Al-Co grain refiner of Mg-Al-based alloy, preparation method and using method thereof

A technology of grain refiner and base alloy, applied in the field of grain refiner and its preparation, can solve the problems of complex preparation process of grain refiner, and achieve easy control of refining effect, easy control of addition amount, Preparation method and simple effect of using method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Metal aluminum and metal cobalt are mixed and batched, wherein the metal aluminum accounts for 30% of the mixed material by weight percentage, and the metal cobalt accounts for 70% of the mixed material by weight percentage to obtain the mixed metal.

[0029] The mixed metal is cleaned with an organic solvent under ultrasonic conditions with a frequency of 40KHz, and the cleaning time is 3 minutes, and the organic solvent is ethanol.

[0030] Put the cleaned mixed metal in the electric arc furnace, evacuate the electric arc furnace, and then fill it with argon until the air pressure in the electric arc furnace is 0.02MPa; the electric arc furnace is evacuated until the air pressure is 1×10 -3 MPa.

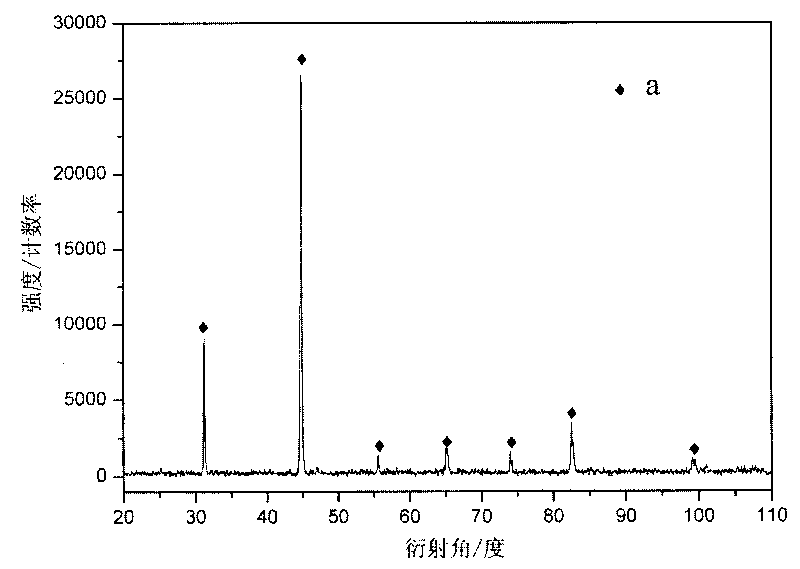

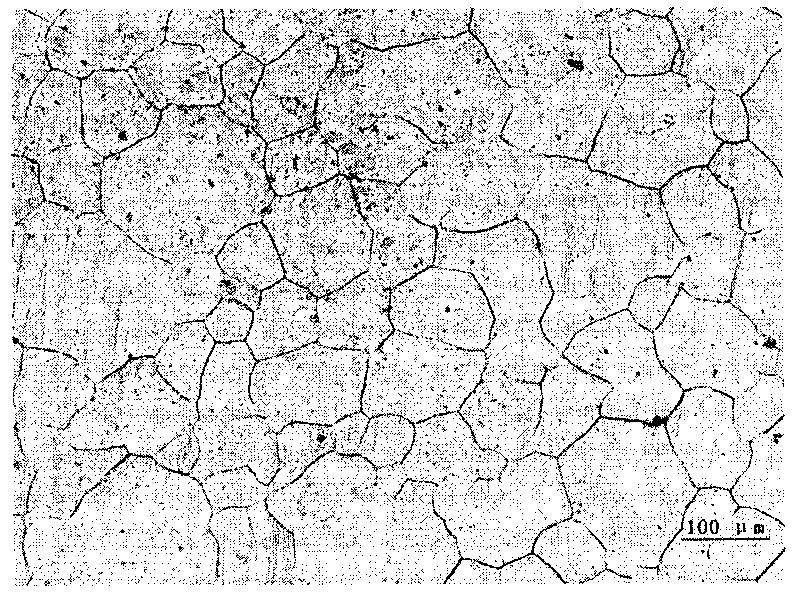

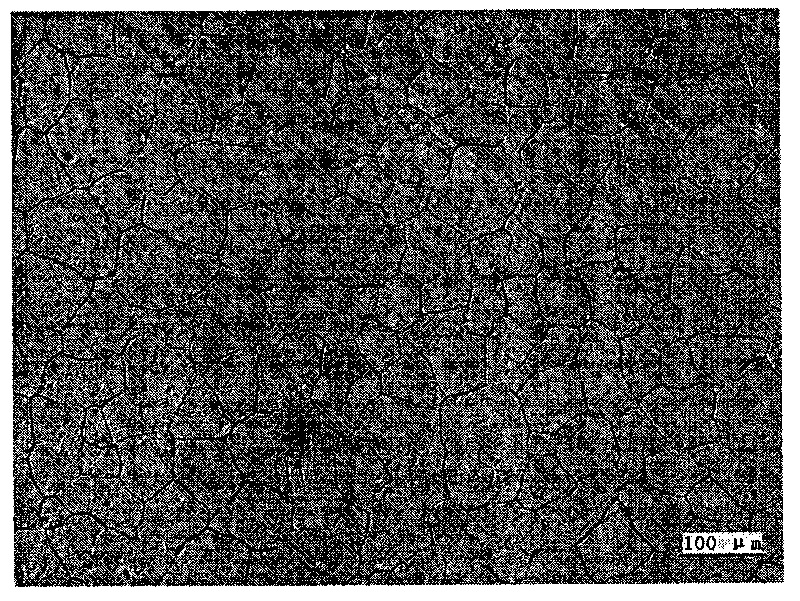

[0031] The mixed metal is smelted, the voltage applied during smelting is 45V, the current is 200A, the smelting time is 2min, and the smelting is repeated four times according to the above method; then physically broken into particles with a particle size of 25-35μm to obta...

Embodiment 2

[0038] Metal aluminum and metal cobalt are mixed and batched, wherein the metal aluminum accounts for 20% of the mixed material by weight percentage, and the metal cobalt accounts for 80% of the mixed material by weight percentage to obtain the mixed metal.

[0039] The mixed metal is cleaned with an organic solvent under ultrasonic conditions with a frequency of 60KHz, and the cleaning time is 5 minutes, and the organic solvent is ethanol.

[0040] Put the cleaned mixed metal in the electric arc furnace, evacuate the electric arc furnace, and then fill it with argon until the air pressure in the electric arc furnace is 0.04MPa; the electric arc furnace is evacuated until the air pressure is 5×10 -3 MPa.

[0041] The mixed metal is smelted, the voltage applied during smelting is 30V, the current is 270A, and the smelting time is 3min. Repeat the smelting four times according to the above method; then physically break into particles with a particle size of 25-35μm to obtain Al-...

Embodiment 3

[0046] Metal aluminum and metal cobalt are mixed and batched, wherein the metal aluminum accounts for 34% of the mixed material by weight percentage, and the metal cobalt accounts for 66% of the mixed material by weight percentage to obtain the mixed metal.

[0047] The mixed metal is cleaned with an organic solvent under ultrasonic conditions with a frequency of 50KHz, and the cleaning time is 4 minutes, and the organic solvent is acetone.

[0048] Put the cleaned mixed metal in the electric arc furnace, evacuate the electric arc furnace, and then fill it with argon until the air pressure in the electric arc furnace is 0.03MPa; the electric arc furnace is evacuated until the air pressure is 3×10 -3 MPa.

[0049] The mixed metal is smelted. The voltage applied during smelting is 20V, the current is 350A, and the smelting time is 2.5min. Repeat the smelting four times according to the above method; then physically break it into particles with a particle size of 25-35μm, and obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com