A kind of environment-friendly water-based aluminum foil ink and preparation method thereof

A production method and water-based technology, which can be used in inks, applications, household appliances, etc., can solve problems such as worker health hazards and production environment impacts, and achieve the effects of clear printing patterns, reduced production costs, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

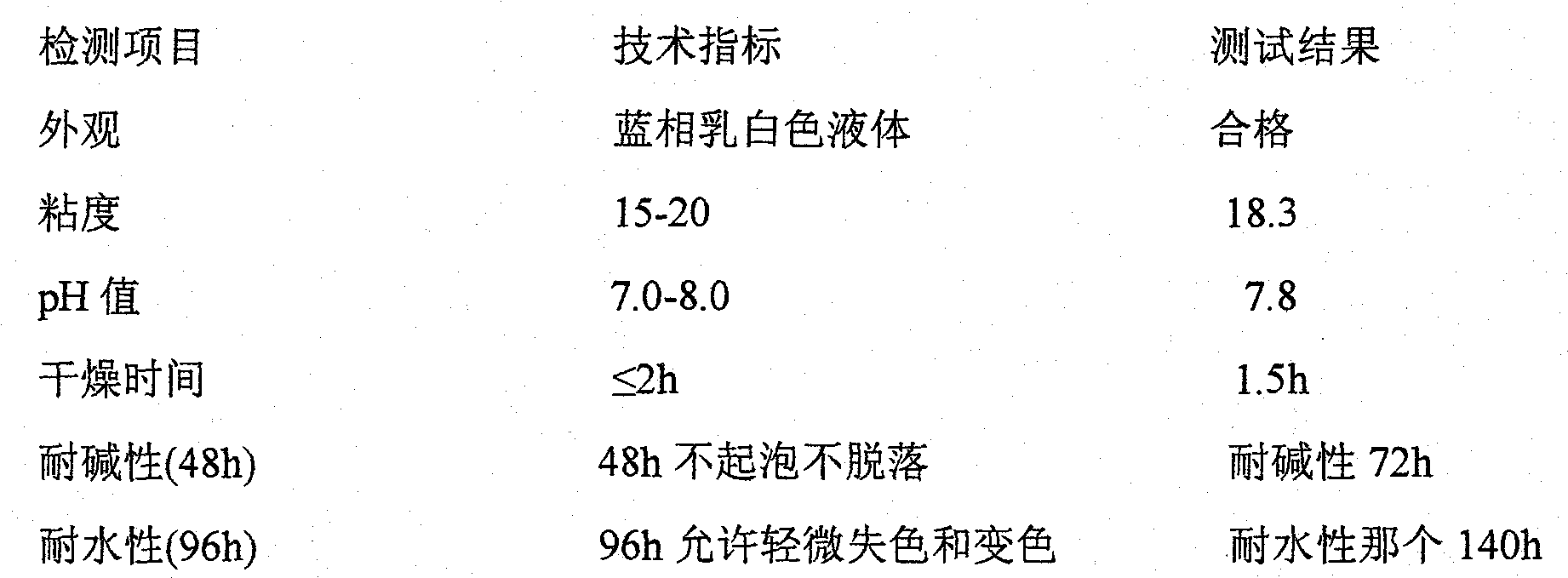

Examples

Embodiment 1

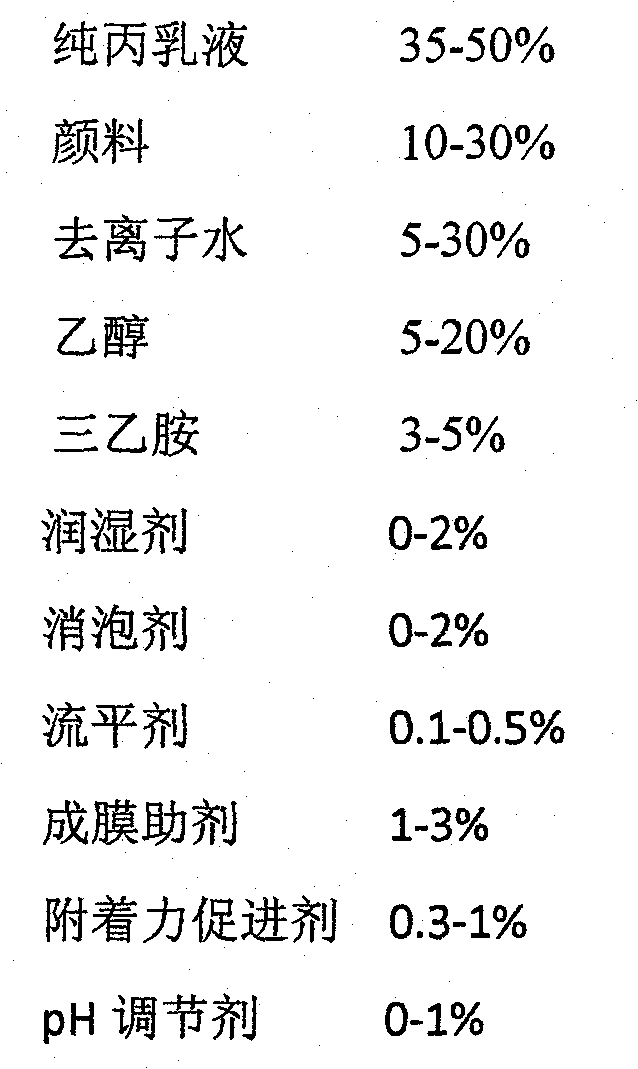

[0039] The raw material composition of present embodiment:

[0040]

[0041]

[0042] Prepare an environmentally friendly water-based aluminum foil ink, the above data is a specific formula,

[0043] The above-mentioned wetting agent refers to sodium dodecylsulfonate; the above-mentioned defoamer refers to polyether modified silicone; the above-mentioned leveling agent refers to silicone, acrylic water-based ink leveling agent; the above-mentioned The film-forming aids refer to monoester organic compounds; the above-mentioned adhesion promoters refer to the special adhesion promoters for water-based coatings and water-based inks that are mainly based on titanate coupling agents and supplemented with various additives; the above-mentioned The pH adjuster refers to ammonia water.

[0044] The pure acrylic emulsion of this embodiment has a viscosity of 25-50 (coated with 4 cups), a minimum film-forming temperature of 20°C, a solid content of 45-60%, and a Tg of 25-27°C; th...

Embodiment 2

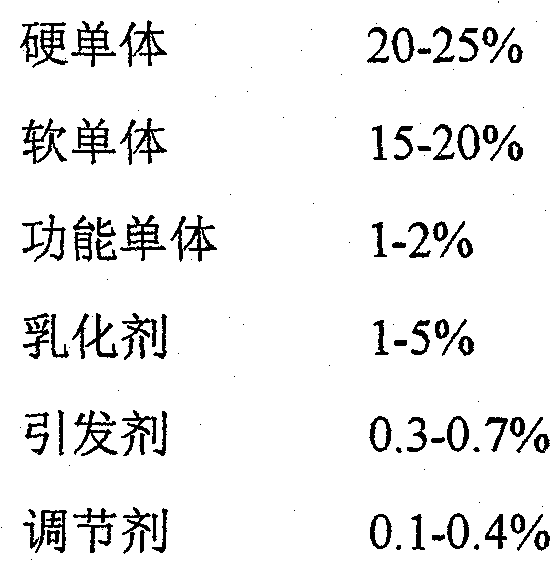

[0055] The raw material composition of present embodiment:

[0056]

[0057] Prepare a kind of environment-friendly water-based aluminum foil ink, the above data is a specific formula, the above-mentioned wetting agent refers to a natural alcohol wetting agent; the above-mentioned defoamer refers to a polyether modified silicone; the above-mentioned leveling agent is Refers to the leveling agent for organically modified polydimethylsiloxane solution water-based ink; the above-mentioned film-forming aid refers to 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate; The above-mentioned adhesion promoter refers to a special adhesion promoter for water-based paint and water-based ink, which is mainly based on a titanate coupling agent and supplemented with various additives; the above-mentioned pH regulator refers to ammonia water.

[0058] The pure acrylic emulsion of this embodiment has a viscosity of 25-50 (coated with 4 cups), a minimum film-forming temperature of 20°C, a solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com