Patents

Literature

98results about How to "Secure adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

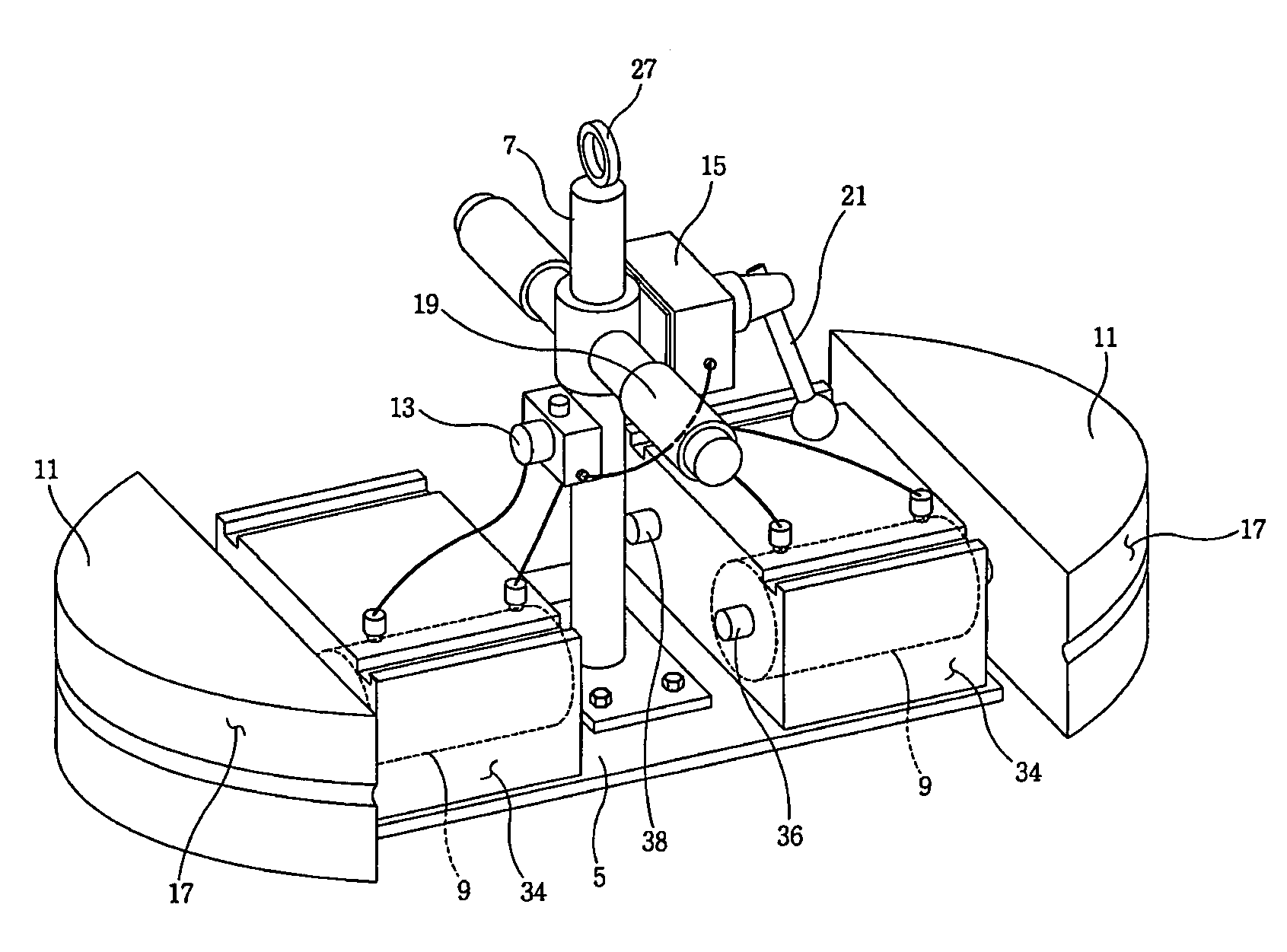

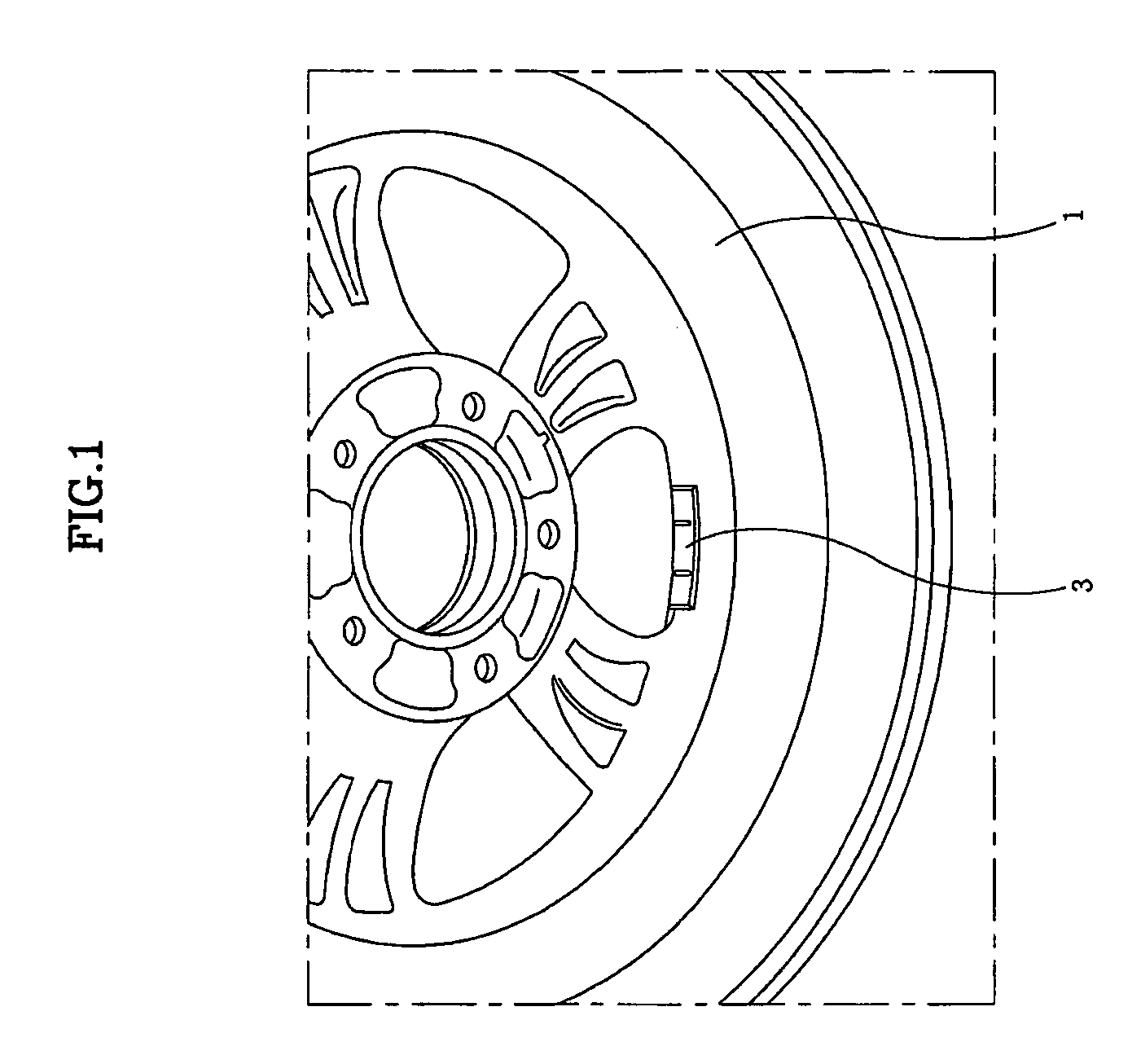

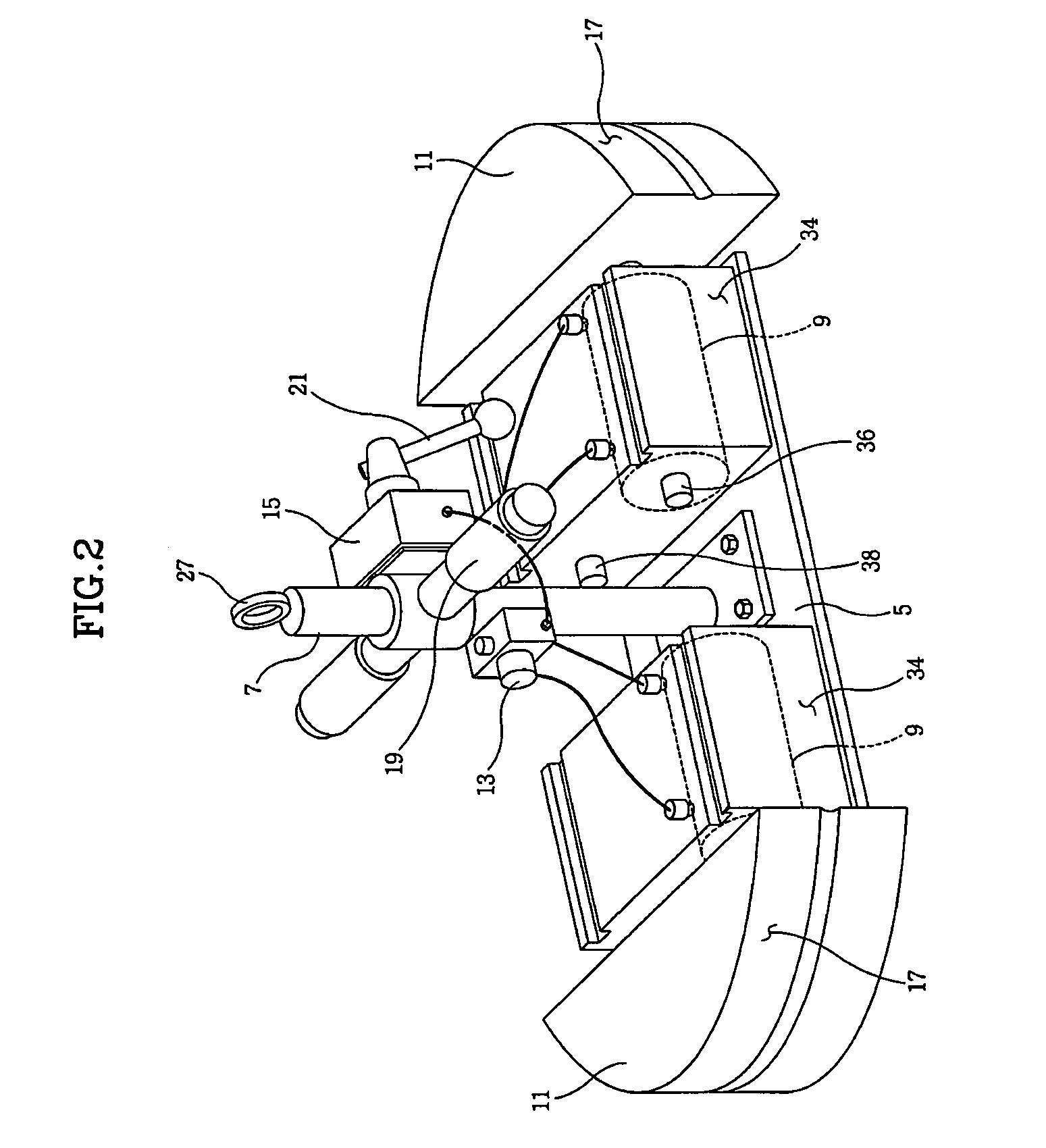

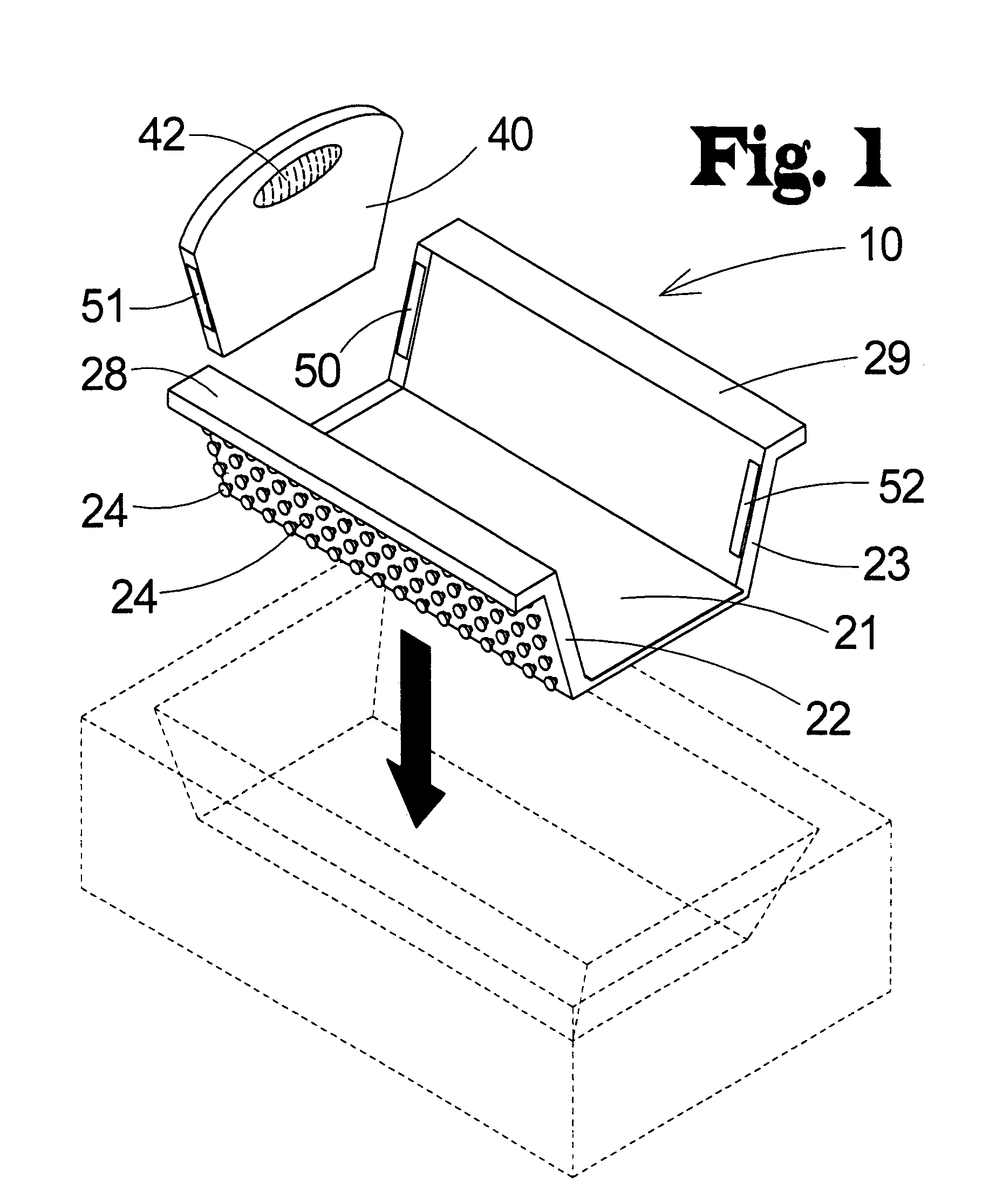

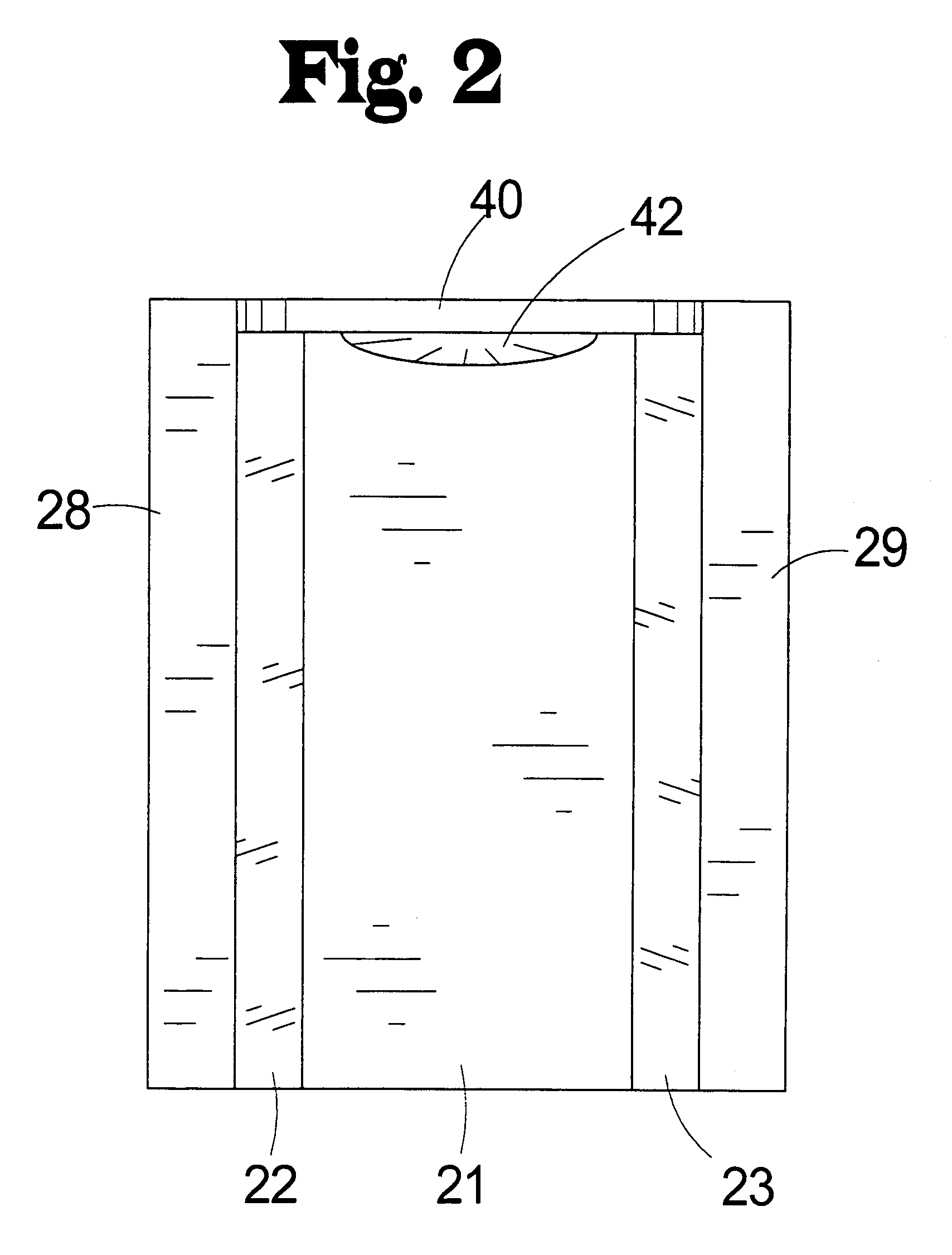

Sticker weight pressurizer for wheels

InactiveUS7478659B2Strong adhesionSecure adhesionHubsControlling laminationPressure transmissionEngineering

A sticker weight pressurizer includes a base plate, a hanger which protrudes upwards from a center portion of the base plate, double-acting cylinders which are disposed on the base plate on opposite sides of the hanger, a pressure block on one end of a piston rod of each of the double-acting cylinders, a regulator valve which adjusts pressure of compressed air supplied from a pneumatic pressure source, and a direction control valve which transfers pressure, supplied from the regulator valve, to the double-acting cylinders while controlling the direction of the pressure.

Owner:KIA MOTORS CORP

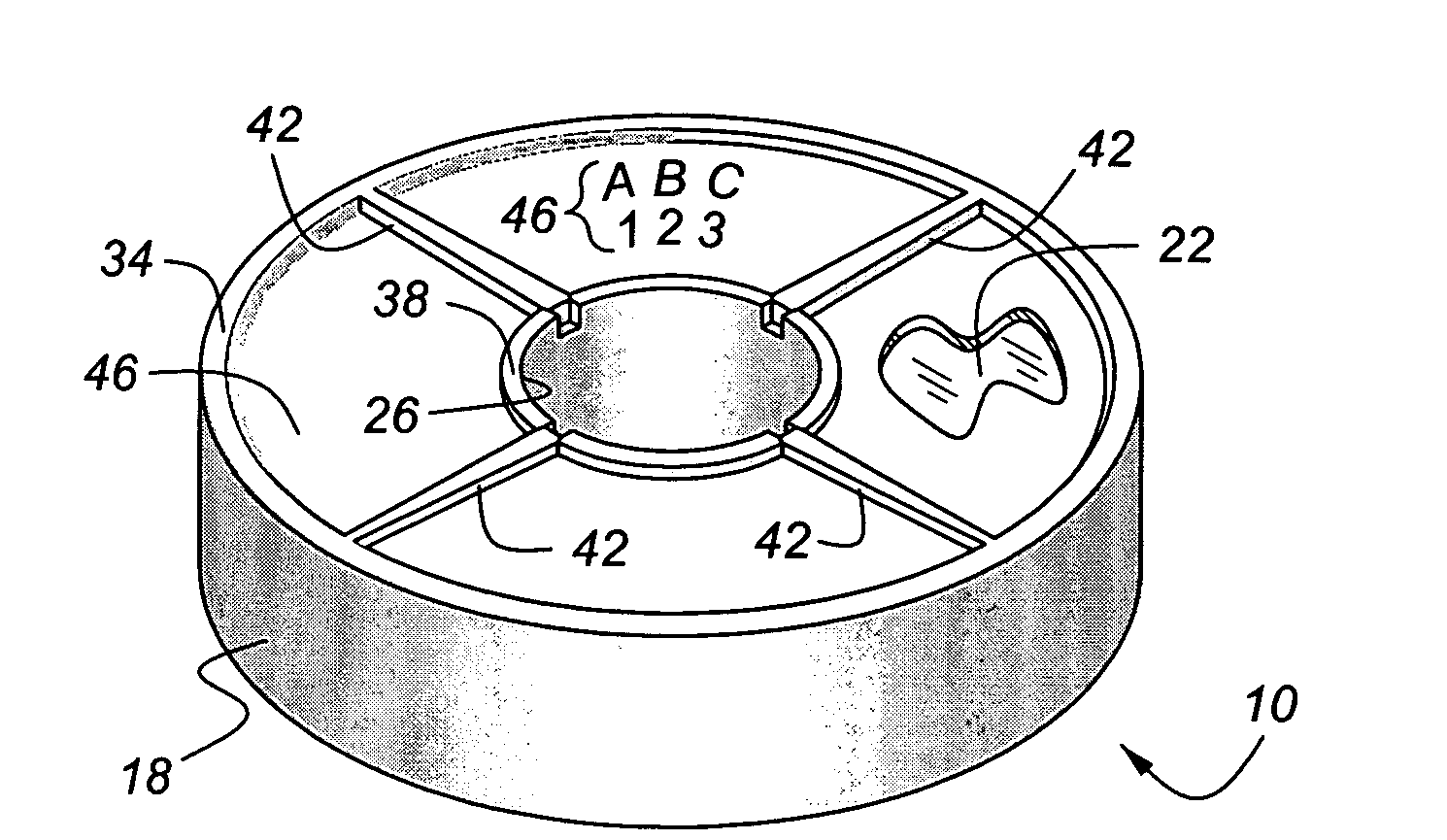

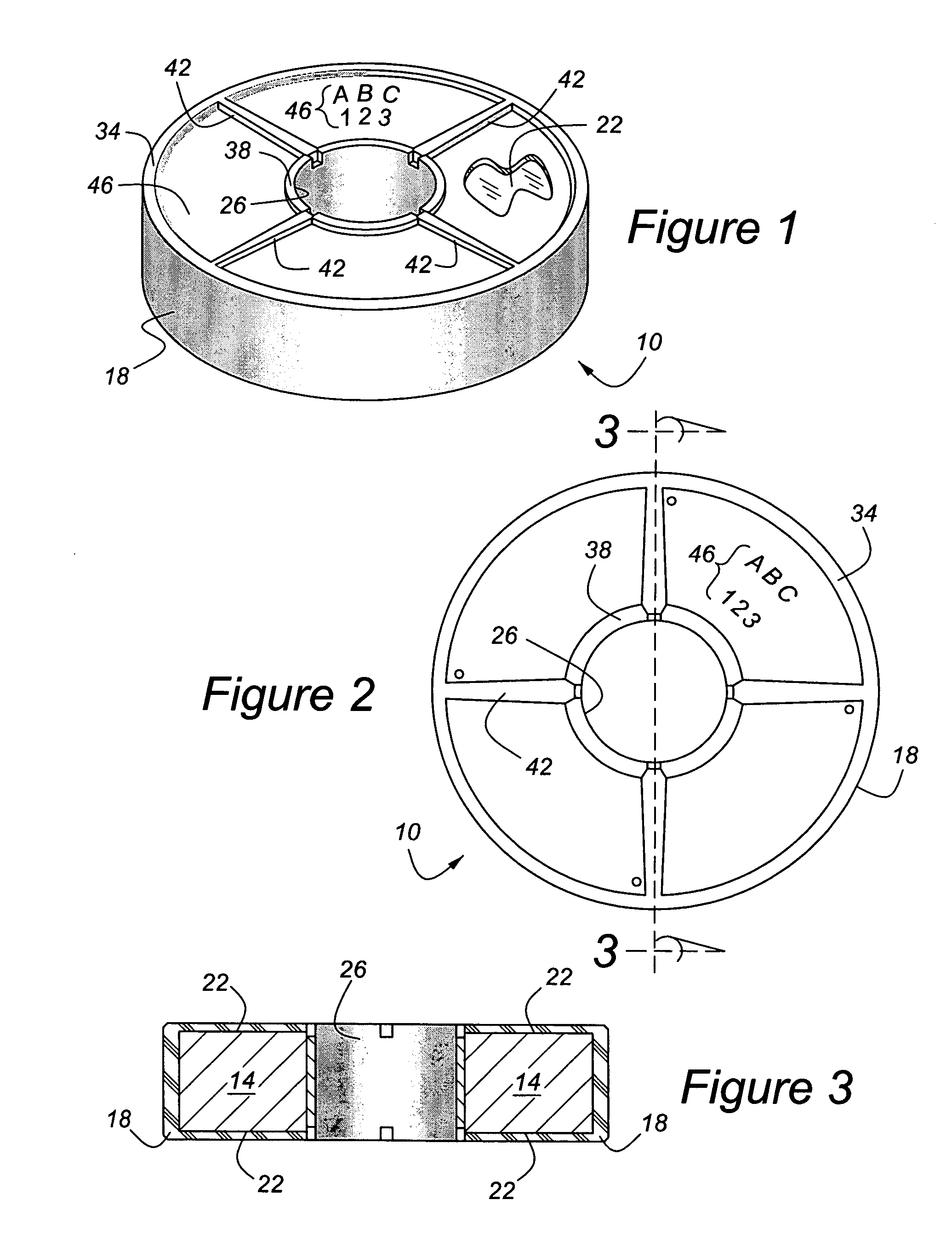

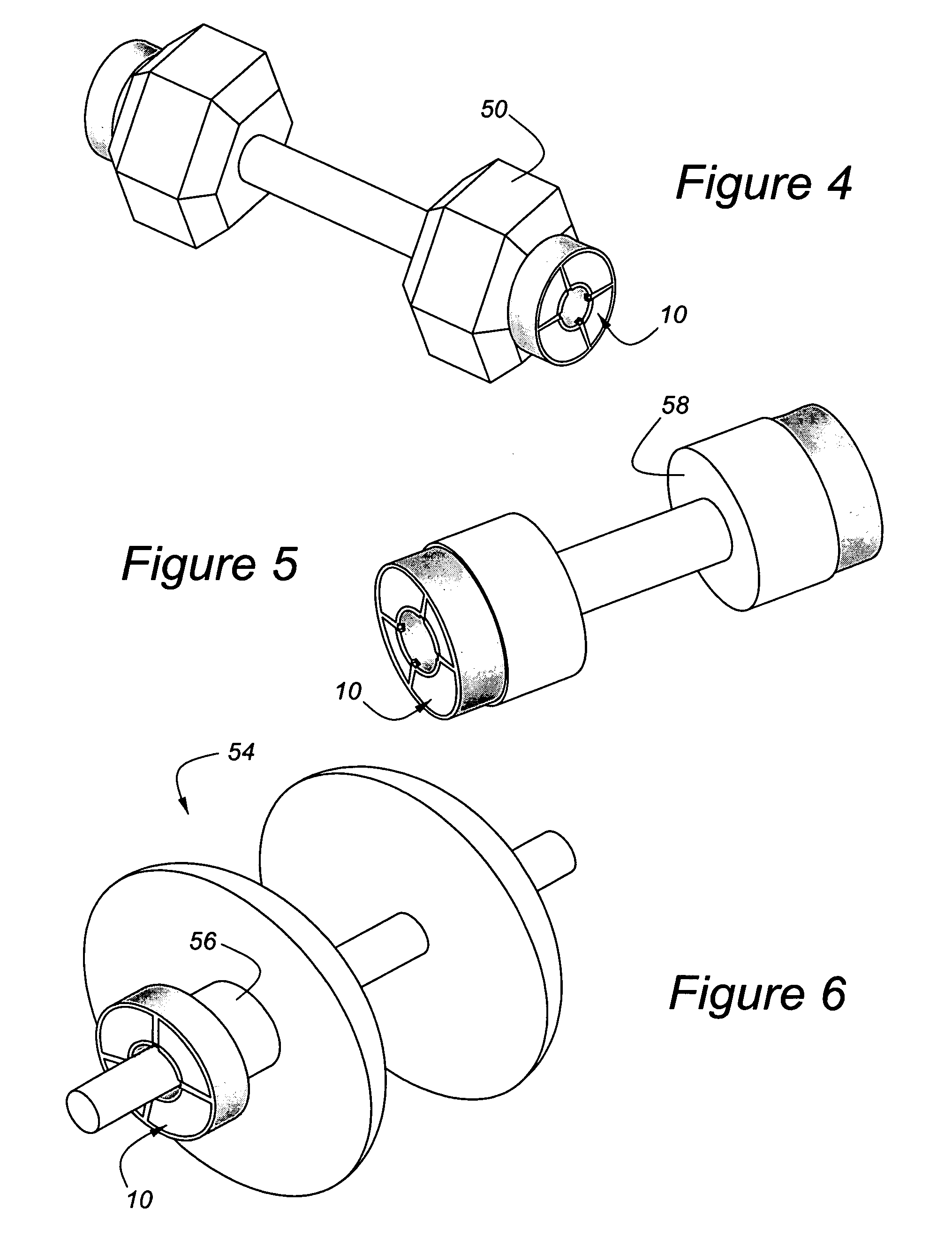

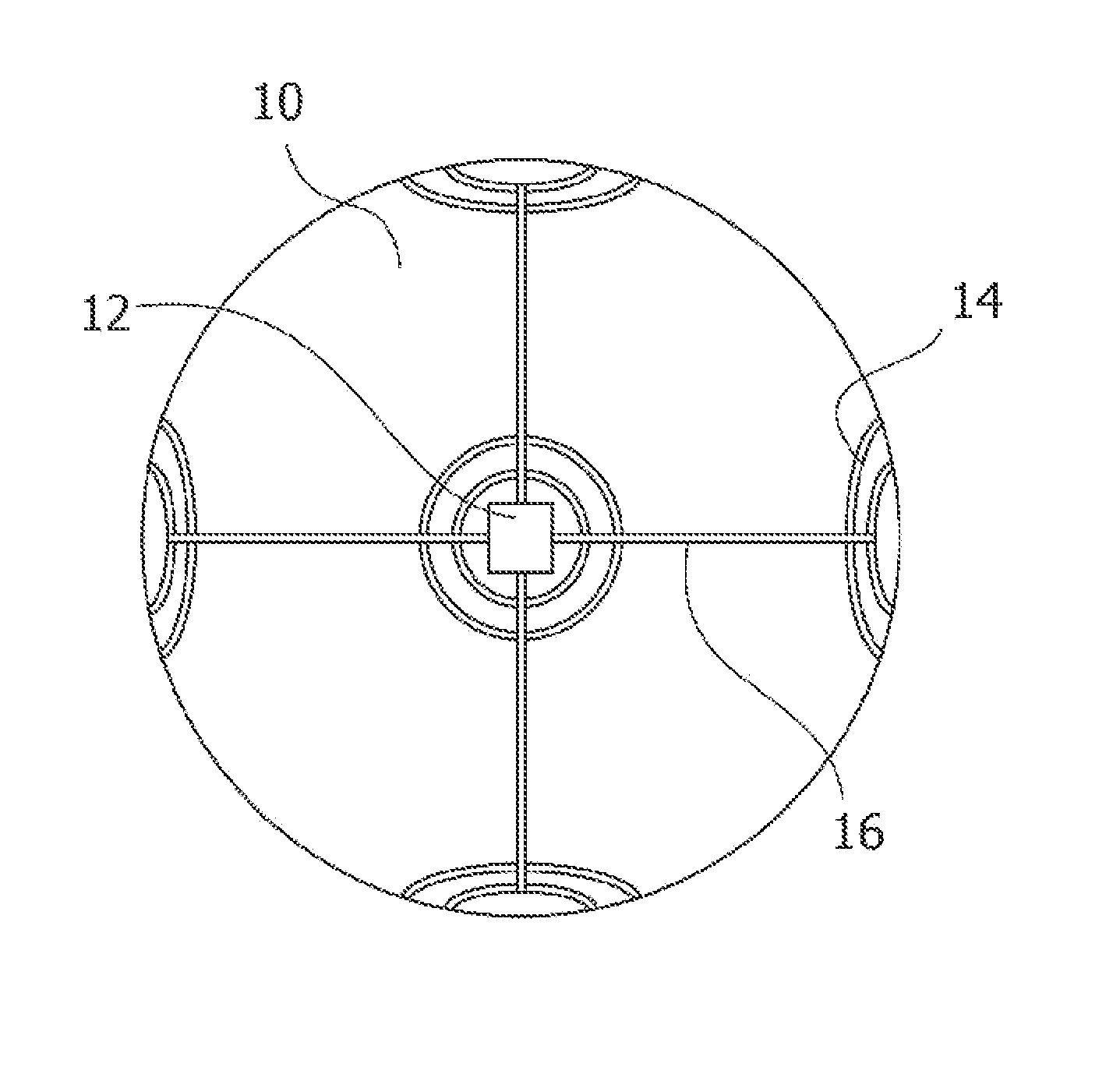

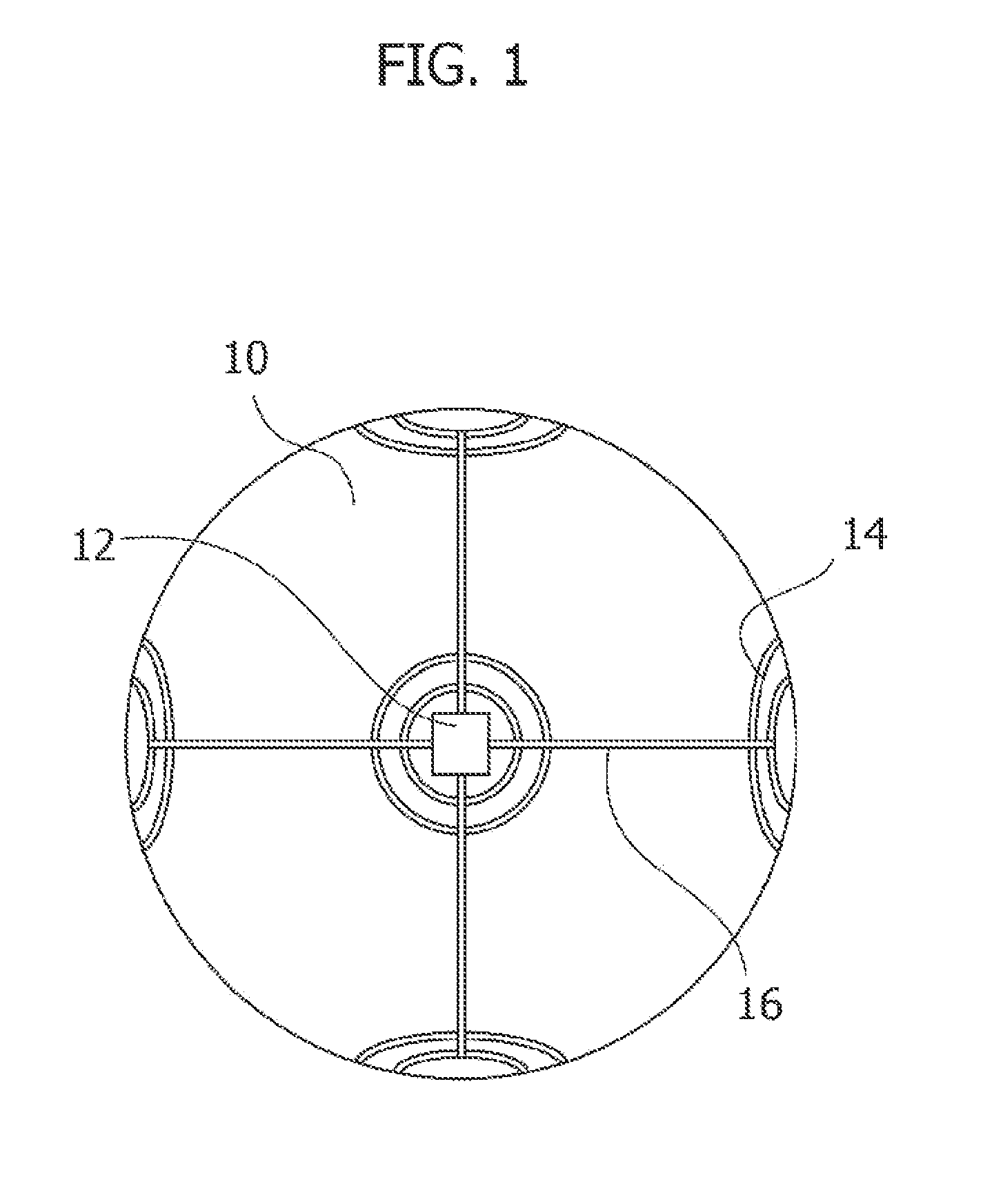

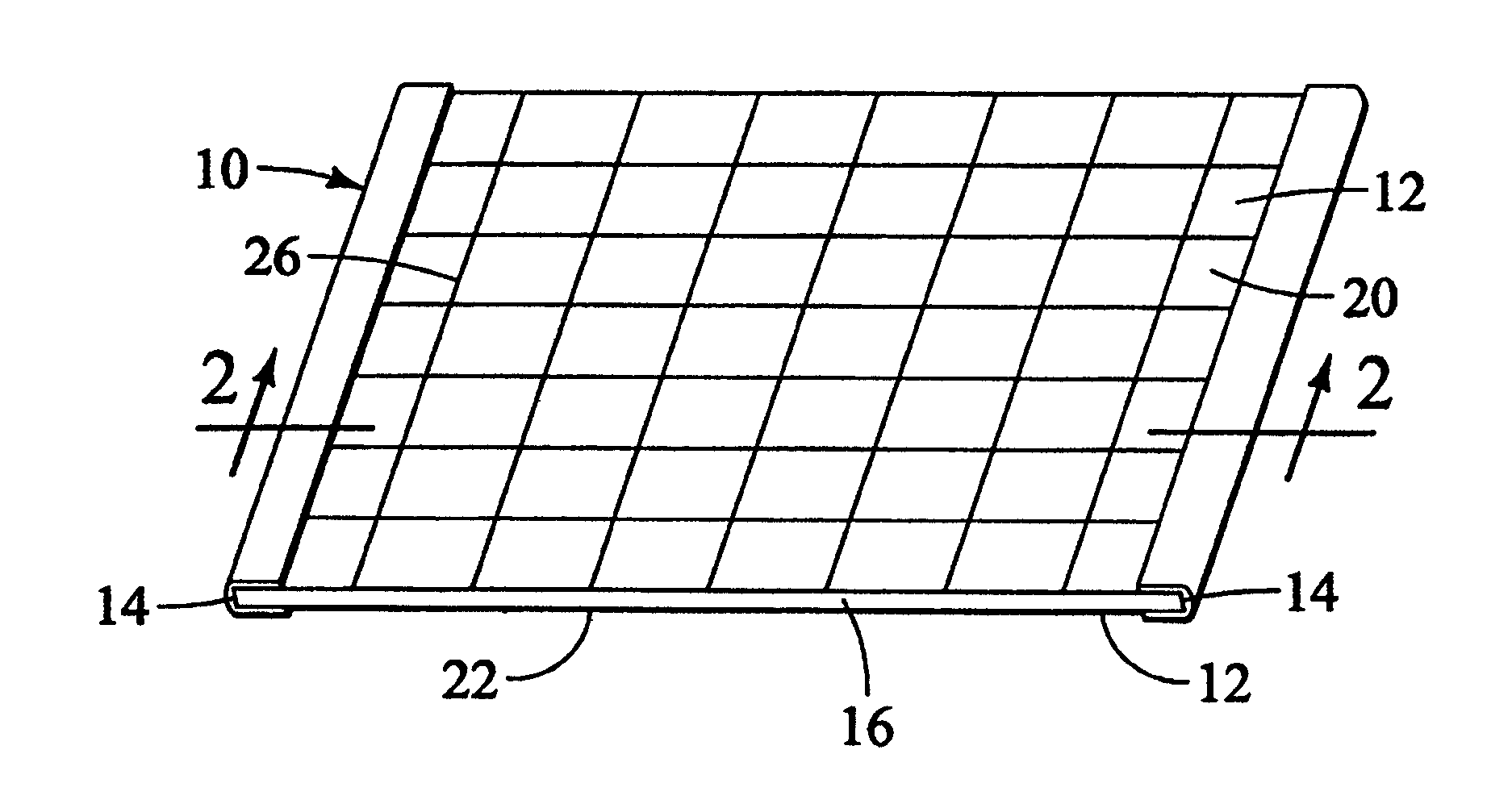

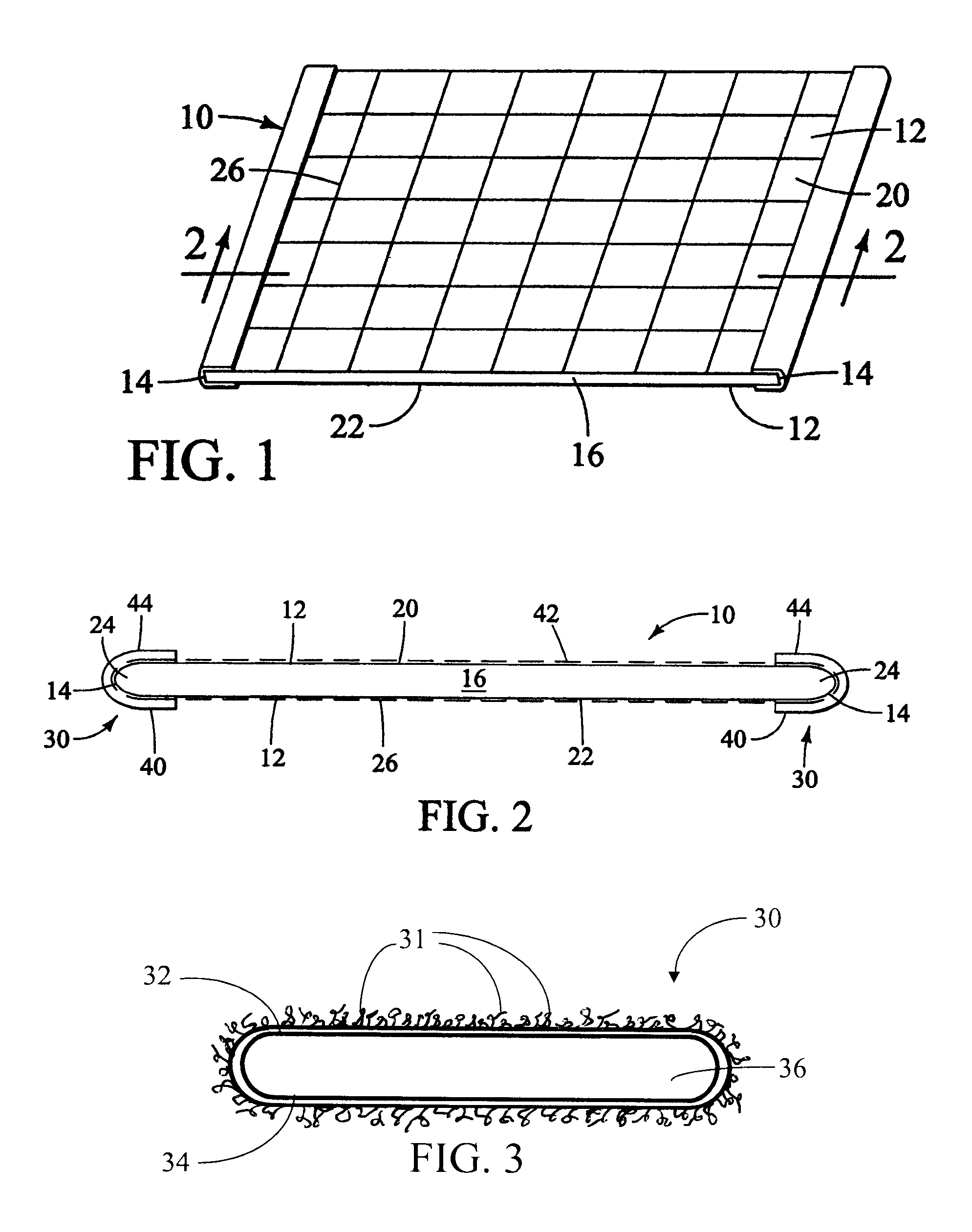

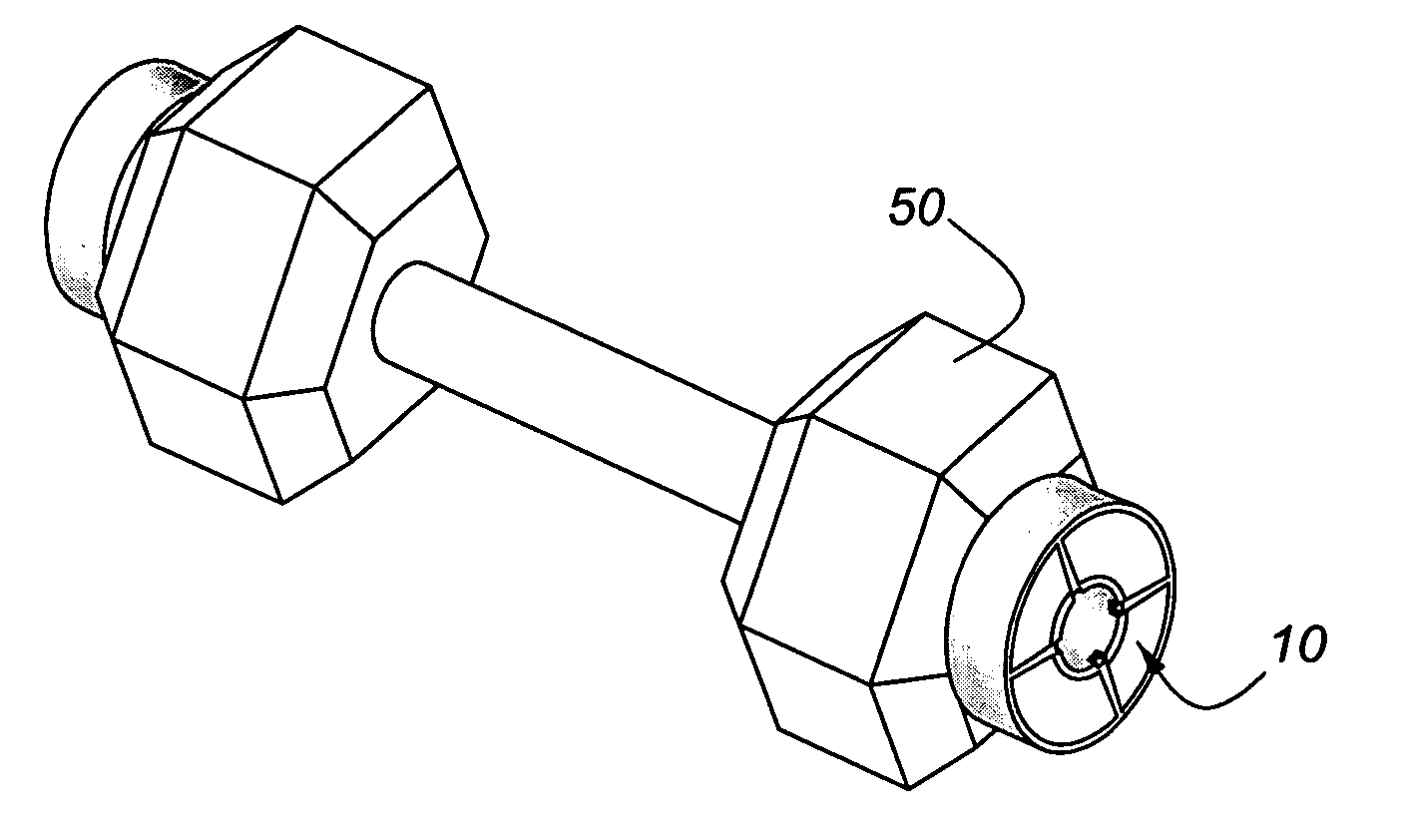

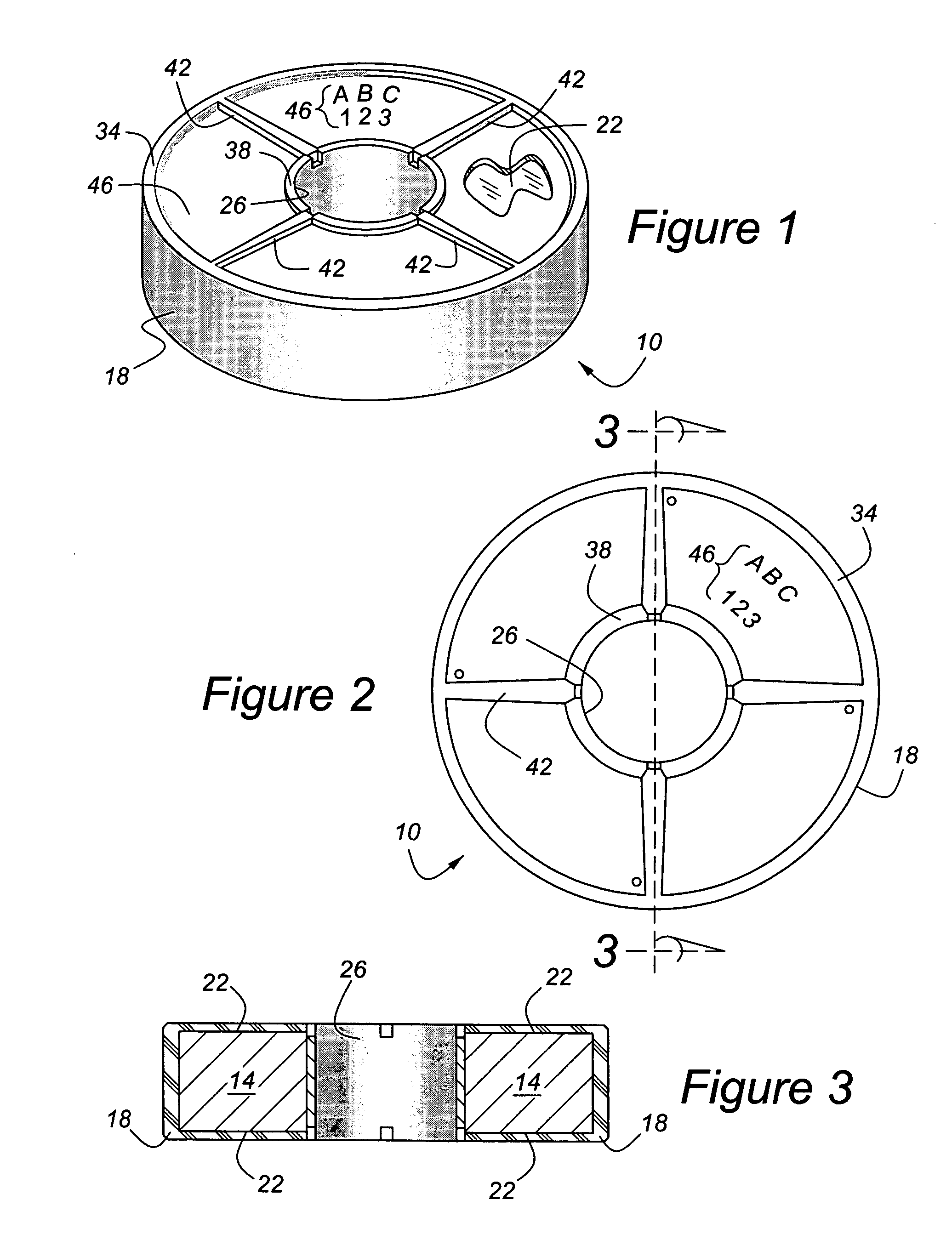

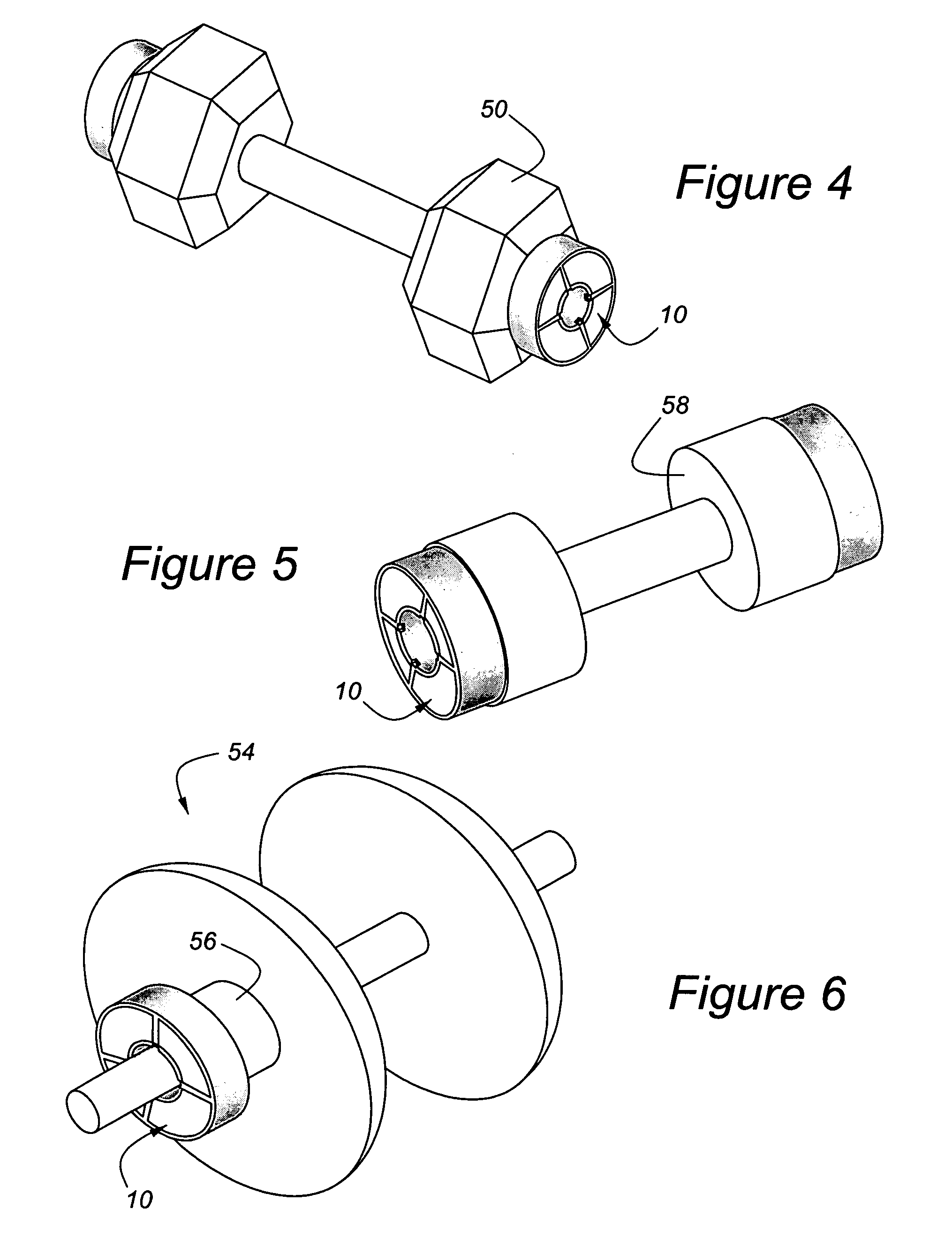

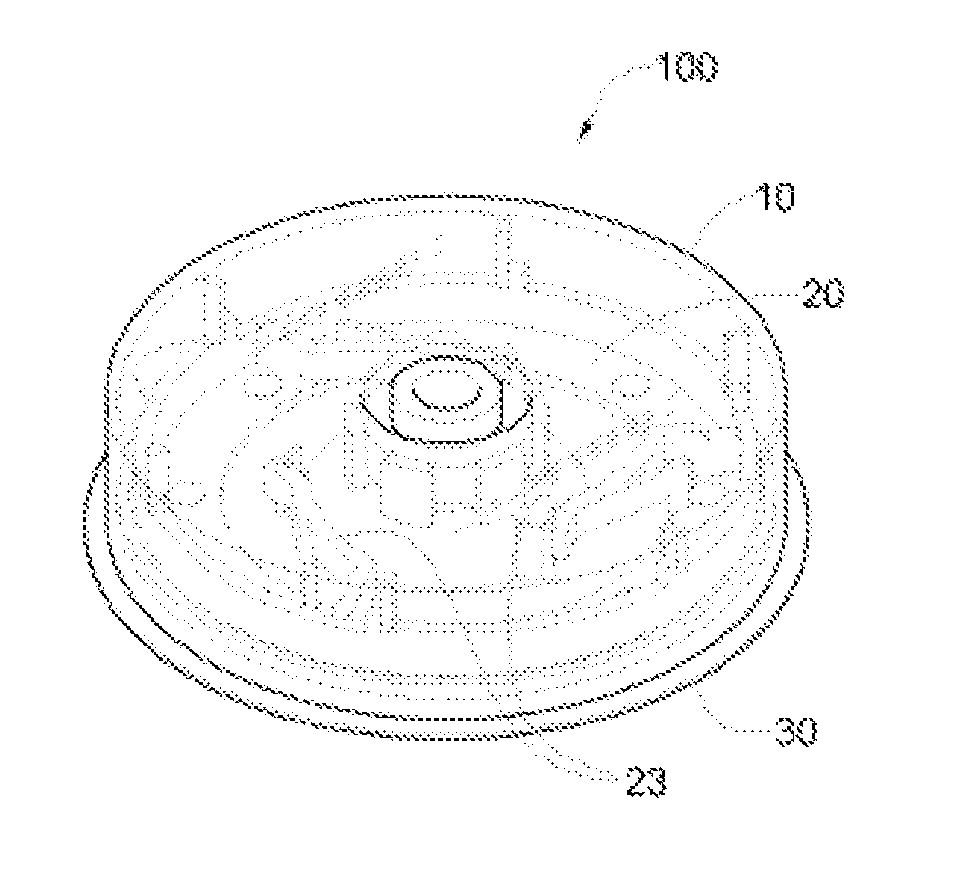

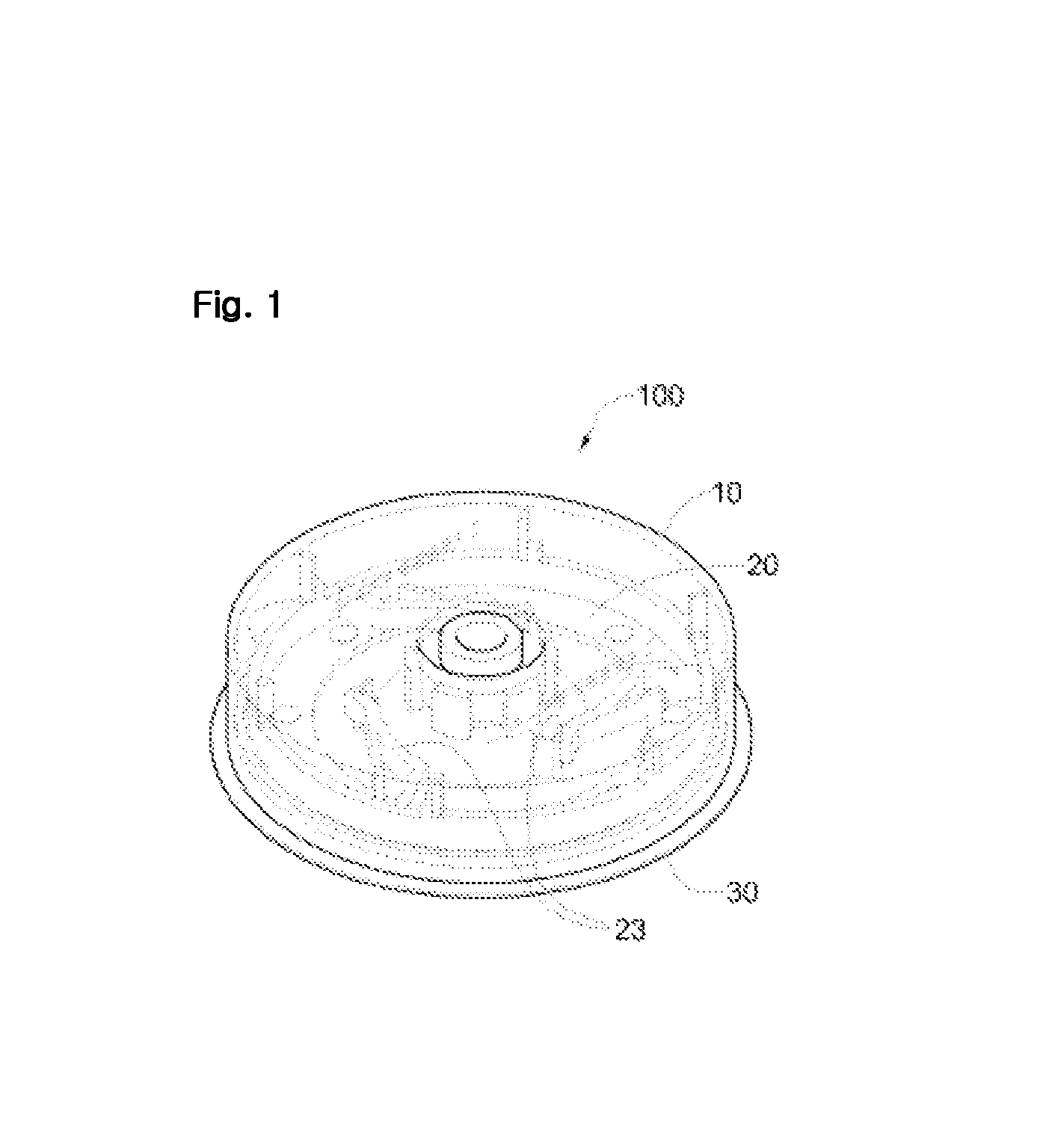

Exercise weight system

An exemplary incremental weight for an exercise system has a generally annular magnet encapsulated within a coating which cushions the magnet, protecting it both from becoming damaged, and from damaging an exercise apparatus, while promoting the adhesive properties of the magnet. In a first exemplary embodiment, the coating comprises a first annular rib and a second annular rib extending respectively about outer and inner peripheries of the generally annular magnet, and a plurality of ribs extending radially between the first and second annular ribs. The generally annular magnet, in exemplary embodiments, comprises at least one of a ceramic magnet, ferrite, or an alnico magnet. Exemplary coatings may be elastomeric, molded silicone, or anti-slip coatings. In another exemplary embodiment, a plurality of mounting pads are attached to a surface of said weight defined by an annular surface of said magnet.

Owner:MCCLUSKY SCOTT

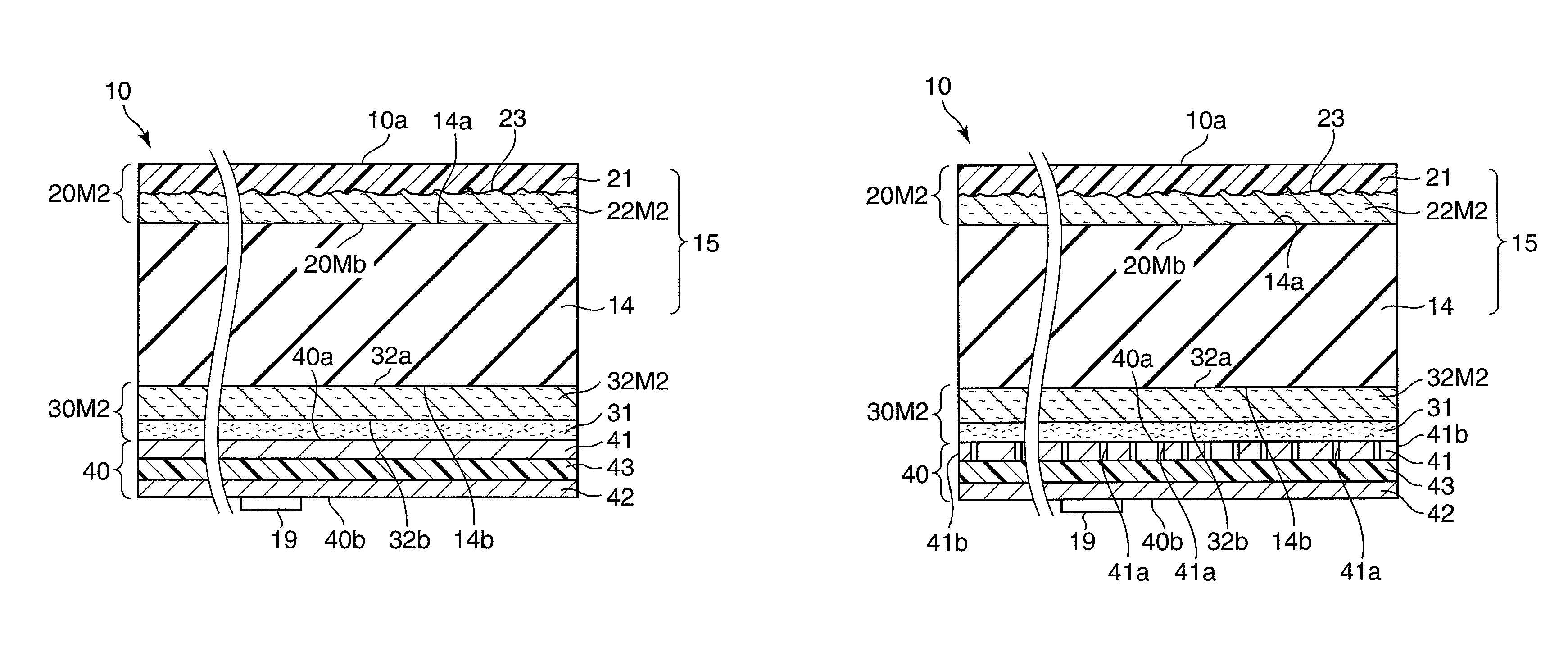

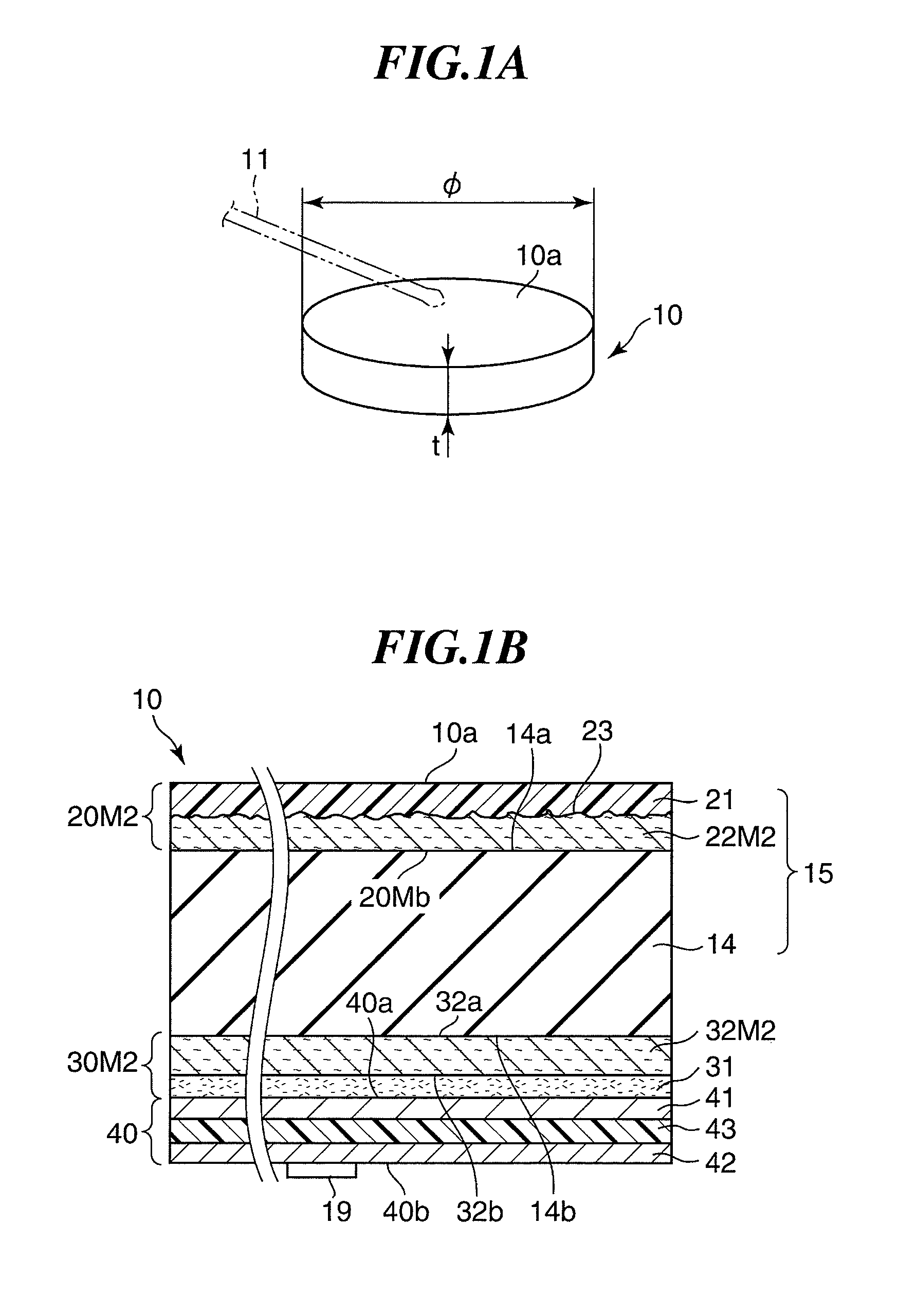

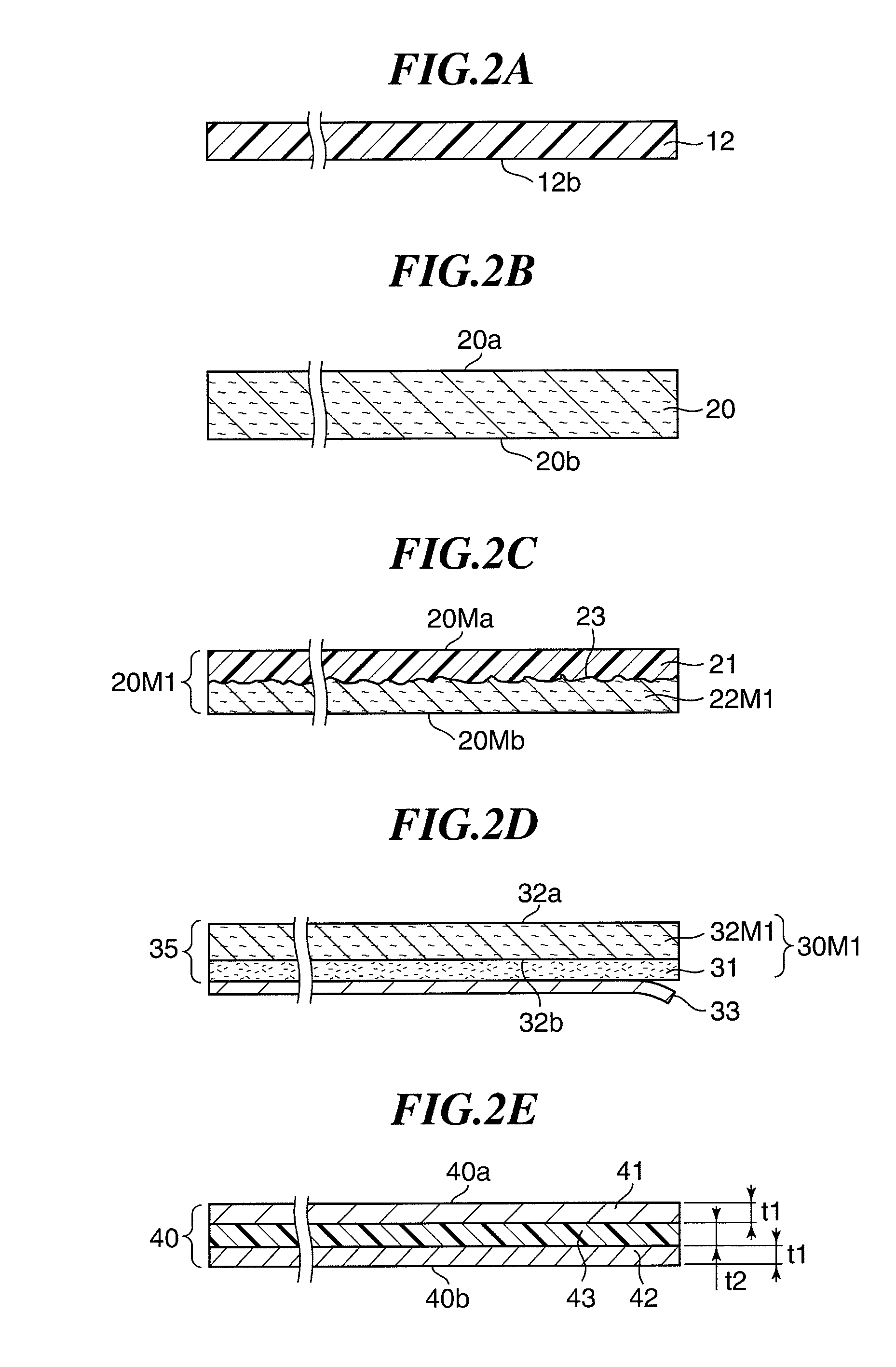

Golf ball with RFID system

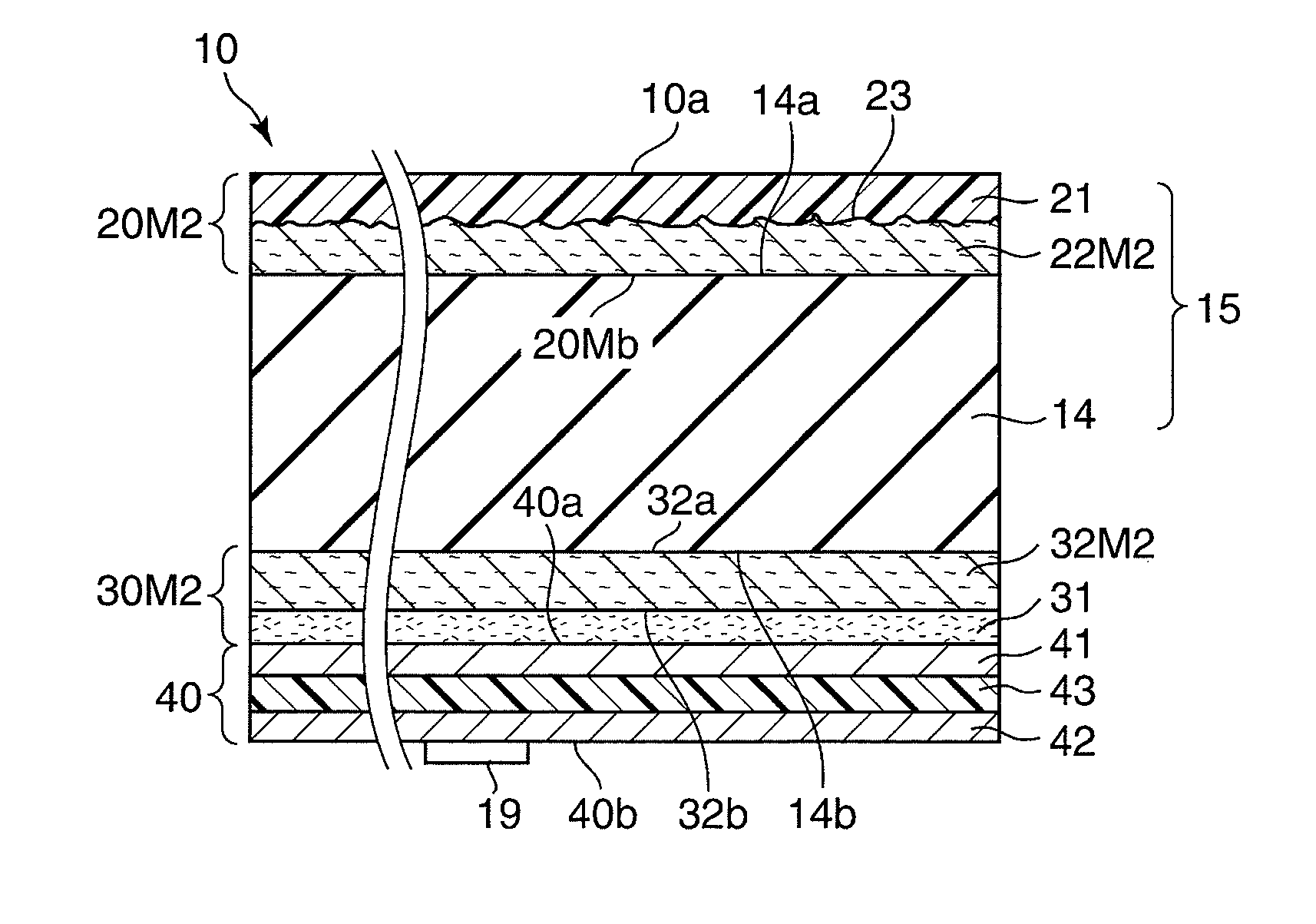

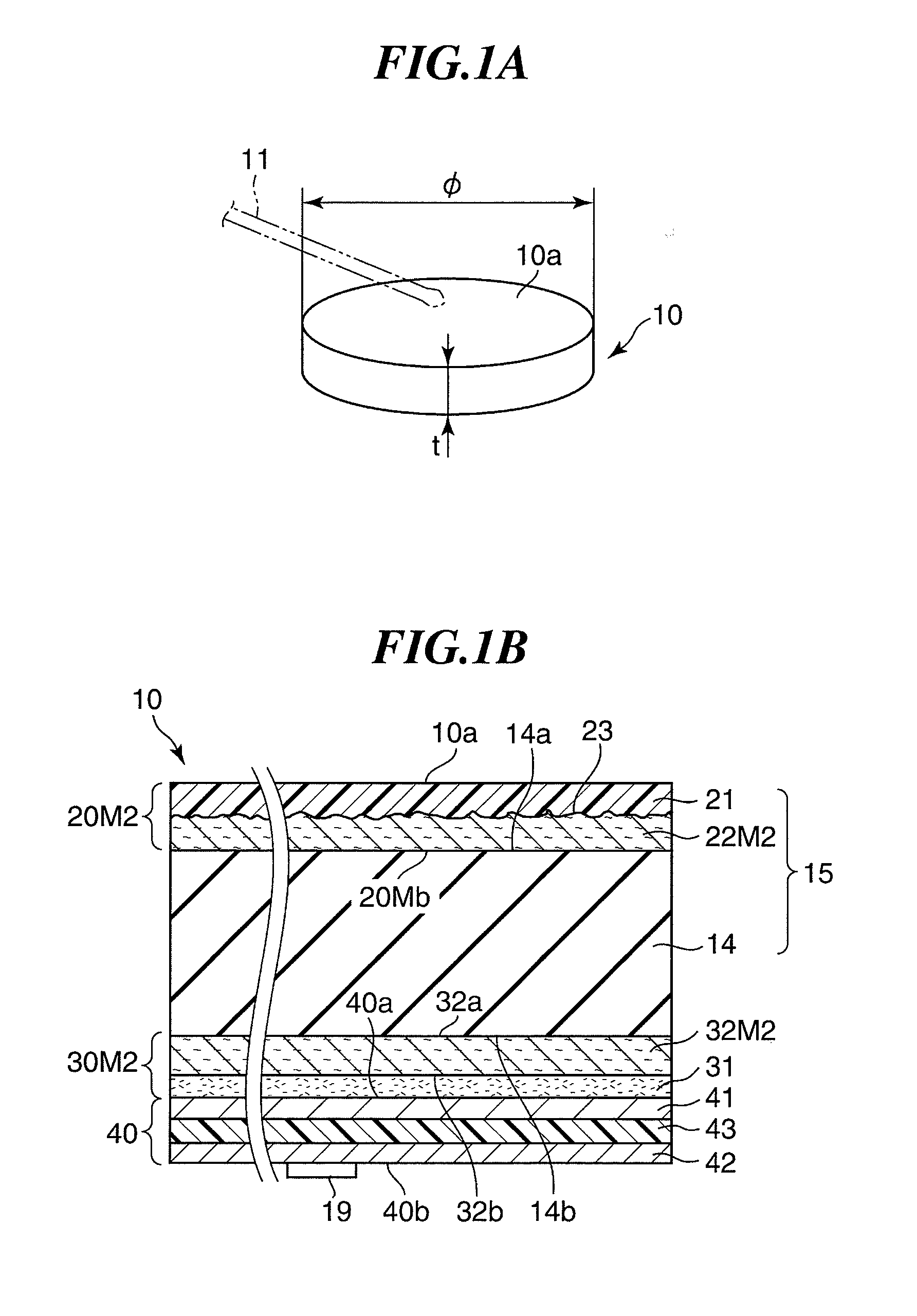

InactiveUS20130196788A1Improve heat resistanceAvoid signalingPrinted electric component incorporationGolf ballsInter layerRadio frequency signal

A golf ball has a radio-frequency identification (RFID) circuit for storing ID information therein, the RFID circuit formed of conductive ink; and an antenna for communicating by using radio frequency signals, the antenna connected to the RFID circuit. The antenna may be formed of conductive ink or paste. The RFID circuit and the antenna may be formed on the surface of the golf ball. The golf ball may further include a core layer, a cover layer disposed on the outside of the core layer, and optionally, an intermediate layer disposed between the core layer and the cover layer. The core or intermediate layer has a groove on the surface thereof, and the RFID circuit and the antenna may be formed within the groove.

Owner:BRIDGESTONE SPORTS

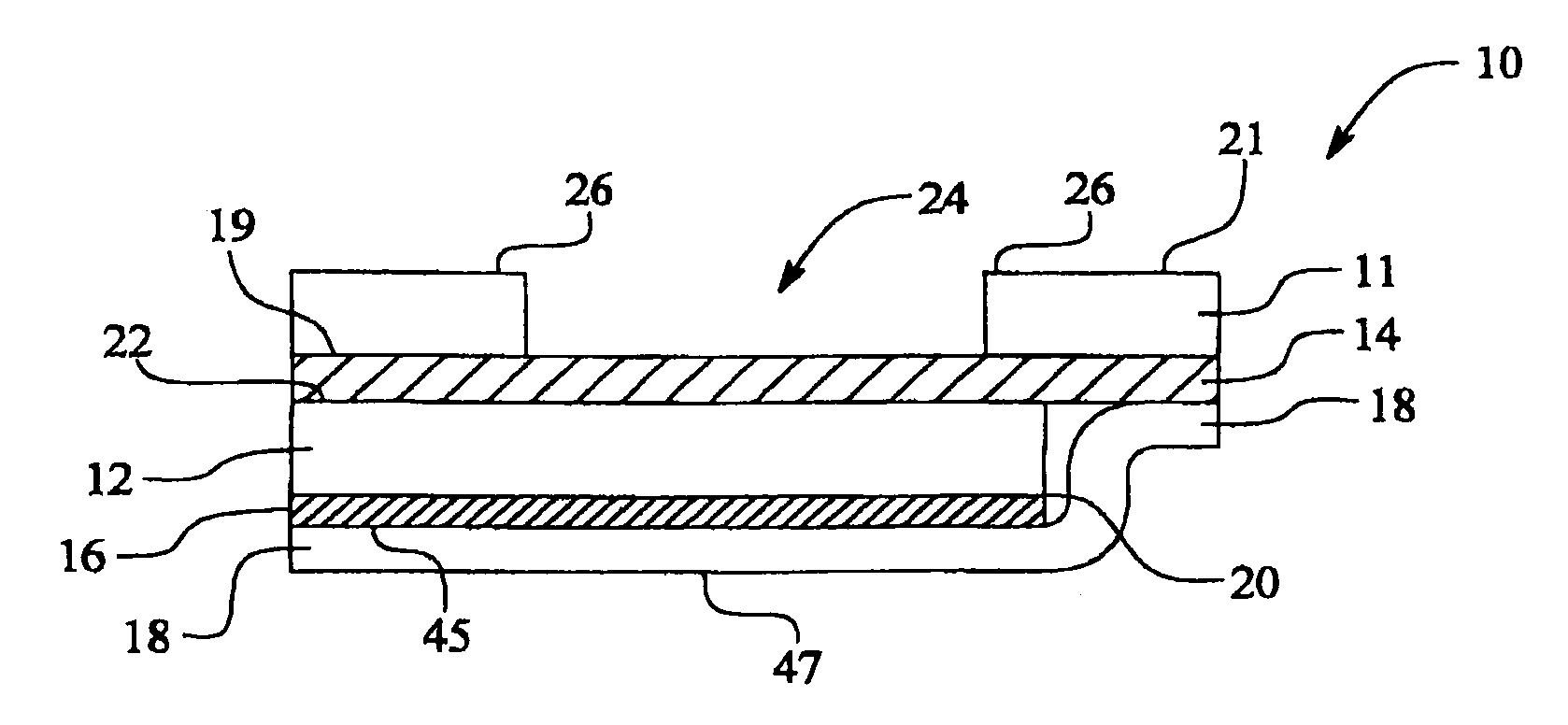

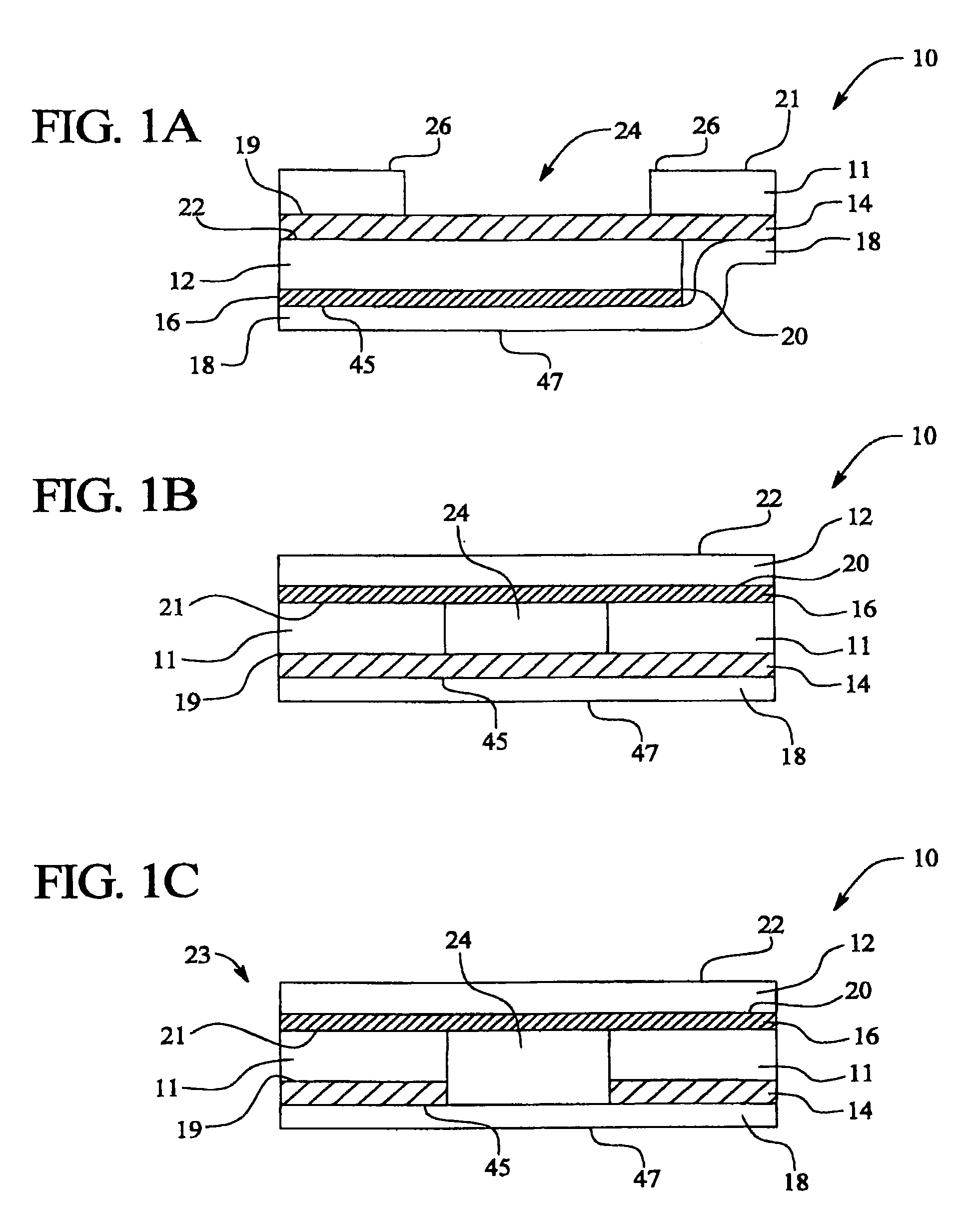

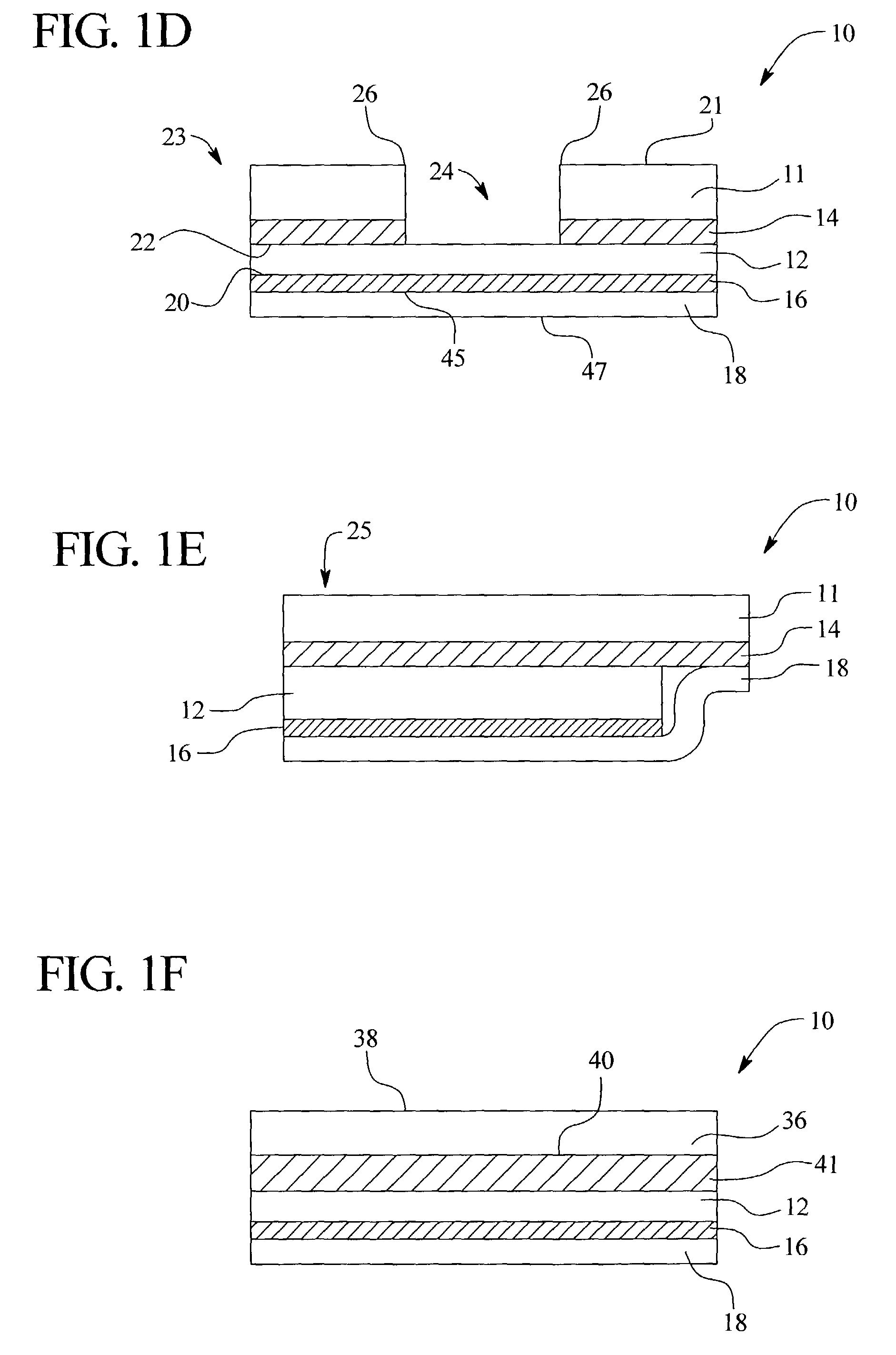

Dressing and a method for making and applying a dressing

A film dressing for catheter sites and a method for applying and making such a dressing are provided. Preferably, the film dressing has a foam layer. A moisture vapor semi-permeable film may be secured to the foam layer. A window in the foam layer allows for viewing of the catheter site. The moisture vapor semi-permeable film may be coated with an adhesive for application to a catheter site. The adhesive may vary in strength and pattern. The dressing may further have a liner coated with silicone for use in protection of the semi-permeable film. A label may be removable attached to the silicone coated liner. The dressing may further have additional foam pieces for use in the application of the dressing to a patient. The dressing may have different colors indicating, for example, the strength of the adhesive used with the dressing.

Owner:CSI MEDICAL INC

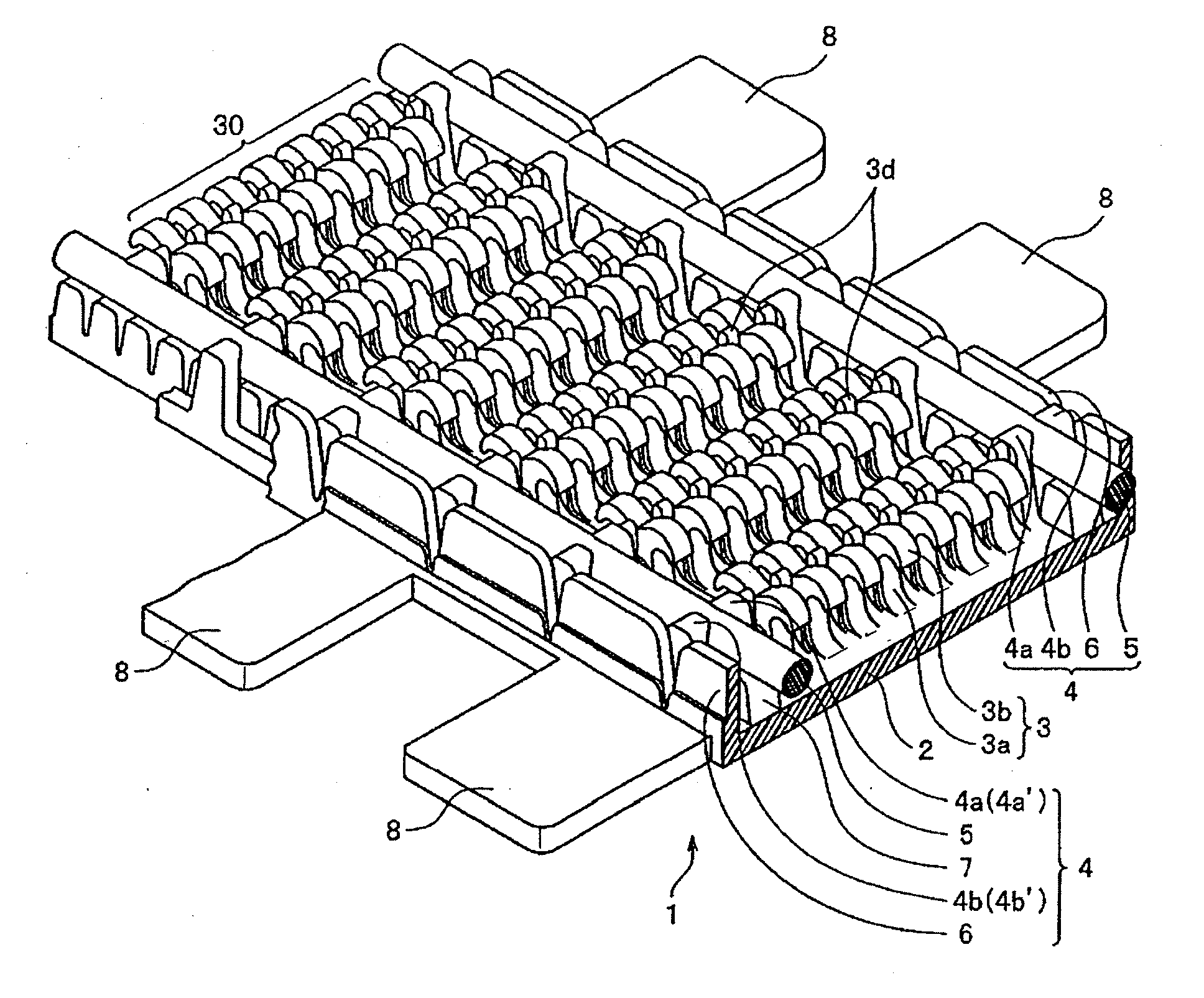

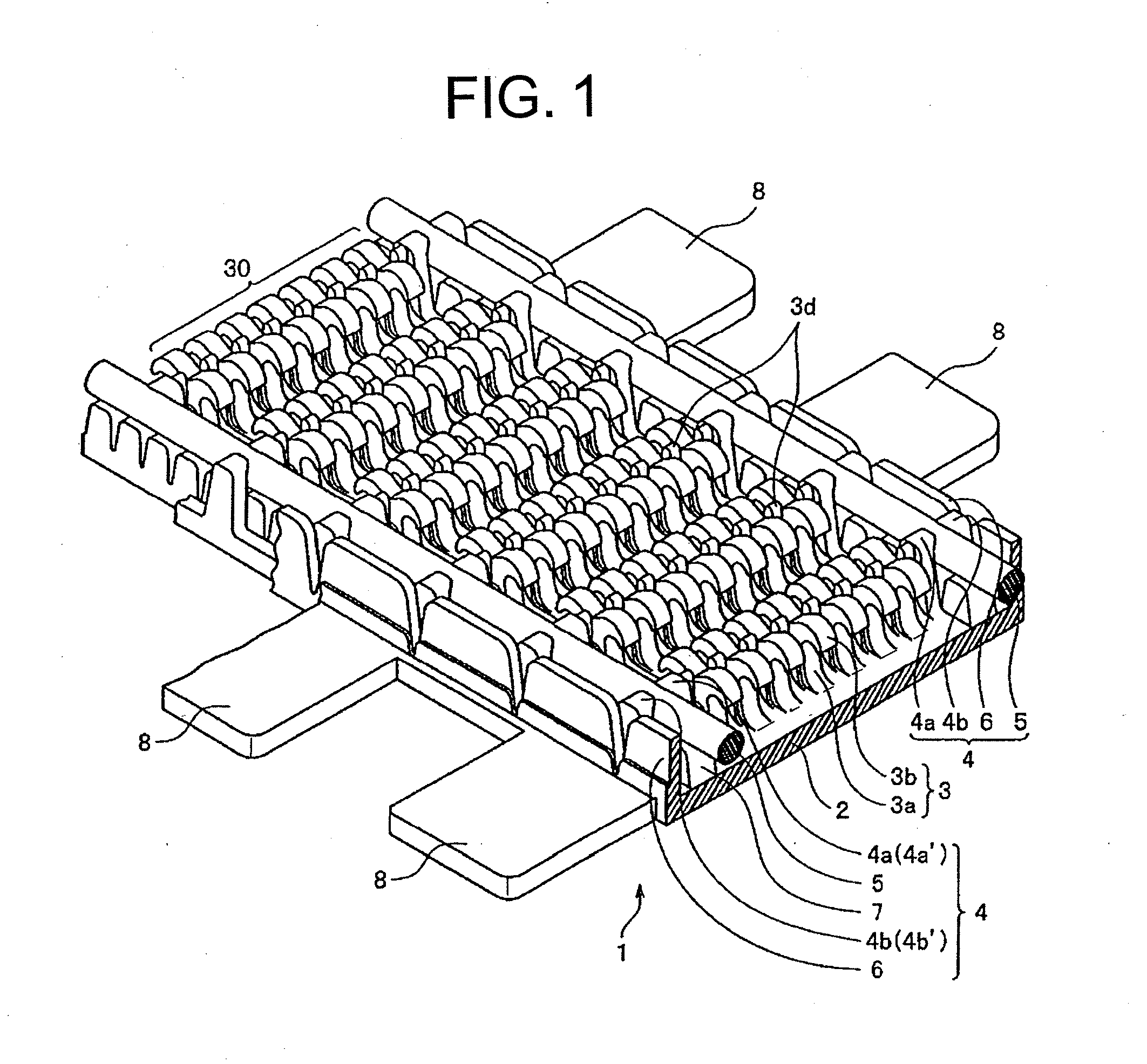

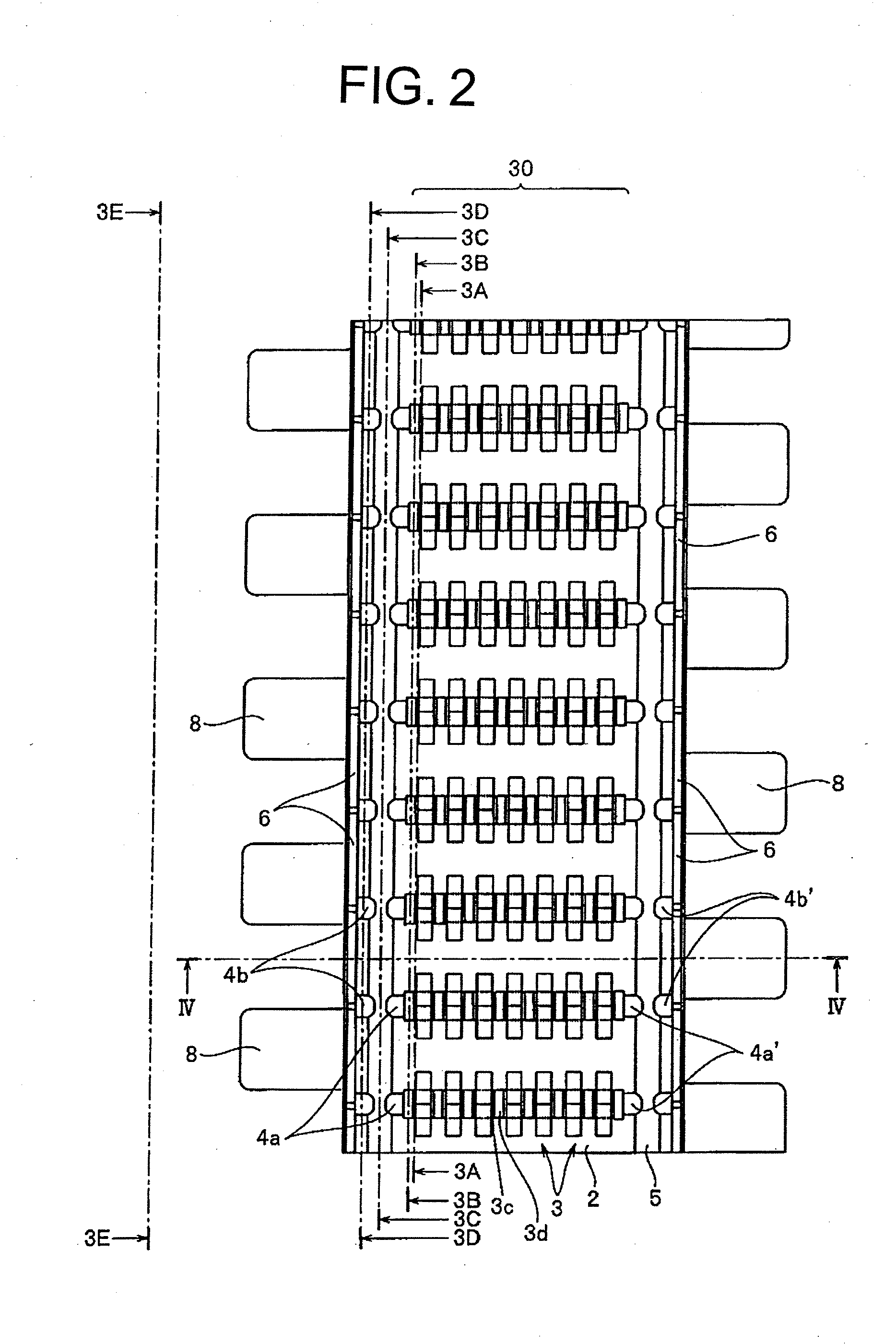

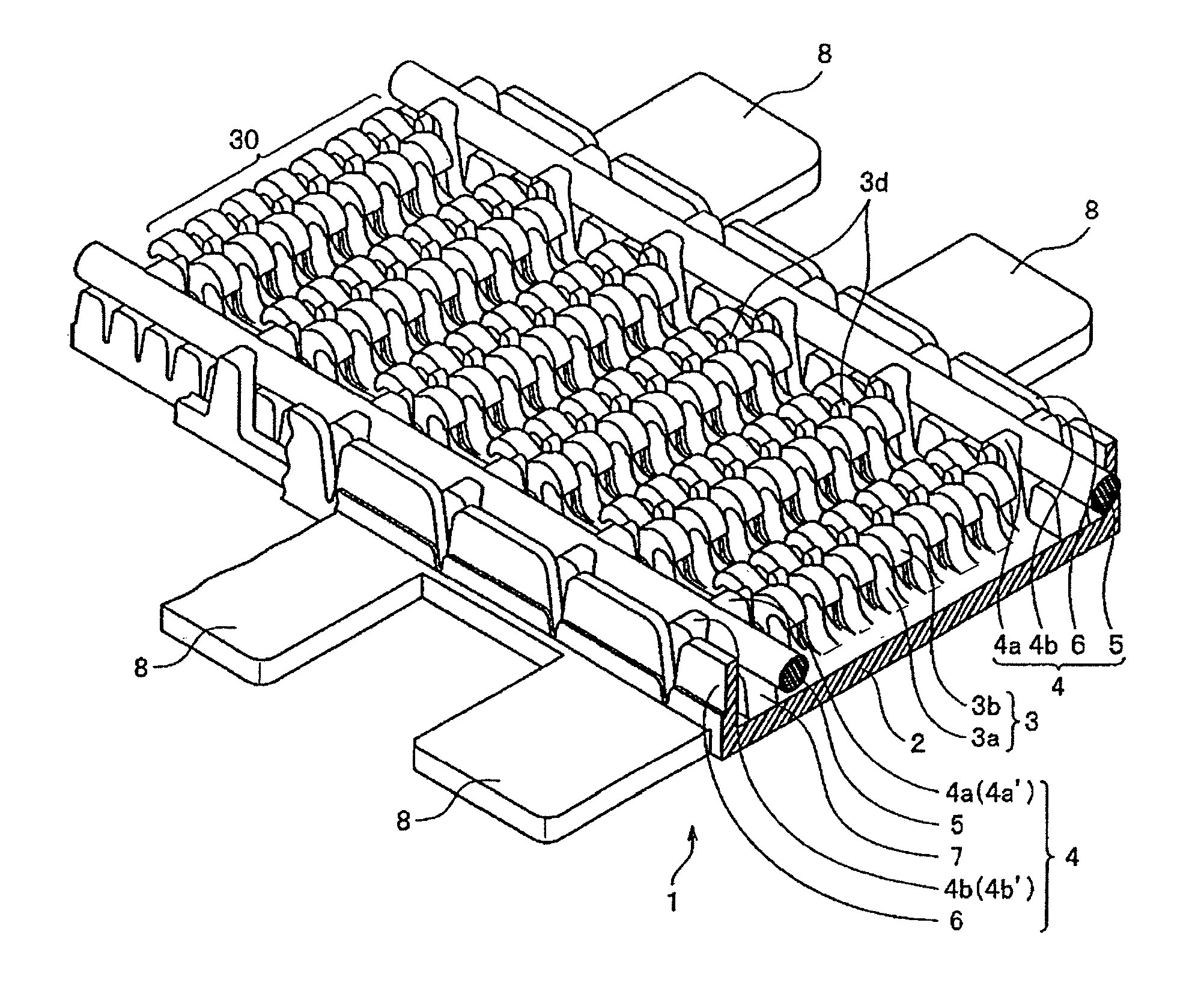

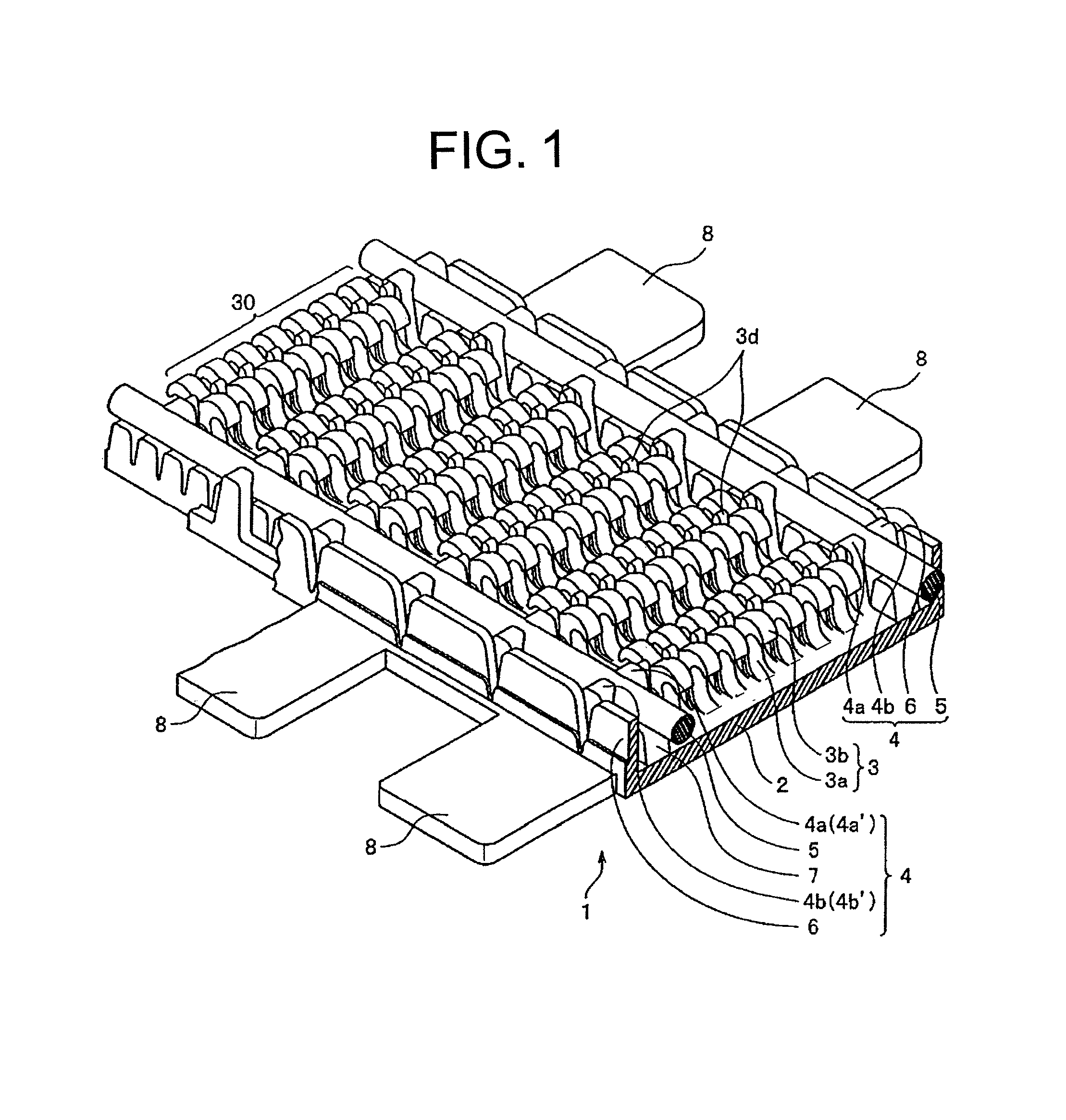

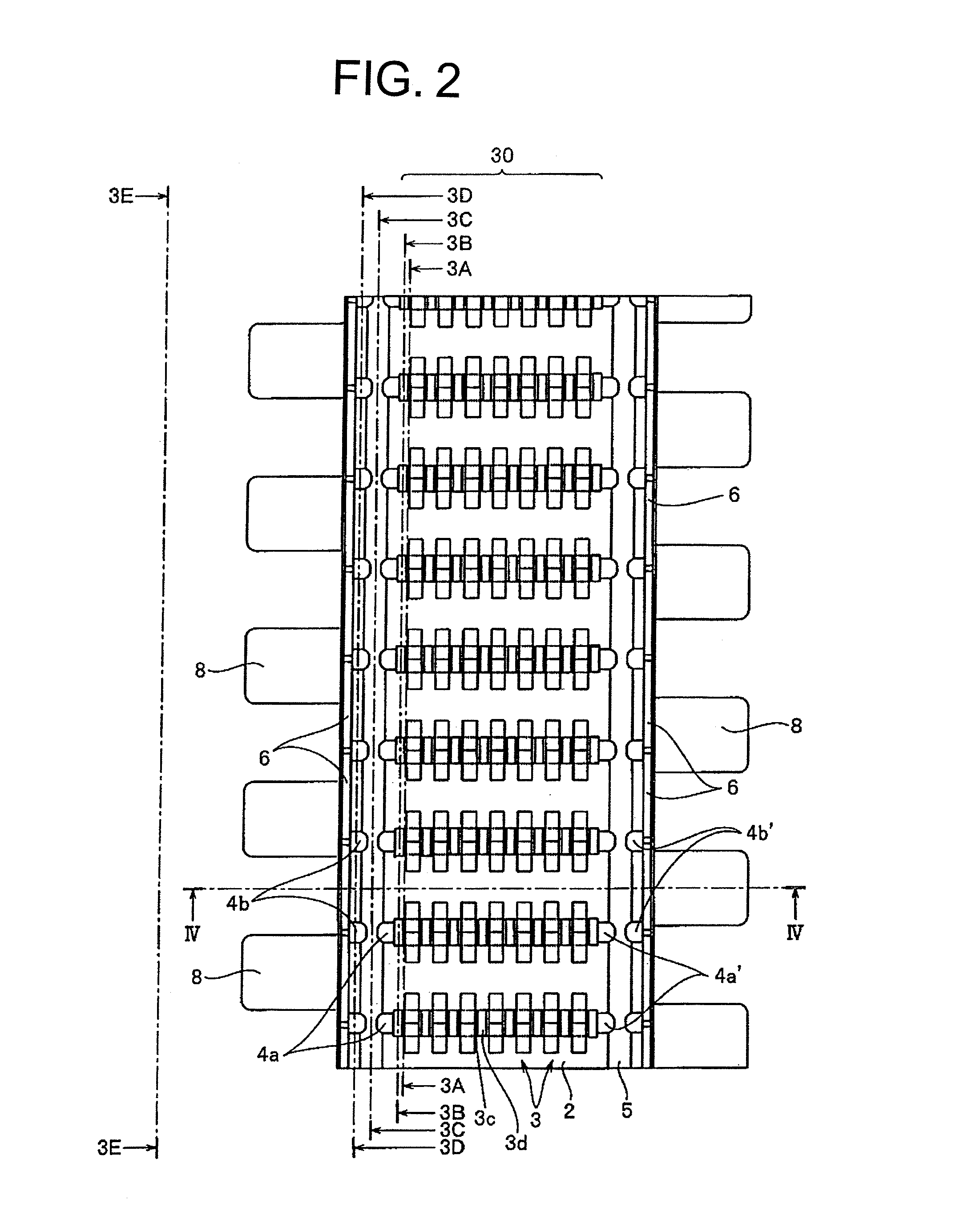

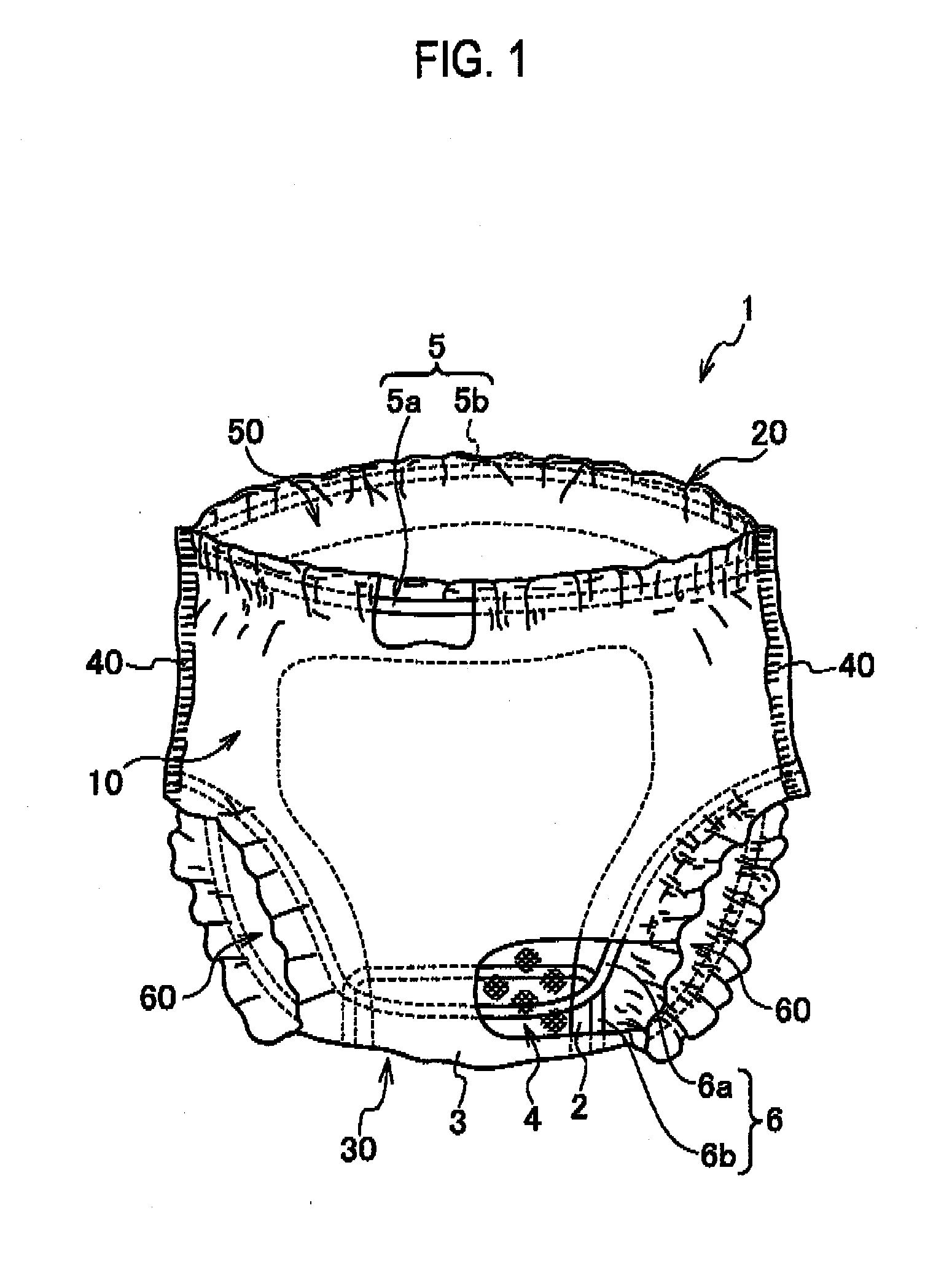

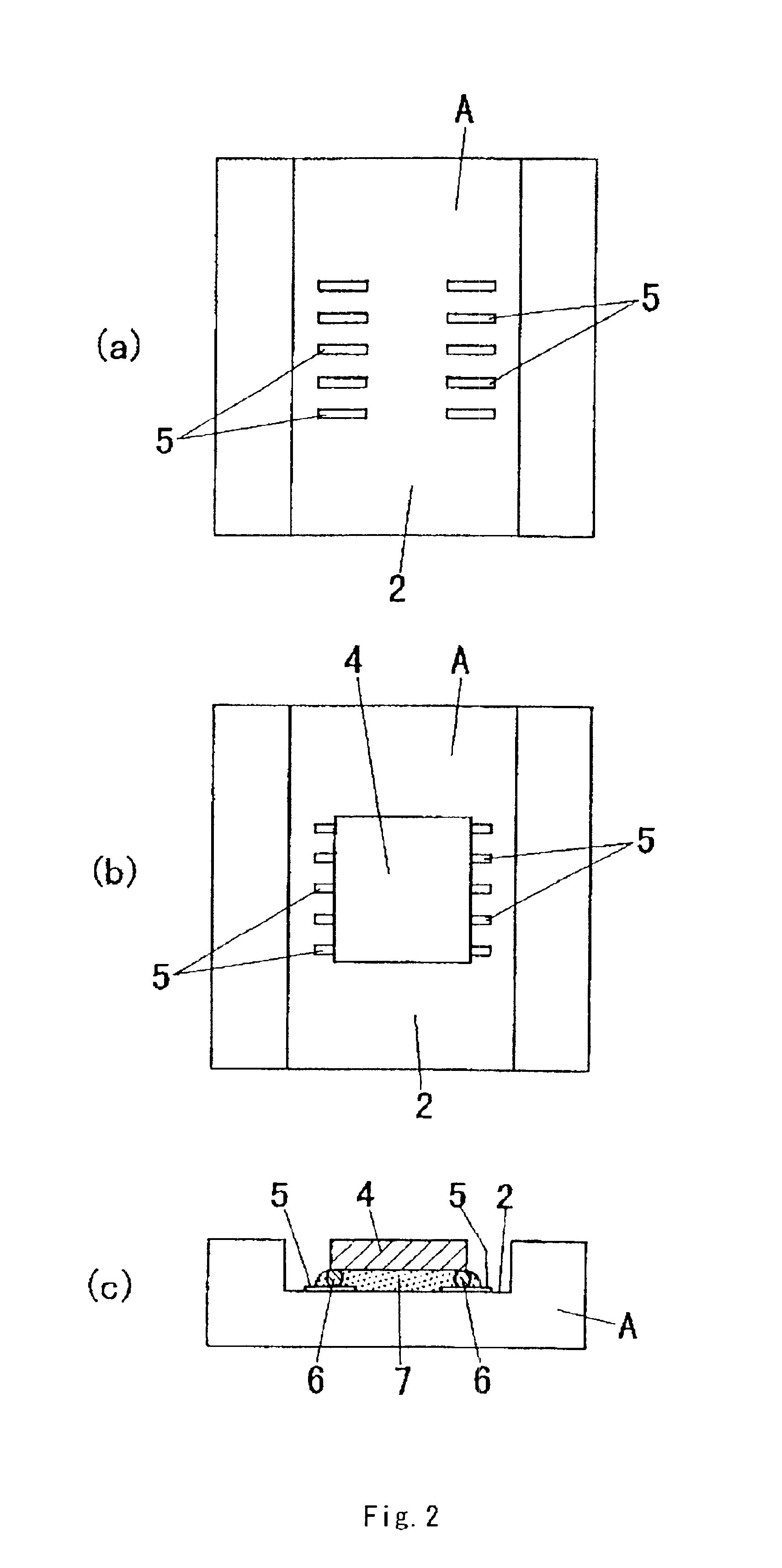

Molded Male Surface Fastener

A molded male surface fastener (1) comprises resin invasion preventing walls (4), which prevent an invasion of a molding foamable resin material of a cushion body, on right and left edge portions along a longitudinal direction of a surface of a flat base member (2) made of a thermoplastic resin, a plurality of engaging elements (3) provided between left and right resin invasion preventing walls (4), and a linear sealing body (5) that is continuously disposed in the longitudinal direction of the base member (2) along a peripheral portion of a top portion of each resin invasion preventing wall (4). When an engaging element forming surface of the surface fastener (1) is placed on a concavo-convex surface of foaming body molding cavities of a foaming mold (100), if the mold has the same magnetic force as that in the related art, the linear sealing body (5) is well adhered along the concavo-convex surface. Therefore, sealing performance between the mold and the resin invasion preventing walls (4) can be greatly improved. As a result, even when foam molding is performed, a foamable resin material (200) is not invaded into an engaging element forming region, and the molded male surface fastener (1) can be accurately molded and integrated at a predetermined position of a foaming body.

Owner:YKK CORP

Building panels with aesthetic edges

ActiveUS7846536B2Secure adhesionSafer and more comfortableDecorative surface effectsFloorsCementCivil engineering

A building composite panel including at least one longitudinal edge is made of a core of hydraulic cement and a multi-ply edge facing material covering and attached to at least one of the longitudinal edges. The facing material includes at least a first ply configured for attachment to the core as it sets and at least a second, water-impermeable ply.

Owner:UNITED STATES GYPSUM CO

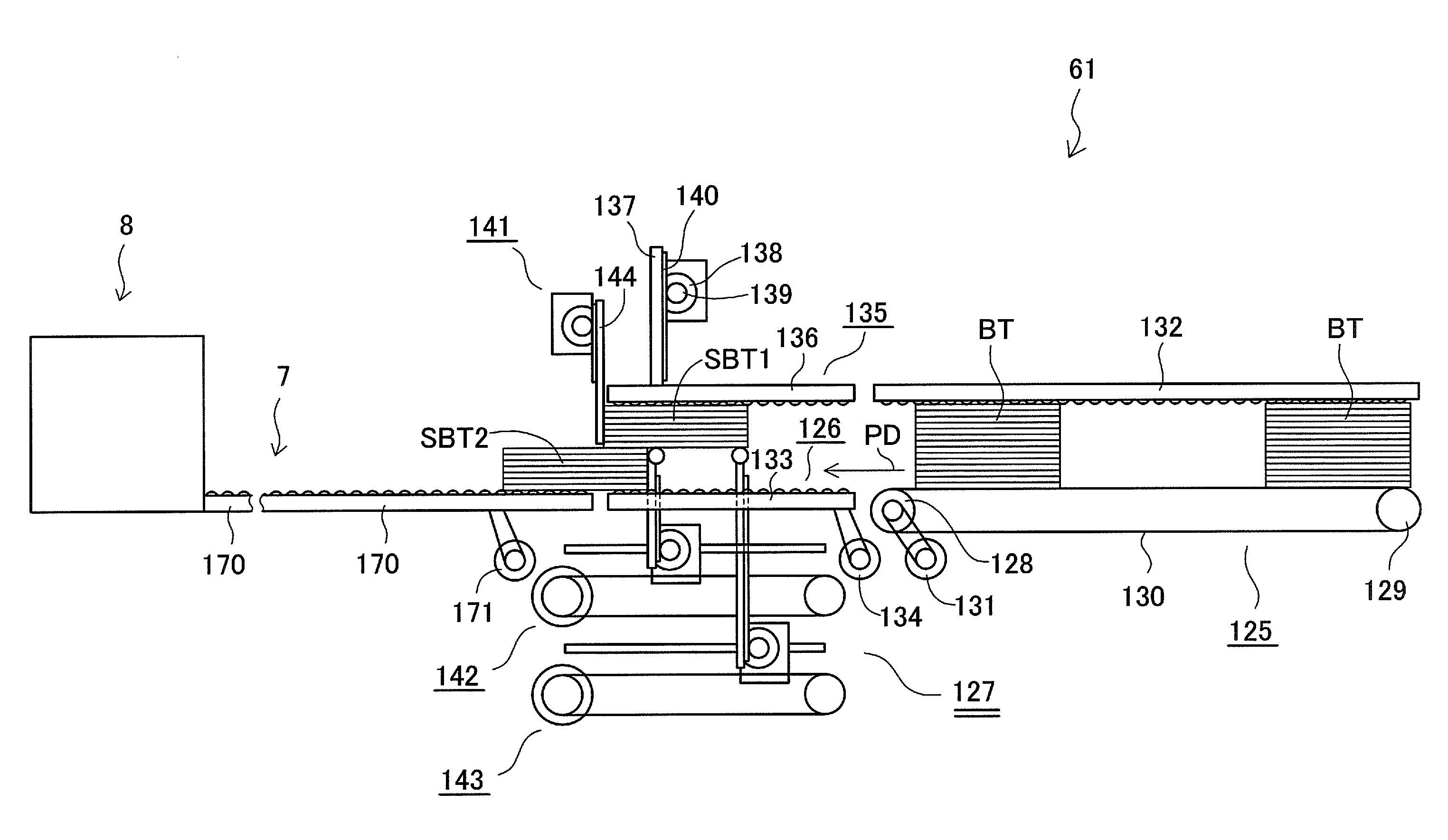

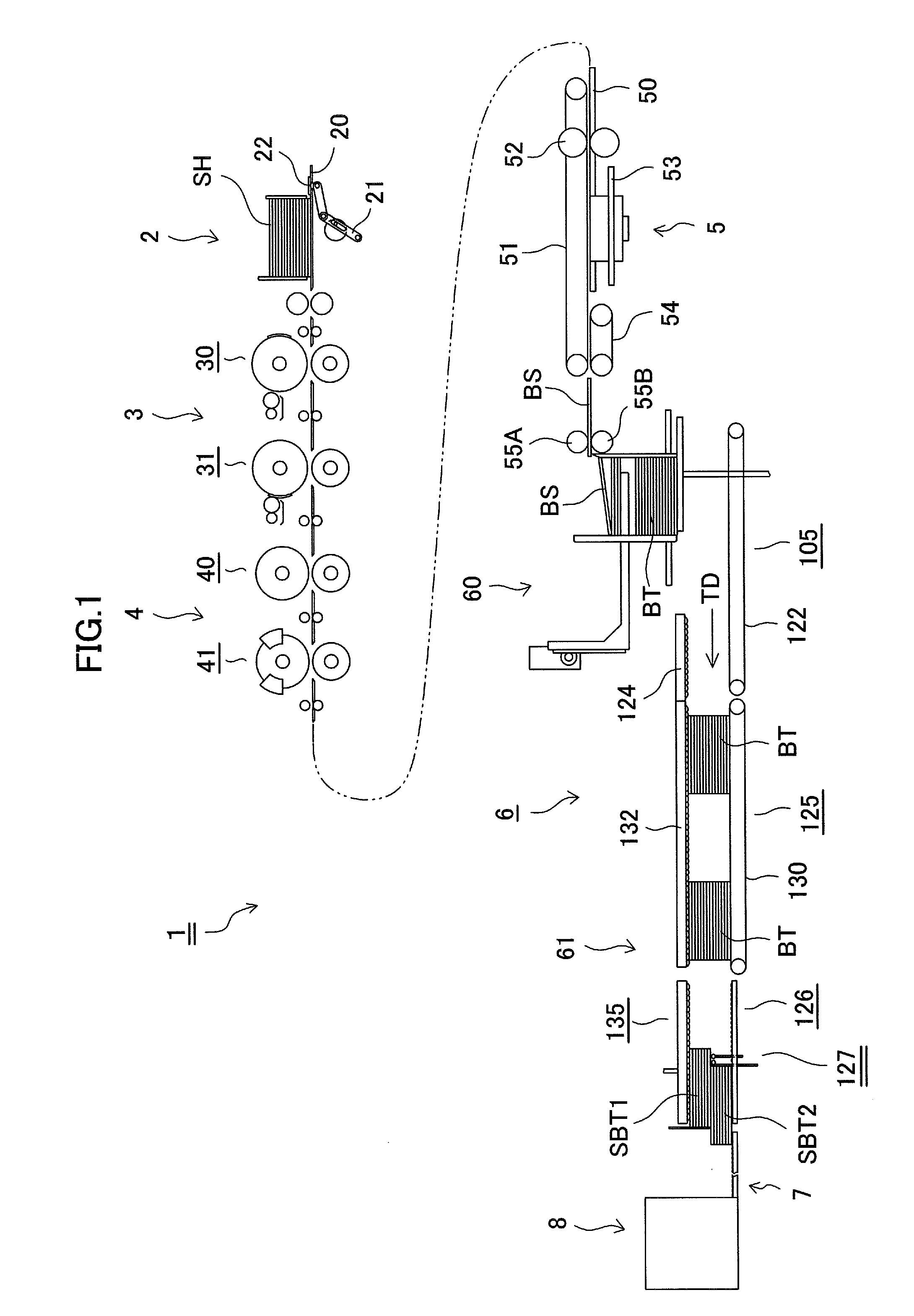

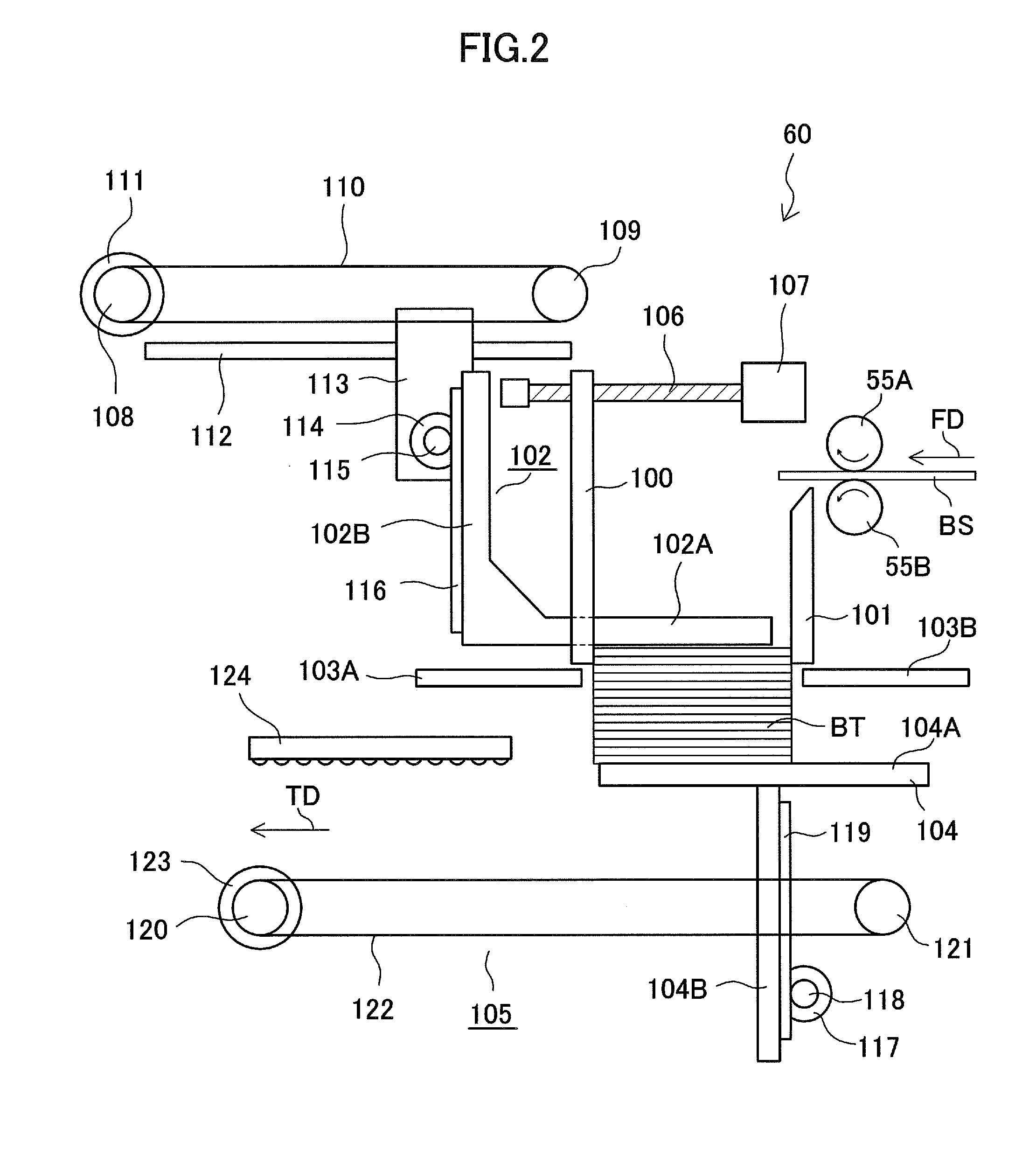

Cardboard sheet batch division device, cardboard sheet counter ejector, and method for dividing cardboard sheet

InactiveUS20110268550A1Quality improvementShorten the counting processLoadersBox making operationsCardboardLeading edge

The present invention is a cardboard sheet batch division device for dividing batches, disposed on the downstream side of a batch-forming device for separating loaded cardboard sheets and forming batches of a predetermined sheet count. The cardboard sheet batch division device for dividing batches comprises: a transfer conveyor for transferring batches formed by the batch-forming device in a predetermined transfer direction; and batch division means furnished with two separating members respectively contacting the leading edge portion and the trailing edge portion of a batch on the transfer conveyor, for dividing the batch into two sub-batches, upper and lower, by moving the two separating members relative to one another in a direction parallel to the predetermined transfer direction.

Owner:ISOWA IND CO LTD

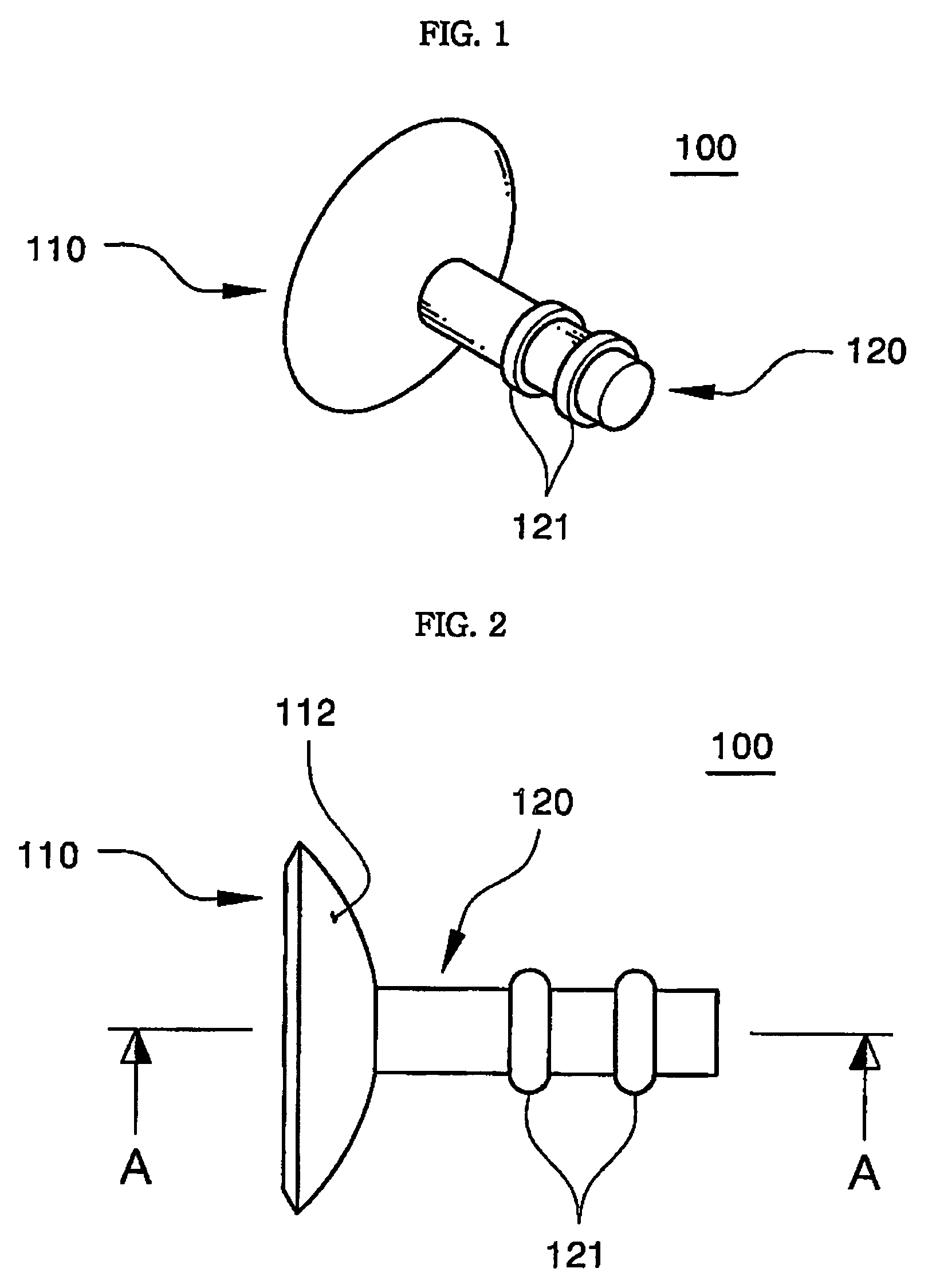

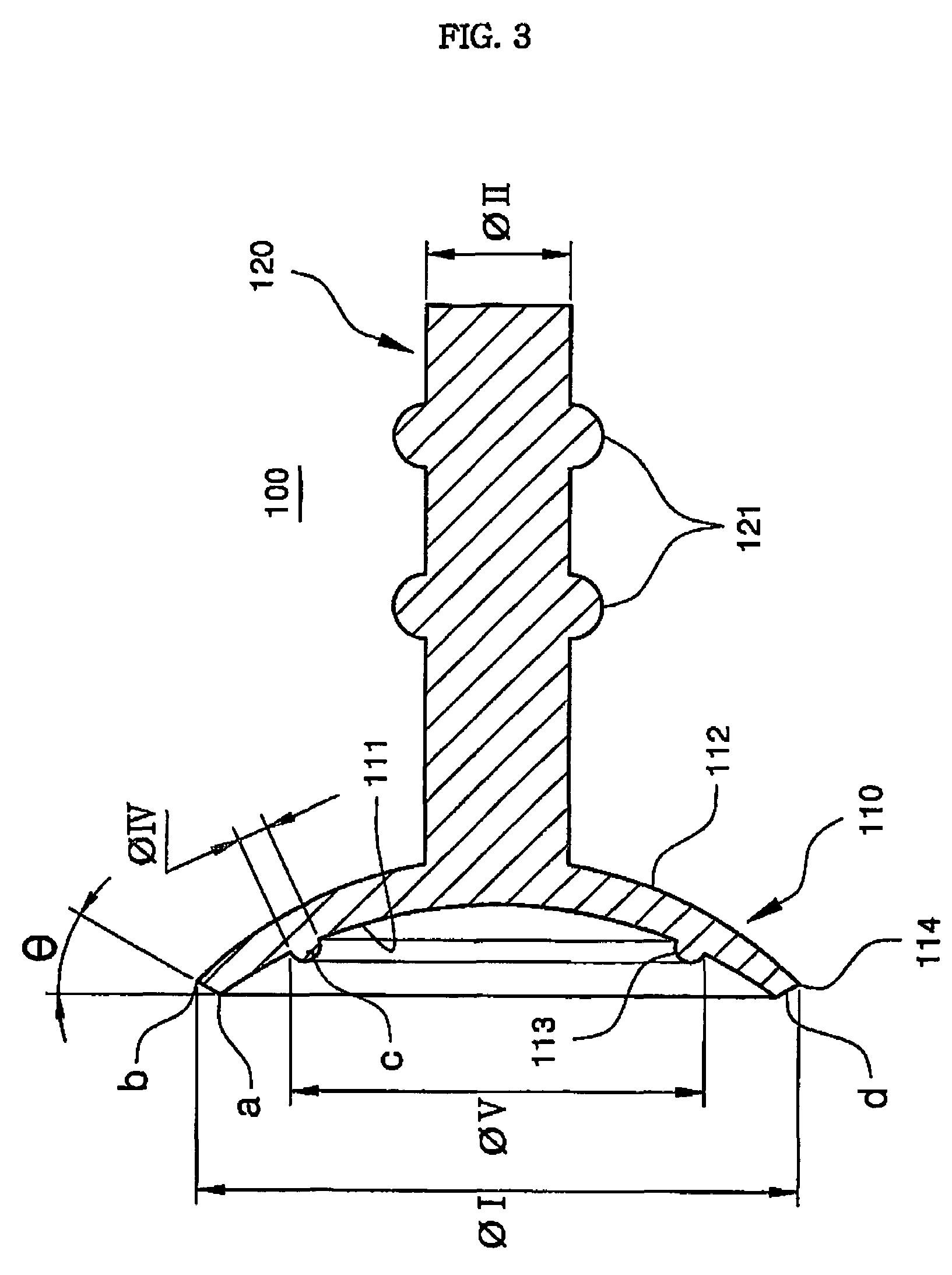

Sucker with an annular projection on adhesion surface and adhesion arrow having the sucker

InactiveUS7364521B2Secure adhesionSmall sizeAmmunition projectilesThrow gamesAdhesion forceSoft materials

Owner:YANG TAE SEONG

Methods for the Manufacture of Colorfast Masonry

ActiveUS20170190617A1Strong color fastnessAlter colorfastness of solid structureLiquid surface applicatorsBacteriaBrickCrushed stone

The invention is directed to compositions and methods for the manufacture of pigmented solids structures for which can be used for construction and / or decoration. Manufacturing comprises fixing one or more pigments to an aggregate material such as crushed rock, stone or sand. The pigmented aggregate is incubated with urease or urease producing microorganisms, an amount of a nitrogen source such as urea, and an amount of calcium source such as calcium chloride forming calcite bridges between particles of aggregate. The resulting solid has a hardness and colorfastness for most any construction material. Using selected aggregate and pigment, the process also provides for the manufacture of simulated-stone materials such as clay or granite bricks or blocks, marble counter-tops, and more. The invention is also directed to composition containing microorganisms and pigment as kits that can be added to most any aggregate materials.

Owner:BIOMASON

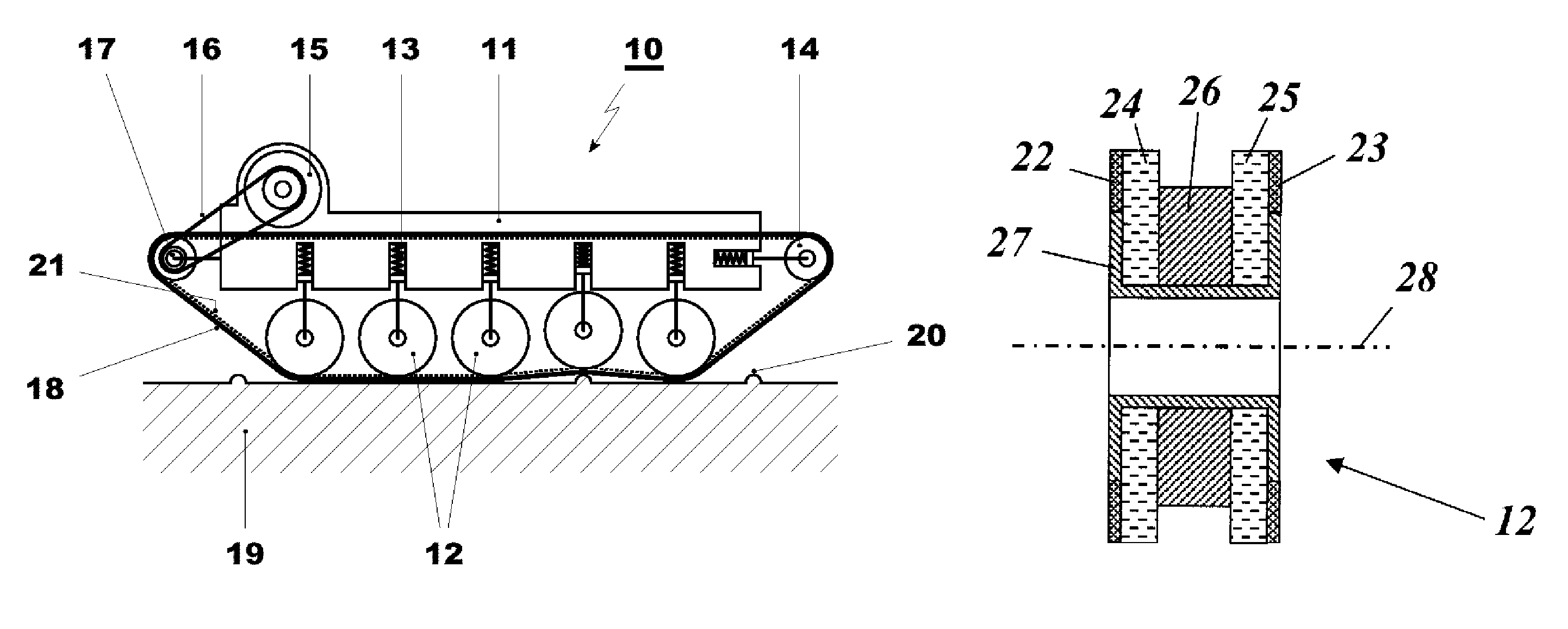

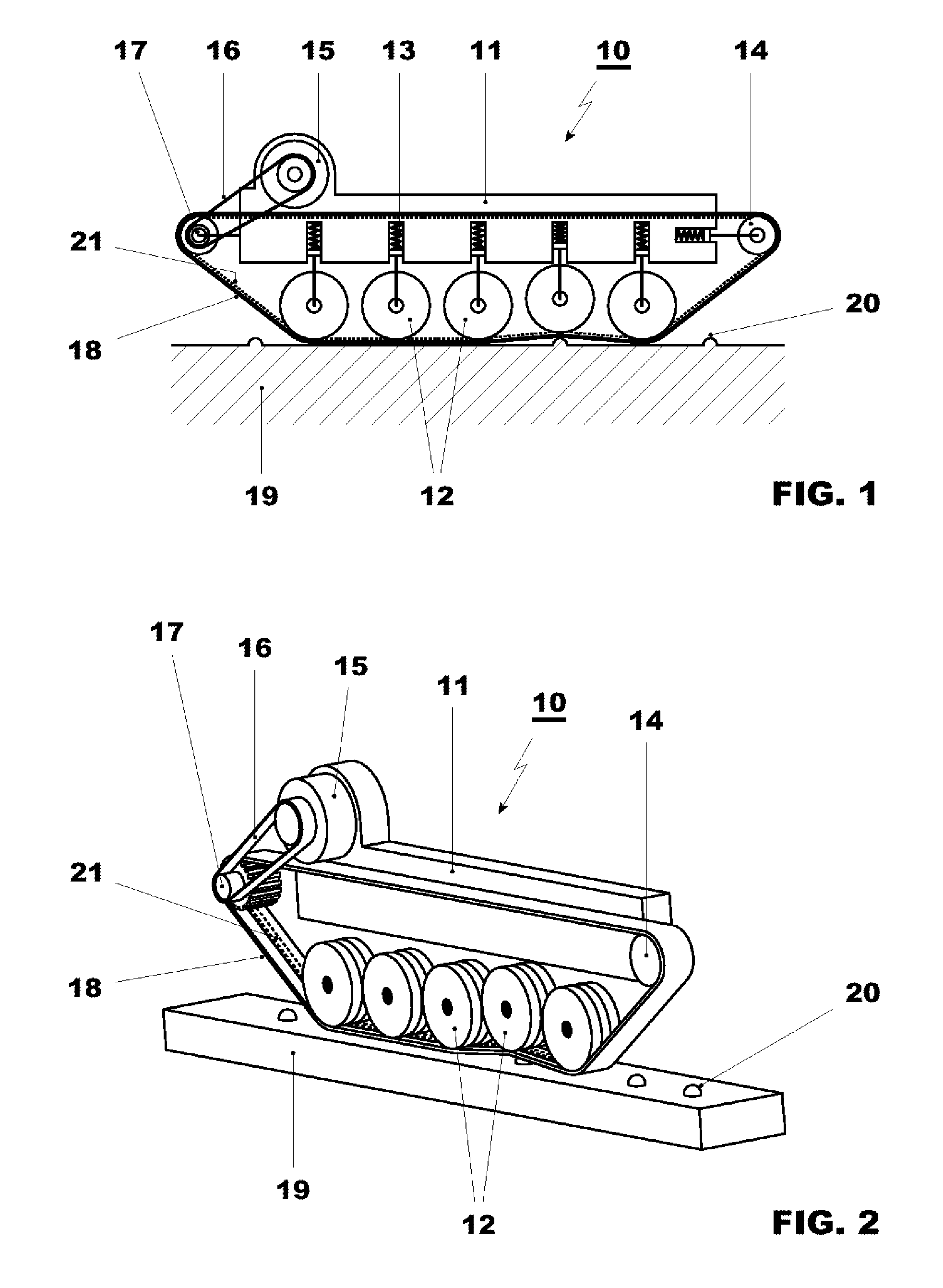

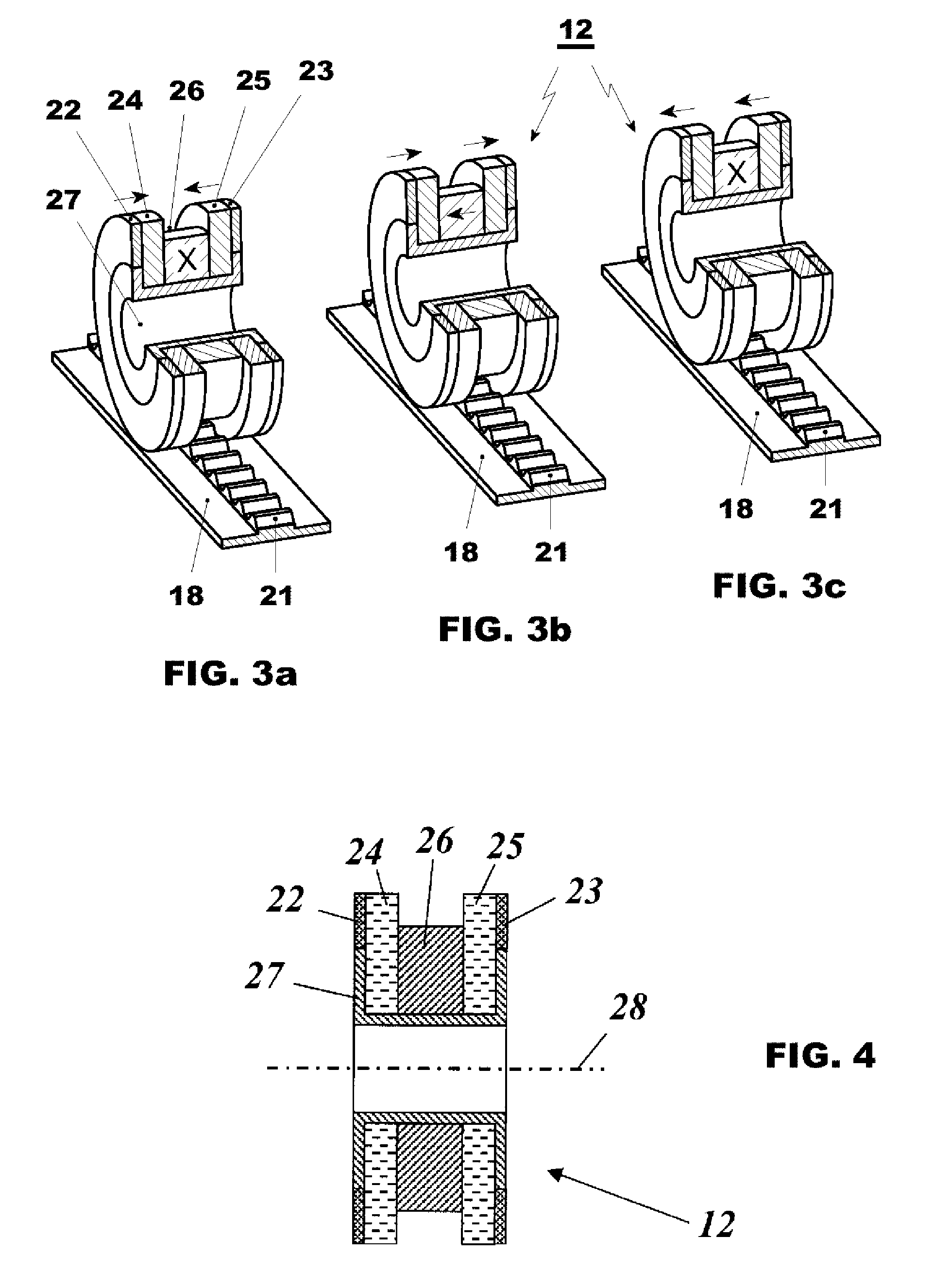

Drive unit for an inspection vehicle and also inspection vehicle with such a drive unit

ActiveUS7624827B2Secure adhesionAvoid disadvantagesControlling membersRail-engaging wheelsMotor power

Owner:GENERAL ELECTRIC TECH GMBH

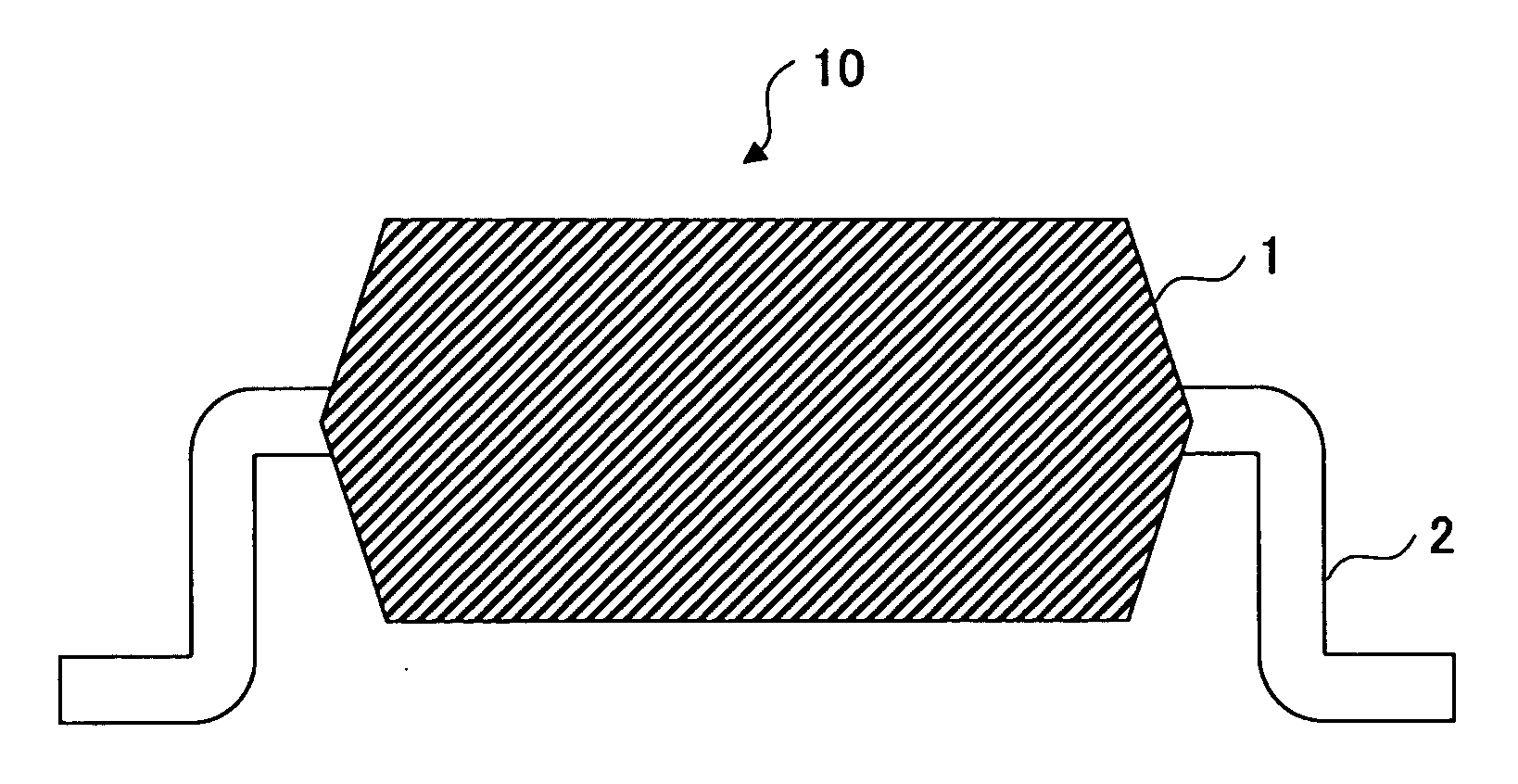

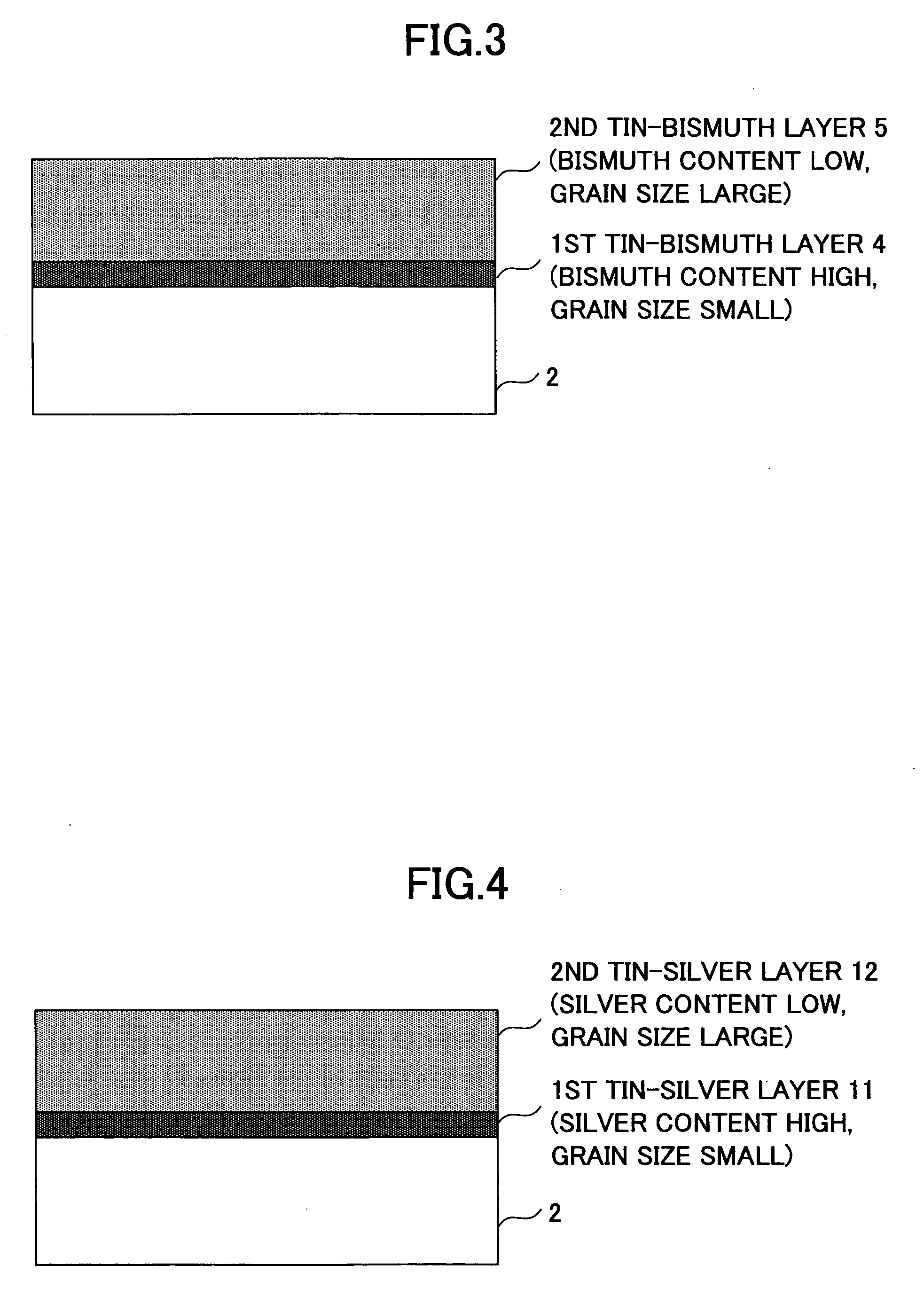

Semiconductor device using multi-layer unleaded metal plating, and method of manufacturing the same

InactiveUS20060071335A1Whisker resistance can be improvedSecure adhesionSemiconductor/solid-state device detailsSolid-state devicesIndiumDevice material

A semiconductor device comprises a semiconductor integrated circuit, an external connection terminal connecting the semiconductor integrated circuit to an external device, and a plurality of tin or tin-alloy plating layers formed on the external connection terminal as multiple unleaded metal plating layers. The multiple unleaded metal plating layers comprise a first layer made of a tin alloy and provided as an inner layer of the multiple unleaded metal plating layers, the tin alloy of the first layer containing as a second element one of bismuth, silver, copper, indium, and zinc, and a second layer made of either 100% tin or a tin alloy and provided as an outer surface layer of the multiple unleaded metal plating layers, the 100% tin or the tin alloy of the second layer having a percentage of tin content greater than that of the first layer.

Owner:SOCIONEXT INC

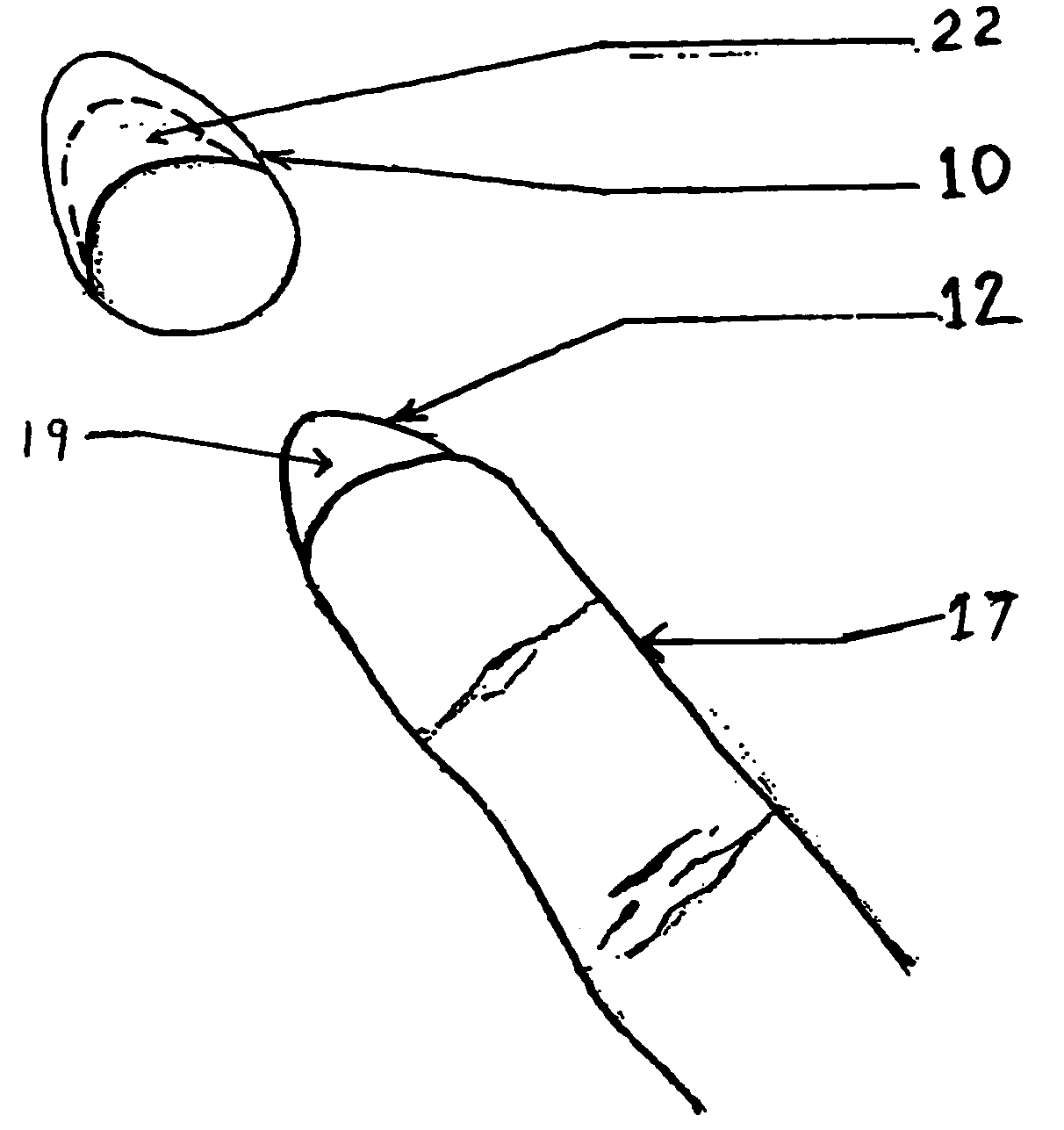

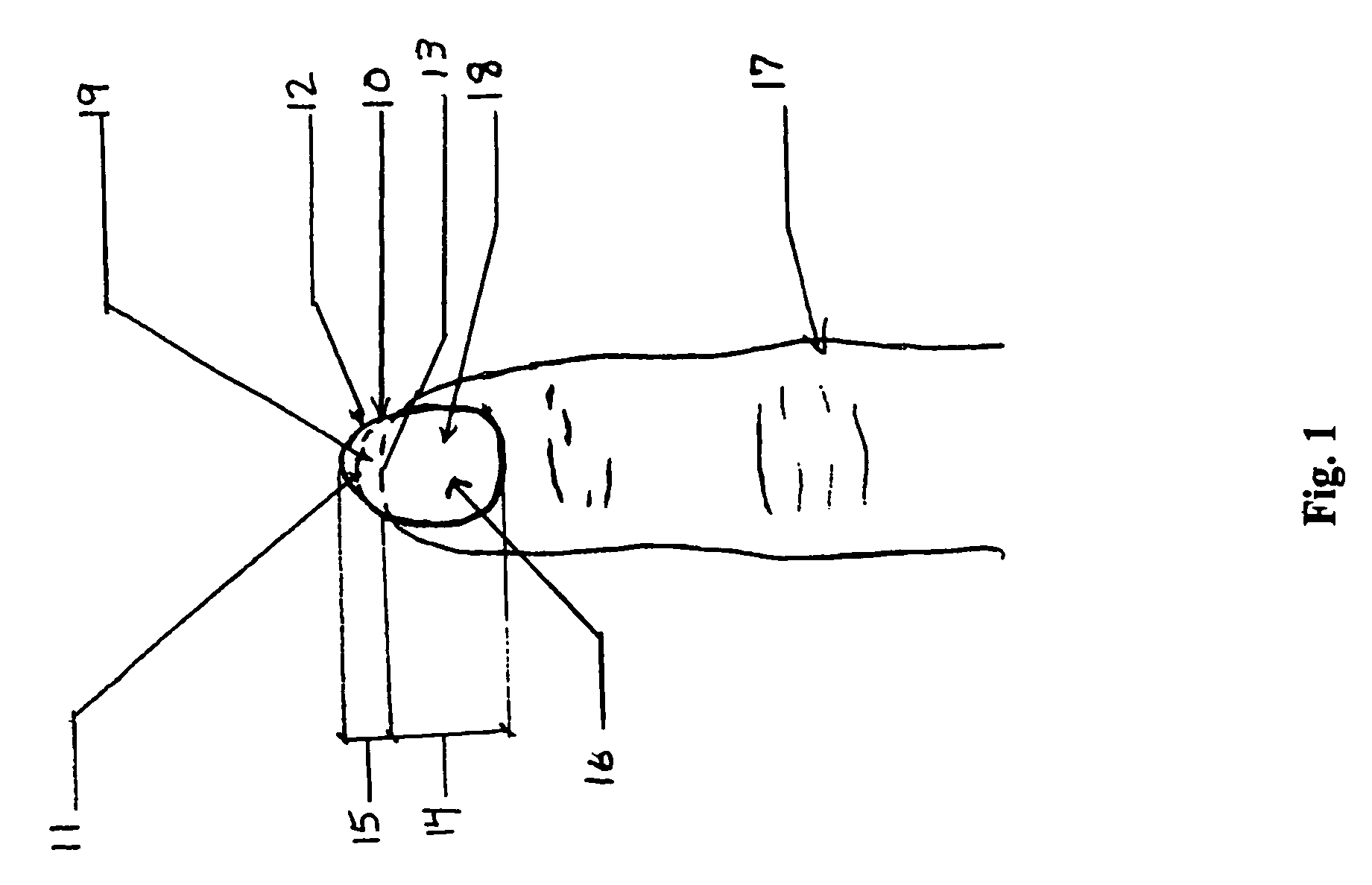

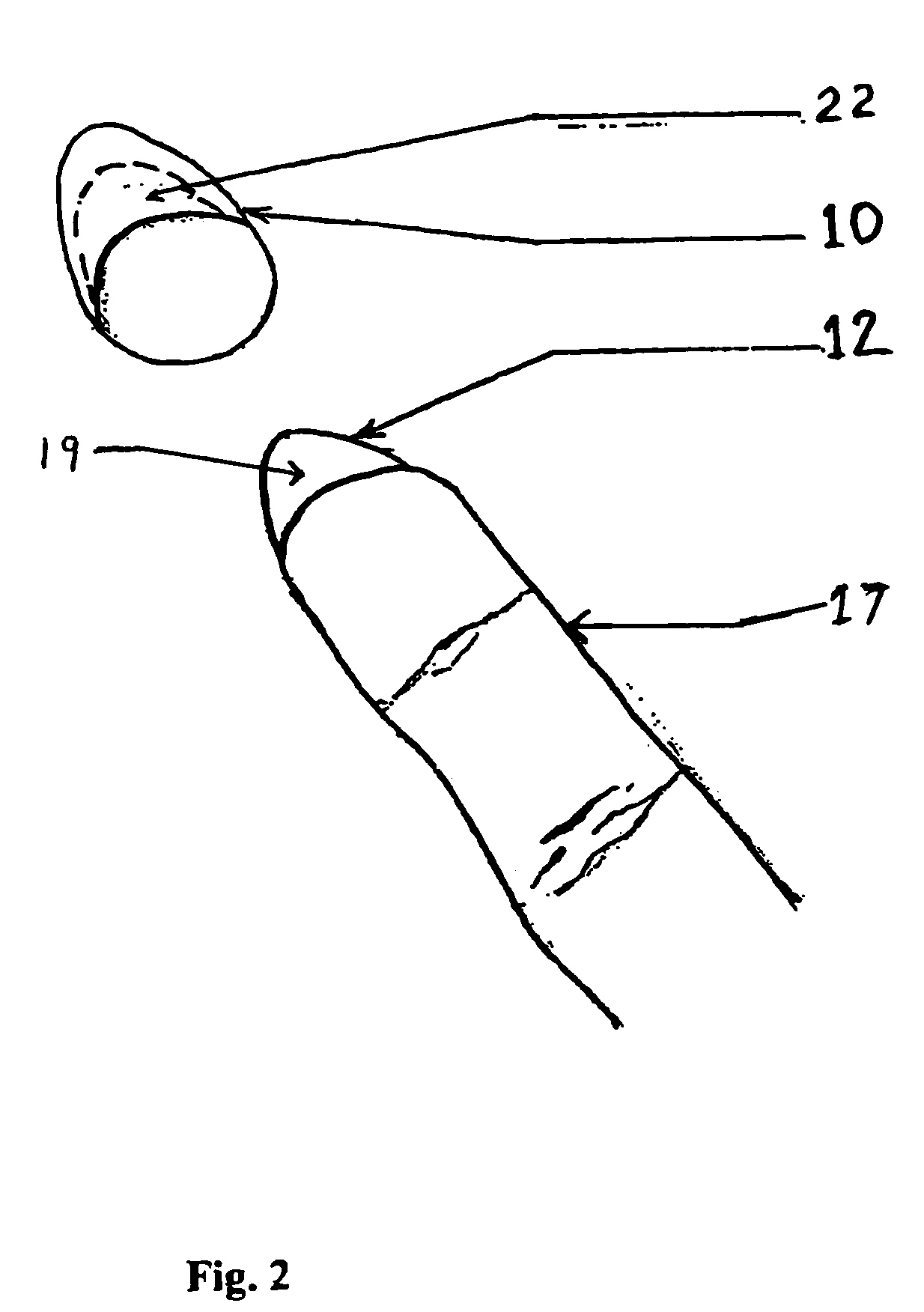

Fingernail pick for stringed instruments

ActiveUS7179976B2Optimize string activationArea maximizationStringed musical instrumentsManicure/pedicureAdhesiveEngineering

A fingernail pick that is removably attachable to a user's fingernail having a primary string contacting portion, an anchor portion which is shaped to fit comfortably and unobtrusively on top of the fingernail, and a mounting portion. The fingernail pick is held in place either by an adhesive, friction between a slot and a cantilevered portion of fingernail, or by a combination of the two. The fingernail pick may be formed in various sizes and shapes or available in custom sizes and shapes for particular users.

Owner:GLISSPHONIC

Exercise weight system

An exemplary incremental weight for an exercise system has a generally annular magnet encapsulated within a coating which cushions the magnet, protecting it both from becoming damaged, and from damaging an exercise apparatus, while promoting the adhesive properties of the magnet. In a first exemplary embodiment, the coating comprises a first annular rib and a second annular rib extending respectively about outer and inner peripheries of the generally annular magnet, and a plurality of ribs extending radially between the first and second annular ribs. The generally annular magnet, in exemplary embodiments, comprises at least one of a ceramic magnet, ferrite, or an alnico magnet. Exemplary coatings may be elastomeric, molded silicone, or anti-slip coatings. In another exemplary embodiment, a plurality of mounting pads are attached to a surface of said weight defined by an annular surface of said magnet.

Owner:MCCLUSKY SCOTT

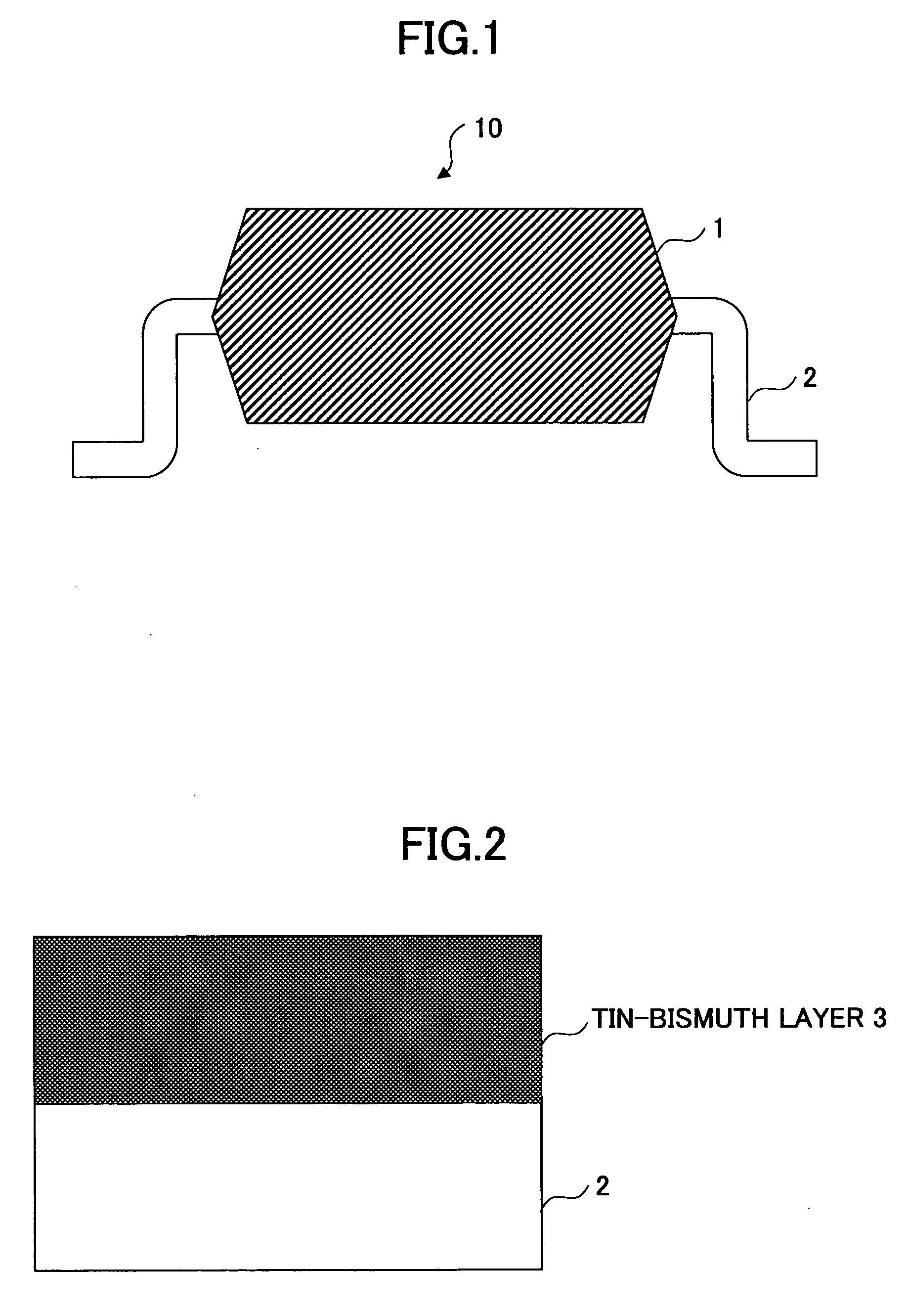

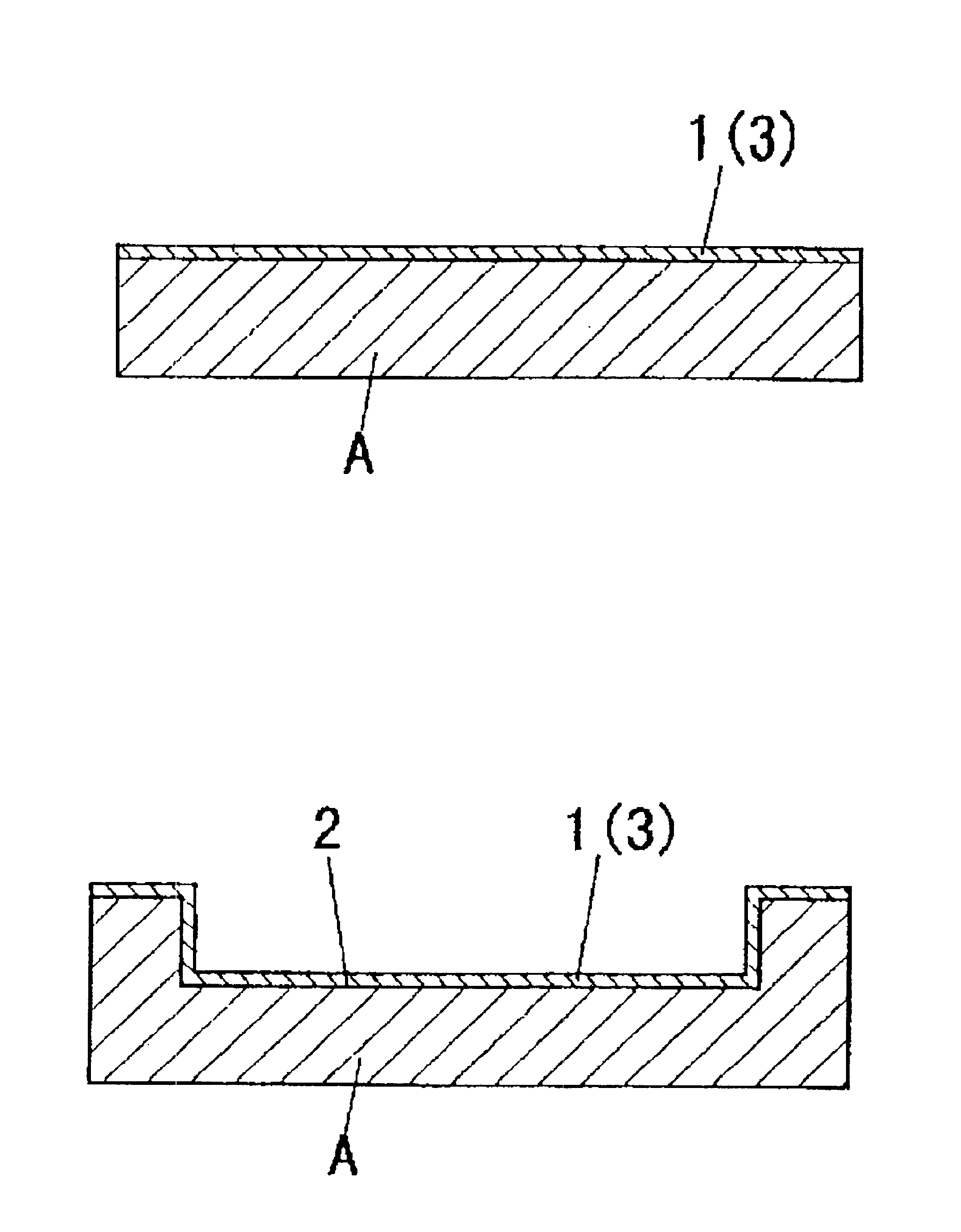

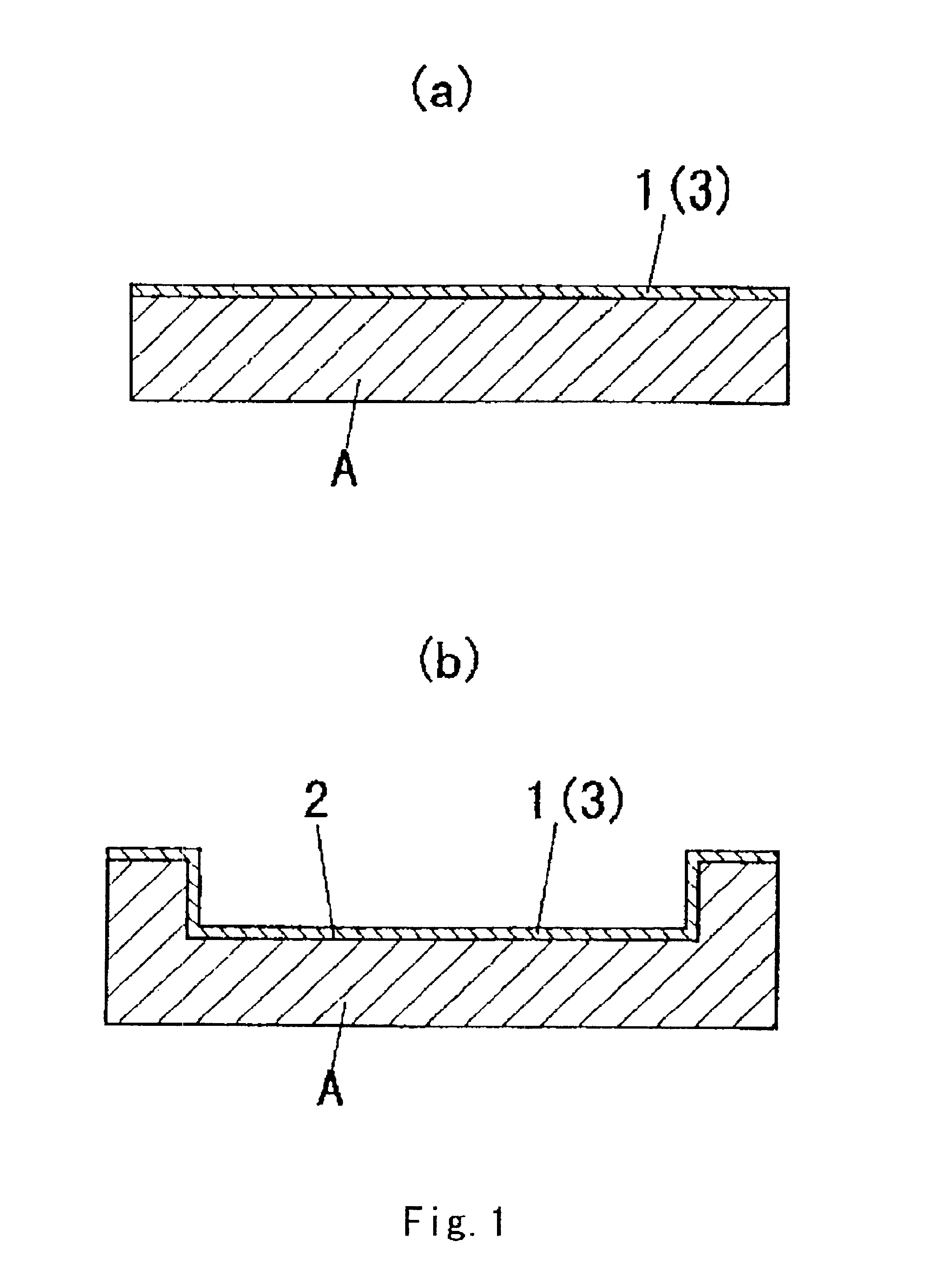

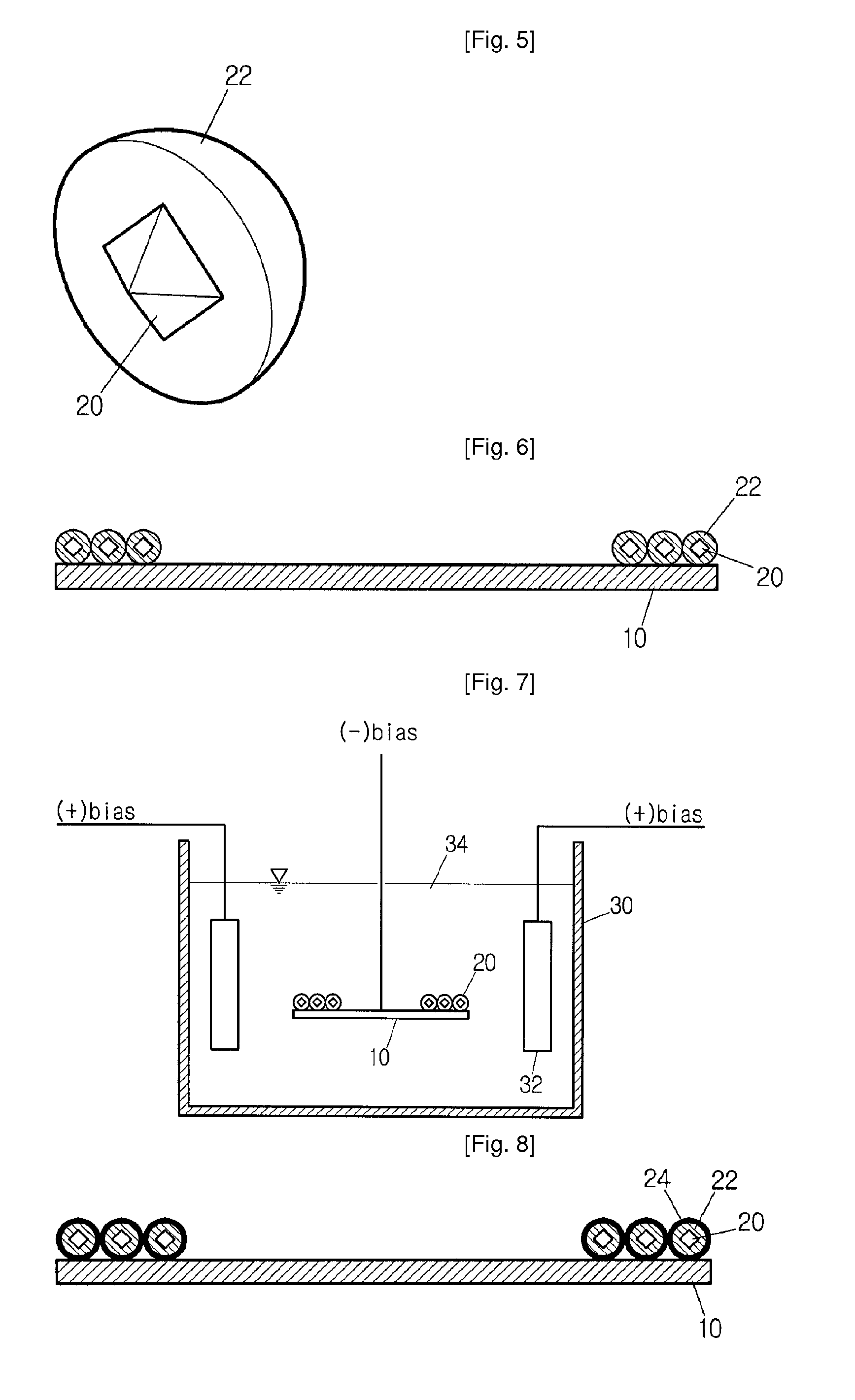

Drum Pad and Manufacturing Method Thereof

ActiveUS20100282048A1Feel goodSecure adhesionElectrophonic musical instrumentsSynthetic resin layered productsMechanical engineeringPressure sensitive

A drum pad capable of providing an excellent percussion feeling and securely adhering a base portion to a body portion made of rubber. The drum pad has a rear-side clothlike material which is provided on a rear surface of the body portion and into which the rubber of the body portion is impregnated. The base portion is fixed to a rear surface of the rear-side clothlike material via a fixing layer made of pressure sensitive adhesive or adhesive and provided on the rear surface of the rear-side clothlike material.

Owner:YAMAHA CORP

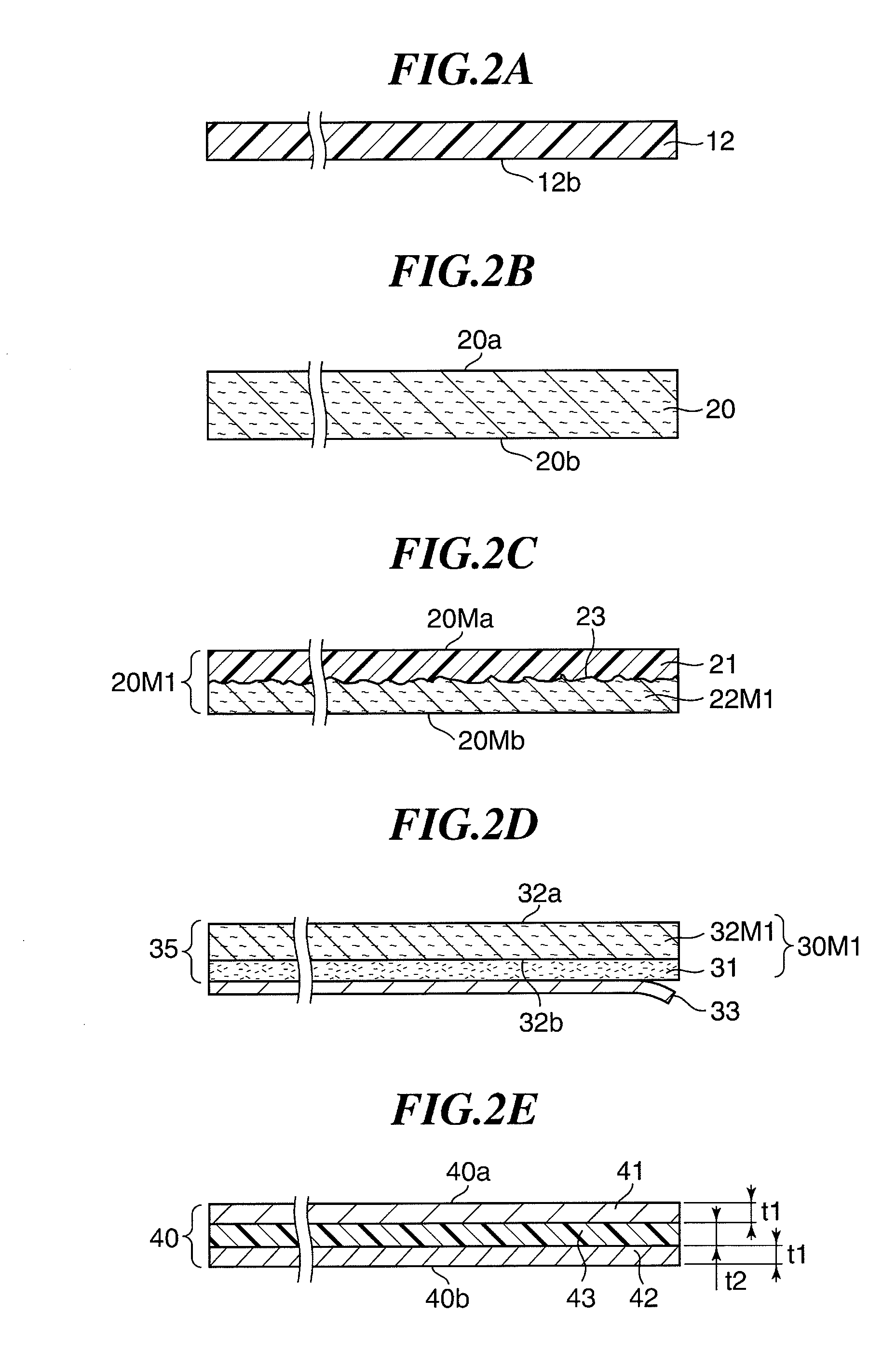

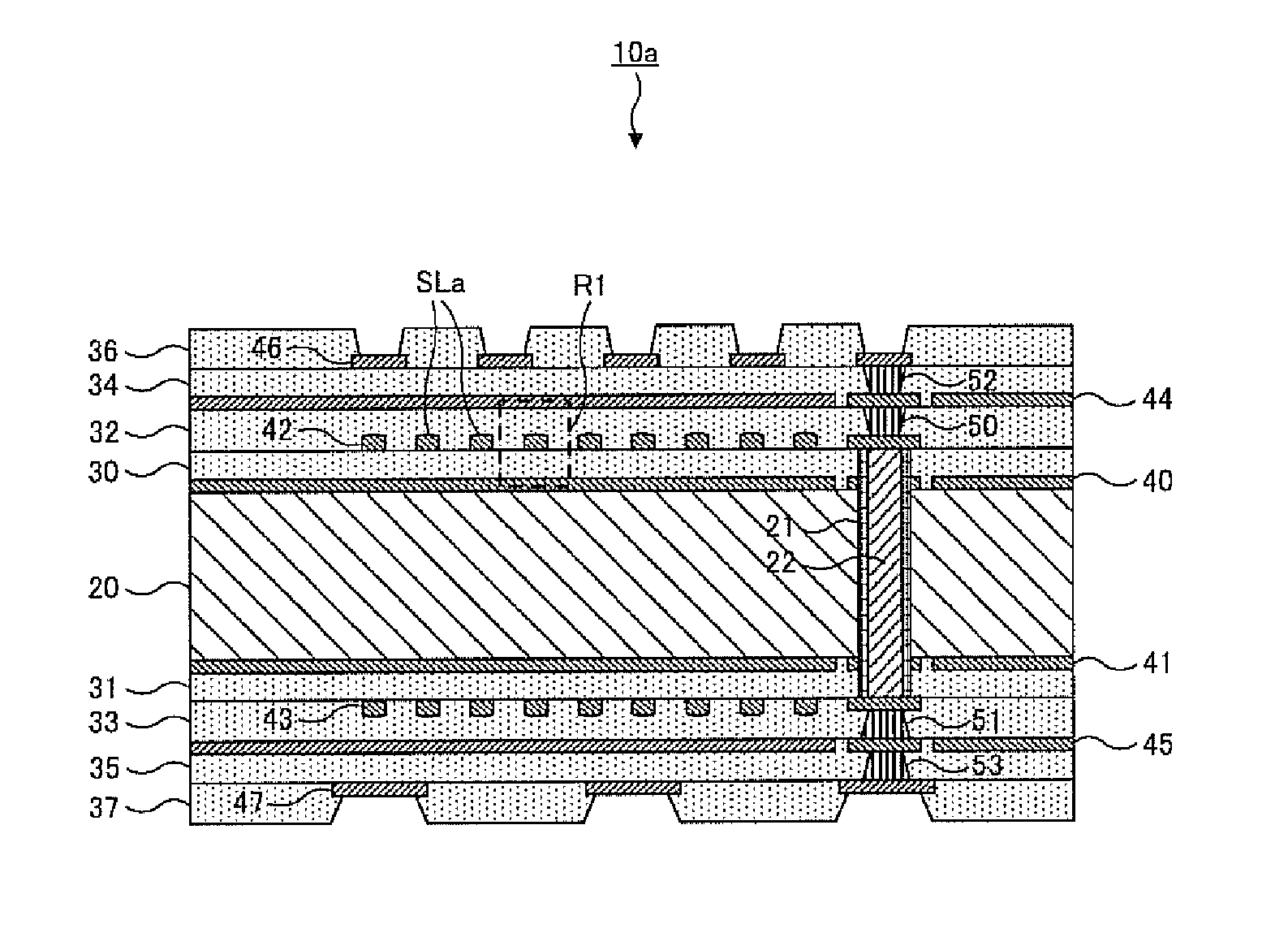

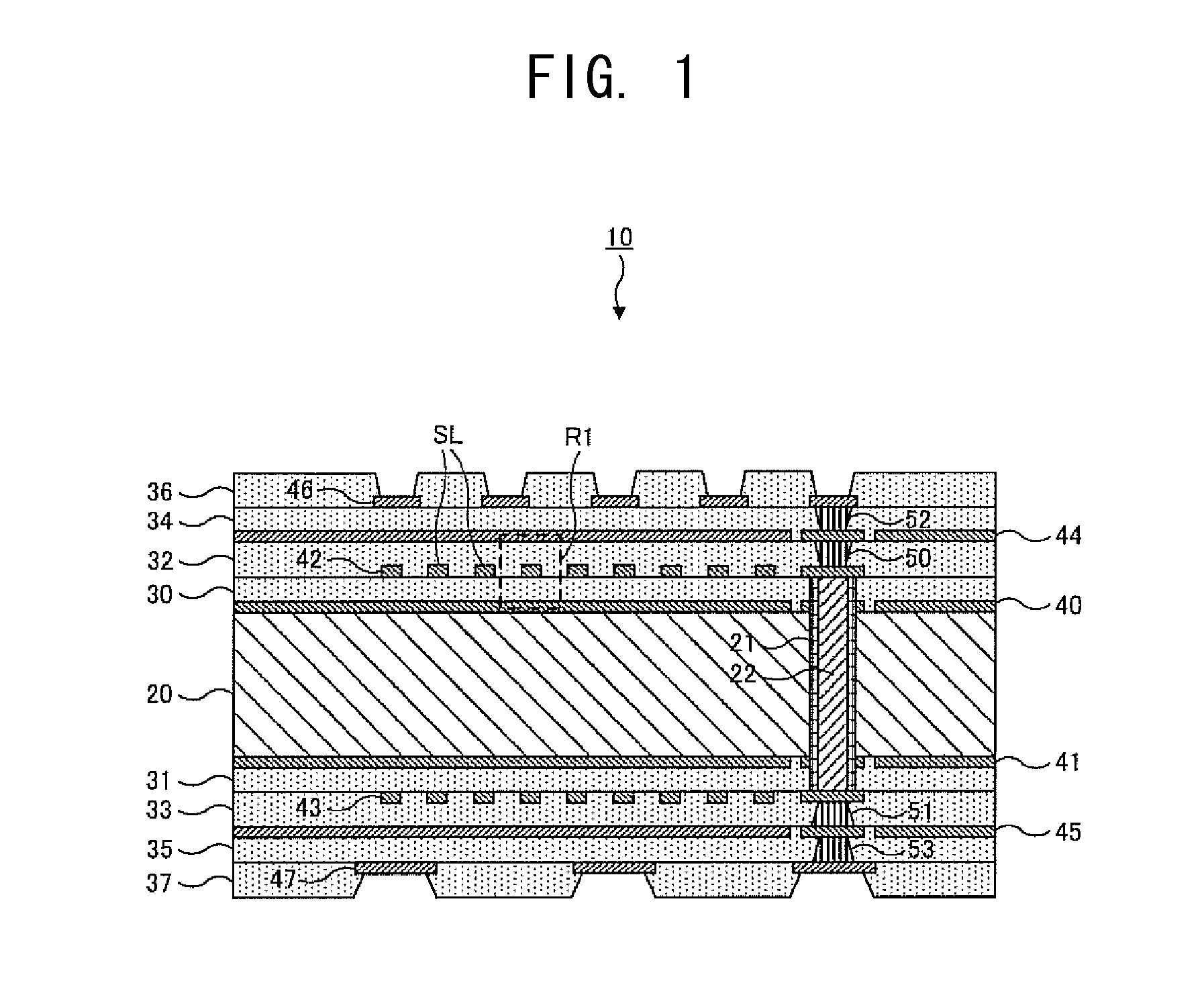

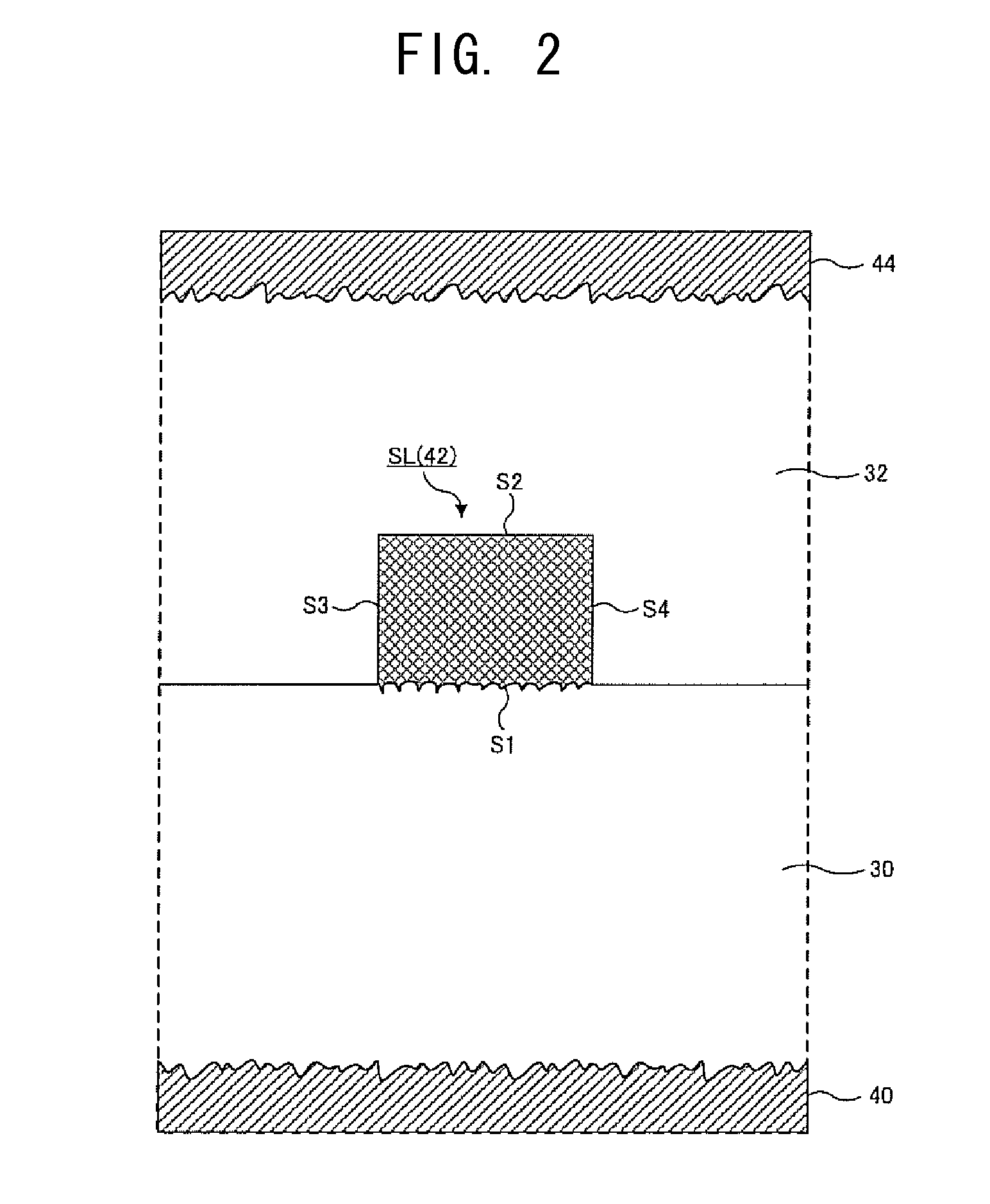

Wiring substrate and method of manufacturing the same

InactiveUS20120205142A1Simple processImproves high-frequency characteristicSemiconductor/solid-state device detailsPrinted circuit aspectsChemical LinkageElectrical conductor

A wiring substrate is configured such that each of laminate portions provided above and below a substrate core includes insulating layers and conductor layers stacked alternately. Of the conductor layers of the laminate portions, signal line layers are treated with a silane coupling treatment, which is a surface modification treatment, so that each signal line comprises a flat surface. A roughening treatment is performed on the remaining conductor layers of the laminate portions such that the surfaces of these layers are roughened. This structure provides an advantage when high-frequency signals are transmitted through the signal line layers. That is, when each signal line comprises a flat surface, an increase in conductor loss due to the skin effect can be prevented. In addition, by means of chemical bonding attained through the silane coupling treatment, the reliability of adhesion between the signal line layers and the insulating layer is sufficiently attained.

Owner:NGK SPARK PLUG CO LTD

Molded male surface fastener

ActiveUS8512845B2Surface of surface of of surface severeUnevenness of of of of severeSnap fastenersLayered productsCushionFastener

Owner:YKK CORP

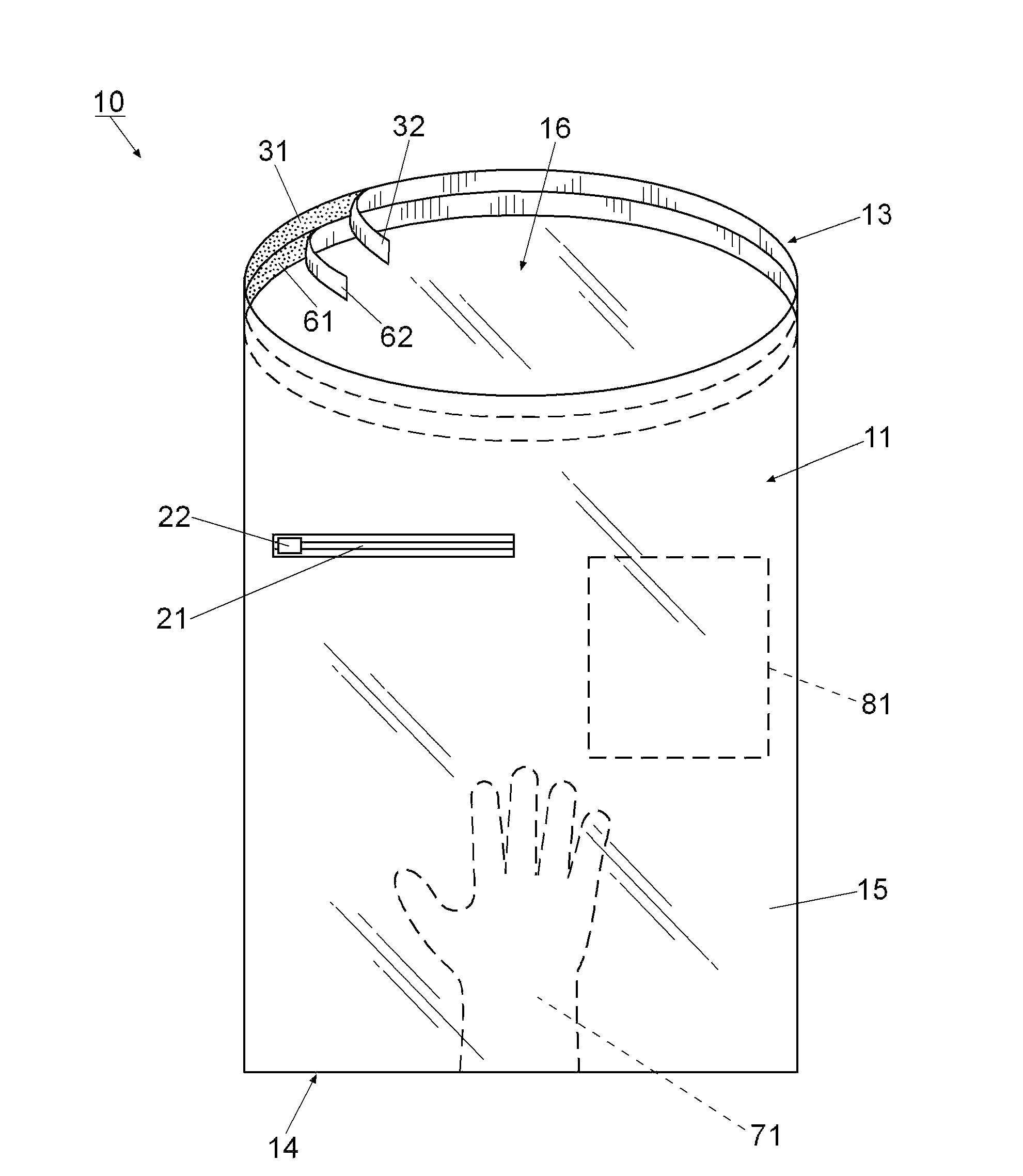

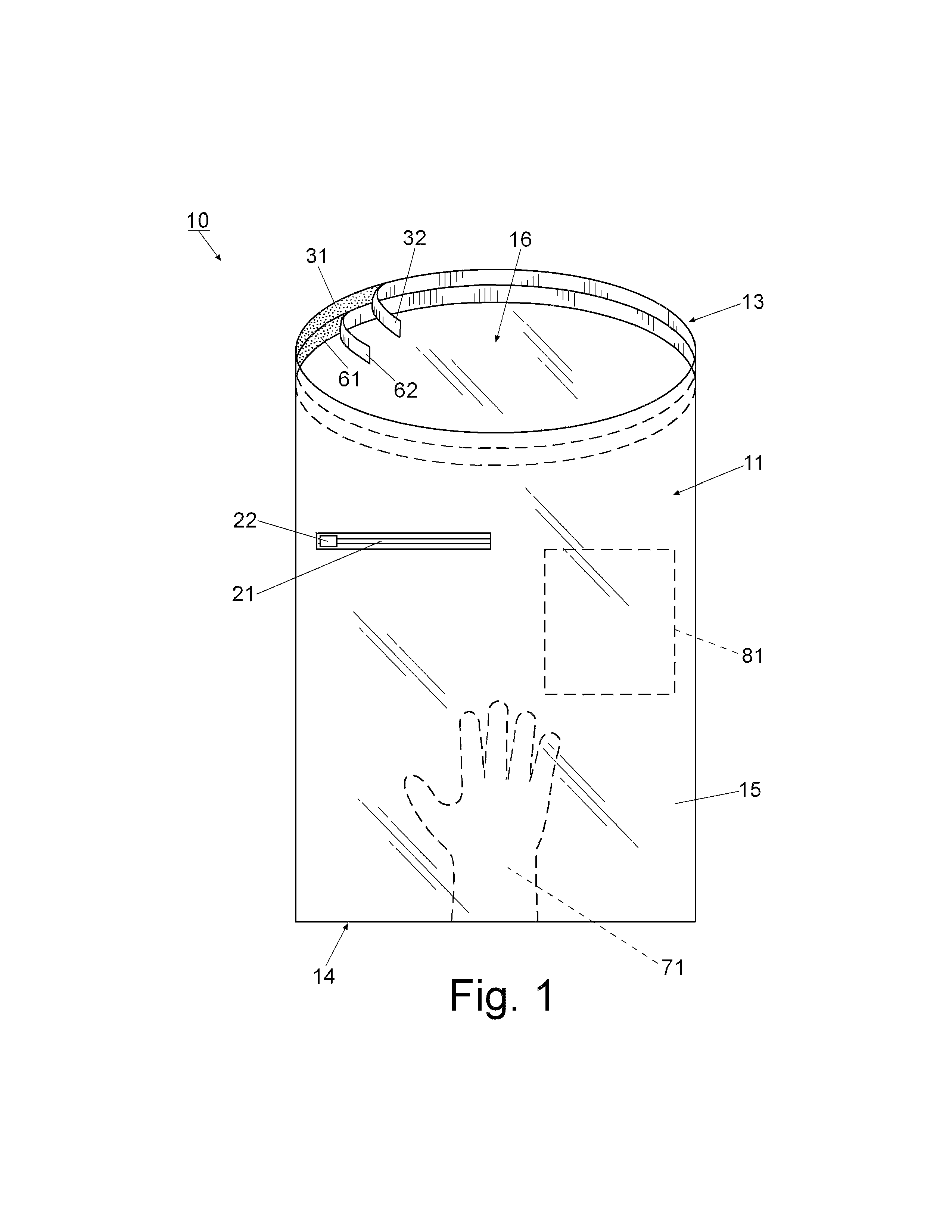

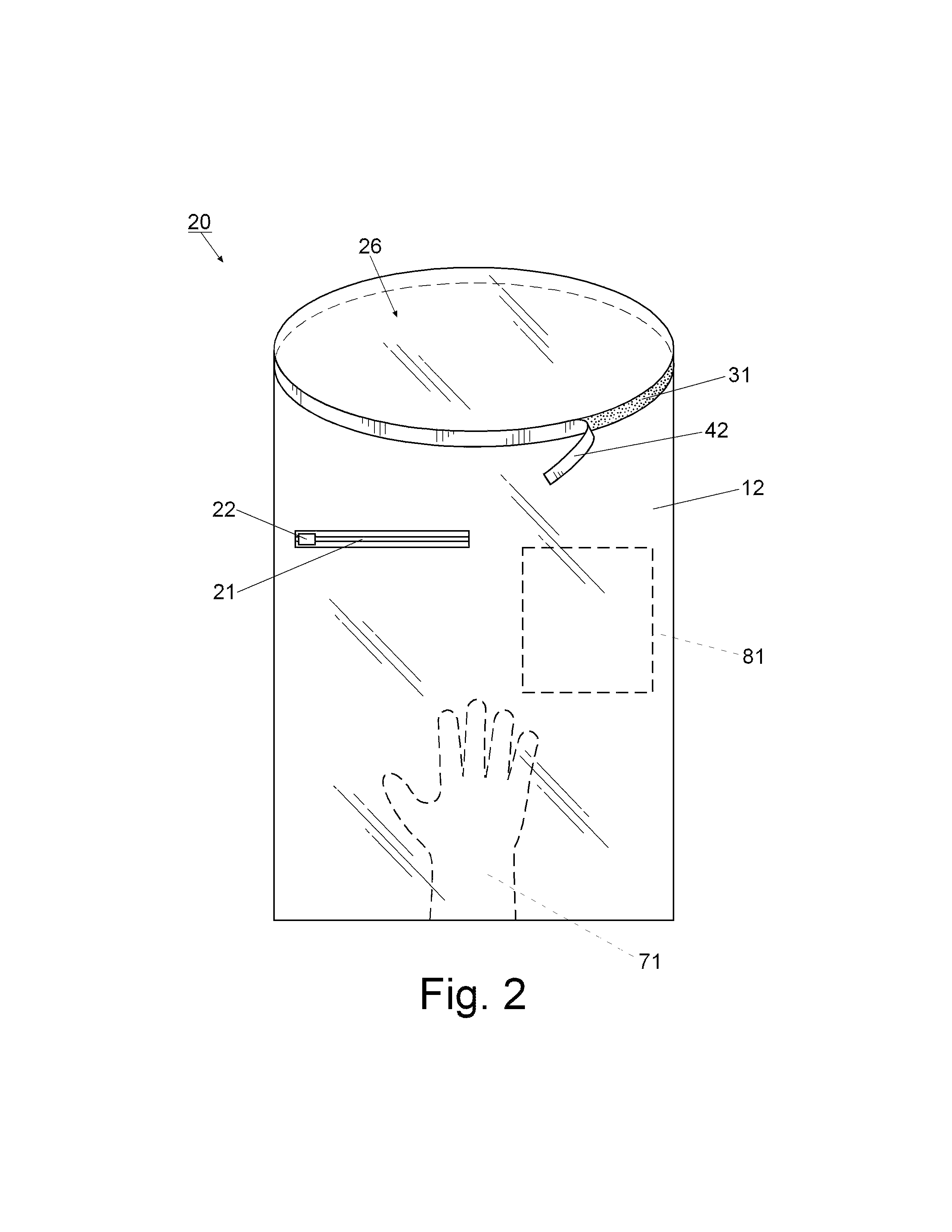

Enclosure apparatus and method

InactiveUS8137156B1Avoid harmAvoid injuryDirt cleaningGrinding/polishing hand toolsEngineeringMechanical engineering

An enclosure apparatus for containing dust and debris such as may be generated while repairing a drywall surface. The enclosure apparatus includes a flexible, transparent body and may include a sealable slit, glove and pouch. The method of use allows the enclosure apparatus to be securely affixed to the drywall surface with a pressure sensitive adhesive. Tools or otherwise can be placed within the enclosure body prior to attachment to the drywall surface. Once the dust generating work is completed the enclosure apparatus can be removed, cleaned and properly disposed.

Owner:GASMAN DANIEL T

Surface preparation agent and surface preparation method

InactiveUS20030168127A1Improve rust resistanceInhibits aluminum corrosionMetallic material coating processesVanadium CompoundsTitanium

An agent suitable for use in preparing metal surfaces, especially surfaces containing aluminum, is provided which contains at least one water-soluble vanadium compound, at least one titanium-containing or zirconium-containing water-soluble complex fluoride, and at least one resin. The agent is capable of forming a strongly rust preventive base coating that is highly adherent for top coats and bonded films.

Owner:HENKEL KGAA

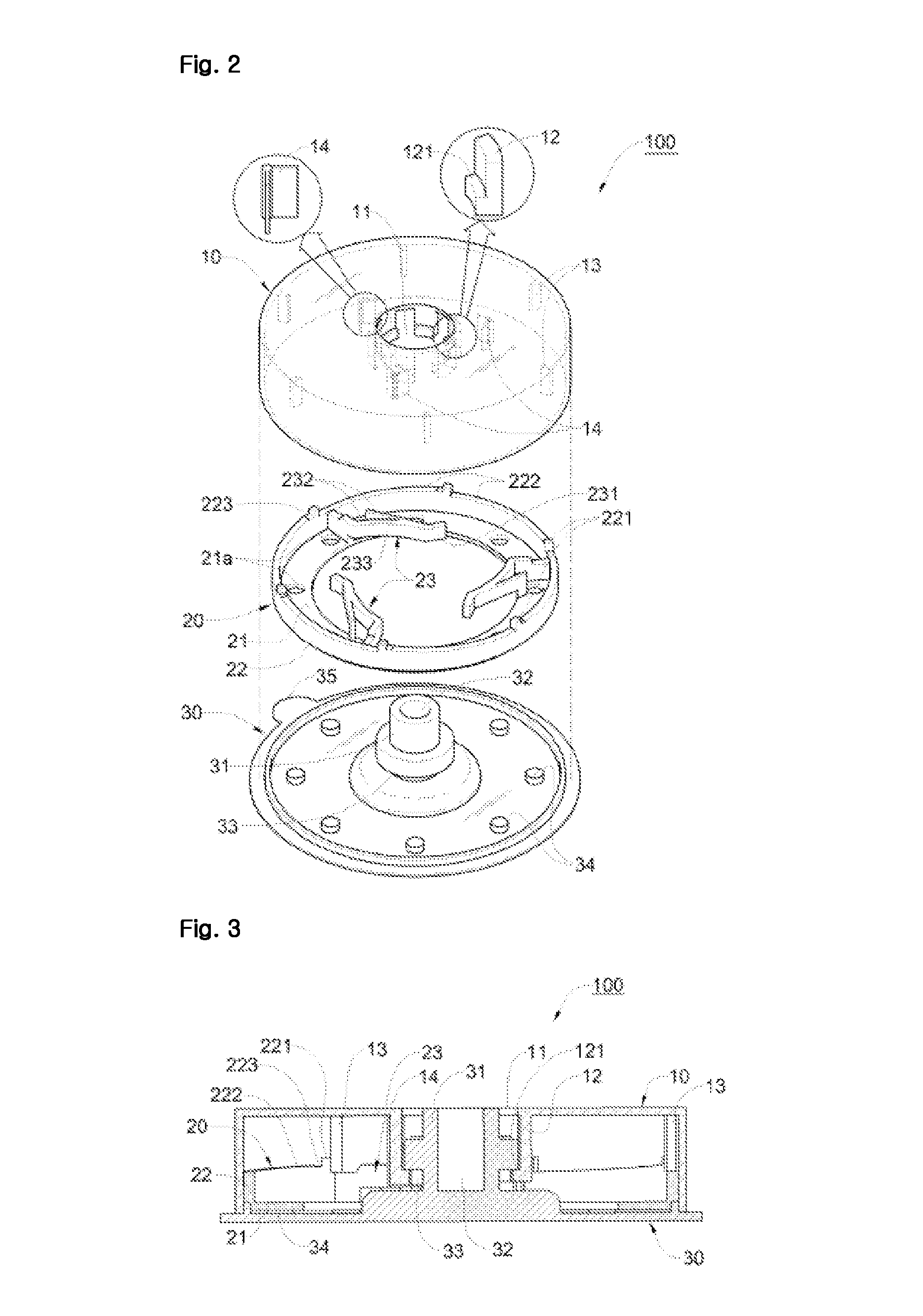

Vacuum adsorbing device

ActiveUS8979046B2Great suctionSecure adhesionAntenna supports/mountingsFurniture partsSuction forceCounter rotation

A vacuum suction device of the present invention comprises: a cover which is rotatably mounted on the upper portion so as to couple to a flat surface by means of vacuum suction; an suction plate, which is coupled to the lower portion of the cover, for vacuum suction to the flat surface; and a height adjustment member, which is arranged between the cover and the suction plate, for moving the suction plate back and forth according to the rotation of the cover; wherein a plurality of fixing pieces are formed on the upper surface of the inside of the cover, a plurality of elastic stoppers are coupled to the inside of the height adjustment member, so as to be movable by sliding when each of the fixing pieces is in contact, and for fixing the cover by each of the fixing pieces being hooked to the end portion of the cover so as to prevent reverse rotation. The vacuum suction device of the present invention enhances suction force so as to couple the vacuum suction device to the flat surface more solidly and for a longer time, enhances assembly between each of the elements for vacuum suction, and prevents unlocking due to outside shock by forming a double locking structure in the vacuum adsorption device.

Owner:WOO CHUL SEOK

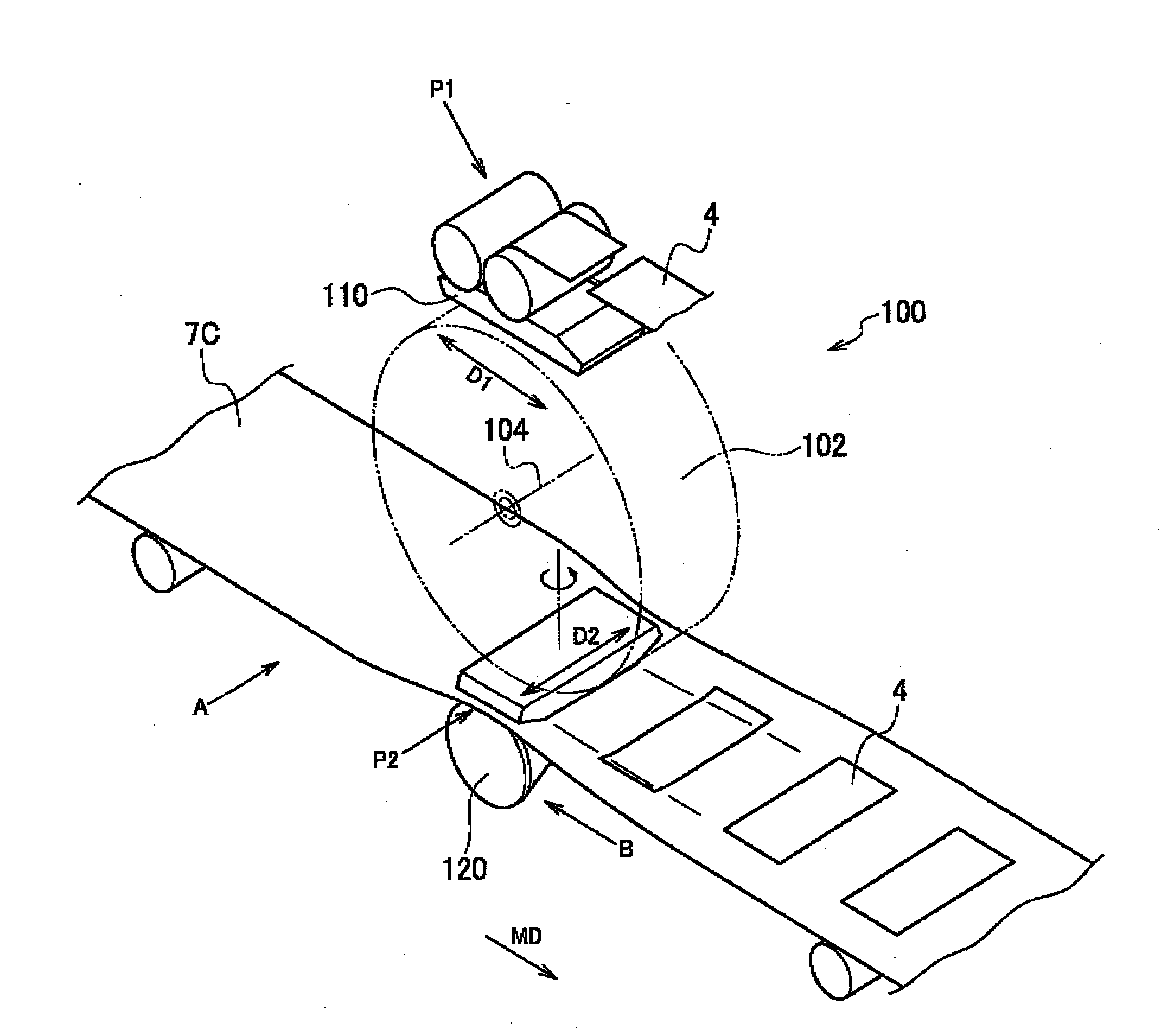

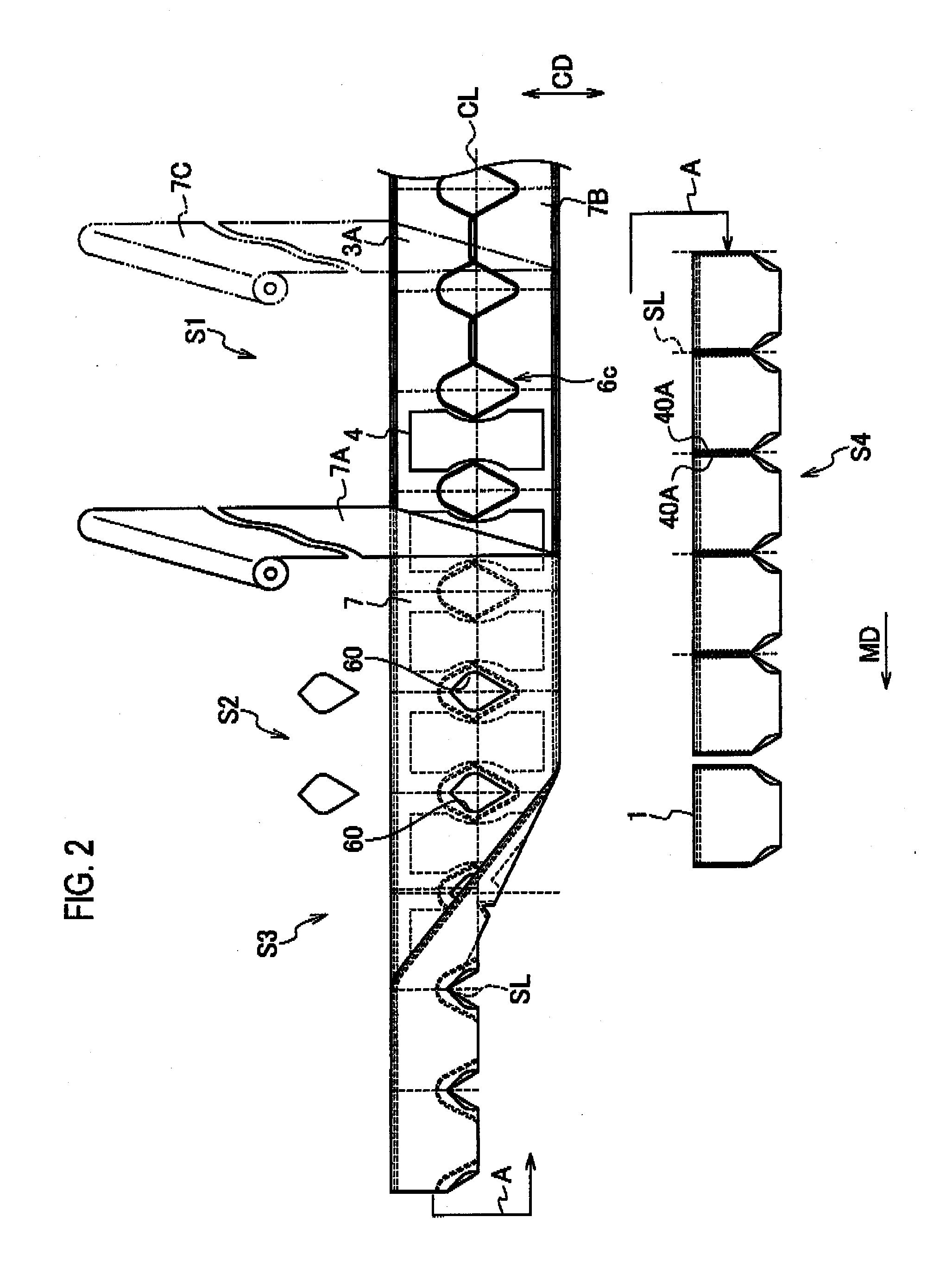

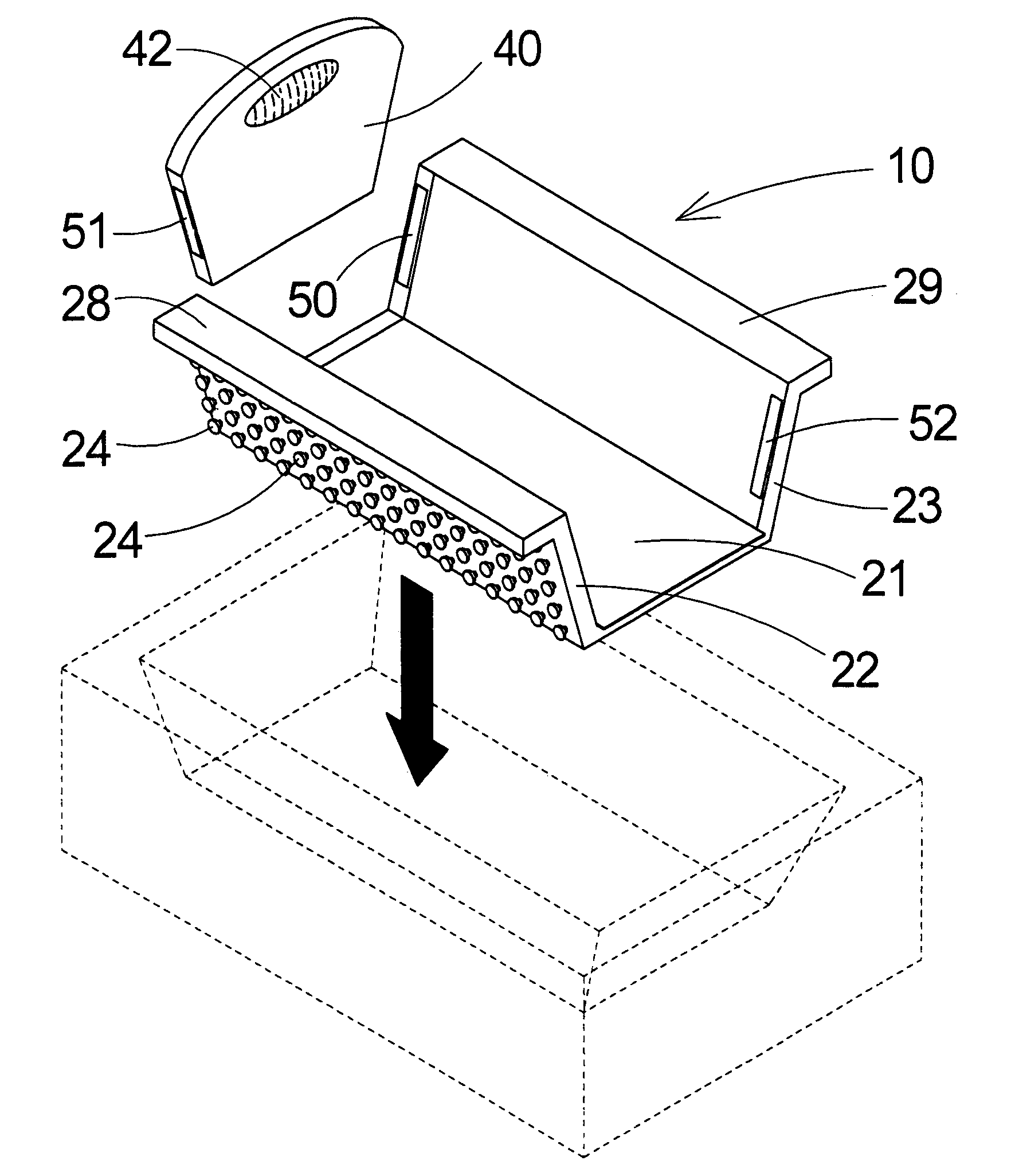

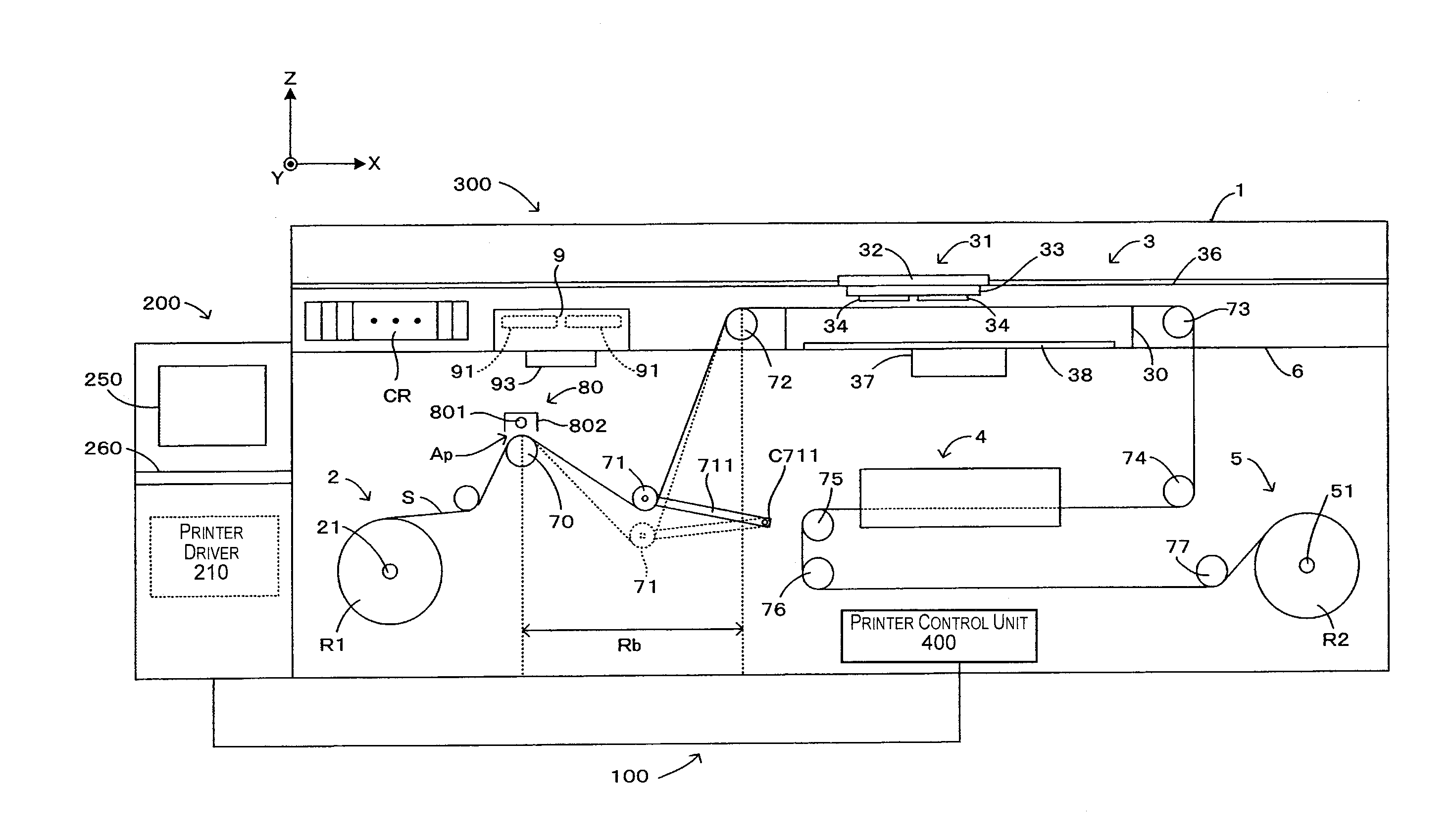

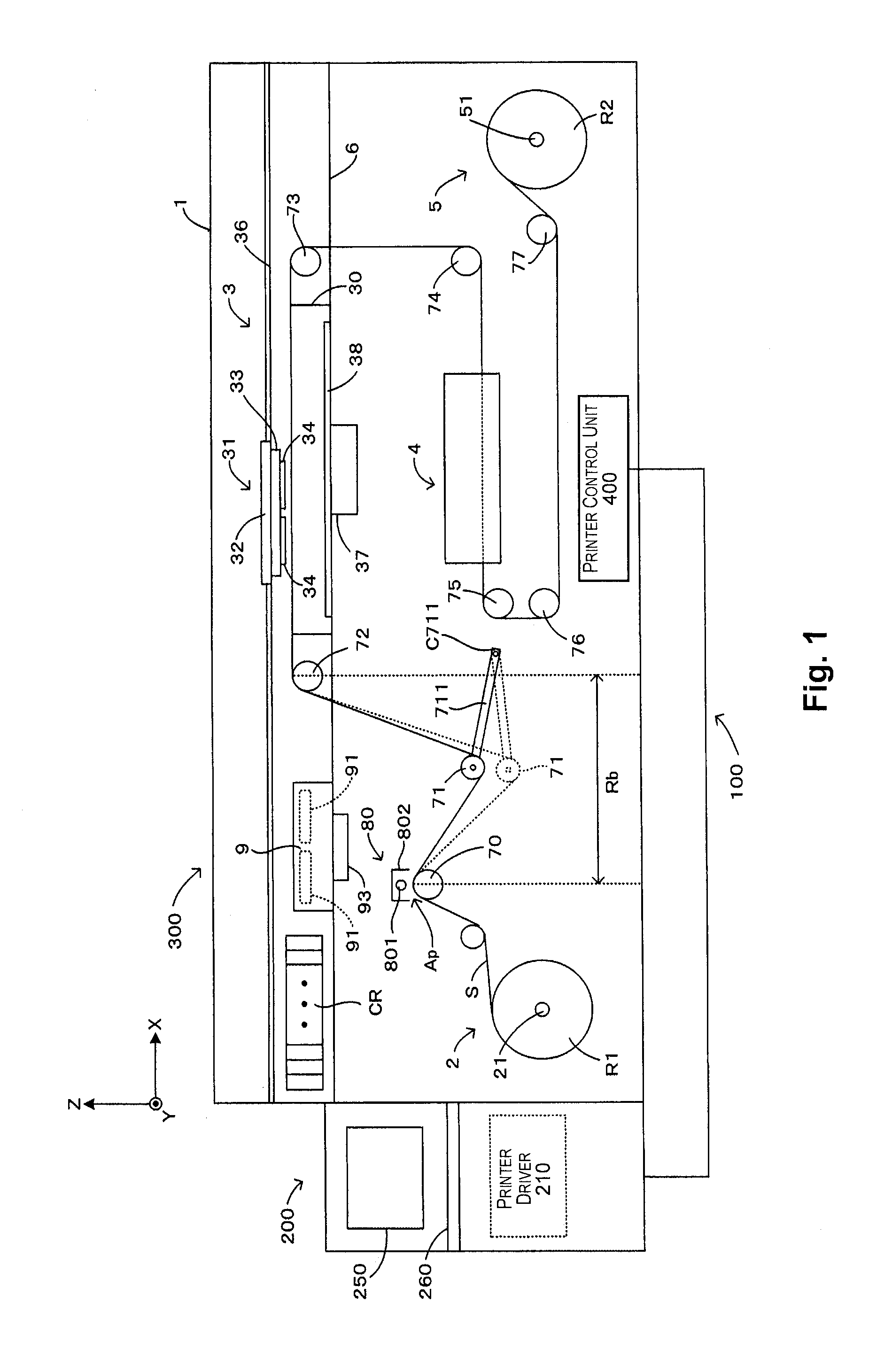

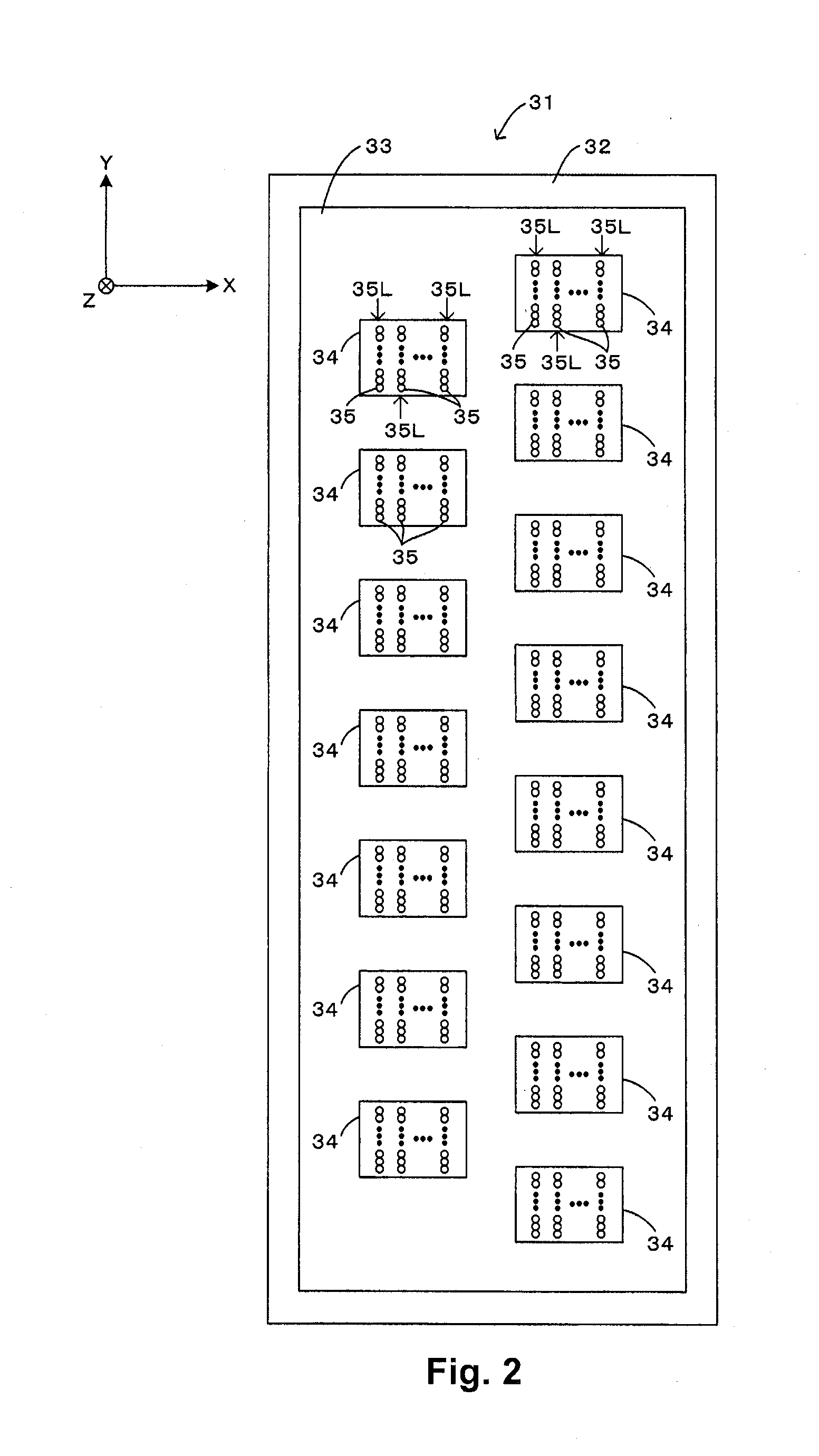

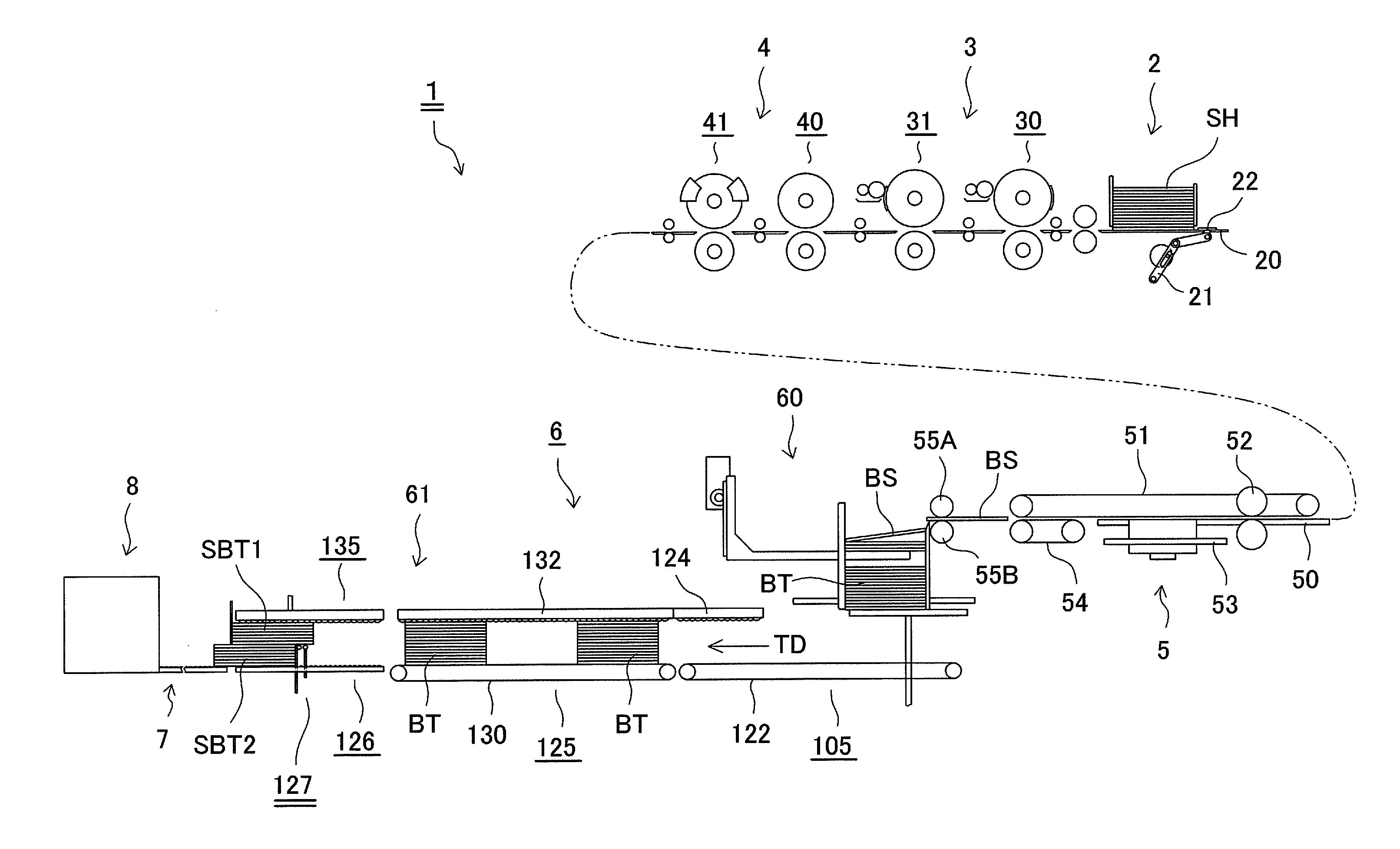

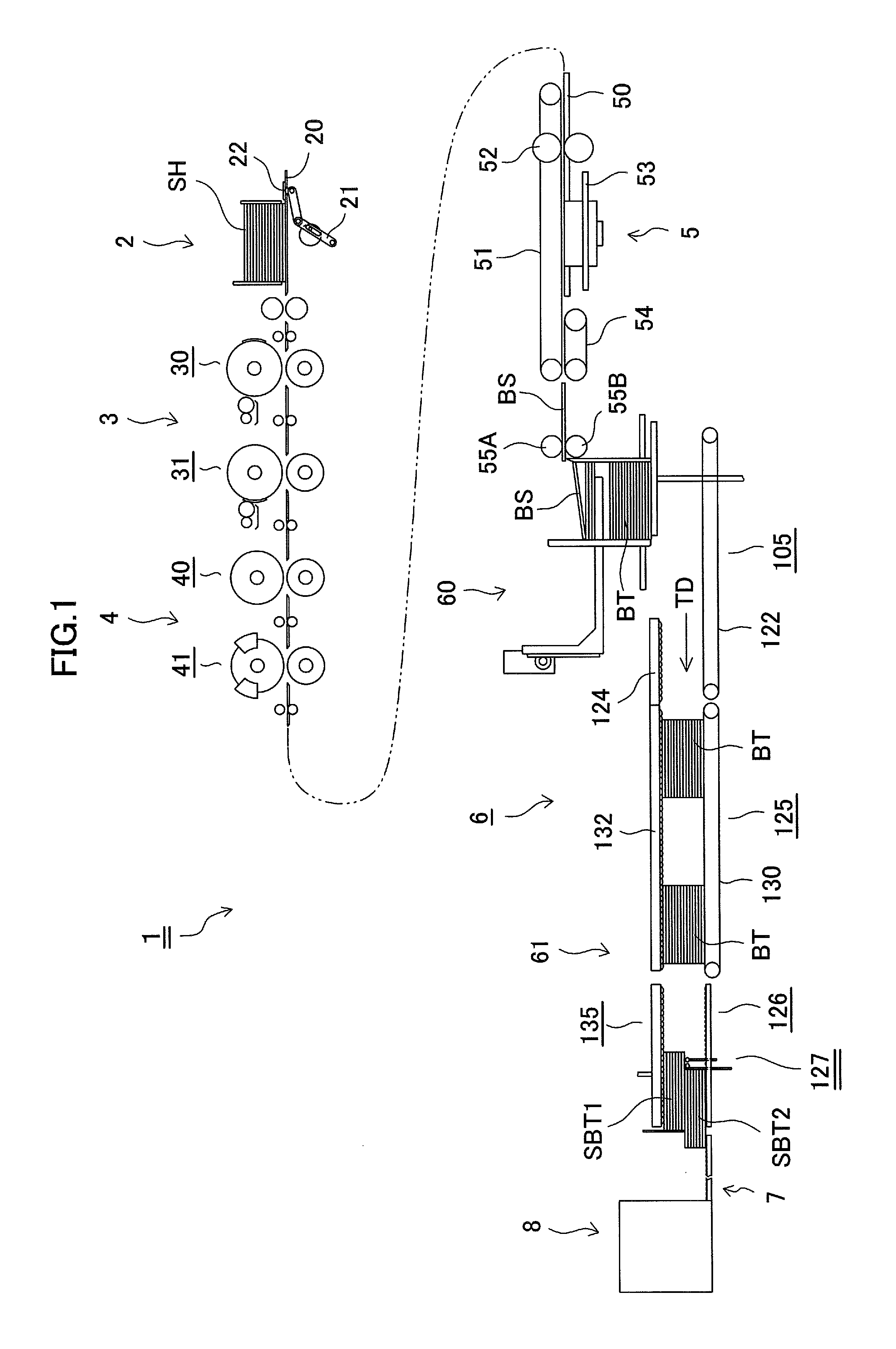

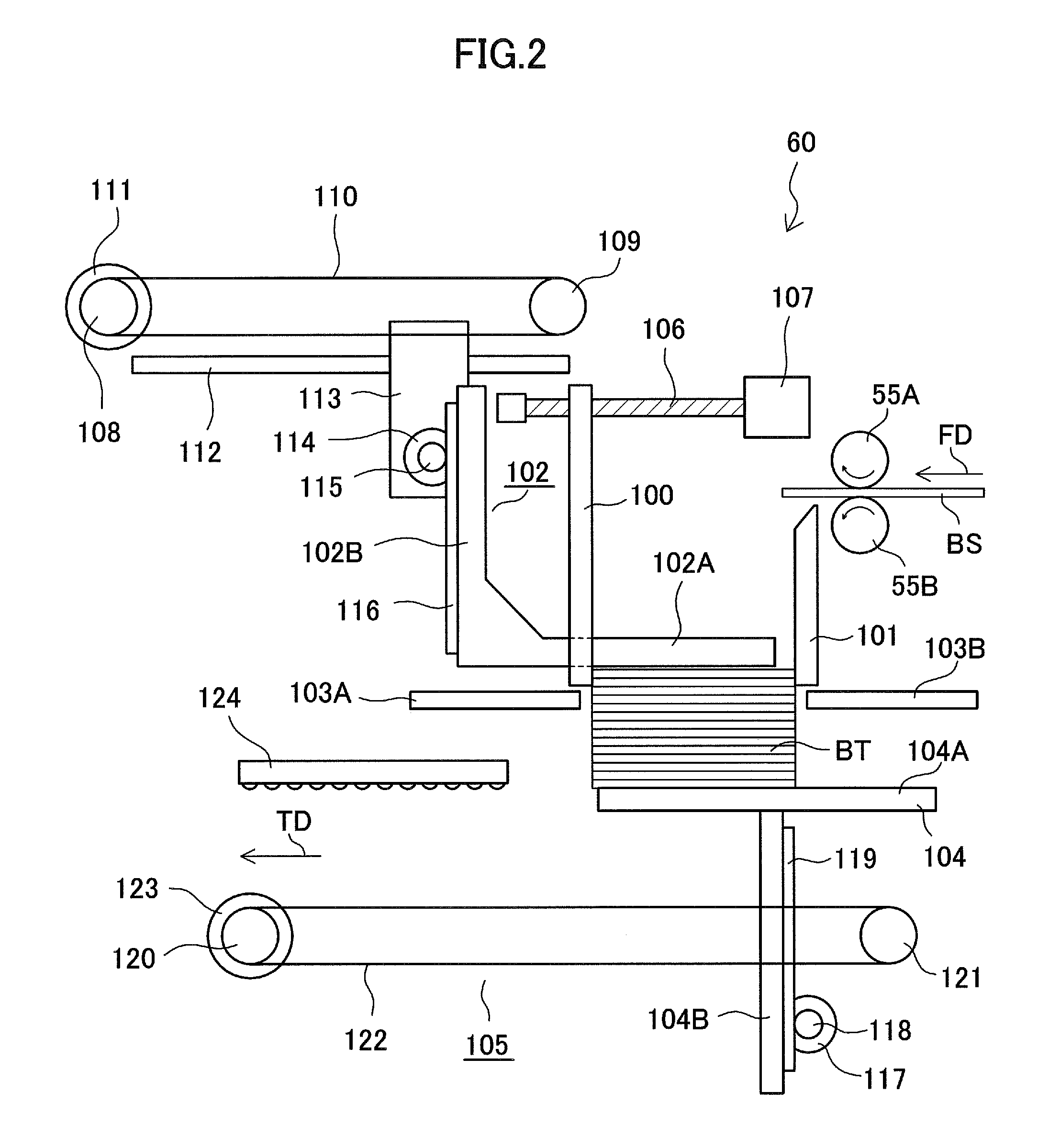

Manufacturing apparatus of absorbent article and manufacturing method of absorbent article

ActiveUS20100122766A1Generation of poorPoor transferThrowing machinesMechanical working/deformationEngineeringMechanical engineering

Owner:UNI CHARM CORP

Antiglare and antiseptic coating material and touchscreen coated with the same

InactiveUS20120177920A1Good weather resistanceImprove anti-corrosion performanceMaterial nanotechnologySilicon organic compoundsArylHydrogen

An antiglare and antiseptic coating material comprises nanoparticles with a molecule having the formula (I):wherein R1 could be substituted with halogens, hydrogen, alkyl groups, alkoxy groups, hydroxyl group, alkenyl groups, alkynyl groups, acyl groups, aryl groups, carboxyl groups, alkoxycarbonyl groups, or aryloxycarboxyl groups, and wherein R2 could be quaternary ammonium functional groups. The antiglare and antiseptic coating material is spread on an outer cover or a conductive layer of a touchscreen to provide antiglare, antiseptic and fingerprint-proof functions for the coated surfaces.

Owner:PROSPER PEAK

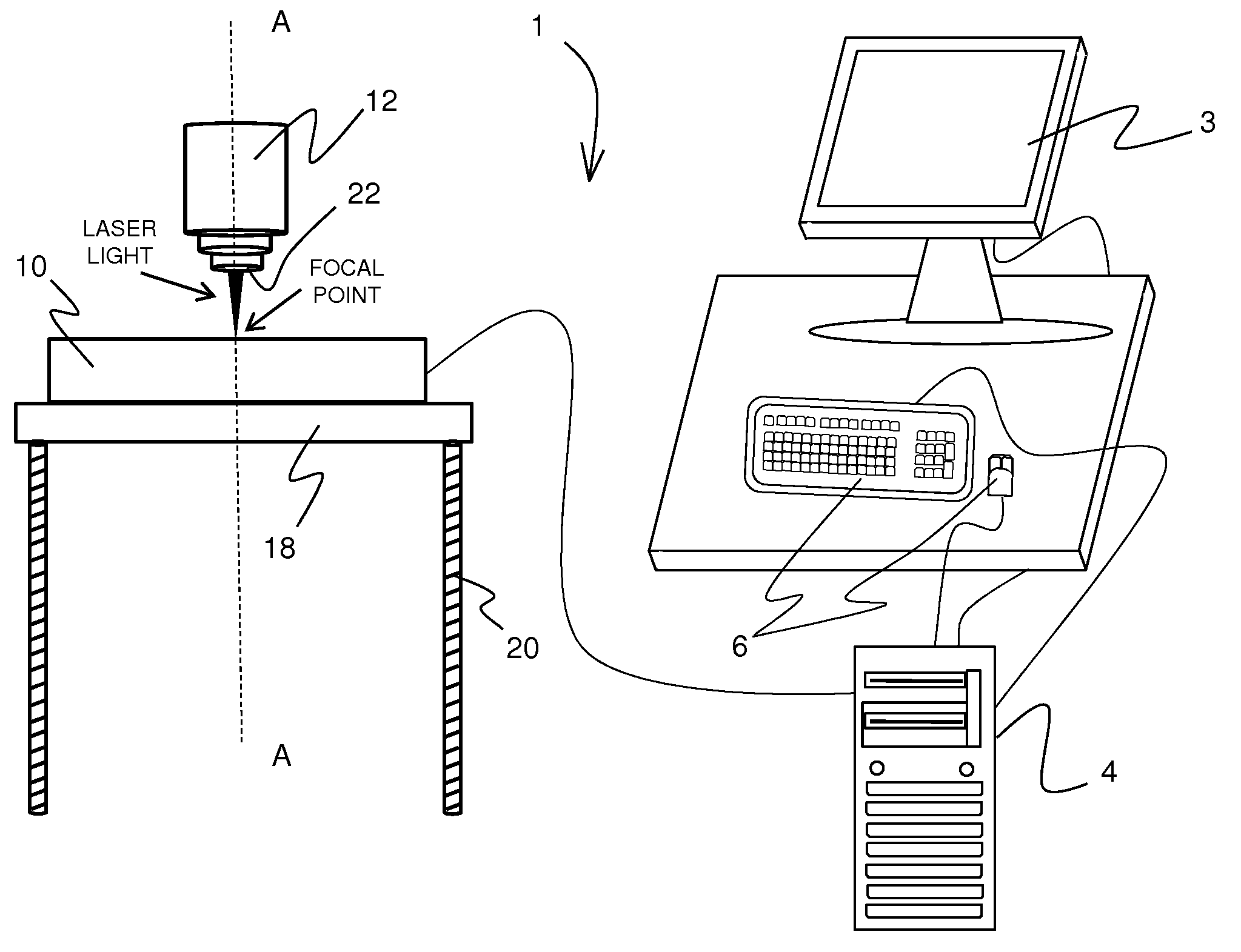

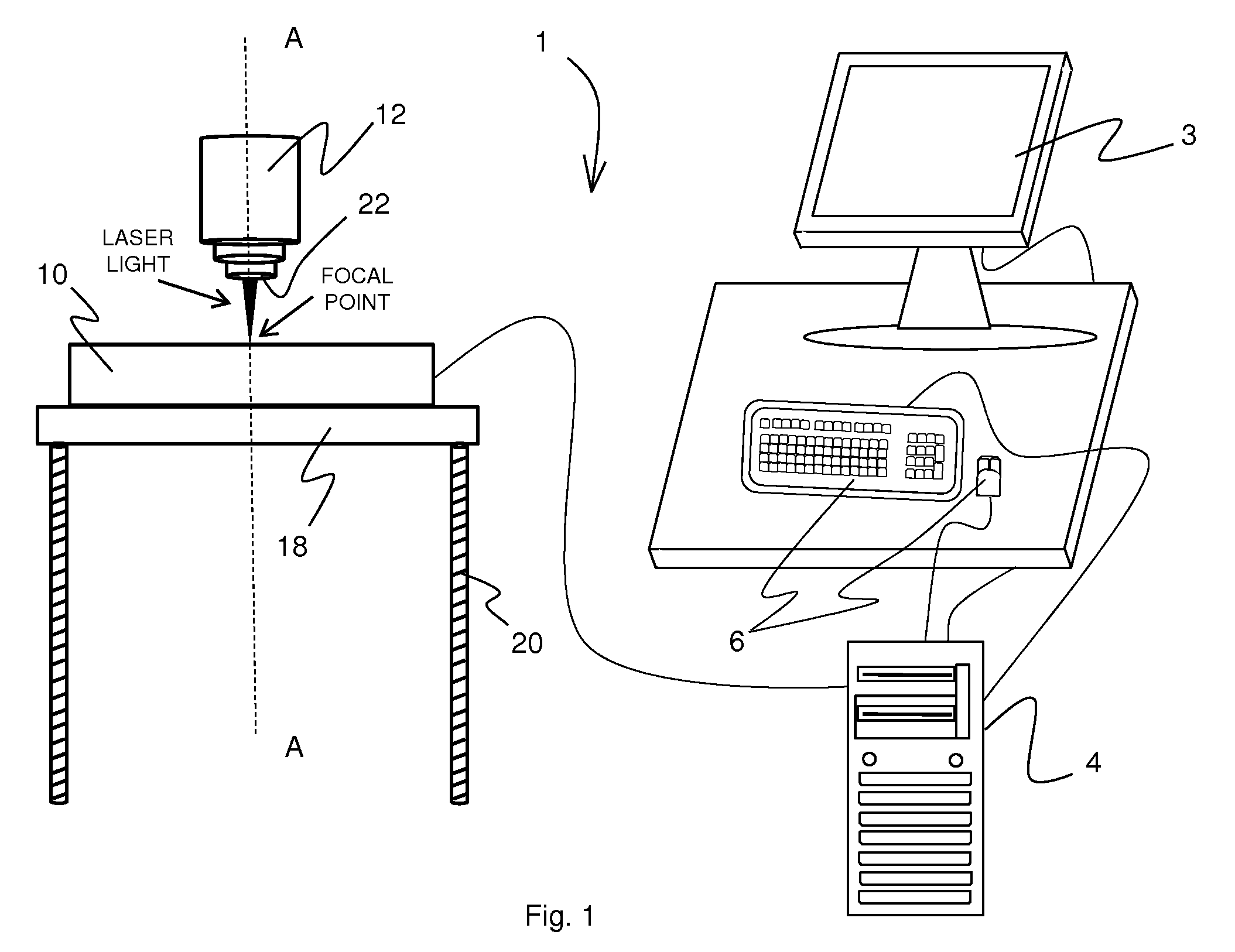

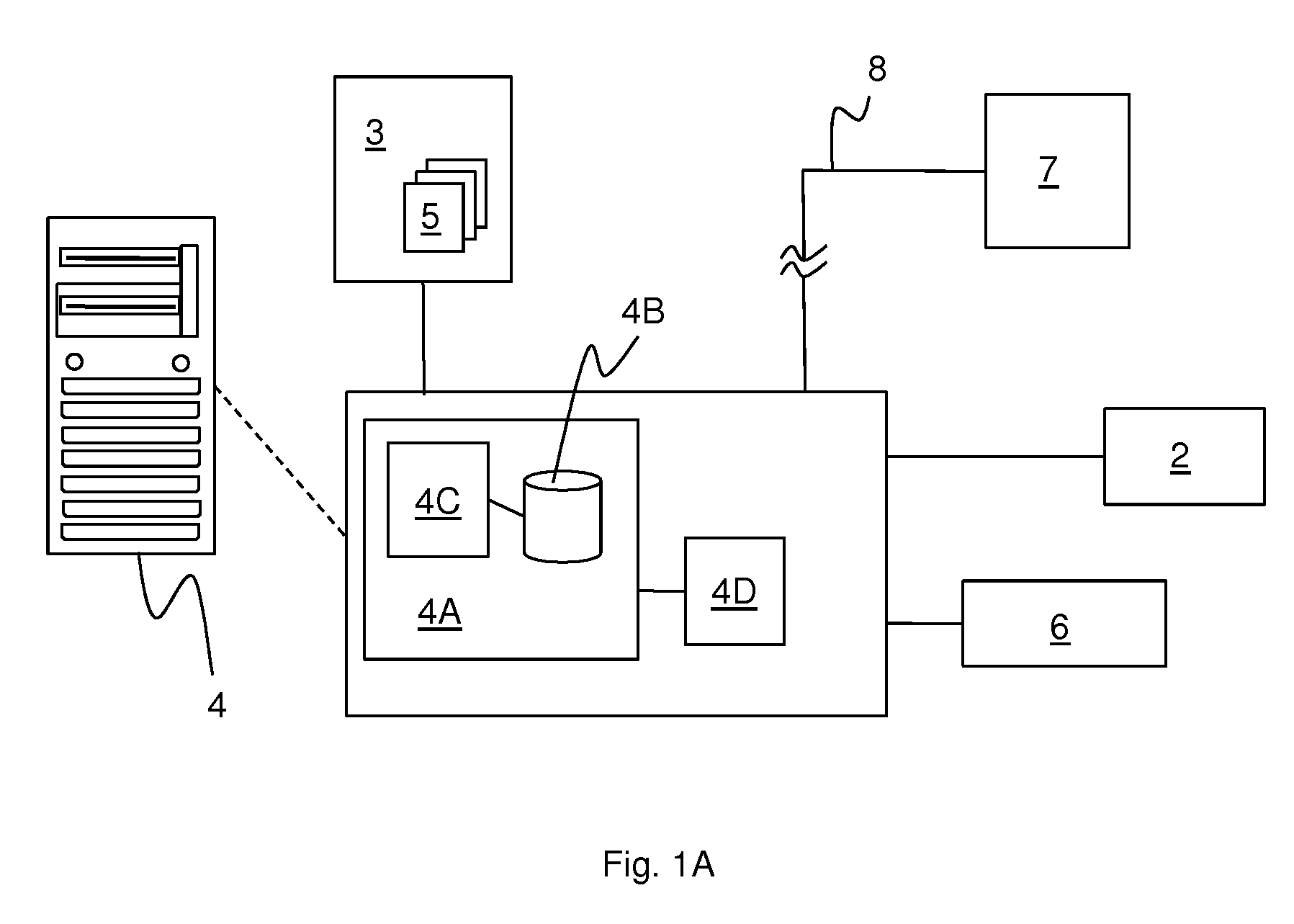

Method and apparatus for fabricating a foam container with a computer controlled laser cutting device

InactiveUS20100260999A1Avoid overall overheatingSoftness of the materialLayered productsWelding/soldering/cutting articlesHigh densityEngineering

A method and apparatus for fabricating a foam container by using a laser cutting apparatus to precisely cut and remove portions of foam in order to form custom and predetermined text, indentations and protective compartments in the foam, and more particularly a method of controlling the laser relative to high density foam to create precise cuts completely through the foam without subsequently adjusting the focal point of the laser, the cuts being made according to exterior dimensions of an object to be supported and protected in the high density foam.

Owner:BATTLE FOAM

Padded tub liner

A padded tub liner for protecting a user from an impact caused by slipping in a bathtub. The padded tub liner includes a bottom portion designed for resting upon a bottom surface of the bathtub; a first side portion operationally coupled to the bottom portion, and designed for abutting a side surface of the bathtub; and a second side portion operationally coupled to the bottom portion opposite the first side portion, and designed for abutting a second side surface of the bathtub.

Owner:ROBERTS HOLLY

Image recording device and image recording method

InactiveUS20130249992A1Secure adhesionImprove propertiesOther printing apparatusImage recordingEngineering

An image recording device includes a support member, a recording head, a surface modifying apparatus, a conveyor unit, and a control unit. The surface modifying apparatus executes surface modification processing to modify a surface of the recording medium at a processing position disposed on an upstream side of the support member. The conveyor unit intermittently passes the recording medium through the processing position at a prescribed passage velocity by feeding the recording medium from the upstream side of the conveyance path to the processing position. The control unit is capable of providing a processing execution signal to the surface modifying apparatus, and provides the processing execution signal to the surface modifying apparatus for a prescribed time within a wait time from when passage of the recording medium through the processing position stops until the recording medium starts passing through the processing position at the prescribed passage velocity.

Owner:SEIKO EPSON CORP

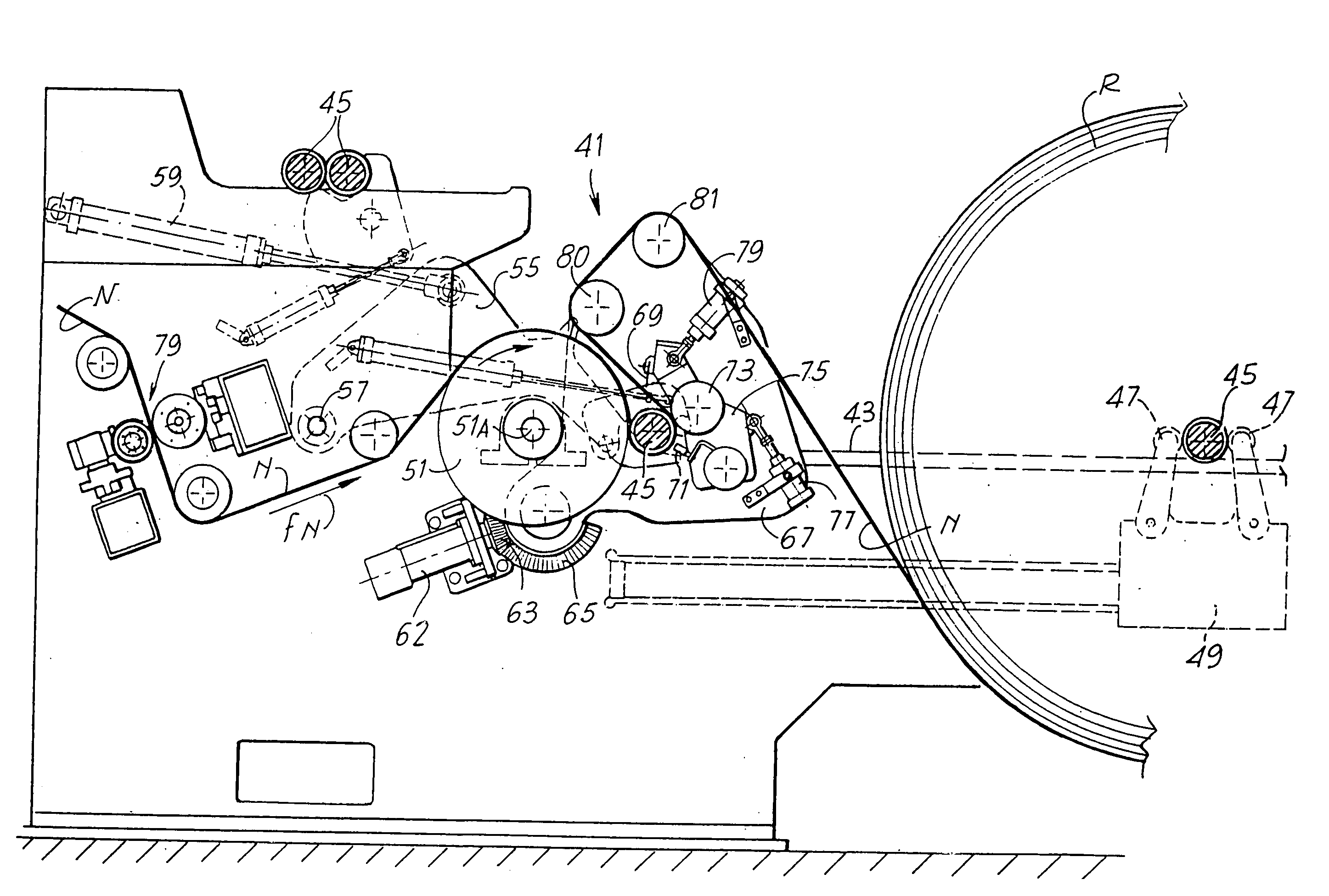

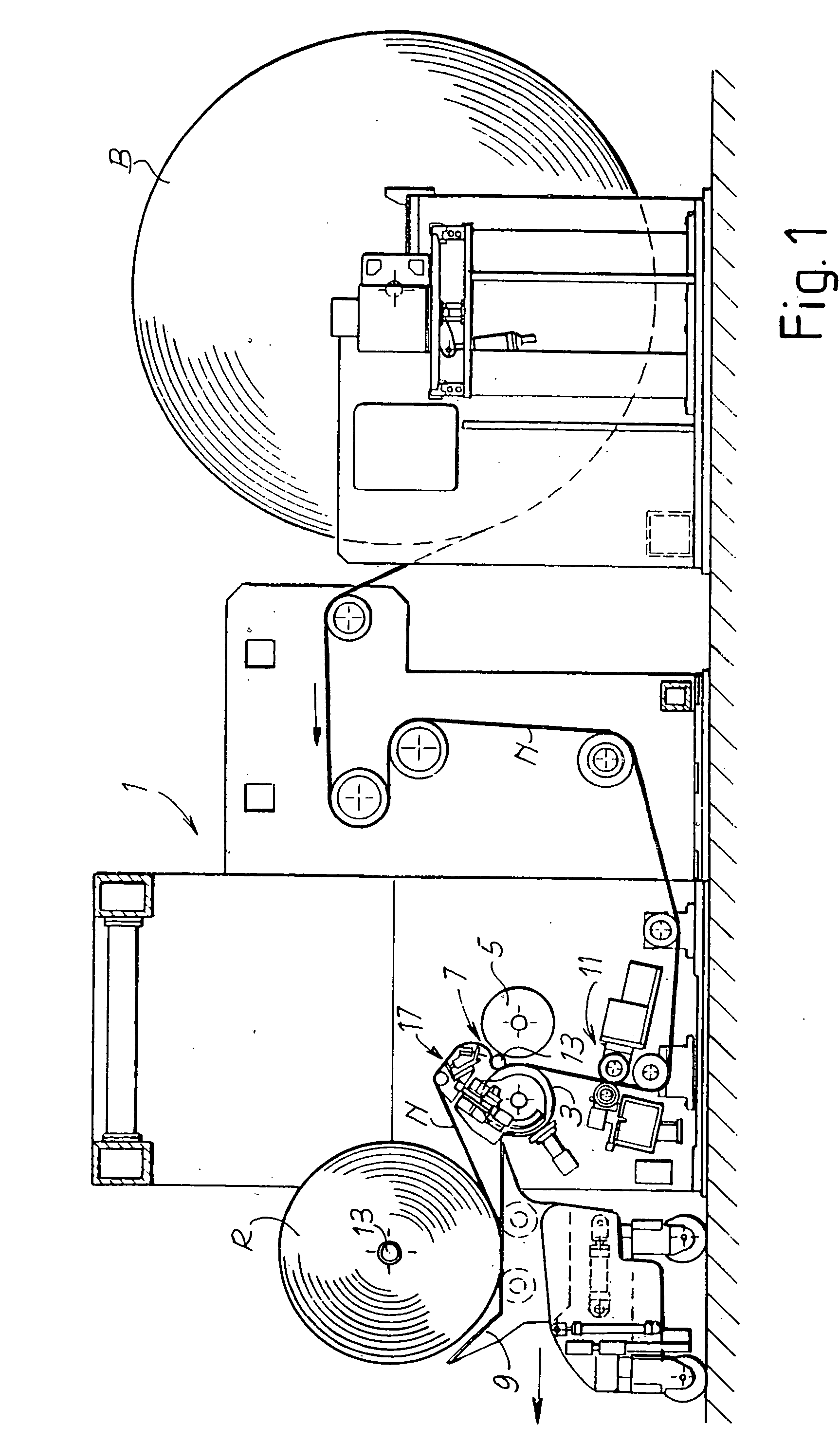

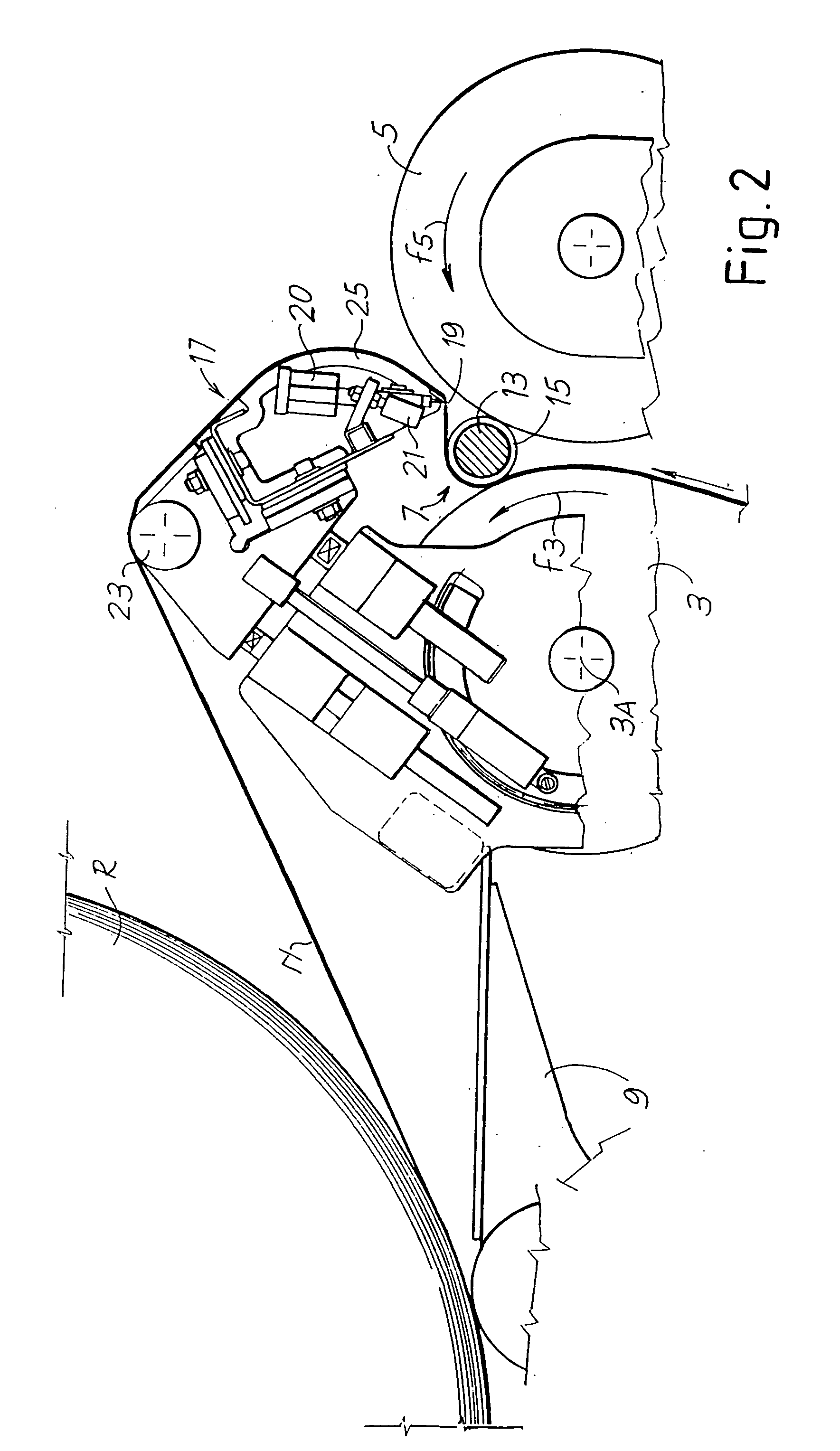

Winding or rewinding machine for producing rolls of web material around a winding spindle and relative winding method

InactiveUS20040144879A1Easily woundReduce capacitanceArticle deliveryWebs handlingConductive materialsConductor Coil

A winding or rewinding machine to wind a web material (N) and form a roll (R) around a winding spindle (13) is disclosed, comprising: at least a roller (5) in contact with said winding spindle in the initial phase of winding the web material around the spindle; a transverse cutting element (19) to cut the web material when a roll has been wound and form an initial free end to wind a subsequent roll around a new winding spindle. Moreover, at least an electrostatic bar (21) to electrostatically charge the web material is also provided. The roller (5) in contact with the spindle is made at least partially in non-electrically conductive material.

Owner:A CELLI NONWOVENS

Drum pad and manufacturing method thereof

ActiveUS8148617B2Feel goodSecure adhesionElectrophonic musical instrumentsSynthetic resin layered productsEngineeringMechanical engineering

A drum pad capable of providing an excellent percussion feeling and securely adhering a base portion to a body portion made of rubber. The drum pad has a rear-side clothlike material which is provided on a rear surface of the body portion and into which the rubber of the body portion is impregnated. The base portion is fixed to a rear surface of the rear-side clothlike material via a fixing layer made of pressure sensitive adhesive or adhesive and provided on the rear surface of the rear-side clothlike material.

Owner:YAMAHA CORP

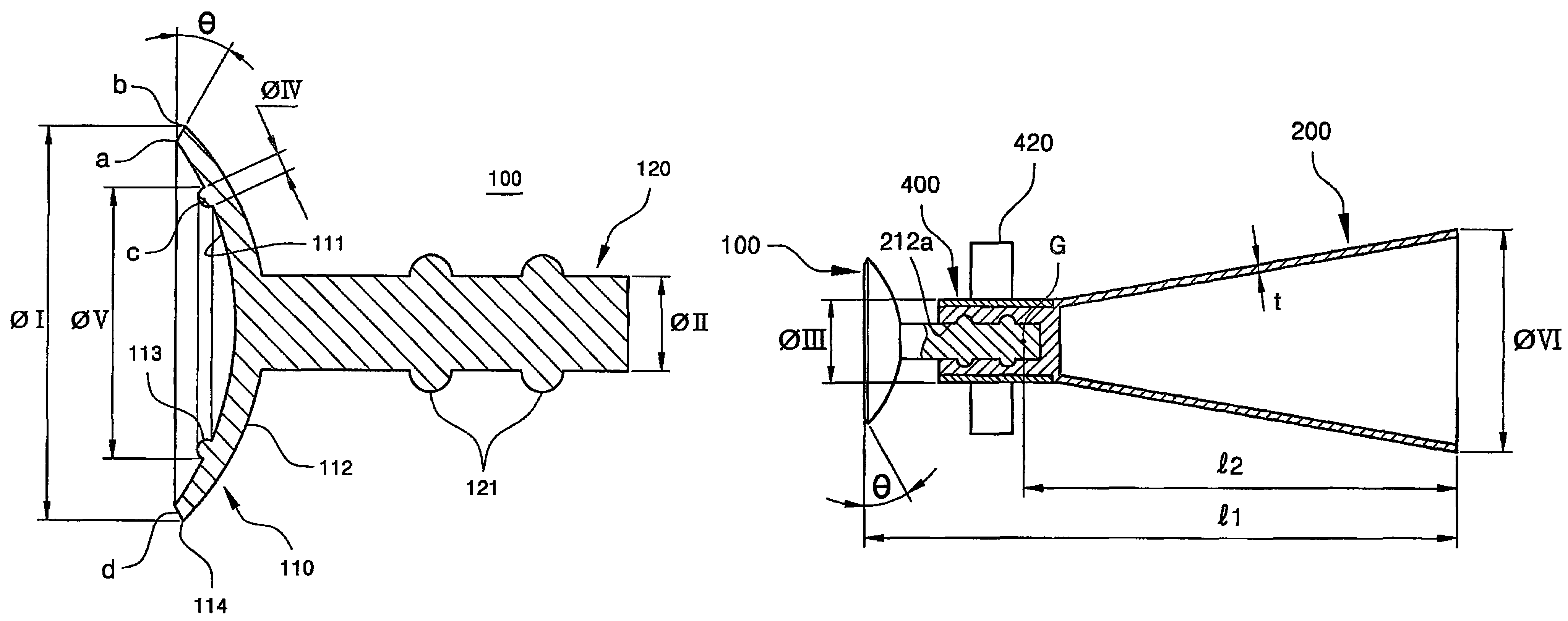

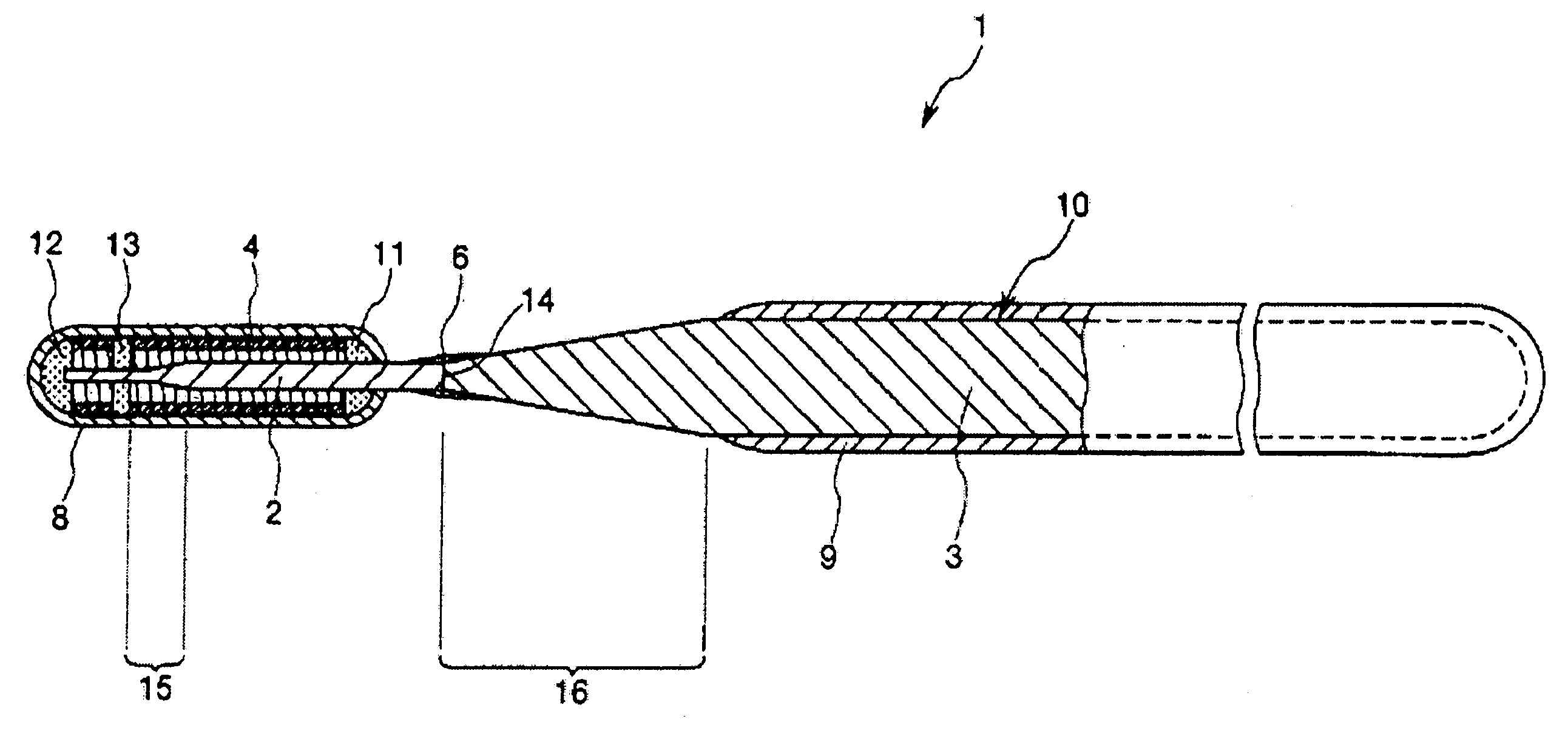

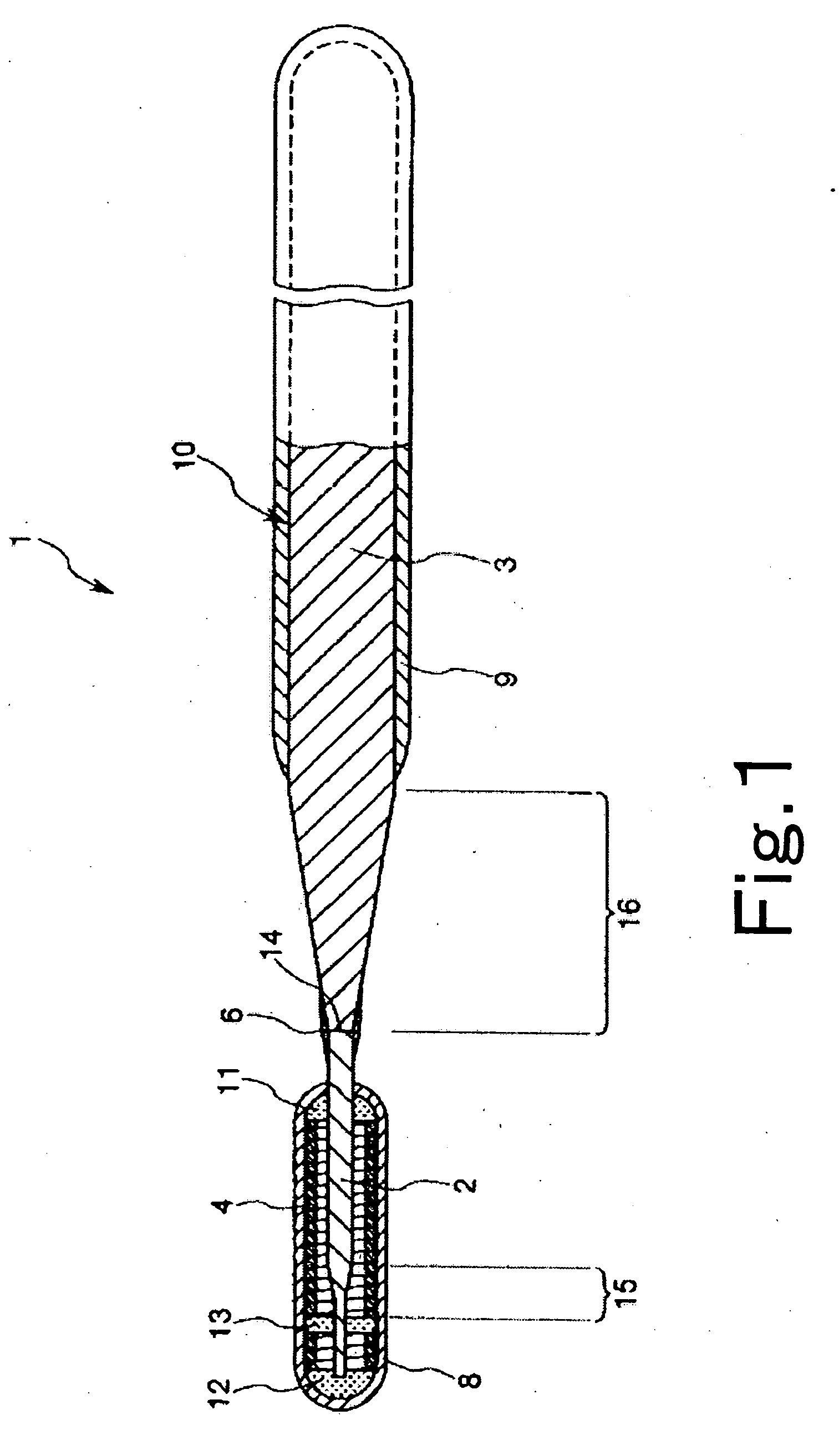

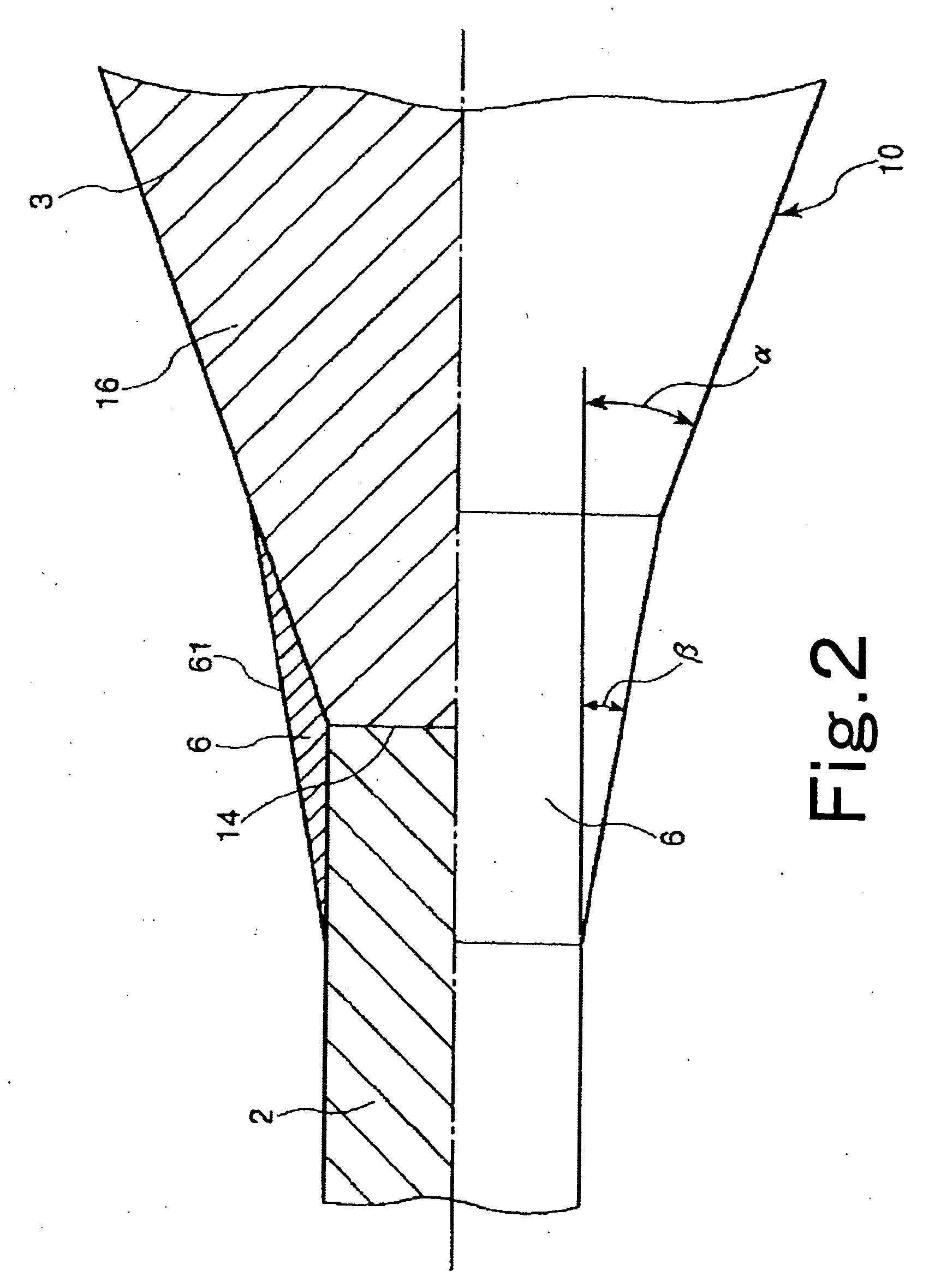

Guide wire

InactiveUS20060235336A1Improve joint strengthSecure transmissionGuide wiresDiagnostic recording/measuringEngineeringGuide wires

A guide wire has a wire body which includes a first wire, and a second wire disposed on the proximal side of the first wire and joined to the first wire. A radiopaque coil is preferably disposed around a distal end portion of the first wire. Preferably, a proximal end portion of the first wire is substantially constant in outside diameter along the longitudinal direction, while a distal end portion of the second wire may be composed of a tapered portion of which the outside diameter is gradually increased in the proximal direction from the distal end thereof. Both the wires may be joined their end faces. The outer periphery of the joined portion is preferably provided thereon with a coating layer.

Owner:TERUMO KK

Cardboard sheet batch division device, cardboard sheet counter ejector, and method for dividing cardboard sheet

InactiveUS9033646B2Quality improvementShorten the counting processLoadersBox making operationsCardboardLeading edge

The present invention is a cardboard sheet batch division device for dividing batches, disposed on the downstream side of a batch-forming device for separating loaded cardboard sheets and forming batches of a predetermined sheet count. The cardboard sheet batch division device for dividing batches comprises: a transfer conveyor for transferring batches formed by the batch-forming device in a predetermined transfer direction; and batch division means furnished with two separating members respectively contacting the leading edge portion and the trailing edge portion of a batch on the transfer conveyor, for dividing the batch into two sub-batches, upper and lower, by moving the two separating members relative to one another in a direction parallel to the predetermined transfer direction.

Owner:ISOWA IND CO LTD

Resin moldings

InactiveUS6916527B2Improve adhesionStructuredVacuum evaporation coatingSolid-state devicesElectroplatingIon plating

A resin molded component, comprising metal coating treatment being provided on the surface by a physical deposition method chosen from among sputtering, vacuum deposition, and ion plating after the surface is activated by plasma treatment, and is produced by forming a resin composition combined a base resin comprising of a thermoplastic resin or a thermosetting resin with a rubber-like elastic material.

Owner:MATSUSHITA ELECTRIC WORKS LTD

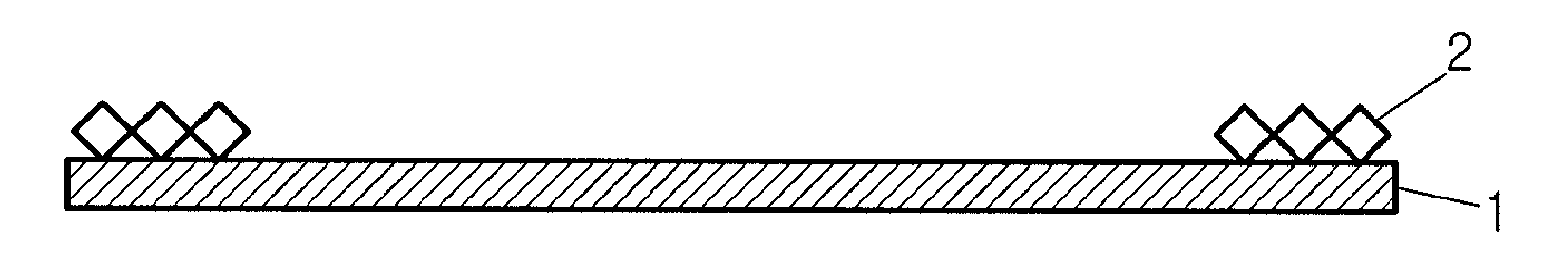

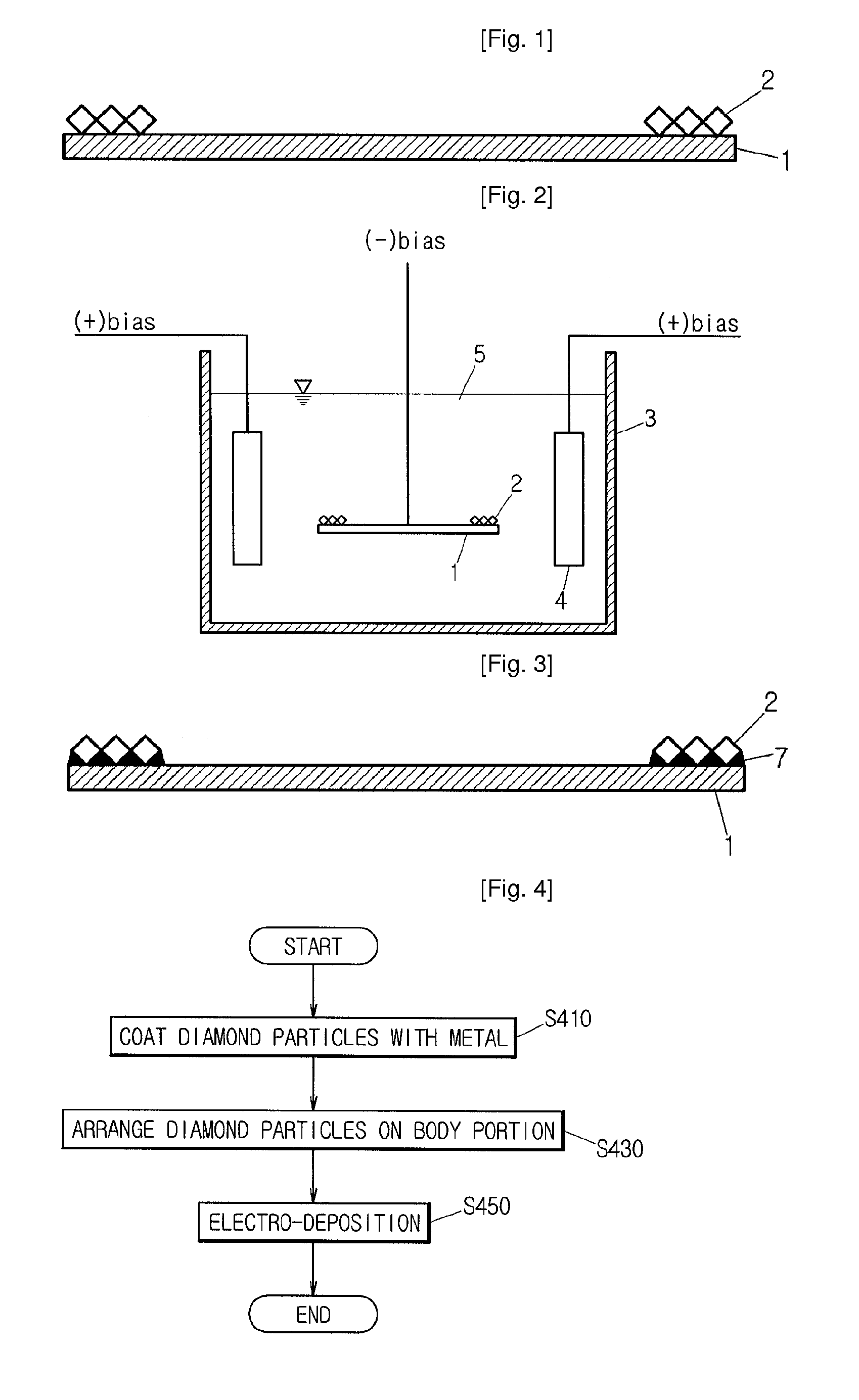

Diamond Cutting Tool and Manufacturing Method Thereof

InactiveUS20080171175A1Shorten production timeSecure adhesionElectrolytic coatingsRecord information storageDiamond cuttingMetal

A manufacturing method of a diamond cutting tool is characterized in that the metal coated diamond particles are arranged on a region of a steel body portion intended to be used as a cutting edge, and then adhered to the body portion through the electro-deposition whereby the manufacturing time is reduced, the diamond particles are securely adhered to the body portion, and the lifetime of the cutting tool is prolonged as well.

Owner:PARK RIN SOON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com