Shed forming device in a jacquard loom, and jacquard loom equipped with such a device

A technology of jacquard and loom, applied in the direction of jacquard, textile and papermaking, weaving, etc., can solve the problem of moving to one or the other of two intermediate positions, unable to obtain four equally spaced warp positions, narrowing Weaving selection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

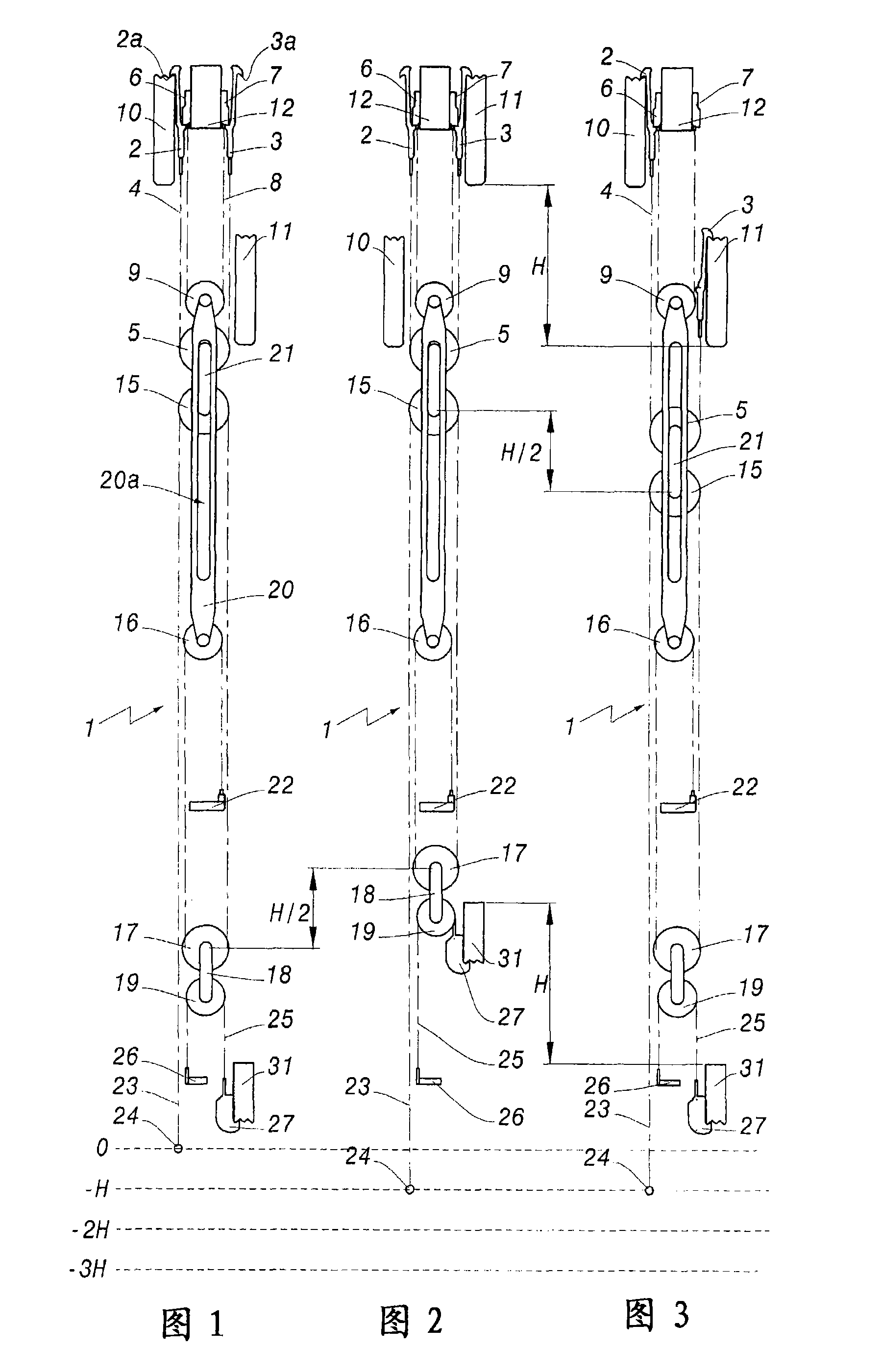

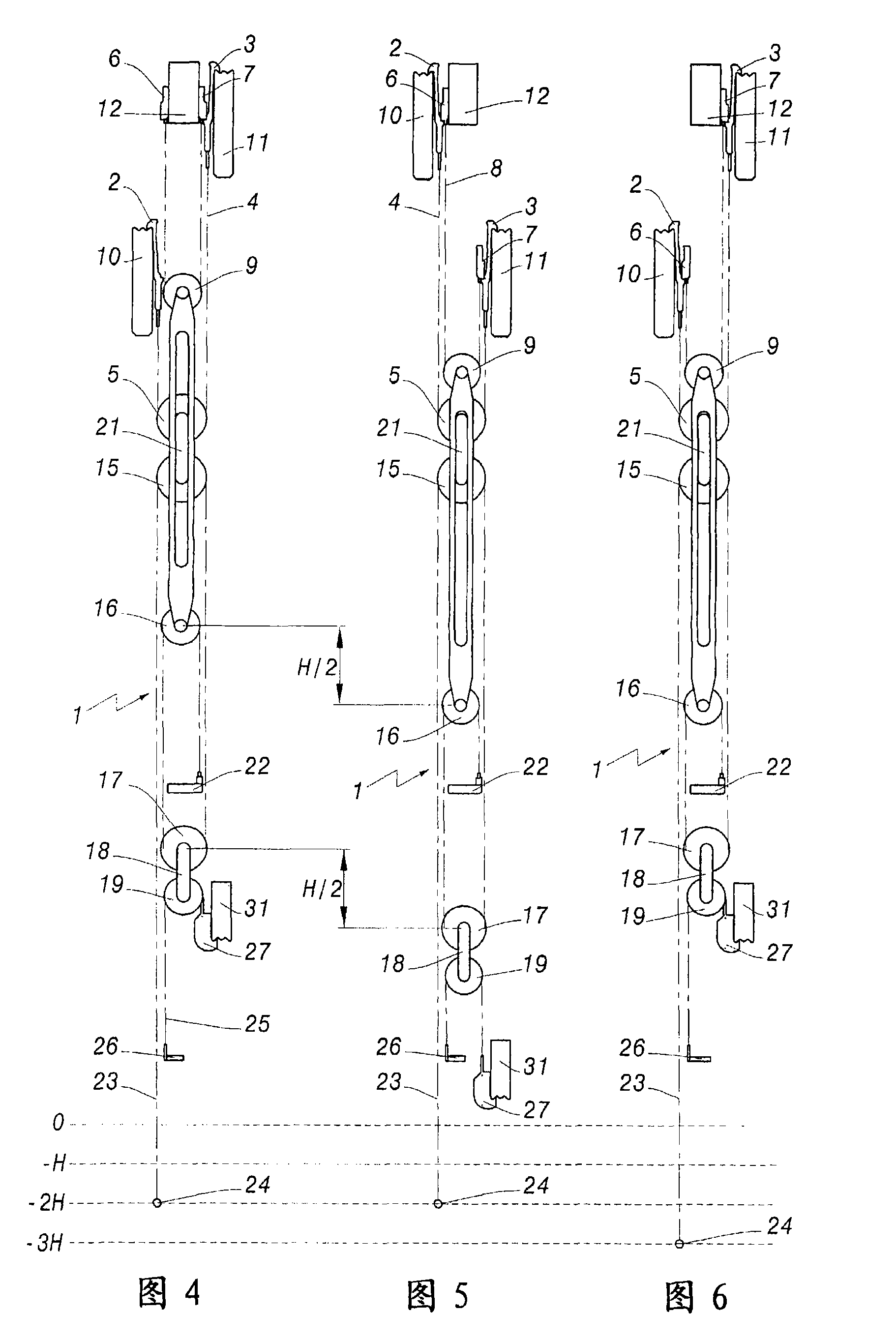

[0030] The shedding device 1 shown in Figure 1 comprises four upper movable carabiners 2, 3, 6 and 7 which are vertically movable in pairs by two lifting knives 10 and 11 which are driven to reciprocate in opposite phases. More specifically, the device 1 comprises two load-carrying movable hooks 2 and 3 and two driven movable hooks 6 and 7 connected by a cable 4 forming a cord-like element that goes around a pulley 5 . The driven movable carabiner is connected by a second cable 8 partially wound around a second pulley 9 . With the lugs 2 a and 3 a belonging to the carrying hooks 2 and 3 , the lifting knives 10 and 11 are able to selectively move said hooks 2 and 3 .

[0031] The driven carabiners 6 and 7 simply rest on the carrying carabiners 2 and 3 respectively, which means that the carabiners 2 and 6 can be moved together by the lifting knife 10, just like the carabiners 3 and 7 can be moved together by the lifting knife 11 Same. Thus, carabiners 2 and 6 form a first pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com