Protein regeneration composite fiber spinning solution and production method thereof

A composite fiber, spinning dope technology, applied in cellulose/protein conjugated rayon, spinning solution preparation, conjugated synthetic polymer rayon, etc., can solve the problem of difficulty in spinning qualified fibers, reducing Protein utilization, limitation of fiber use range, etc., to achieve good economic and social benefits, strong color fastness, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

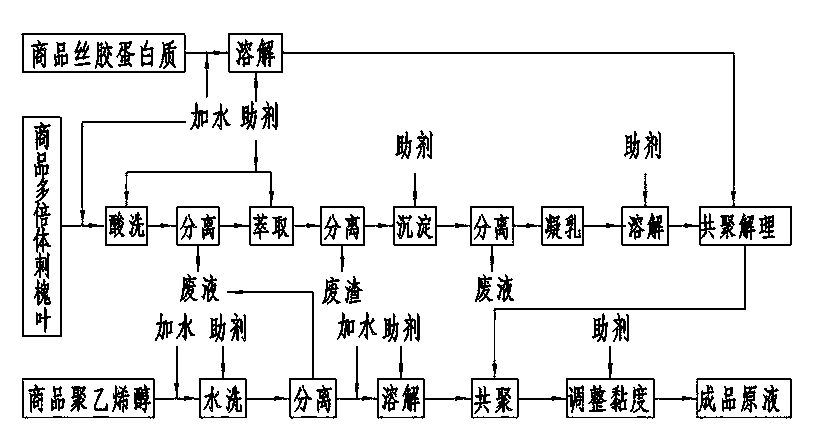

Image

Examples

Embodiment 11

[0028]Soak the sericin protein with an animal commodity content of 97% in a ratio of 1:2 to water at room temperature for 90 minutes, add water to make a solution with a weight concentration ratio of 12% to water, and raise the temperature to 50°C and add Aqueous sodium hydroxide solution was used to make the pH value to 7.8, and the mixture was incubated and stirred for 60 minutes. That is, the animal protein solution to be used. Or take the sericin protein curd milk recovered by the silk reeling enterprise, and mix it into a solution with a weight concentration ratio of 12% of the material and water after testing, and raise the temperature to 50°C at the same time, add aqueous sodium hydroxide solution to make the pH value 7.8, and keep stirring for 60 minutes . That is, the animal protein solution to be used.

Embodiment 12

[0030] Soak the sericin protein with an animal product content of 97% in a ratio of 1:2 to water at room temperature for 120 minutes, add water to make a solution with a weight concentration ratio of 13% to water, and raise the temperature to 52°C and add Aqueous sodium hydroxide solution was used to make the pH value to 8.5, and the mixture was incubated and stirred for 60 minutes. That is, the animal protein solution to be used. Or take the sericin protein curd milk recovered by the silk reeling enterprise, and mix it into a solution with a weight concentration ratio of 13% of the material and water after laboratory testing. At the same time, raise the temperature to 52°C and add aqueous sodium hydroxide solution to make the pH value 8.5, and keep stirring for 60 minutes . That is, the animal protein solution to be used.

Embodiment 13

[0032] Soak the sericin protein with an animal product content of 97% in a ratio of 1:2 to water at room temperature for 105 minutes, add water to make a solution with a weight concentration ratio of 12.5% to water, and raise the temperature to 51°C and add Aqueous sodium hydroxide solution made the pH value to 8.2, and kept stirring for 60 minutes. That is, the animal protein solution to be used. Or take the sericin protein curd milk recovered by the silk reeling enterprise, and mix it into a solution with a weight concentration ratio of 12.5% of the material and water after laboratory testing. At the same time, heat up to 51°C and add aqueous sodium hydroxide solution to make the pH value 8.2, and keep stirring for 60 minutes. . That is, the animal protein solution to be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com