A machine for cutting leathers

A cutting machine, leather technology, applied in leather punching/punching/cutting, small raw hide/large raw hide/leather/fur mechanical processing, raw hide/leather/fur manufacturing equipment, etc., can solve high labor costs, limit leather Cutting machine productivity and other issues to achieve the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

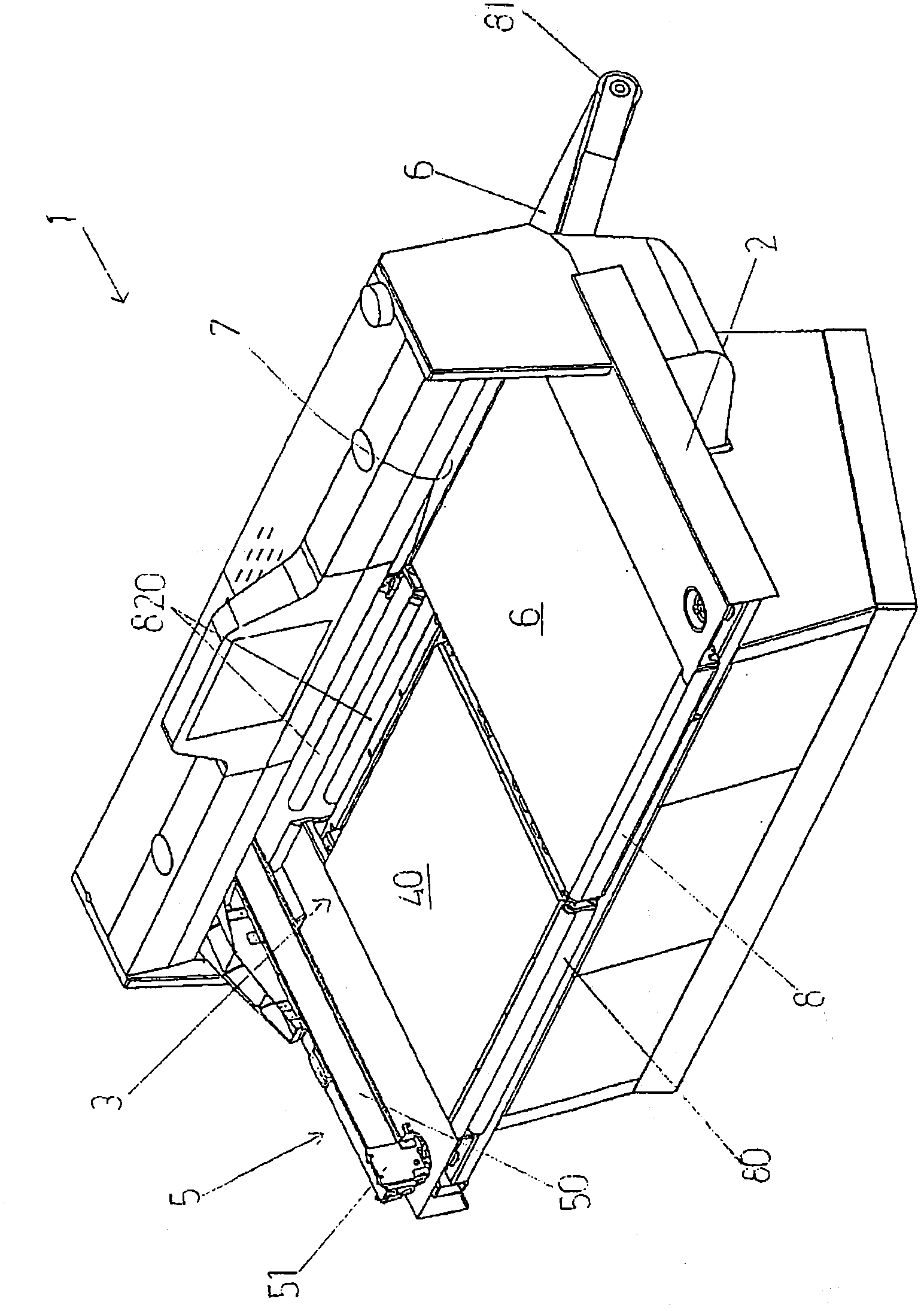

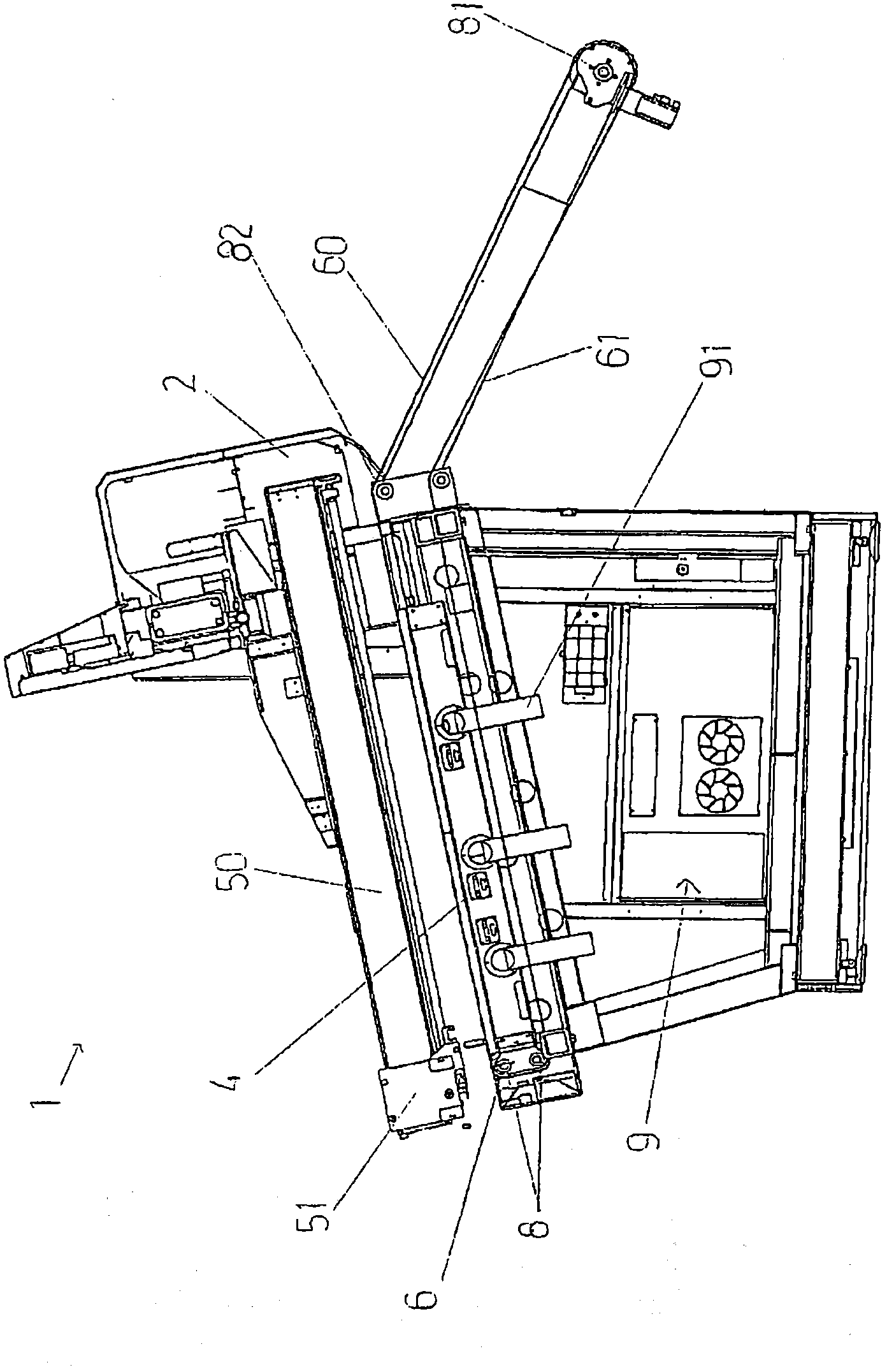

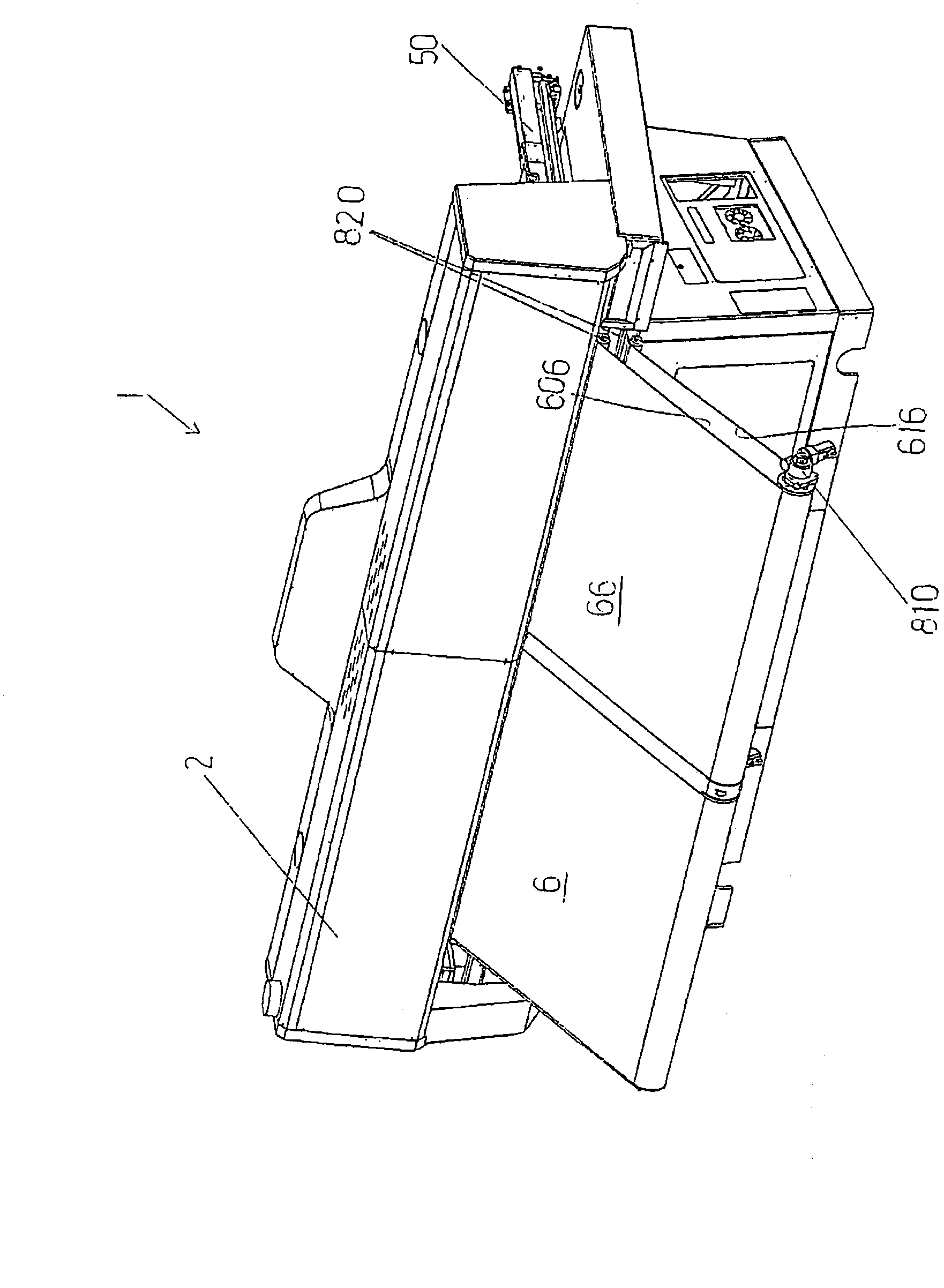

[0024] With reference to the attached figures, 1 generally indicates a leather cutting machine according to the invention.

[0025] The leather cutting machine 1 comprises: a structure 2 defining an operating area 3 in which the hides are to be placed and kept unfolded and stationary in order to allow the cutting operation; at least one suction plane 4, 40, It is arranged at the operating area 3 and is connected to a low pressure source 9 in order to keep the leather unrolled and stationary after activation of said low pressure source 9 .

[0026] The leather cutting machine 1 further comprises: a cutting unit 5, carried by the structure 2, arranged above the operation area 3 and movable relative to the operation area 3, so as to cut the Leather (ie the cut area of the leather completely coincides with the unfolded area of the leather).

[0027] The leather cutter 1 further comprises at least two closure strips 6, 66 made of permeable material and their sides abutting eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com