Rare-earth colorful anticorrosive water-based paint and preparation method thereof

A water-based paint, anti-corrosion technology, applied in the field of paint, can solve the problems of water resistance, chemical resistance and weather resistance of paint film, poor furniture surface gloss, poor brightness and other problems, achieve strong color fastness, stickiness Good knot, high brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

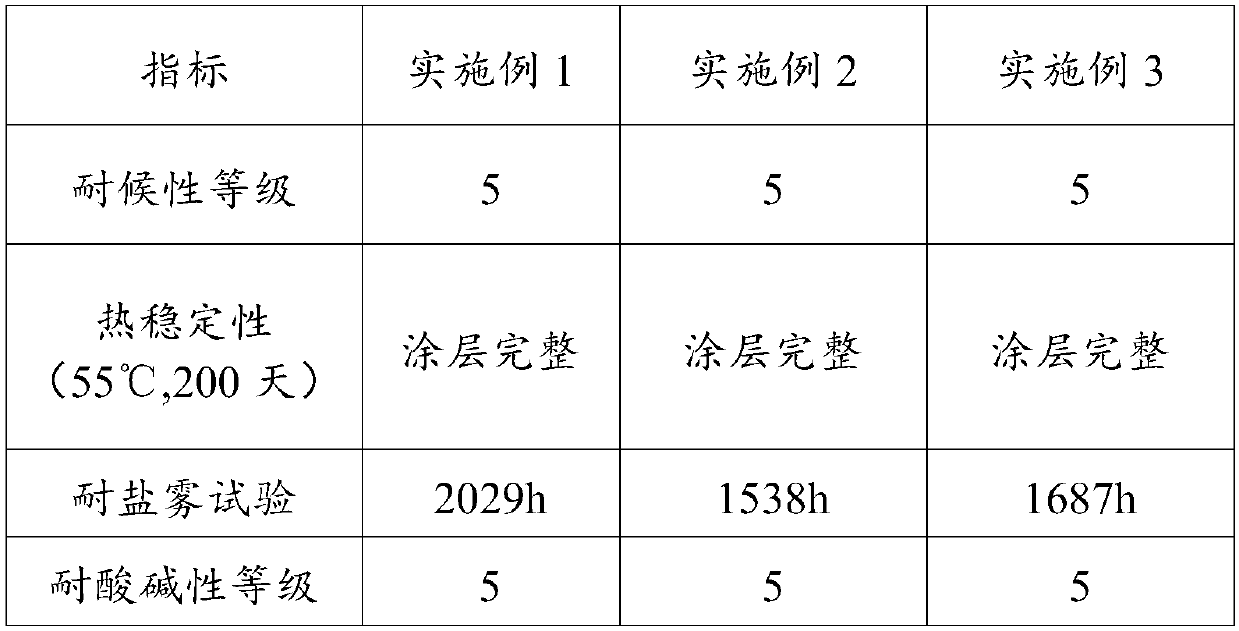

Examples

Embodiment 1

[0032] This embodiment provides a rare earth red anti-corrosion water-based paint, the raw material components include:

[0033] Polystyrene-acrylic resin 12kg, water-based polyurethane 30kg, 3-isocyanatopropyltriethoxysilane 0.2kg, disodium edetate 0.2kg, water 40kg, rare earth cerium sulfide solution system 30kg, acetylene glycols 0.1kg of polymer, 1kg of filler (the specific composition is 0.5kg of nano silicon dioxide, 0.2kg of sodium borate, 0.1kg of aluminum silicate, 0.1kg of zinc phosphate, 0.1kg of bentonite), 0.1kg of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.1 kg of methyl acrylate, 0.5 kg of methyl p-hydroxybenzoate, and 0.5 kg of UV-531.

[0034] The preparation method of the rare earth cerium sulfide solution system is as follows: respectively take 40kg of rare earth cerium sulfide colorant, 28kg of water, 1.5kg of phosphoric acid, and 0.5kg of sodium phosphate, add them to a high-speed stirrer in turn, stir at 20°C for 5 hours, and then add water...

Embodiment 2

[0041] This embodiment provides a kind of rare earth yellow anti-corrosion water-based paint, and the raw material components include:

[0042] Polystyrene-acrylic resin 18kg, water-based polyurethane 30kg, 3-aminopropyltriethoxysilane 7kg, sodium dodecylsulfonate 0.7kg, water 60kg, rare earth samarium oxysulfide and samarium sulfide (1:1) solution System 50kg, polyether siloxane polymer 0.5kg, filler (the specific composition is nano-titanium dioxide 12kg, porous calcium carbonate 1kg, boron carbide 0.1kg, magnesium aluminum silicate 0.4kg, barium sulfate 1.5kg, talcum powder 10kg, stearin Barium acid 2.5kg, magnesium stearate 2.5kg) 30kg, polyoxyethylene polyoxypropanolamine ether 0.5kg, butyl acrylate 1.5kg, butyl p-hydroxybenzoate 2kg, 2-(2-hydroxyphenyl)- 1,3,5-triazine 2kg.

[0043] The preparation method of the rare earth samarium oxysulfide and samarium sulfide (1:1) solution system is as follows: respectively take 50kg of rare earth samarium sulfide and samarium sulf...

Embodiment 3

[0050] This embodiment provides a kind of rare earth colorful anti-corrosion water-based paint, and the raw material components include:

[0051] Polystyrene-acrylic resin 15kg, water-based polyurethane 25kg, 2-(3,4-epoxycyclohexane)ethyltriethoxysilane 0.5kg, dioctyl sodium sulfosuccinate 0.5kg, water 50kg, rare earth Colorant solution system 10kg, polyoxyethylene alkyl ether 0.5kg, filler (the specific composition is sodium silicate 5kg, sodium borate 2kg, aluminum silicate 2kg, magnesium silicate 2kg, magnesium aluminum silicate 2kg, sodium aluminosilicate 2kg , zinc oxide 2kg, kaolin 2kg, calcium stearate 1kg) 20kg, polyoxypropylene glyceryl ether 0.3kg, dioctyl ester 1kg, salicylaldehyde 1.2kg, 2-(2'-hydroxyphenyl) benzotriazole 0.7 kg.

[0052] The preparation method of the rare earth colorant solution system is as follows: respectively take the rare earth colorant YIn 0.9 mn 0.1 o 3 50kg, water 28kg, phosphoric acid 5kg, potassium dihydrogen phosphate 5kg, add to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com