Computer jacquard and cut loop velvet machine

A computerized jacquard and machine foot technology, which is applied in the direction of cut pile loops and double-sided fleece fabric cut pile, can solve the problems of high cost, complicated printing process, and large environmental pollution, and achieve compact structure, reduce production costs, and improve production efficiency. The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

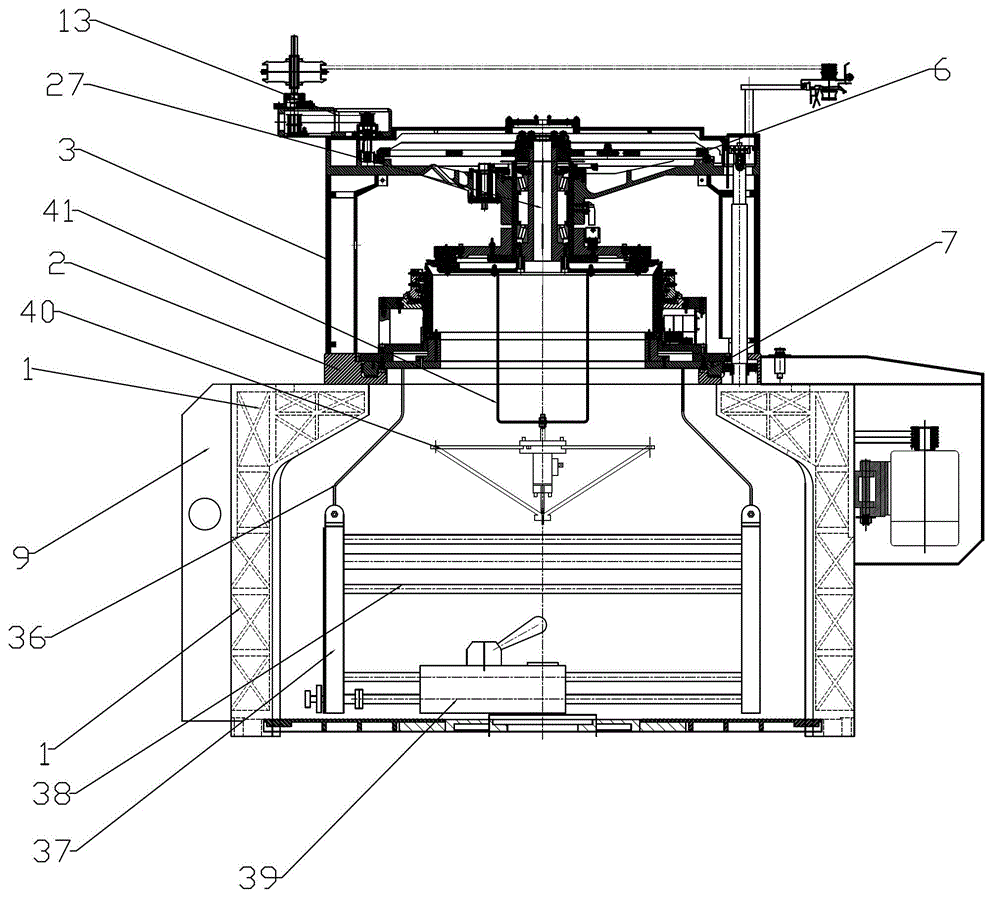

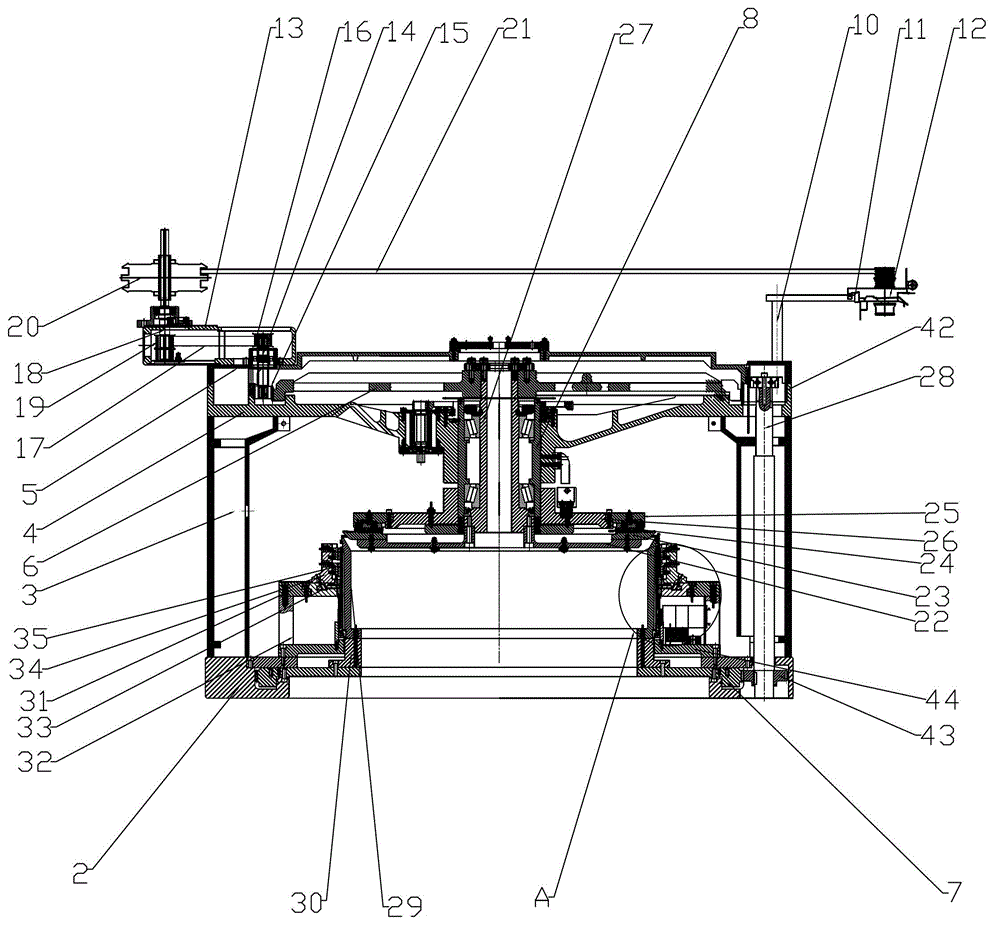

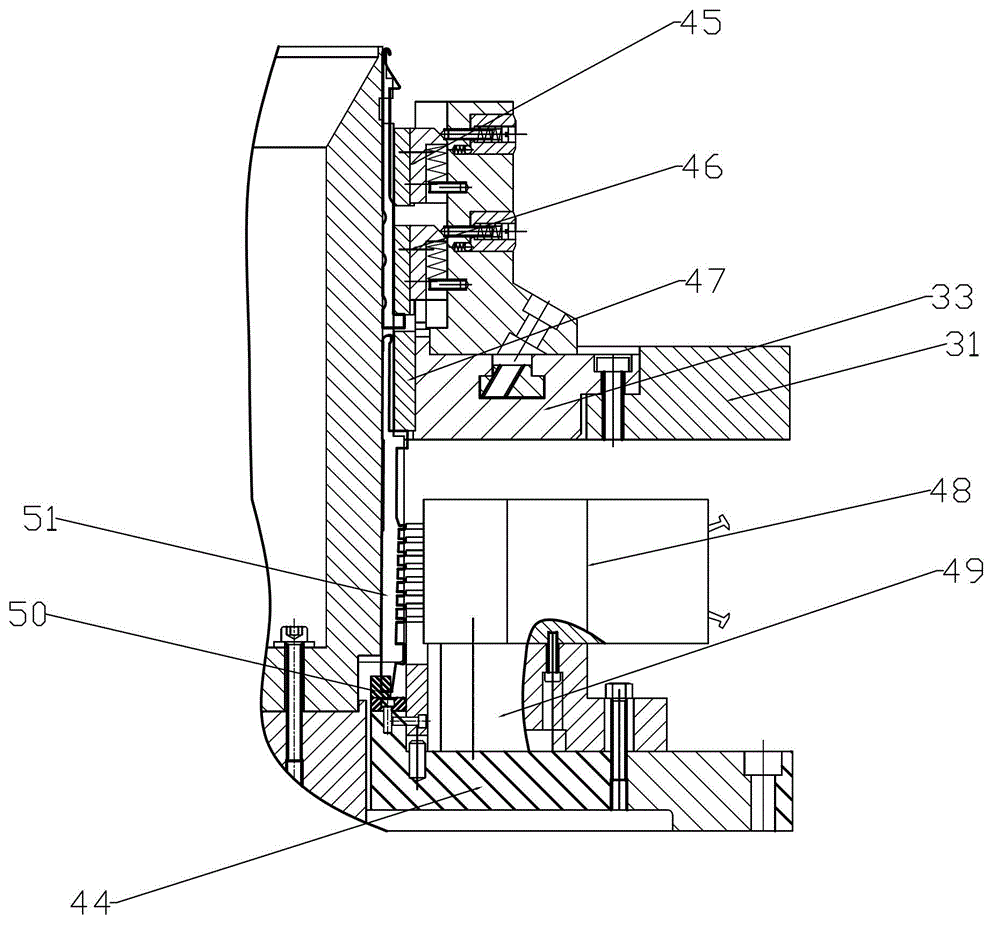

[0019] Such as Figure 1~4 As shown, the present invention mainly includes a machine foot 1, an outer table surface 2, an outer support foot 3, a large tripod 4, a large tripod cover 5, an upper transmission gear 6, a lower transmission gear 7, a sleeve 8, an electrical box 9, a column 10, Wire feeder ring 11, wire feeder 12, wire feeder box 13, first wire feeder shaft 14, first wire feeder gear 15, second wire feeder gear 16, first synchronous belt 17, second wire feeder shaft 18, third Line transmission gear 19, transmission disc 20, second synchronous belt 21, upper needle cylinder seat 22, upper needle cylinder 23, first Huff 24, sector plate 25, upper triangle 26, main shaft 27, transmission shaft 28, lower needle cylinder 29. Lower needle cylinder seat 30, inner table surface 31, inner support foot 32, middle shell 33, second half 34, lower tria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com