Highly-anticorrosive water-based coating for containers, and preparation method thereof

A water-based coating and corrosion-resistant technology, applied in the field of coatings, can solve the problems of poor corrosion resistance, poor fire resistance, poor adhesion, etc., and achieve the effects of good thermal stability, good fire resistance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

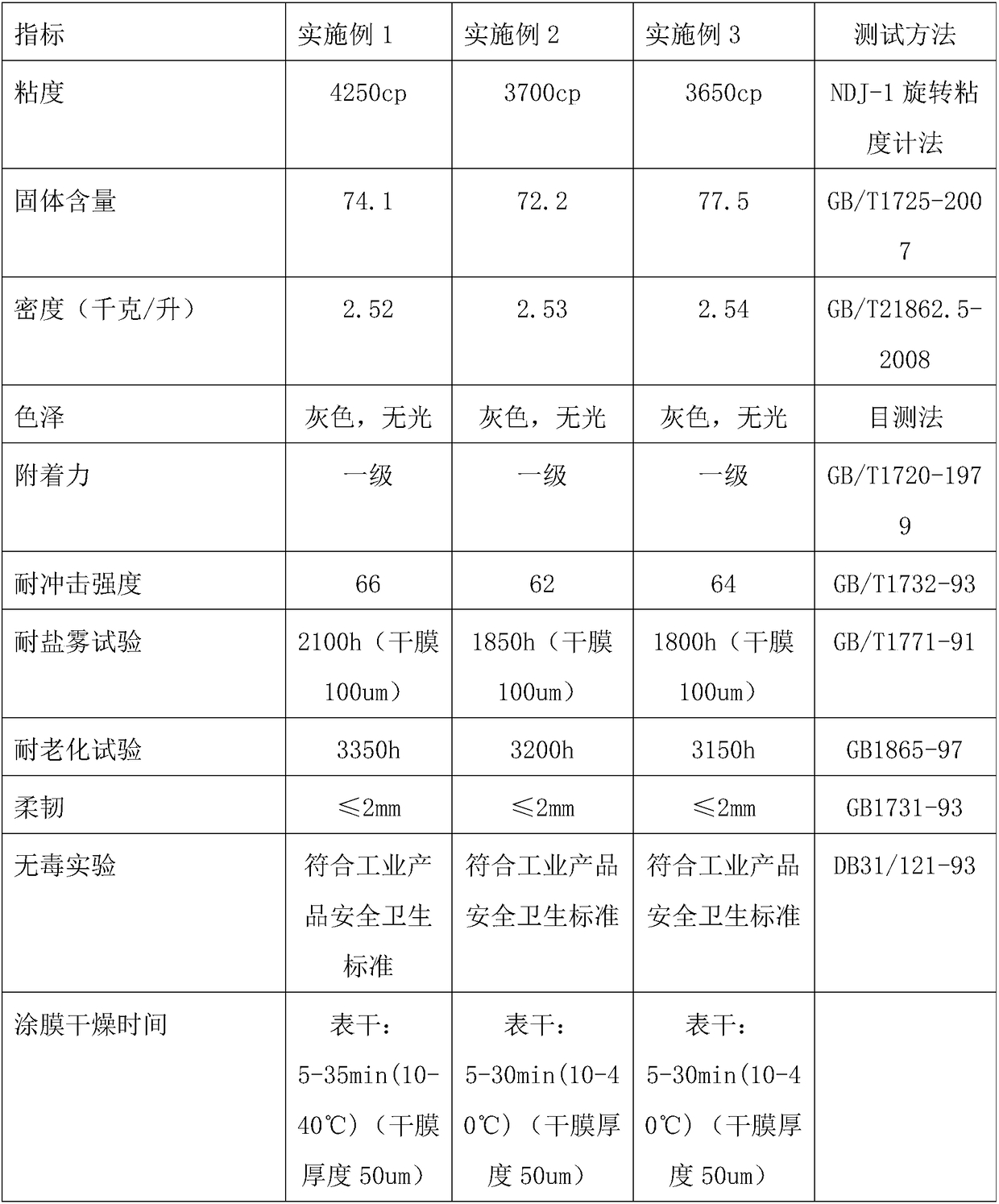

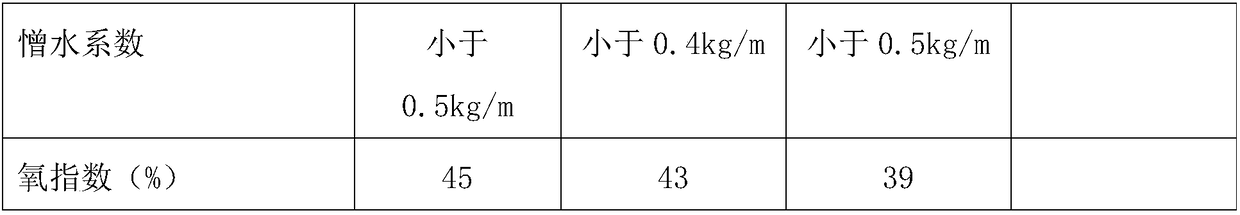

Examples

Embodiment 1

[0028] A high-corrosion-resistant water-based paint for containers, including the following raw materials: 50kg of a mixture of polyurethane resin and polystyrene-acrylate copolymer emulsion, 27kg of silicon-acrylic emulsion, 40kg of heavy calcium carbonate, 8kg of talc, titanium White powder 12kg, kaolin 20kg, boron carbide 5kg, aluminum silicate 5kg, graphite powder 7kg, iron pigment 1.5kg, borax 0.45kg, film-forming aid 0.4kg, thickener 0.4kg, anti-aging agent 1.25kg, antioxidant Agent 3010 1.25kg, defoamer HT6520 1.75kg, dispersant 1.55kg, heat stabilizer 0.55kg, surfactant 0.4kg, ammonia 0.55kg, polytetrafluoroethylene 6.5kg and water 37.5kg; the anti-aging agent It is a mixture of ultraviolet absorber UVP-327 and light stabilizer 744, and its mixing ratio is: 1.5:1.

[0029] The film-forming aid is propylene glycol butyl ether.

[0030] The thickener is fumed silica, sodium bentonite, diatomaceous earth, modified sodium polyacrylate, hydrophobic polyether compound, modi...

Embodiment 2

[0038] A high-corrosion-resistant water-based coating for containers, including the following raw materials: 40kg of a mixture of polyurethane resin and polystyrene-acrylate copolymer emulsion, 20kg of silicon-acrylic emulsion, 30kg of heavy calcium carbonate, 5kg of talc, titanium White powder 10kg, kaolin 15kg, boron carbide 4kg, aluminum silicate 3kg, graphite powder 5kg, iron pigment 0.5kg, borax 0.1kg, film-forming aid 0.2kg, thickener 0.3kg, anti-aging agent 0.5kg, antioxidant Agent 3010 0.5g, defoamer HT6520 0.5kg, dispersant 0.1kg, heat stabilizer 0.1kg, surfactant 0.2kg, ammonia 0.1kg, polytetrafluoroethylene 5kg and water 25kg; The mixture of absorbent UVP-327 and light stabilizer 744, the mixing ratio is: 1-2:1.

[0039] The film-forming aid is propylene glycol methyl ether acetate.

[0040] The thickener is fumed white carbon black.

[0041] The dispersant is sodium lauryl sulfate.

[0042] The heat stabilizer is calcium stearate.

[0043] The surfactant is polys...

Embodiment 3

[0048] A high-corrosion-resistant water-based paint for containers, including the following raw materials: 60kg of a mixture of polyurethane resin and polystyrene-acrylate copolymer emulsion, 34kg of silicon-acrylic emulsion, 50kg of heavy calcium carbonate, 11kg of talc powder, titanium White powder 14kg, kaolin 25kg, boron carbide 6kg, aluminum silicate 7kg, graphite powder 9kg, iron pigment 2.5kg, borax 0.8kg, film-forming aid 0.6kg, thickener 0.5kg, anti-aging agent 2kg, antioxidant 3010 2kg, defoamer HT6520 3kg, dispersant 3kg, heat stabilizer 1kg, surfactant 0.6kg, ammoniacal liquor 1kg, polytetrafluoroethylene 8kg and water 50kg; Described antiaging agent is ultraviolet absorber UVP-327 and The mixture of light stabilizer 744, the mixing ratio is: 1-2:1.

[0049] The film-forming aid is propylene glycol butyl ether.

[0050] The thickener is diatomaceous earth.

[0051] The dispersant is sodium lauryl sulfate.

[0052] Heat stabilizer is barium stearate.

[0053] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com