A double-feed casting mold adopting the principle of split-end horizontal quantitative

A horizontal and feeding technology, applied in the field of molds, can solve problems such as the inconsistency of the filling amount of the mold cavity, the inaccurate control of the flow rate of the two molds, and the inconsistent appearance of the product, so as to avoid detection errors, automatically and quickly limit changes, and ensure consistent appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

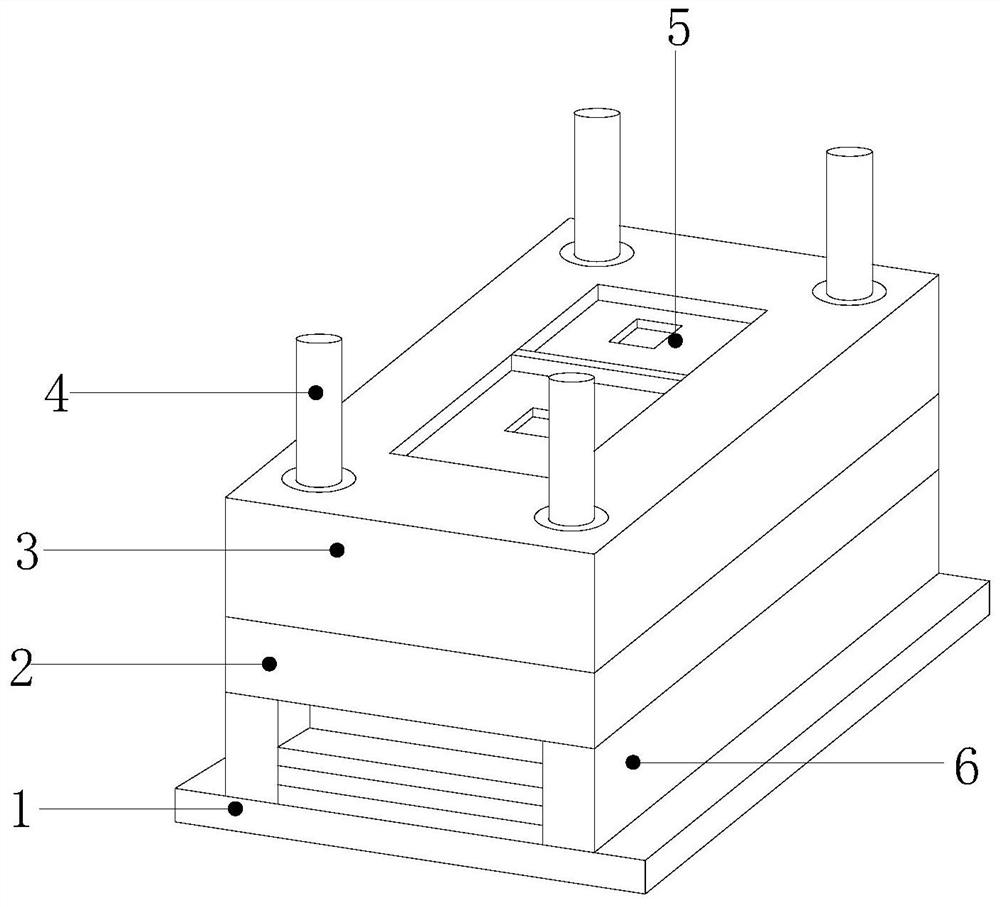

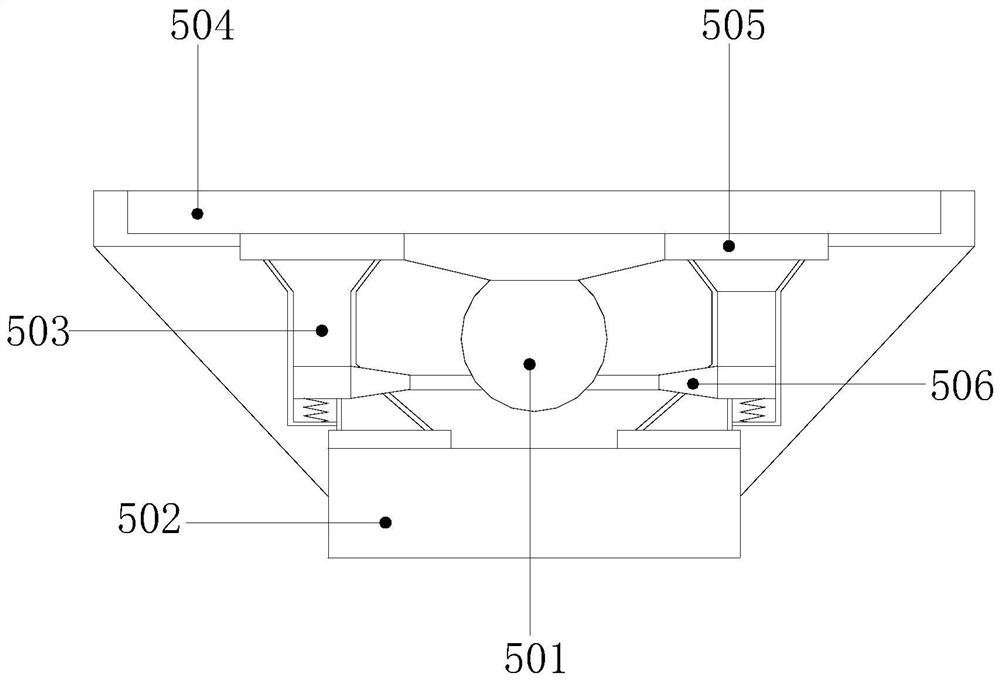

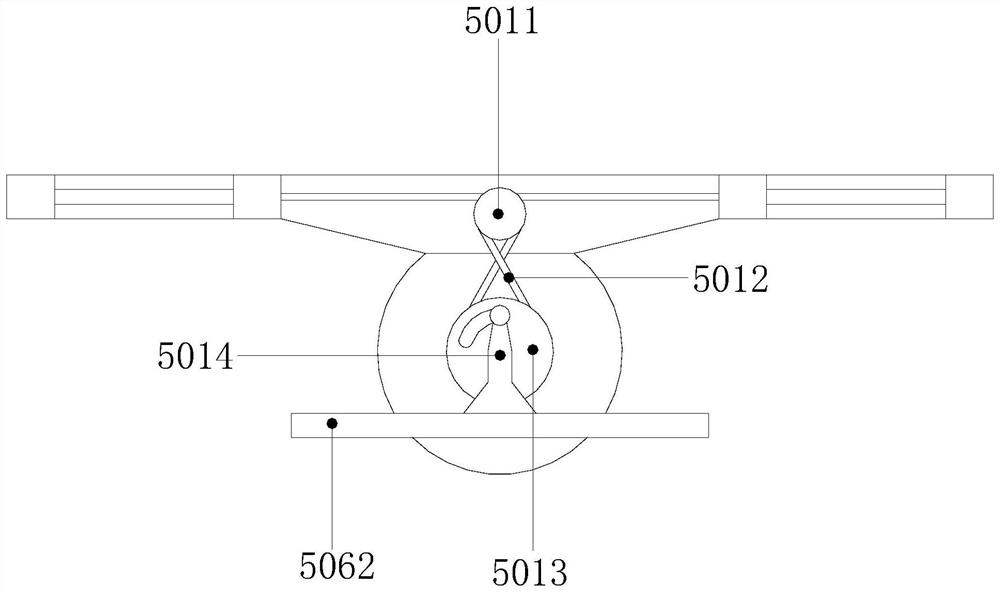

[0029] see Figure 1-Figure 6 , the present invention provides a double-side feeding casting mold adopting the principle of split-end horizontal quantitative, its structure includes a fixed bottom plate 1, a lower mold 2, an upper mold 3, positioning pins 4, a feeding structure 5, a spaced beam 6, the There are two interspace beams 6, which are installed on both ends of the top of the fixed base plate 1 by welding. The lower die 2 is a rectangular structure, and the bottom is connected to the upper end of the interspace beam 6 by means of fitting. The bottom of 3 is fastened with the top of lower mold 2, the feeding structure 5 is set in the middle of the upper end of upper mold 3, and is an integrated structure, and four positioning pins 4 are provided, and are connected through the four ends of upper mold 3 After the lower mold 2 and the upper mold 3 are aligned, they are fixed by the fixed bottom plate 1, and the positioning pins 4 are used to fix the position of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com