Indoor wide seamless glass bead composite decorative material and preparation technology thereof

A decorative material and preparation process technology, applied in the field of wall decoration, can solve the problems of seam warping, peeling and cracking, and poor handling, and achieve good adhesion, good curing and strong color fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below by specific examples.

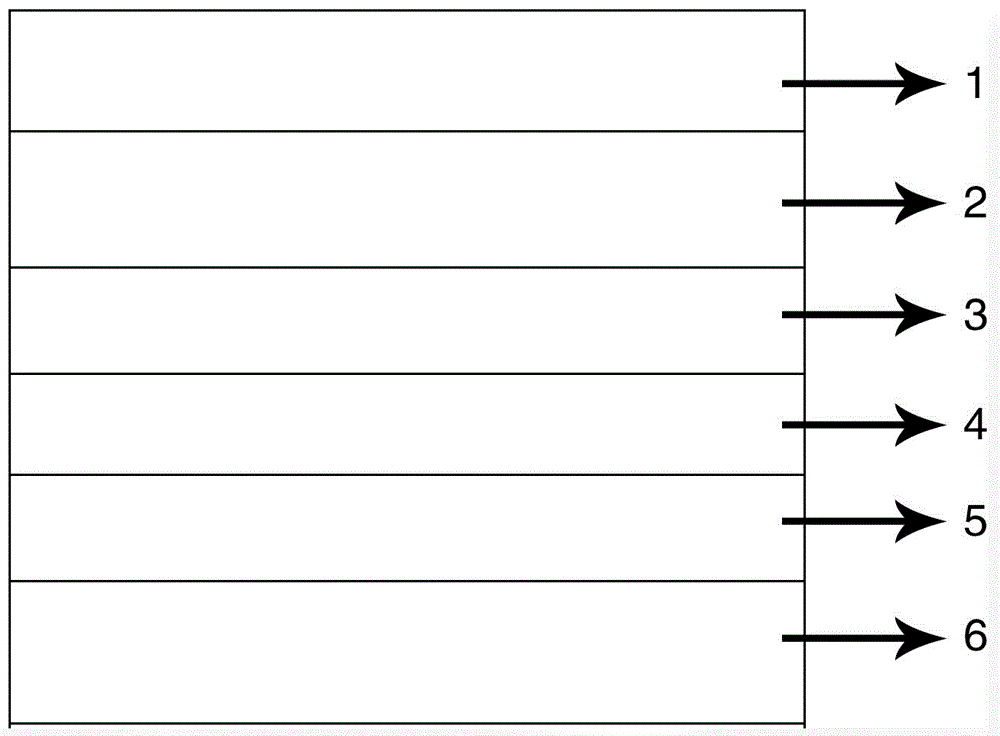

[0025] An indoor wide seamless glass bead synthetic decoration material as attached figure 1 As shown, it includes substrate 1, ink-absorbing resin coating 2, picture layer 3, adhesive layer 4, glass bead particle conjunctiva layer 5, and protective layer 6 in sequence, wherein the substrate is a PVC foam substrate, and the substrate After coating with ink-absorbing resin coating, add an adhesive layer, then drop glass beads to form a conjunctival layer of glass beads, and cover the outer layer with a protective layer. A picture layer can also be provided between the ink-absorbing resin coating and the adhesive base layer, and the picture layer is a gold foil / silver foil soft film handmade layer or a painting layer or an inkjet layer or a printing layer. Picture layers can be added or not. The main substrates include leather, non-woven fabric, non-woven paper, cloth, etc. The adhesive can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com