Thermoplastic film cutting device for adhesive tape packaging

A cutting device and packaging technology, applied in the directions of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of affecting the neat position of the incision, poor heat resistance performance, increasing equipment cost, etc., and achieve a stable and coherent cutting process. , Improve the overall aesthetics, improve the effect of external quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

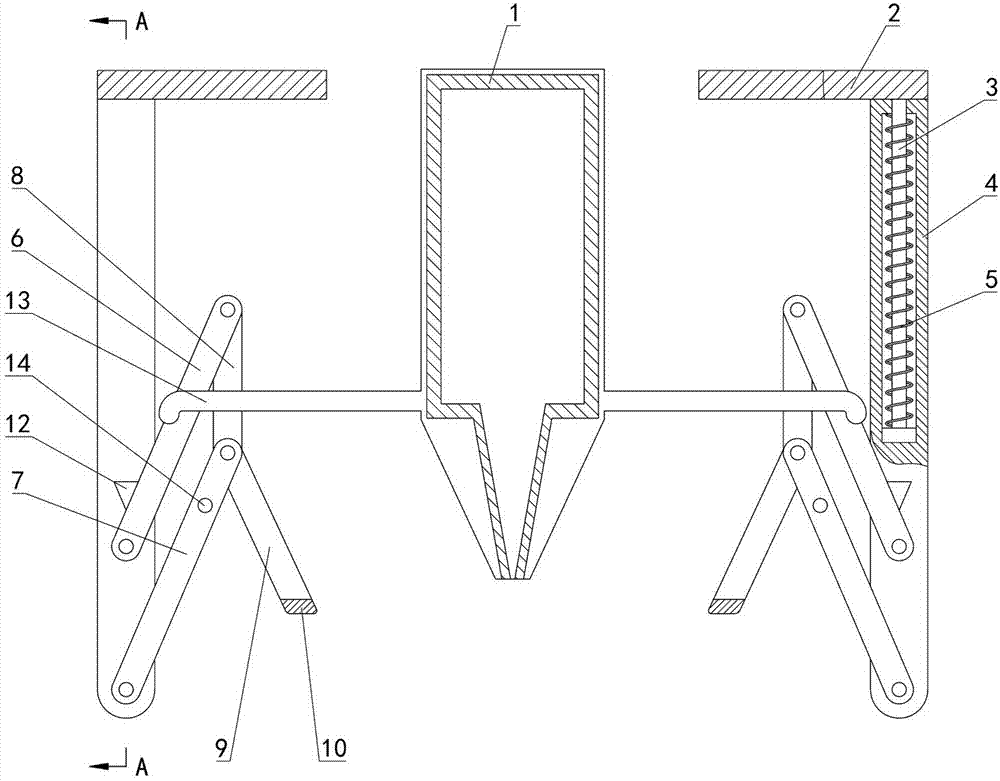

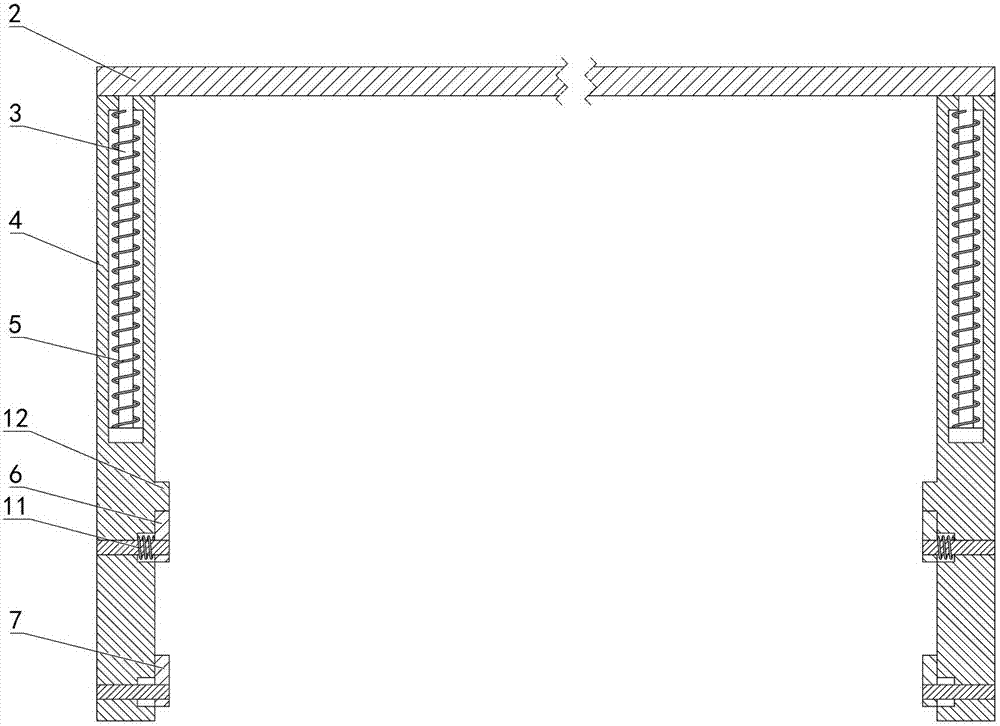

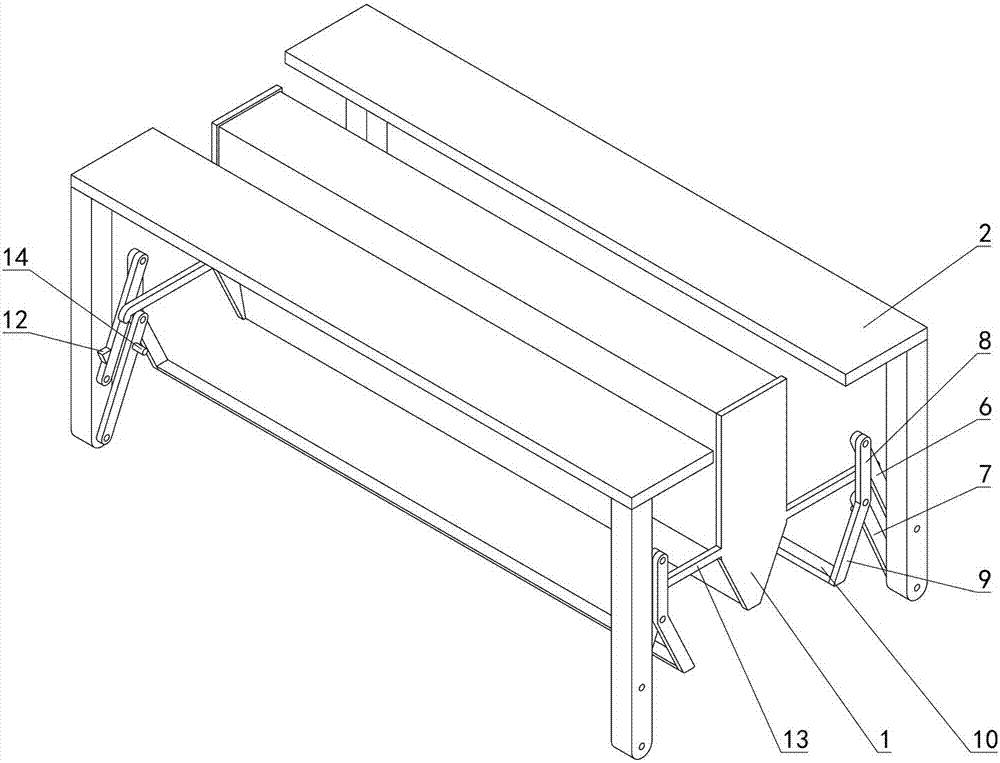

[0016] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Depend on Figure 1 to Figure 5 Provide, the present invention comprises hot-air knife 1, and hot-air knife 1 both sides have the fixed plate 2 that is consistent with hot-air knife 1 length direction respectively, and the fixed plate 2 is equipped with and is placed on the fixed plate 2 below and distributes along the fixed plate 2 length direction. A column 3, a slide block 4 that can slide vertically is housed on the column 3, and a spring 5 is housed between the column 3 and the slide block 4, forming a structure that the slide block 4 slides upward on the column 3 through the elastic force of the spring 5;

[0018] The first connecting rod 6 and the second connecting rod 7 parallel to each other are arranged on the described slider 4, and one end of the first connecting rod 6 and one end of the second connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com