Golf ball with RFID system

a radiofrequency identification and golf ball technology, applied in the incorporation of printed electrical components, printed circuits, electrical appliances, etc., can solve the problems of preventing the transmission efficiency of signal energy from dropping, and achieve the effect of reducing the thickness of the antenna, preventing deformation and separation of the antenna, and ensuring the durability of the antenna against an impact from the golf ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

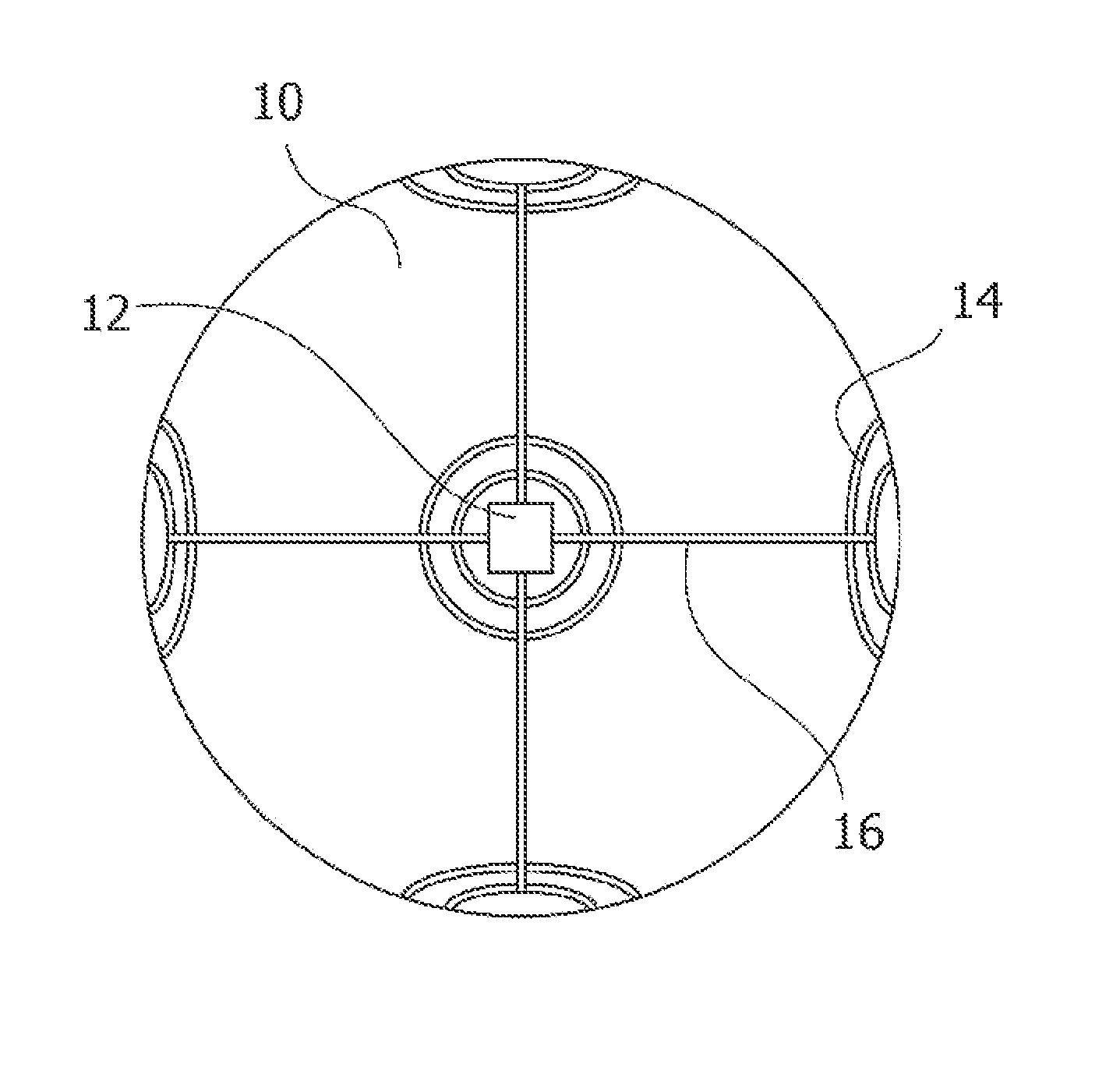

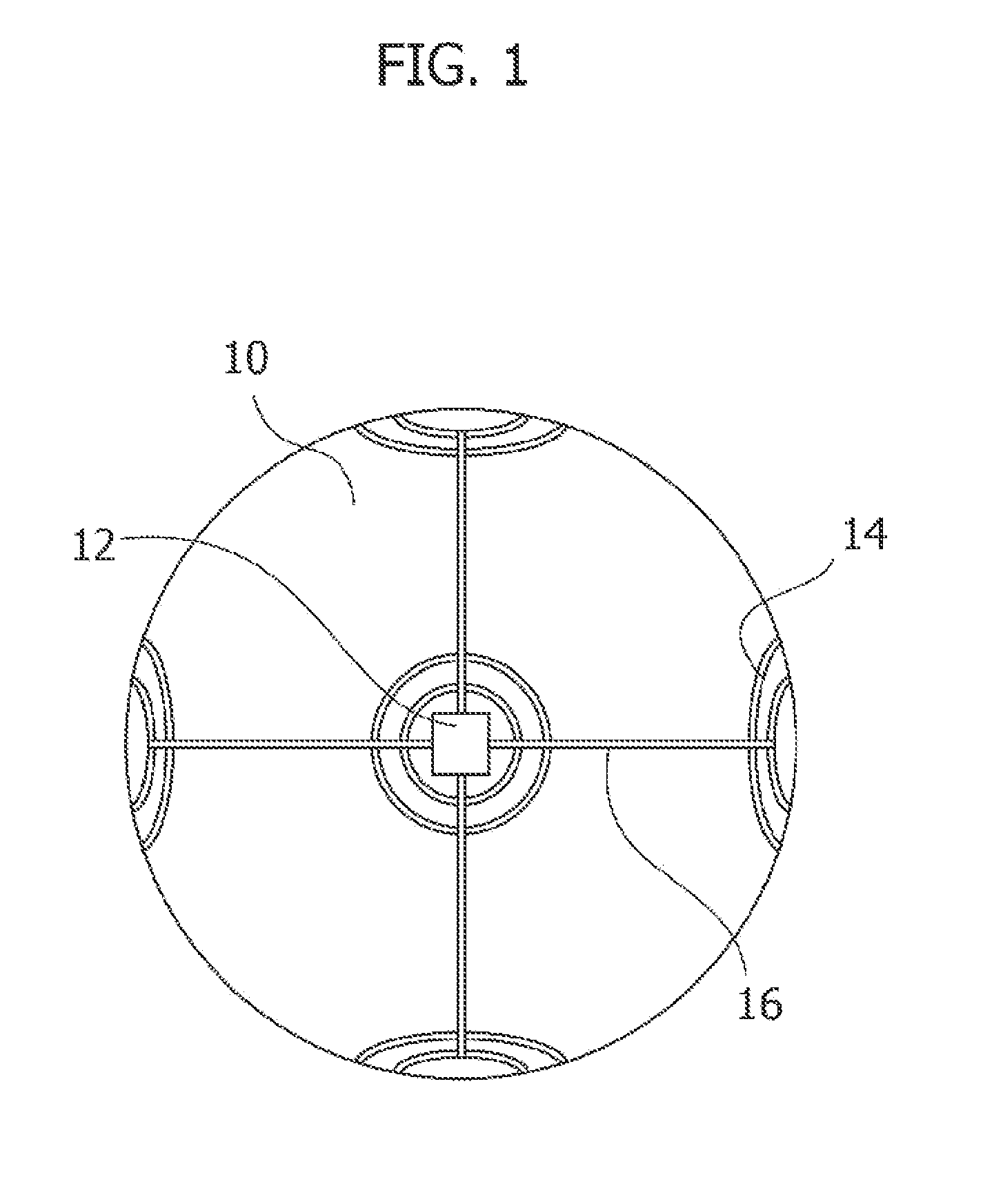

Image

Examples

second embodiment

[0030]For example, the golf ball includes a core layer having a groove in its surface, a cover layer which covers the core layer, and an intermediate layer disposed between the core layer and the cover layer. The RFID circuit may be formed of conductive ink within the groove of the core layer. The groove of the core layer is not limited to any particular shape as long as it has a shape suitable for accommodating the RFID circuit and may be quadrangular such as square or rectangular or of other shape. Furthermore, the number of the core layers is not limited to any particular one as long as the groove has a depth sufficient for accommodating the RFID circuit. The RFID circuit may be formed of conductive ink within the groove in the surface of the golf ball using an ink jet printer like the surface of the golf ball.

[0031]In the present invention, the antenna may be formed of conductive ink within the groove in the core layer. The groove for the antenna is not limited to any particula...

third embodiment

[0032] the golf ball includes a core layer, an intermediate layer which covers the core layer and has a groove on its surface and a cover layer which covers the intermediate layer, and the RFID circuit may be formed of conductive ink within the groove of the intermediate layer. The groove of the intermediate layer is not limited to any particular one as long as it has a shape suitable for accommodating the RFID circuit, and may be formed in a predetermined shape like the groove of the core layer. Furthermore, the groove of the intermediate layer is not limited to any particular one as long as it has a depth sufficient for accommodating the RFID circuit.

[0033]In the present embodiment, the antenna may be formed of conductive ink within the groove of the intermediate layer. The groove for the antenna is not limited to any particular one as long as it has a shape suitable for accommodating the antenna, and it may be formed in a predetermined shape like the groove of the core layer. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com