Two-sided etched-out velvet fabric

A velvet and double-sided technology, which is applied to fabric surface trimming, textiles and papermaking, layered products, etc., can solve the problems of poor three-dimensionality of flower patterns, poor color fastness, and monotonous colors, so as to improve the three-dimensional effect of printing. Strong three-dimensional, not easy to fade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0020] The technical scheme of concrete implementation of the present invention is:

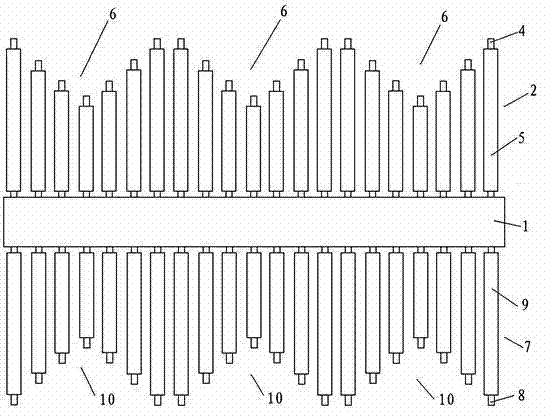

[0021] A double-sided burnt-out velvet fabric, comprising a flat gray cloth layer 1, the top surface of the gray cloth layer 1 is fixed with a first fluff layer 2 formed by fluffing the gray cloth on one side, and each fluff of the first fluff layer 2 4 are covered with the first paint layer 5, the first fluff layer 2 is provided with more than two first depressions 6 formed by roller printing; the bottom surface of the gray cloth layer 1 is fixed with the second fluff formed by single-sided fleece fluffing of the gray cloth Layer 7, each pile 8 of the second pile layer 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com