PVC and ASA co-extrusion profile and preparation method thereof

A technology of extruded profile and ASA resin, applied in the field of PVC and ASA co-extruded profile and its preparation, can solve the problems of insufficient weather resistance and mechanical properties, poor PVC fluidity, poor processing performance of PVC/PVC co-extruded profile, etc., to achieve High weather resistance and mechanical properties, good electrical insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

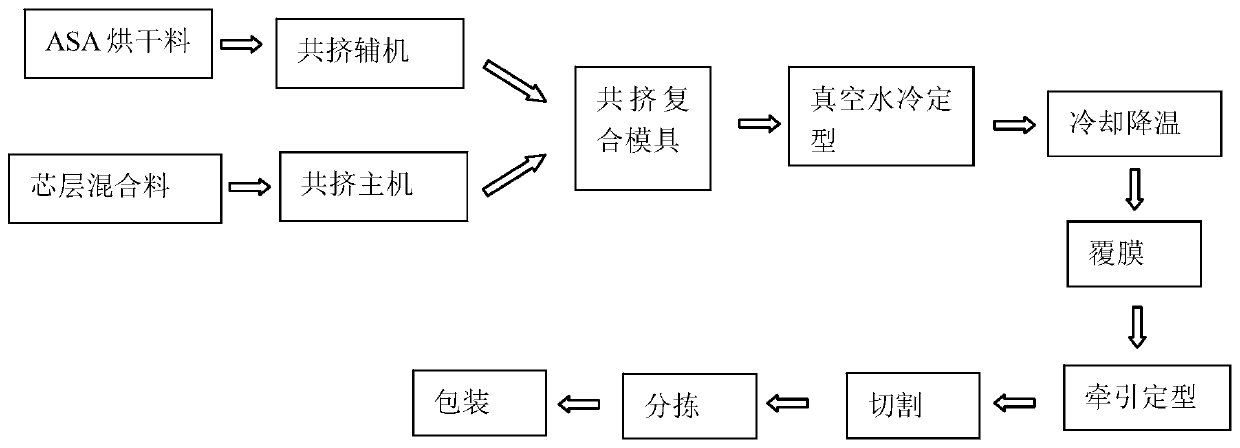

Method used

Image

Examples

Embodiment 1

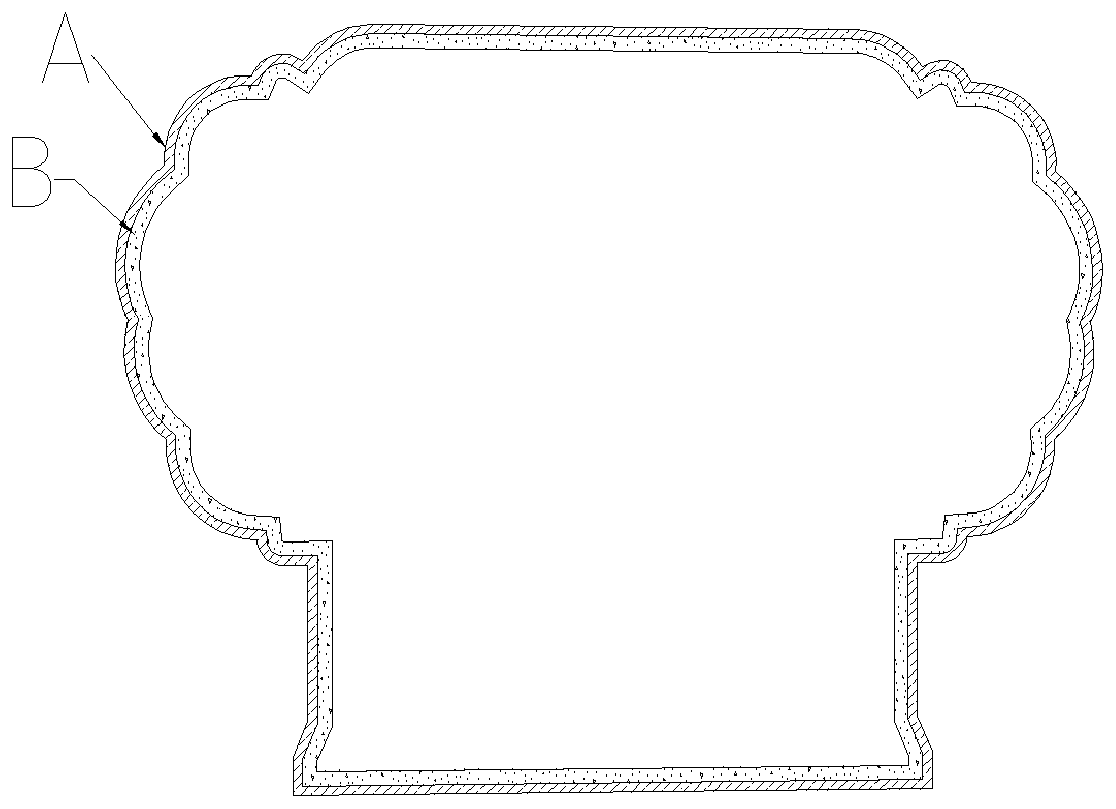

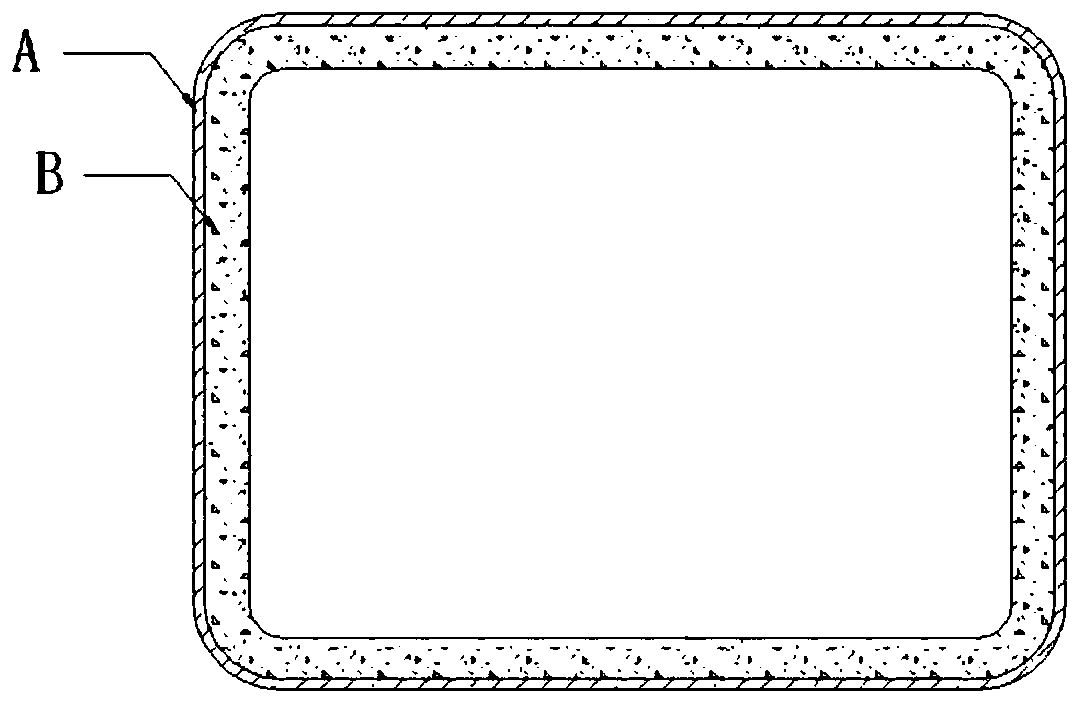

[0039] The PVC and ASA co-extruded profiles, including the core layer and the cortex, are made of the following raw materials in parts by mass:

[0040] Core material:

[0041]

[0042] Leather material:

[0043] ASA resin 12 parts.

[0044] The PVC resin is polyvinyl chloride resin SG-5, and the degree of polymerization is 1000. The ASA resin described above is a toughened ASA resin co-extrusion pellet produced by Wuhu Chuangke New Material Technology Co., Ltd., model BKBT1261Y.

[0045] The filler is light calcium carbonate with a particle size of 900 mesh; the heat stabilizer is a type of calcium-zinc composite heat stabilizer synthesized mainly with calcium stearate and zinc stearate.

[0046] The light stabilizer is rutile titanium dioxide; the antioxidant is a high-efficiency phenolic antioxidant.

[0047] The anti-violet modifier is an ultraviolet composite absorber, which is compounded by benzophenones and benzotriazole ultraviolet absorbers in a mass ratio of 1...

Embodiment 2

[0059] The PVC and ASA co-extruded profiles, including the core layer and the cortex, are made of the following raw materials in parts by mass:

[0060] Core material:

[0061]

[0062]

[0063] Leather material:

[0064] 15 parts of ASA resin.

[0065] The PVC resin is polyvinyl chloride resin SG-5, and the degree of polymerization is 1000. The ASA resin described above is a toughened ASA resin co-extrusion pellet produced by Wuhu Chuangke New Material Technology Co., Ltd., model BKBT1261Y.

[0066] The filler is light calcium carbonate with a particle size of 1000 meshes; the heat stabilizer is a type of calcium-zinc composite heat stabilizer synthesized mainly from calcium stearate and zinc stearate.

[0067] The light stabilizer is rutile titanium dioxide; the antioxidant is a high-efficiency phenolic antioxidant.

[0068] The anti-violet modifier is an ultraviolet composite absorber, which is compounded by benzophenones and benzotriazole ultraviolet absorbers in a...

Embodiment 3

[0080] The PVC and ASA co-extruded profiles, including the core layer and the cortex, are made of the following raw materials in parts by mass:

[0081] Core material:

[0082]

[0083] Leather material:

[0084] 20 parts of ASA resin.

[0085] The PVC resin is polyvinyl chloride resin SG-5, and the degree of polymerization is 1100. The ASA resin described above is a toughened ASA resin co-extrusion pellet produced by Wuhu Chuangke New Material Technology Co., Ltd., model BKBT1261Y.

[0086] The filler is light calcium carbonate with a particle size of 1300 mesh; the heat stabilizer is a type of calcium-zinc composite heat stabilizer synthesized mainly from calcium stearate and zinc stearate.

[0087] The light stabilizer is rutile titanium dioxide; the antioxidant is a high-efficiency phenolic antioxidant.

[0088] The anti-violet modifier is an ultraviolet composite absorber, which is compounded by benzophenones and benzotriazole ultraviolet absorbers in a mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com