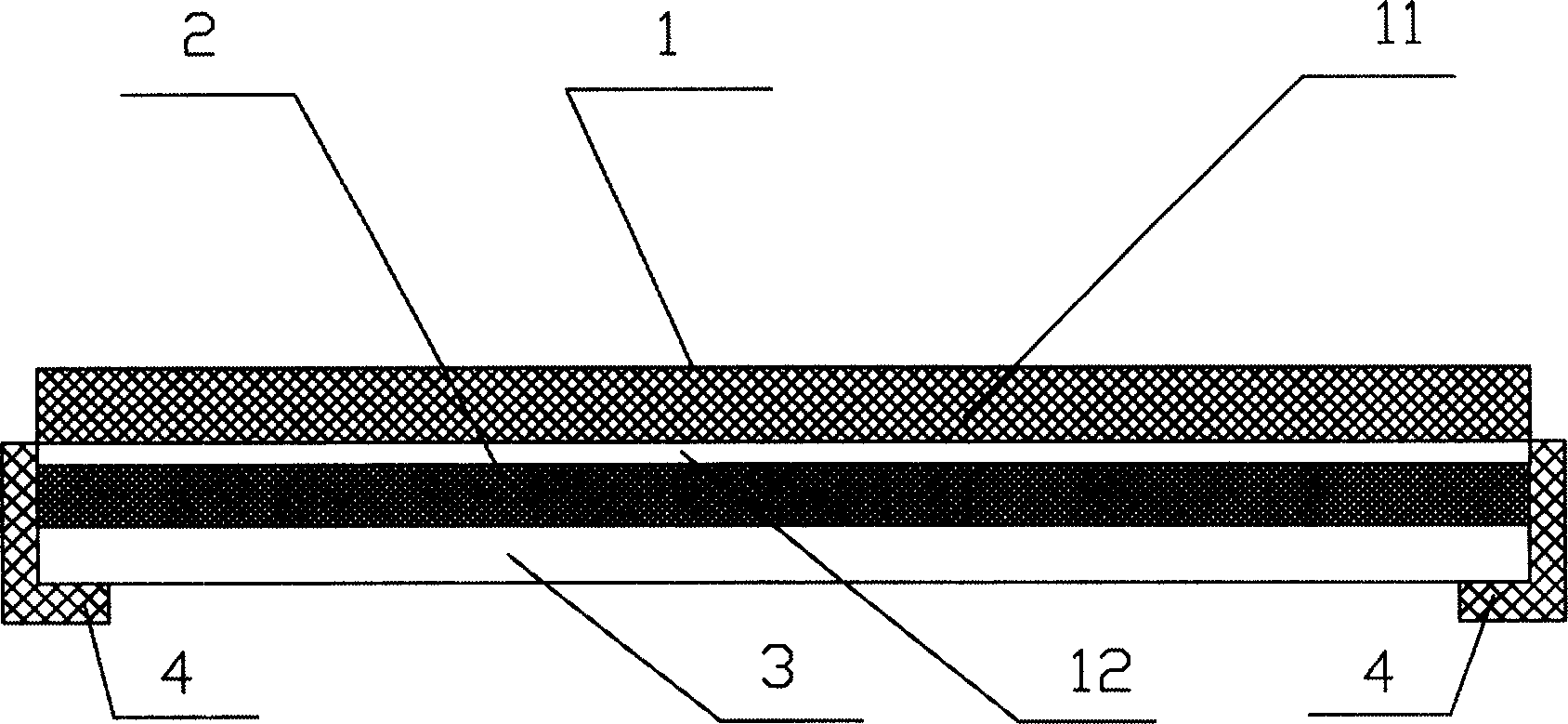

A woven back-cloth plastering carpet and method for manufacturing the same

A production method and carpet technology, applied to carpets, fleece products, fabrics, etc., can solve the problems of carpet fading, easy wear of the carpet surface, and easy peeling off of rubber or plastic, so as to achieve realistic patterns and even carpet surfaces , The effect of neat carpet edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The raw material is acrylic yarn combed and spun into yarns of 3 to 24 counts; the above-mentioned combed and spun yarns are punched into shaft yarns with a wire punching machine; polypropylene cloth is used as the base cloth, and the wool height is made on the loom. 2 mm, tufted original white carpet weighing 250 grams per square meter; use computer spraying on the front of the original white carpet to use cationic red X-GRL, cationic yellow X-GL, cationic blue X-GRRL as raw materials, on the white carpet surface Carpets with various patterns and different specifications and shapes are printed on them; the above-mentioned printed carpets are extruded by an infiltration machine with a pressure of 0.5MPa, so that the color paste penetrates into the two-thirds of the pile of the carpet, and the excess color Scrape off the pulp; use hot steam to fix the carpet in a steamer at 80°C for 20 minutes; add water to the detergent at a ratio of 1 / 100, and wash away floating stains ...

Embodiment 2

[0024] The raw material is wool yarn combed and spun into yarns of 3 to 24 counts; the above-mentioned combed and spun yarns are spun into bobbins with a wire punching machine; polypropylene cloth is used as the base cloth, and the wool height is made on the loom. 20 mm, 2000 grams per square meter loop pile original white carpet; using screen printing technology on the front of the original white carpet, using cationic red X-GRL, cationic yellow X-GL, cationic blue X-GRRL as raw materials, in Carpets of various patterns and shapes are printed on the white carpet surface; the above-mentioned printed carpets are extruded by a permeating machine with a pressure of 10 MPa, so that the color paste penetrates into the roots of the carpet fluff, and the excess color paste is scraped off; In a steamer at 120°C, use hot steam to fix the color of the carpet for 60 minutes; add water to the soda ash at a ratio of 1 / 1000, and the water temperature is at 50°C to wash away the floating colo...

Embodiment 3

[0026] The raw material is acrylic yarn combed and spun into yarns of 3 to 24 counts; the above-mentioned combed and spun yarns are punched into shaft yarns with a wire punching machine; polypropylene cloth is used as the base cloth, and the wool height is made on the loom. 10 mm, tufted original white carpet weighing 1,000 grams per square meter; use computer spraying on the front of the original white carpet to use cationic red X-GRL, cationic yellow X-GL, cationic blue X-GRRL as raw materials, on the white carpet surface Carpets with various patterns and different specifications and shapes are printed on them; the above-mentioned printed carpets are extruded by a 5MPa pressure infiltrator to make the color paste penetrate into the two-thirds of the pile height of the carpet, and the excess color paste Scrape off; in a 100°C steam box, use hot steam to fix the color of the carpet for 40 minutes; add water to the hydrosulfite, the ratio is 1 / 500, and the water temperature is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com