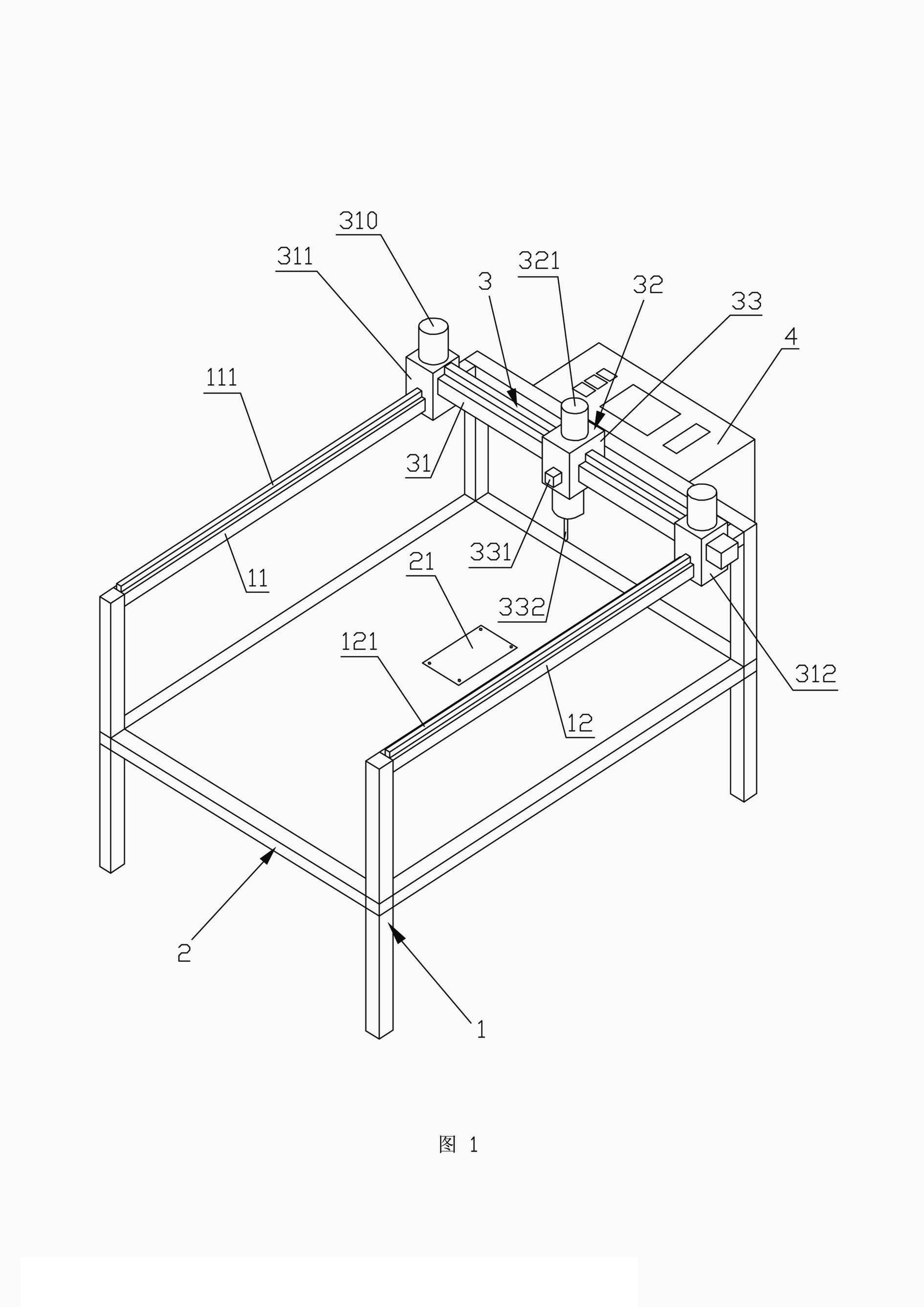

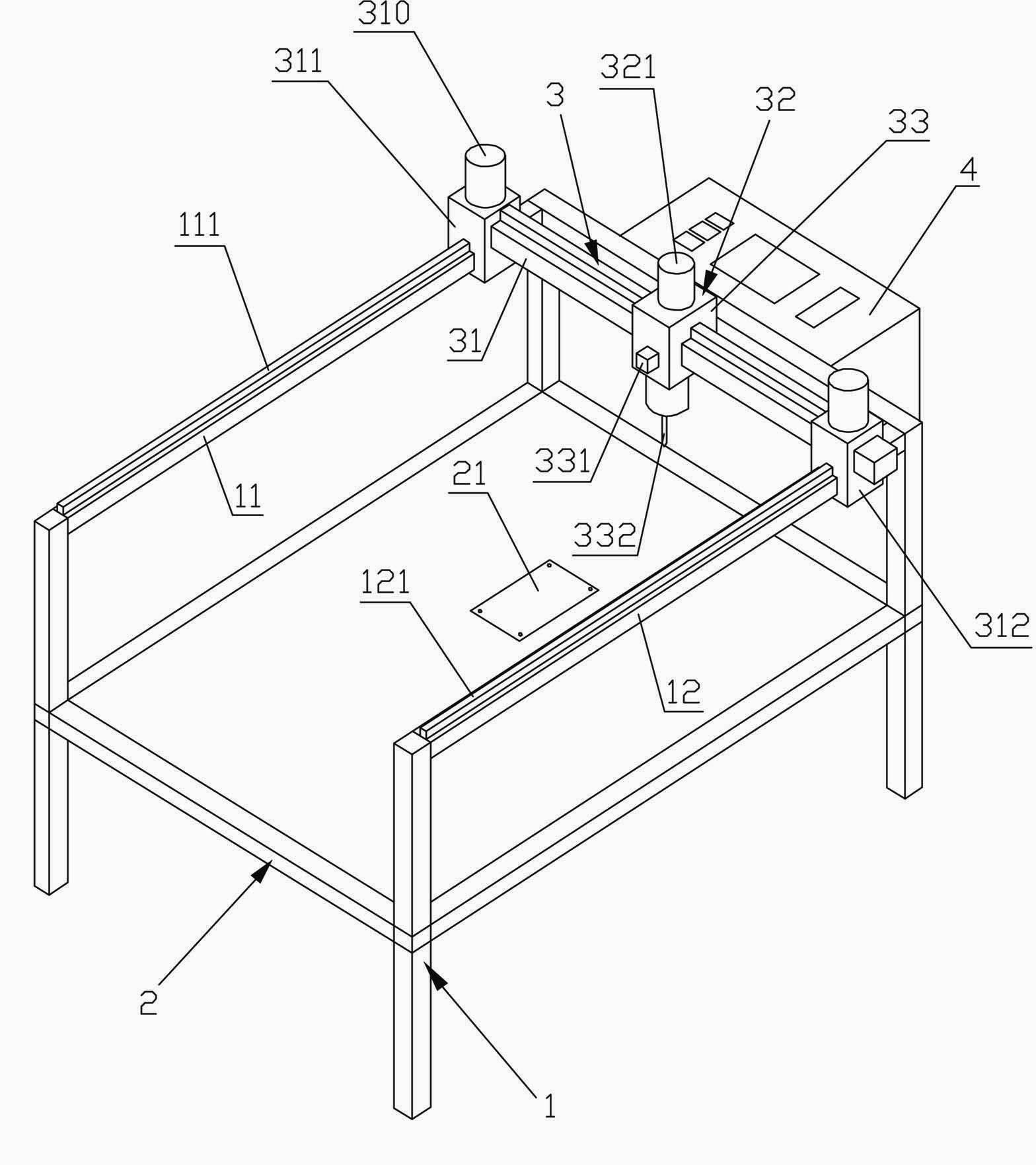

[0025] refer to figure 1 , a new type of leather high-speed cutting machine, including a frame 1, a workbench 2 set on the frame 1 and a cutting mechanism 3 erected on the frame 1 and above the workbench 2, and the workbench 2 is provided with Leather positioning plate 21, the cutting mechanism 3 includes a knife rest beam 31 and a longitudinal drive mechanism 310 that drives the knife rest beam 31 to slide back and forth on the frame 1, and the frame 1 is provided with left and right longitudinal supports 11, 12. The left and right longitudinal brackets 11 and 12 are provided with a left slide rail 111 and a right slide rail 121, and the two ends of the tool rest beam 31 are provided with left sliders matching the left and right slide rails 111 and 121 311, right slide block 312, described knife rest beam 31 is provided with cutter device 32 and lateral drive mechanism 321 that can slide left and right thereon, described cutter device 32 comprises a knife rest 33, is provided...

Embodiment 2

[0033] The main difference between this embodiment and Embodiment 1 is that the new leather high-speed cutting machine is provided with two parallel knife rest beams, the two knife rest beams are respectively provided with knife rests, and the knife heads and The rest of the laser head is the same as the first embodiment. The cutting head and the laser head of this embodiment can realize cutting of the leather material at the same time, which greatly improves the working efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com