Passage wall section for an annular flow passage of an axial turbomachine with radial gap adjustment

A technology of axial-flow turbines and flow channels, which is applied to axial-flow pumps, machines/engines, gas turbine devices, etc., can solve problems such as failure, guide ring warping, space consumption, etc., to avoid warping, uniform force introduction, The effect of reliable adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

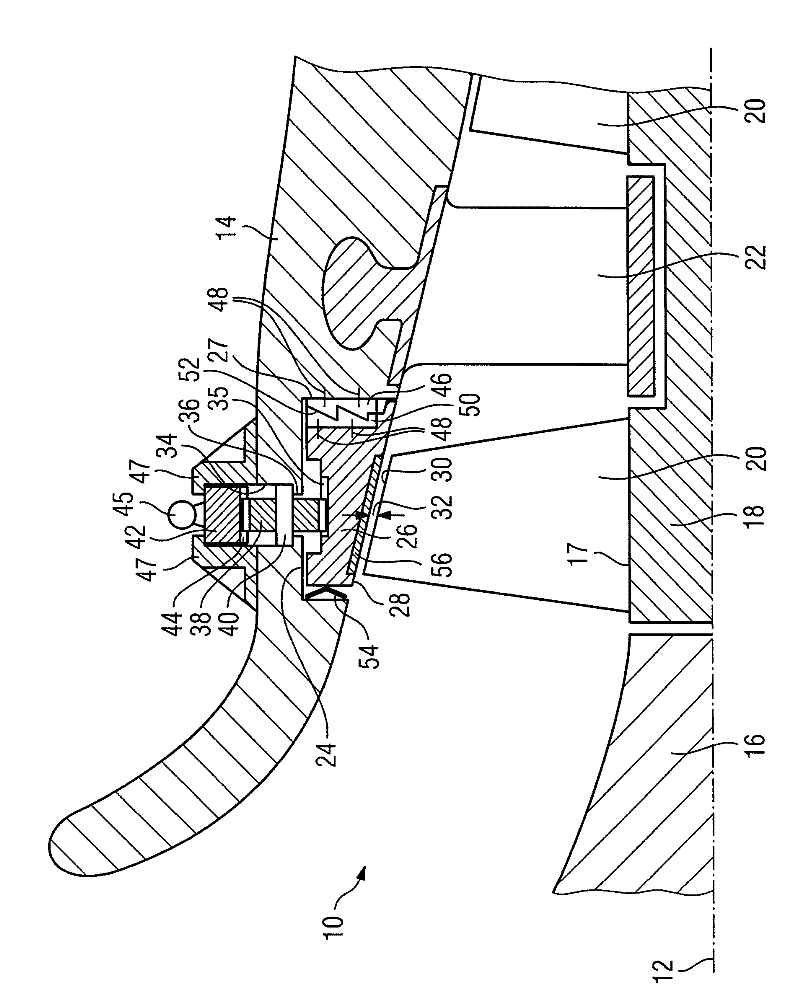

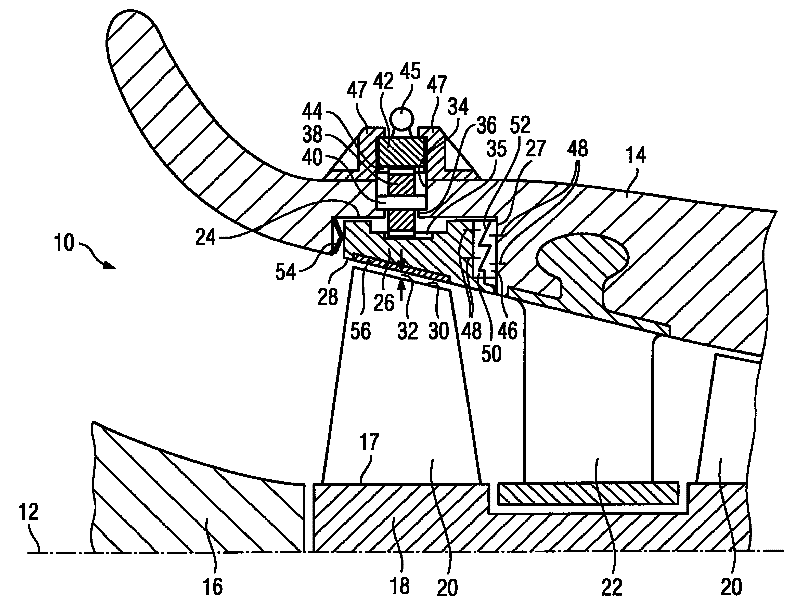

[0017] The single FIGURE shows a section of an annular flow channel 10 in longitudinal section. The annular flow channel 10 extends concentrically along the machine axis 12 of the axially flowing turbine. The turbine shown here is designed as a compressor of a gas turbine. The flow channel 10 includes a wall section 14 which defines the radially outer limit of the flow path. Radially on the inside, the flow path is limited either by the inner wall 16 or by the outer surface of the rotor 18 . The rotor blades 20 are arranged in edge rings at different axial positions on the rotor 18 . Between the two shown rotor blade rings is located a guide vane ring with a plurality of guide vanes 22 distributed over the circumference, which are each held on the duct wall section 14 by means of hammer-shaped fastening elements.

[0018] in the compressor at the figure 1 Upstream of the flow channel 10 , which flows from left to right, a guide ring 26 consisting of several segments is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com