Method for dyeing plant straw with gradient color

A technology for plant straws and sundries, which is applied in the field of gradient color dyeing of plant straws, which can solve the problems of incoherent patterns, single color of plant straws or strips, and poor printing of plant straw joints, etc., and achieve strong color fastness , colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

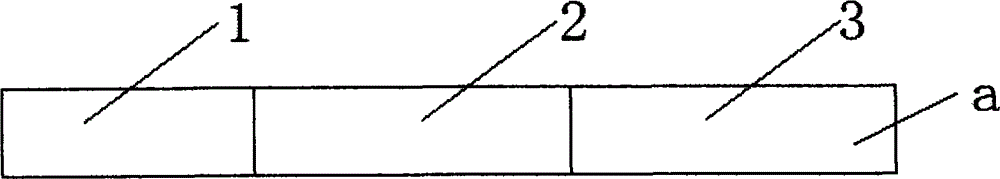

[0026] see figure 1 , a method for dyeing gradation colors to plant stalks according to the present invention, the technical solution adopted is: it comprises the following steps to complete:

[0027] A. Remove the head and tail of the plant straw or rattan a; since the head and tail of the plant straw or rattan a are affected by sunlight, the color difference is relatively large, and the original color difference is large, so in order to eliminate the color difference after dyeing, remove the plant straw or Rattan with a head and tail end.

[0028] B. Clean the plant straw or rattan a to remove sundries and impurities covering the outer surface of the plant straw or rattan a; if the dust and impurities on the outer surface of the plant straw or rattan a are not removed, the coloring effect will be affected, and Poor surface gloss and unevenness after coloring. In order to eliminate the above problems, it is necessary to align the surface for cleaning.

[0029] C. Soak the p...

Embodiment 2

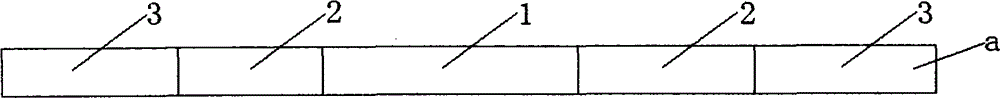

[0040] see figure 2 , a method for dyeing gradation colors to plant stalks according to the present invention, the technical solution adopted is: it comprises the following steps to complete:

[0041] A. Remove the head and tail of the plant straw or rattan a; since the head and tail of the plant straw or rattan a are affected by sunlight, the color difference is relatively large, and the original color difference is large, so in order to eliminate the color difference after dyeing, remove the plant straw or Rattan with a head and tail end.

[0042] B. Clean the plant straw or rattan a to remove sundries and impurities covering the outer surface of the plant straw or rattan a; if the dust and impurities on the outer surface of the plant straw or rattan a are not removed, the coloring effect will be affected, and Poor surface gloss and unevenness after coloring. In order to eliminate the above problems, it is necessary to align the surface for cleaning.

[0043]C. Soak the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com