Cable end connection

A technology of end connection and rope, applied in the field of rope end connection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

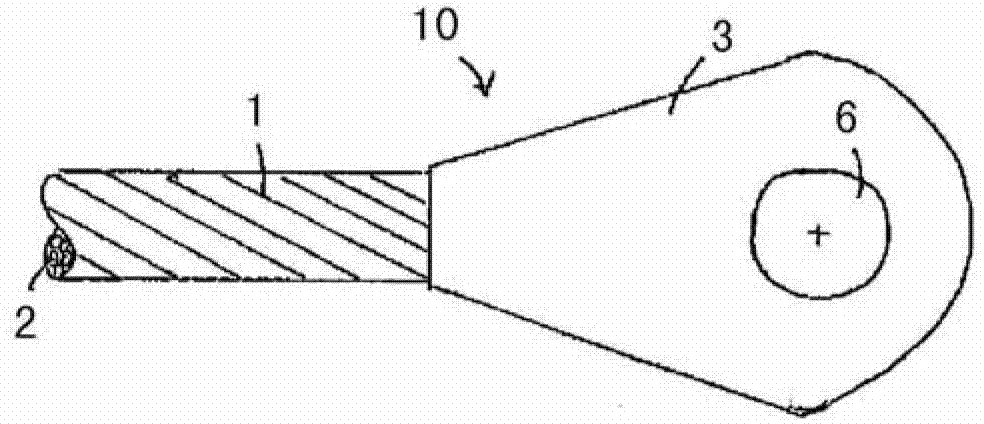

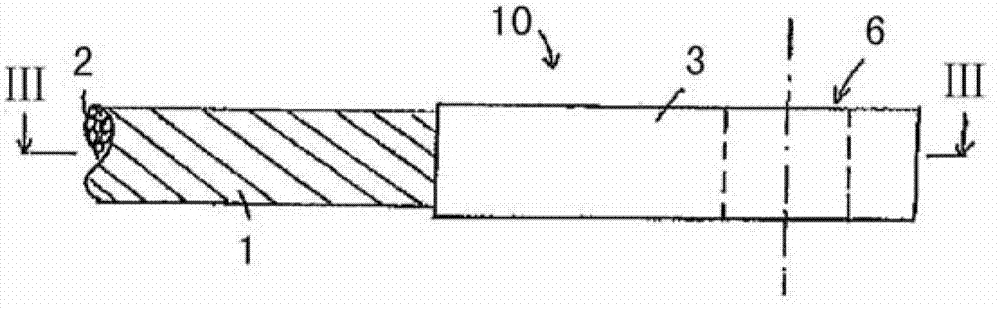

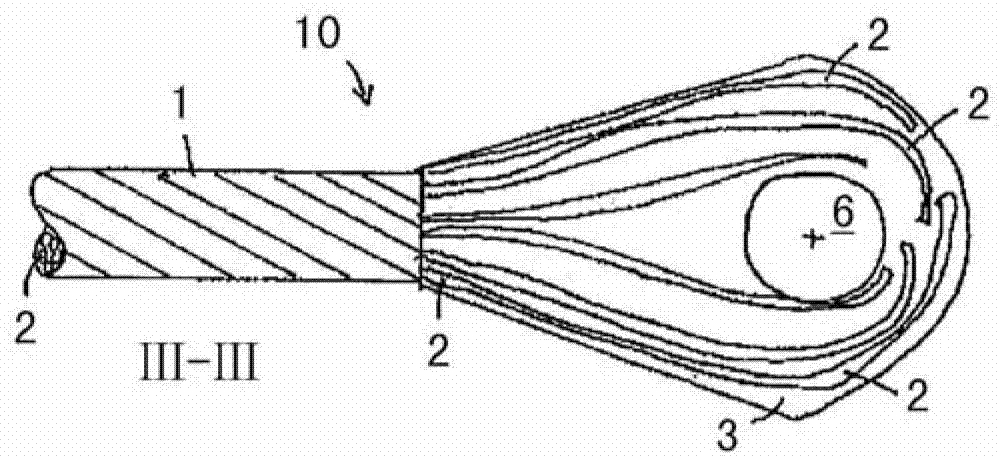

[0024] exist figure 1 , 2 In and 3, a first embodiment of the rope end connection device 10 of the present invention is shown in plan view, side view and cross-sectional view to clarify the internal structure. The cable end connection 10 has in this exemplary embodiment an end piece 3 which has approximately the shape of a drop. The end of the rope 1 is provided with an end piece 3 made of synthetic resin by casting, which first widens conically to form a widened, approximately circular area at its end, in which A through hole 6 is formed in the region. The through-holes 6 are intended to receive, for example, fixing bolts for assembling the rope 1 at the installation site. The rope 1 can be a plastic part made of wire 2 or wire. Other types of ropes 1 can also be provided with the rope end connection device 10 of the invention.

[0025] The cable end connection 10 according to the invention has an end piece 3 made of a castable, hardenable material which, without additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com