Twist beam axle

A technology for beams and longitudinal beams, used in vehicle components, interconnection systems, springs, etc., to solve problems such as broken and unstable fiber composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

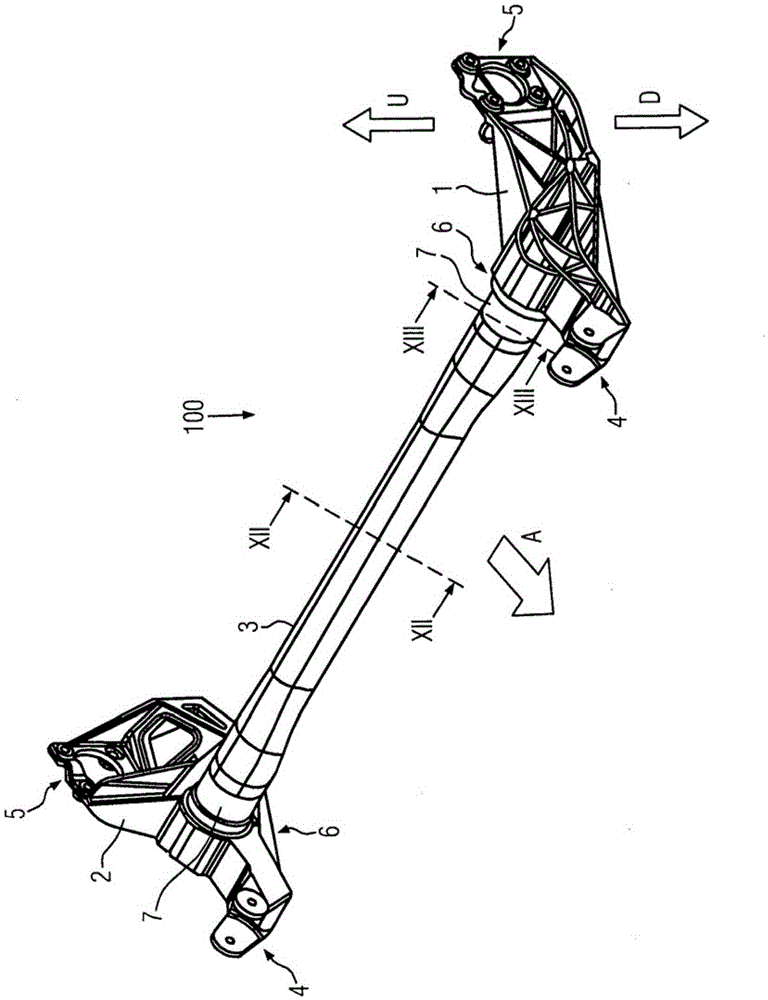

[0049] figure 1 An assembly 100 according to the invention is shown for a vehicle using, for example, a torsion beam axle. The torsion beam axle shown is the rear axle of the vehicle. However, it is also conceivable that the component according to the invention can be the front axle of a vehicle.

[0050] However, the invention is not limited to torsion beam axles. According to the claims, the invention comprises all components for a vehicle which have at least two side members and at least one cross member arranged between them, as well as the remaining features of the independent claims. Here, for example, subframes, stabilizers, ladder frames and the like are included.

[0051] exist figure 1 Arrow A shown in indicates the direction of travel of the vehicle. Accordingly, a side member 1 arranged on the left side of the vehicle in the direction of travel A and a side member 2 arranged on the right side of the vehicle in the direction of travel A are formed. A transvers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com