Patents

Literature

55 results about "Bronze color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

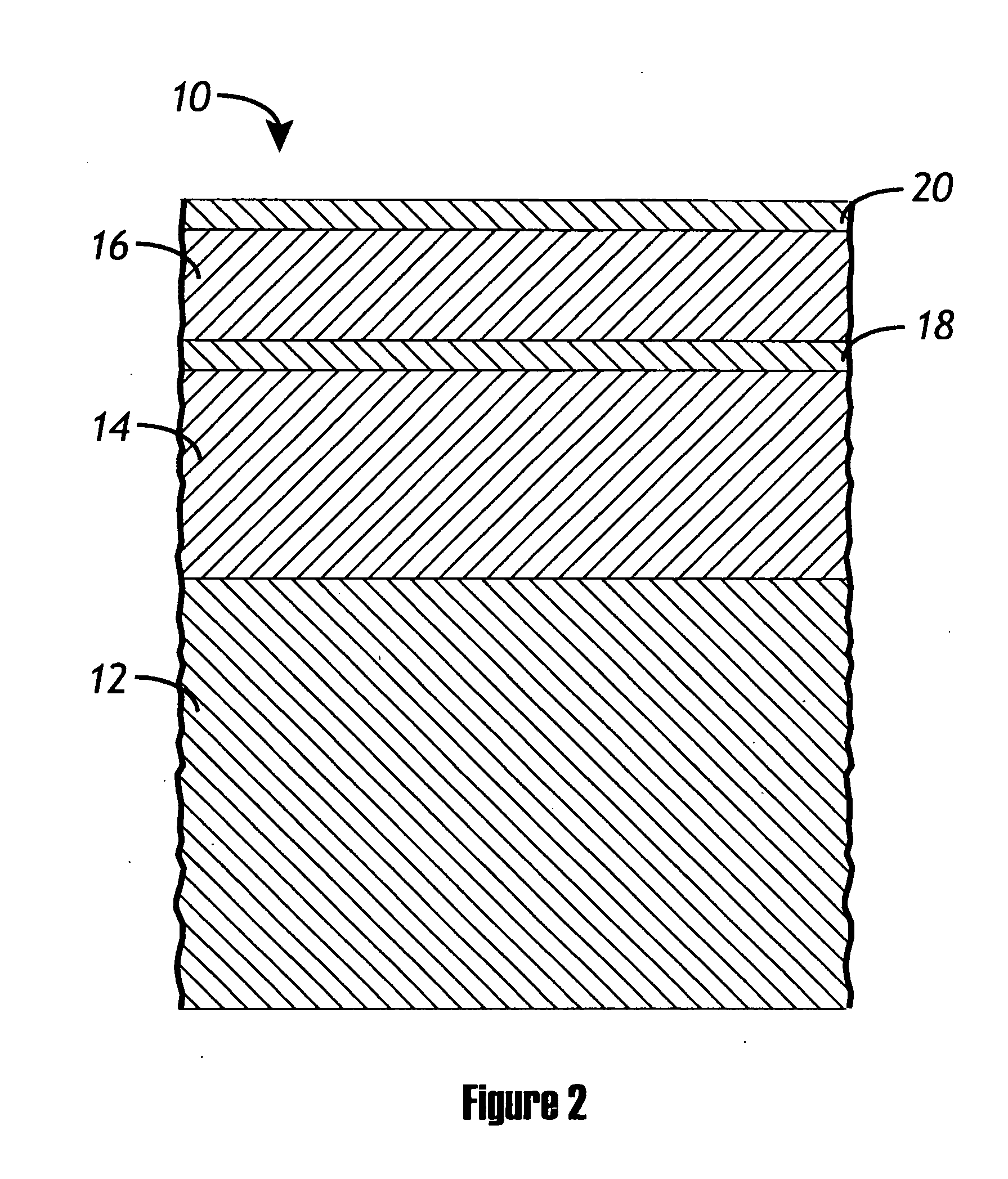

Coated article with dark color

An article is coated with a coating having a dark gray or bronze color. In a preferred embodiment, the coating comprises a nickel or polymer basecoat layer, and a color and protective stack layer comprised of layers of oxygen-rich refractory metal oxycarbides. The preferred dark grey, oxygen rich color layer is zirconium oxycarbide. A refractory metal adhesion layer and a refractory metal oxide top coat layer also may be used.

Owner:VAPOR TECH INC

Production method of fruit odor red tea

The invention discloses a production method of fruit odor red tea, which is characterized by comprising a primary processing stage and a refined processing stage, wherein the primary processing stage comprises the steps such as fresh leaves acceptance, management, withereding, thickening, rolling, fermenting and drying; and the refined processing stage comprises the steps of screening, sorting and repeated fire. Red tea which is produced through the method has unique flavor, excellent quality, tender, straight and homogenous of streak appearance, black color, strong fragrance, red and bright soup color, remarkable fruit odor, pure heavy and sweet taste and thick and smooth leaves which are bronze-colored.

Owner:QINGDAO LAOXIANG TEA PROD

Chemical coloring method for copper and alloys of copper

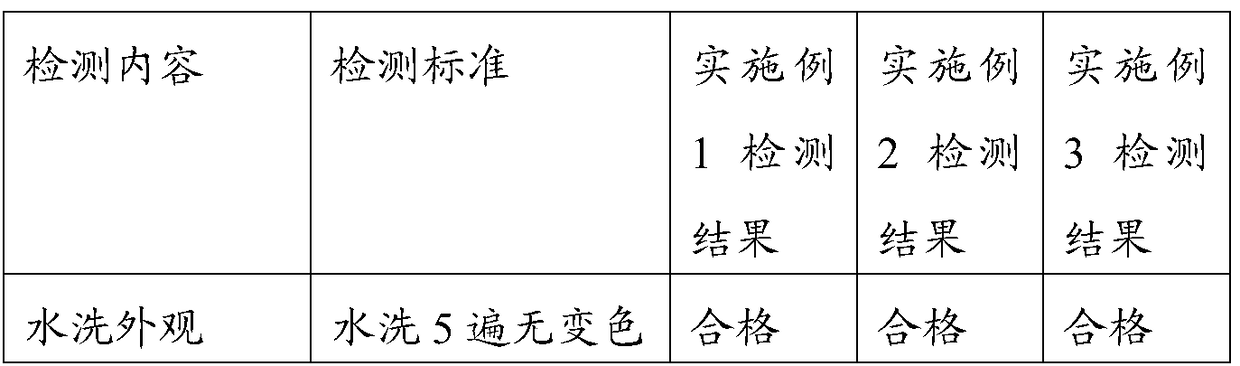

ActiveCN102031509AUniform tooth colorStrong color fastnessMetallic material coating processesZincBronze color

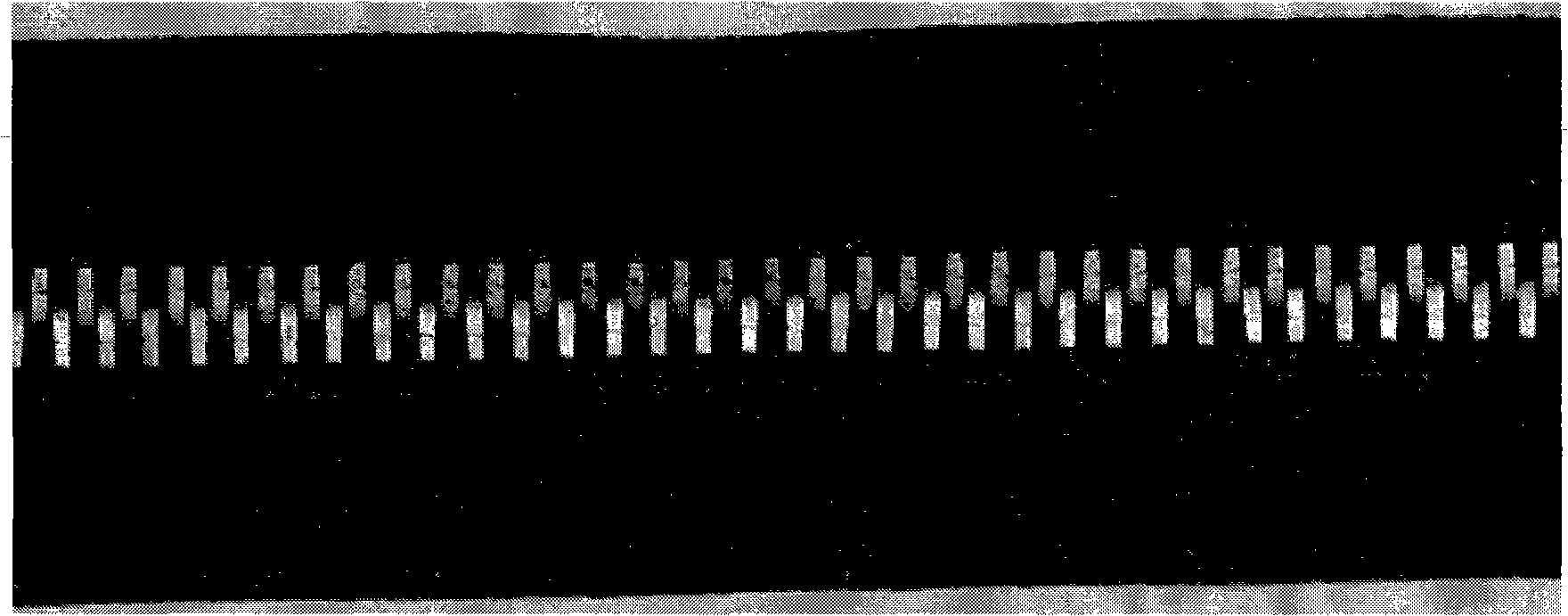

The invention discloses a chemical coloring method for copper and alloys of copper, which comprises the following steps of: firstly, abrading and polishing the surface of an copper alloy to be colored; and then, activating the surface of the copper alloy to be colored and washing; microetching the surface of the copper alloy to form a light yellow zinc-enriched membrane layer on the surface of the copper alloy; reacting making the zinc-enriched membrane layer on the surface of the copper alloy react with chemical coloring liquid to generate a metallic compound membrane layer of selenium, wherein the color of the metallic compound membrane layer is reddish black, also calledi.e. red bronze color. A zipper made by the method disclosed in the invention has simulated bronze teeth which have even color and strong color fastness.

Owner:HUA SHENG ZIPPER

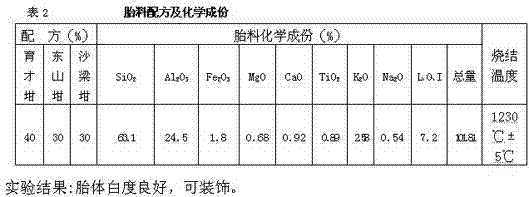

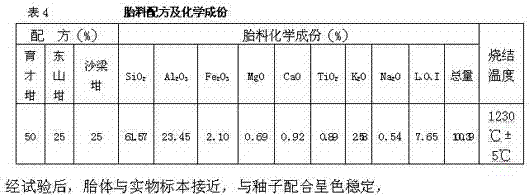

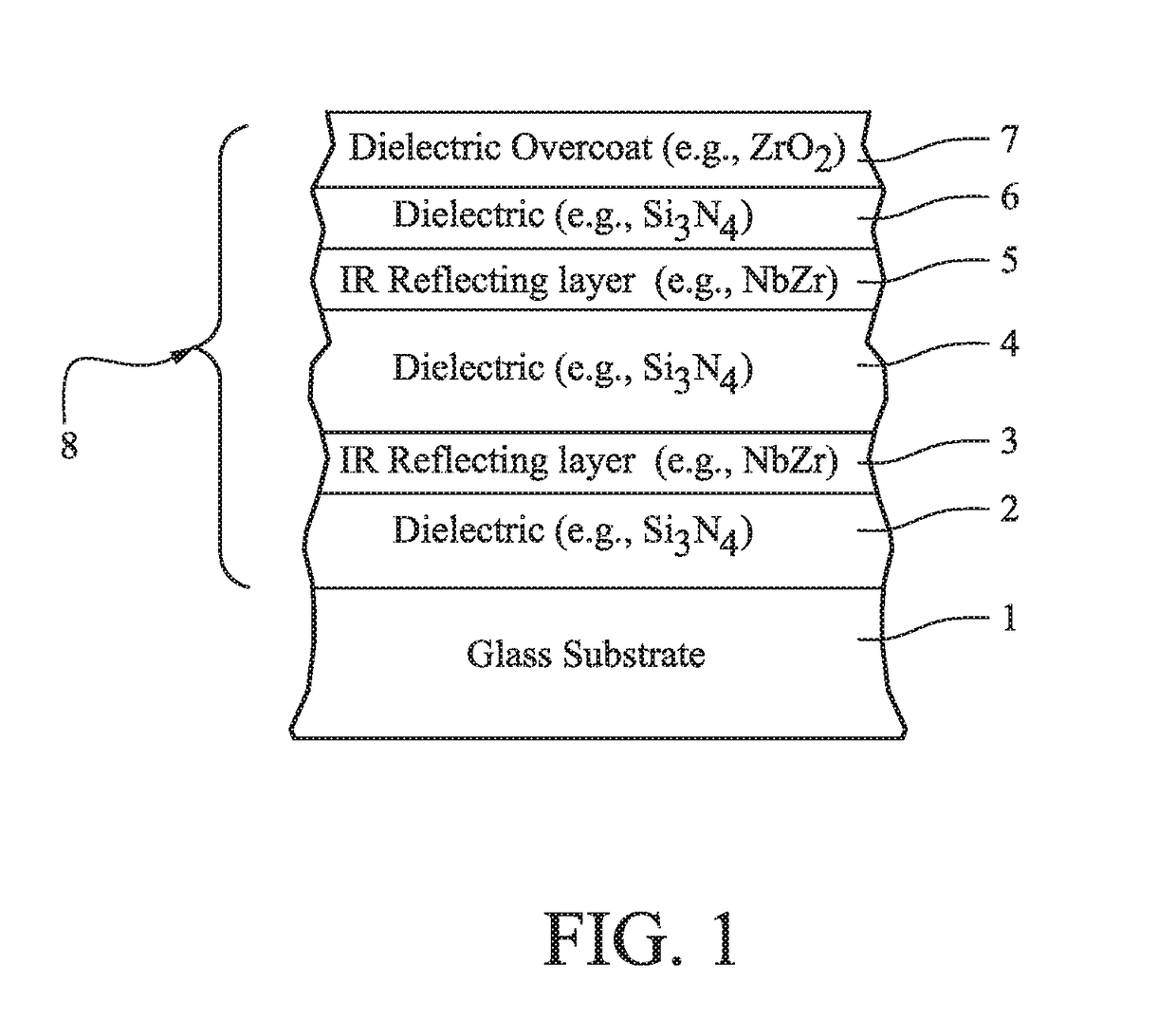

Tea foam vitreous enamel produced in Yaozhou kiln and manufacturing method thereof

The invention particularly relates to a tea foam vitreous enamel produced in a Yaozhou kiln and a manufacturing method thereof. The tea foam vitreous enamel is in a matte glazing color which is yellowing in dark brown green; dense crystal points are formed in microcosm and are gorgeous and colorful; the glazing colors comprise cacalia blueness, snakeskin green, color of mud eel's skin, eel yellow, bronze color and the like, thus diversifying the series of the tea foam vitreous enamel. The tea foam vitreous enamel produced in the Yaozhou kiln comprises a tire material and glaze; the tire material comprises the following raw materials in parts by weight: 40-50 parts of Yucai crucible soil, 20-30 parts of Dongshan crucible soil and 15-30 parts of Shaliang crucible soil; the glaze comprises the following raw materials in parts by weight: 70-80 parts of black powder soil, 5-10 parts of potassium feldspa and 10-20 parts of kaolin. The vitreous enamel is prepared by adopting a certain preparation method.

Owner:孟树锋

Method for preparing copper nanometer granules

InactiveCN102114545AImprove performanceLow reaction temperatureNanotechnologyCopper nitrateReaction temperature

The invention discloses a method for preparing copper nanometer granules, which comprises the following steps: respectively preparing clear copper nitrate solution with concentration of 0.1-0.9 g / L, clear ethanolamine solution with concentration of 2-8g / L, and clear polyvinylpyrrolidone solution with concentration of 3-9g / L by taking low-molecular alcohol as solvent, mixing the three solutions into reaction liquid at the temperature of 60 DEG C to 80 DEG C for reaction until presenting a stable bronze color, and carrying out cooling, evaporation and drying to obtain copper nanometer granules;in the method, the reaction temperature is lower, the normal reaction can be carried out even at the temperature lower than 70 DEG C, the production cost is lower, the equipment is simple, the production is convenient, the average granule diameter of the obtained copper nanometer granules is no more than 10nm, and the copper nanometer granules are uniform monodisperse granules without binding, therefore, the material performance is better.

Owner:NINGBO UNIV

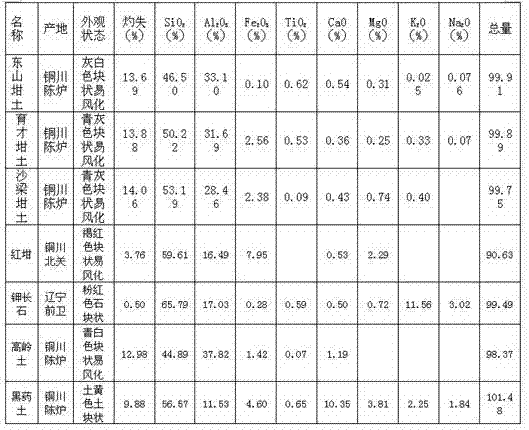

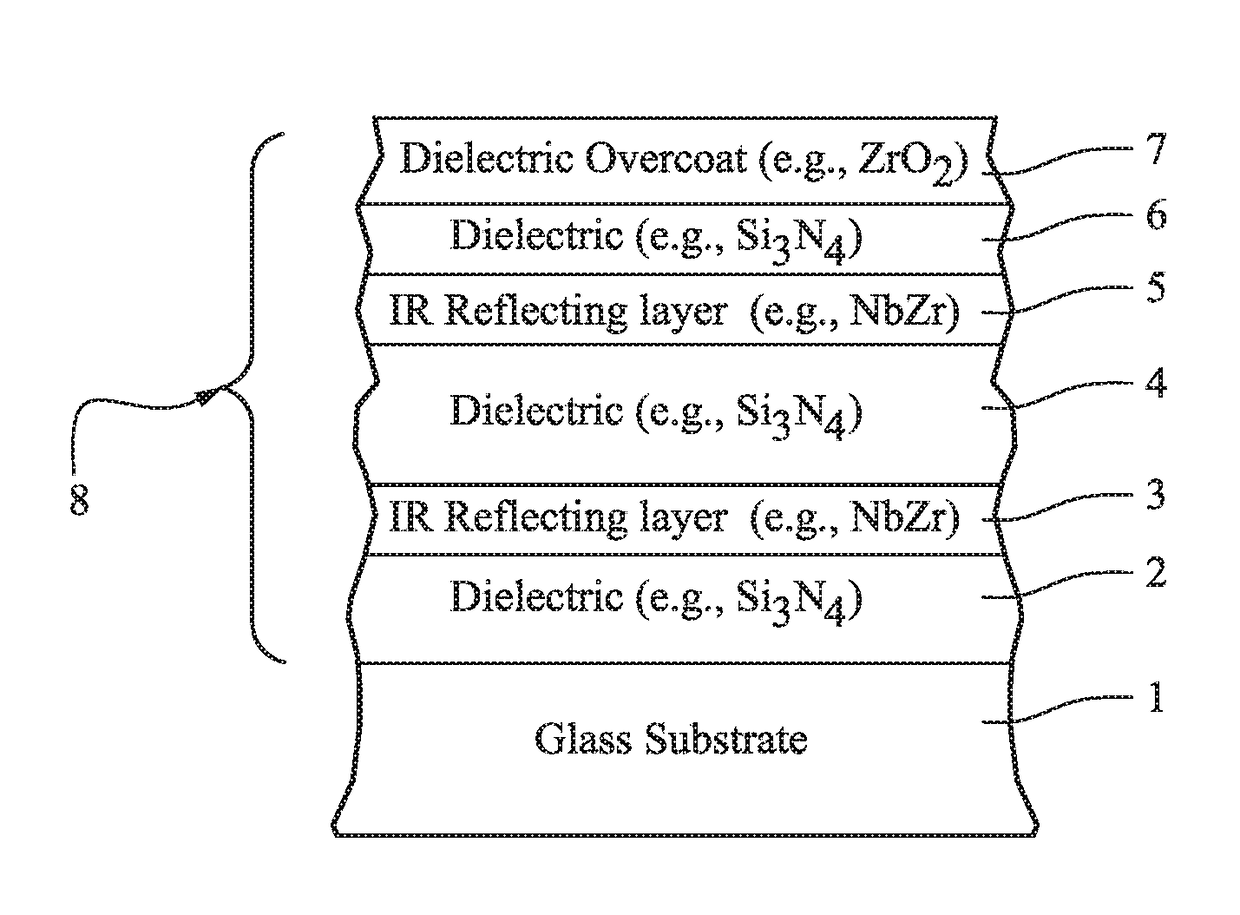

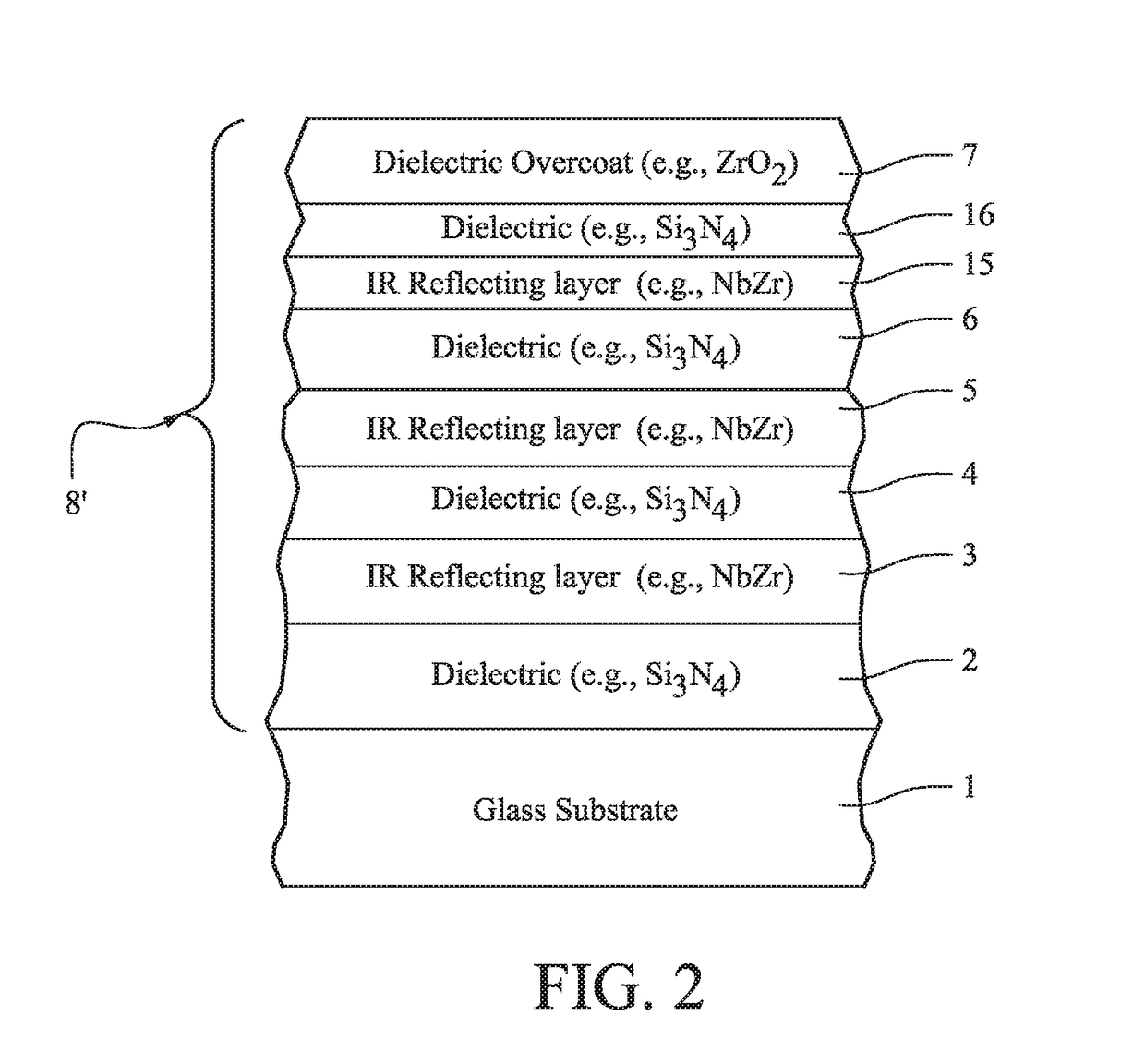

Bronze colored heat treatable coated article having low solar factor value

ActiveUS20170267580A1Sufficient for thermal temperingVacuum evaporation coatingSputtering coatingGain coefficientSolar factor

There are provided coated articles that include two or more infrared (IR) reflecting layers (e.g., of or including NbZr, Nb, NiCr, NiCrMo, and / or a nitride thereof) sandwiched between at least dielectric layers, and / or a method of making the same. The coating may be designed so that the coated articles realize bronze glass side reflective coloration in combination with a low solar factor (SF) and / or a low solar heat gain coefficient (SHGC). Such coated articles may be used in the context of monolithic windows, insulating glass (IG) window units, laminated windows, and / or other suitable applications, and may optionally be heat treated (e.g., thermally tempered) in certain instances.

Owner:GUARDIAN GLASS LLC +1

Preparation method and application of purple-bronze ceramic art glaze

The invention relates to art ceramics, particularly a manufacturing method and application of purple-bronze ceramic art glaze. The purple-bronze ceramic art glaze is prepared from the following raw materials in parts by weight: 25-35 parts of chrome oxide green, 30-40 parts of white clay and 30-40 parts of red lead. The preparation method comprises the following steps: mixing the raw materials according to the formula, carrying out ball milling with an enamel bottle until the 205-mesh screen residue of the glaze is less than 1.5%, and adding water until the mass percent of the glaze is 30-36%. The purple-bronze ceramic art glaze is easy for construction and lower in cost. When being applied to a figure sculpture, the purple-bronze ceramic art glaze has short firing time, thereby greatly enhancing the production efficiency and lowering the production cost and energy consumption. After being fired, the ceramic sounds clear and crisp, has very close sound as the sculpture prepared from metallic copper. The fired ceramic appears bronze, and completely has the same effect as a copper sculpture; and thus, the purple-bronze ceramic art glaze can be used instead of copper to preparing various sculptures, thereby greatly saving the copper resources and lowering the sculpture cost.

Owner:长沙起鼎文化艺术传播有限公司

Technological process for dying black antique bronze color on surface of brass products

InactiveCN101311310ASimple processEasy to operateNatural patternsArtistic surface treatmentSurface finishStaining

The invention relates to a technique of painting black paint bronze on the surface of a brass (copper-zinc alloy) device, which belongs to the technique field of processing technology of metal surface finish and plating. The method of the invention is characterized in that a copper device with black paint bronze surface can be got by treating the brass device with dezincification solution, etching solution and staining solution and then by buffing and waxing. The black paint bronze staining solution is K2S solution with certain concentration. The method of the invention is a brass device staining method which is simple in technique, easy in operation and low in cost. The method has the advantages that the dyeing quality is uniform and good and the color layer is steady and not easy to fall off. More particularly, the method is suitable for making antique reproduction brass artwork and has good effect.

Owner:SHANGHAI UNIV

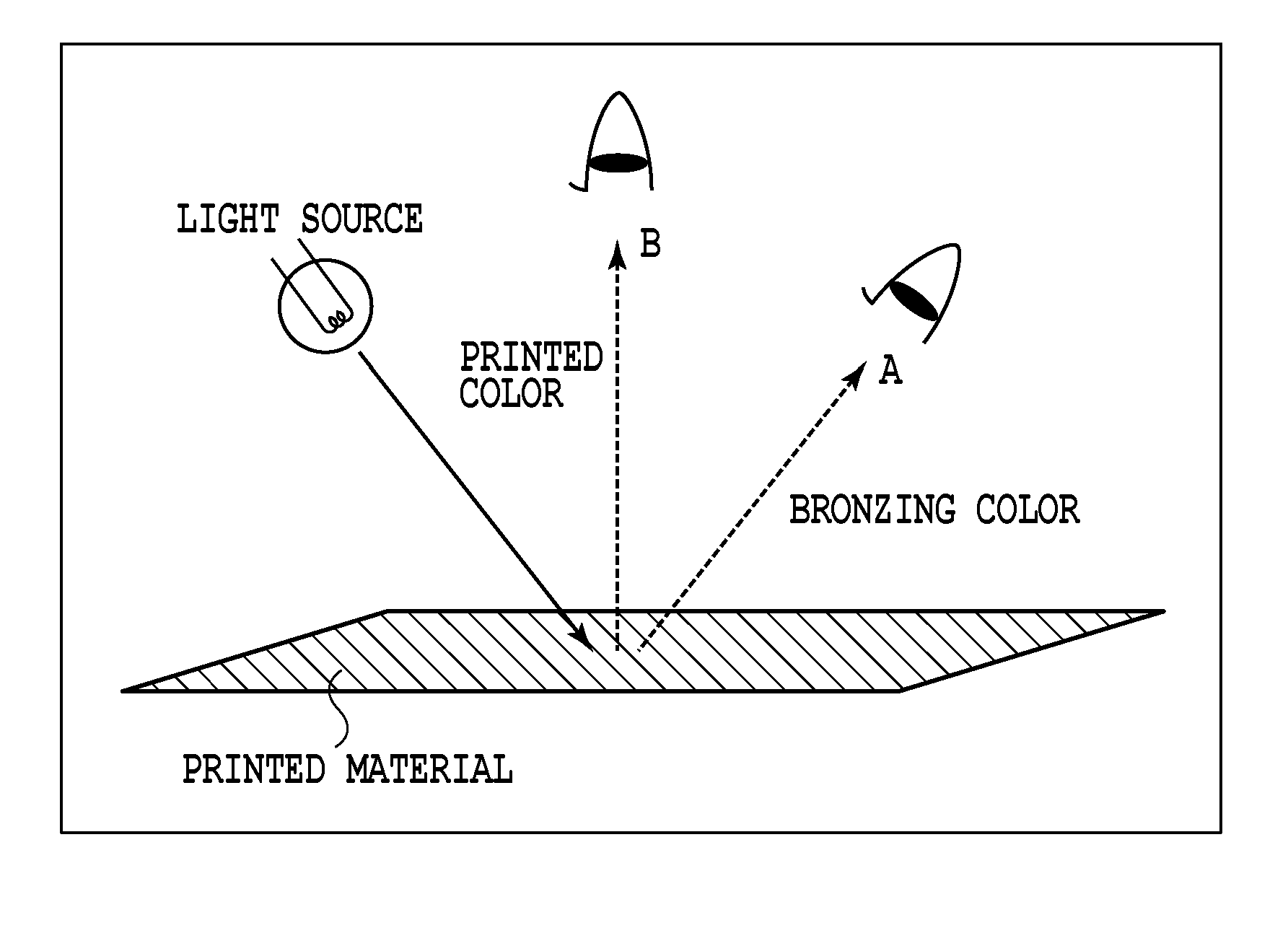

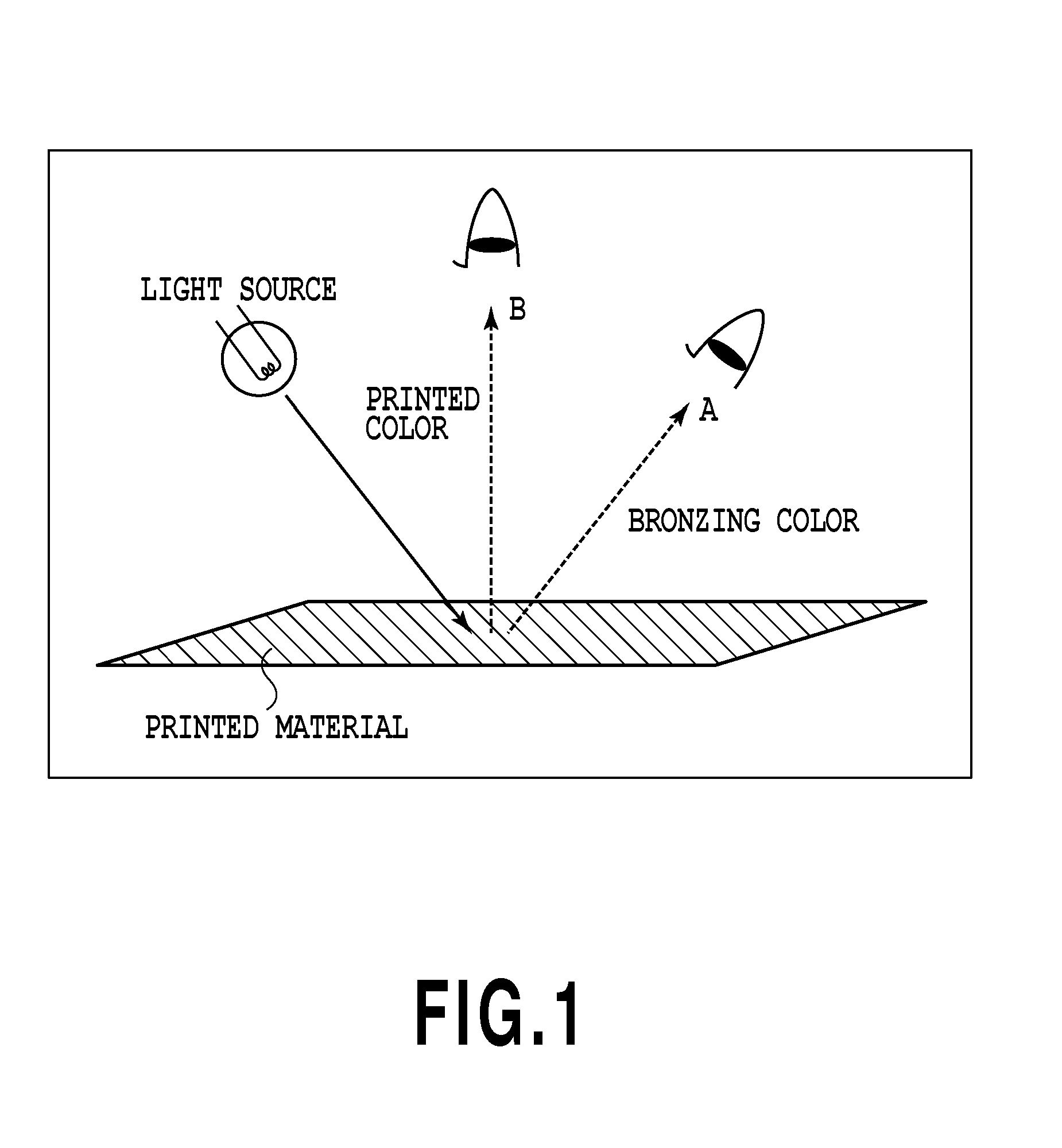

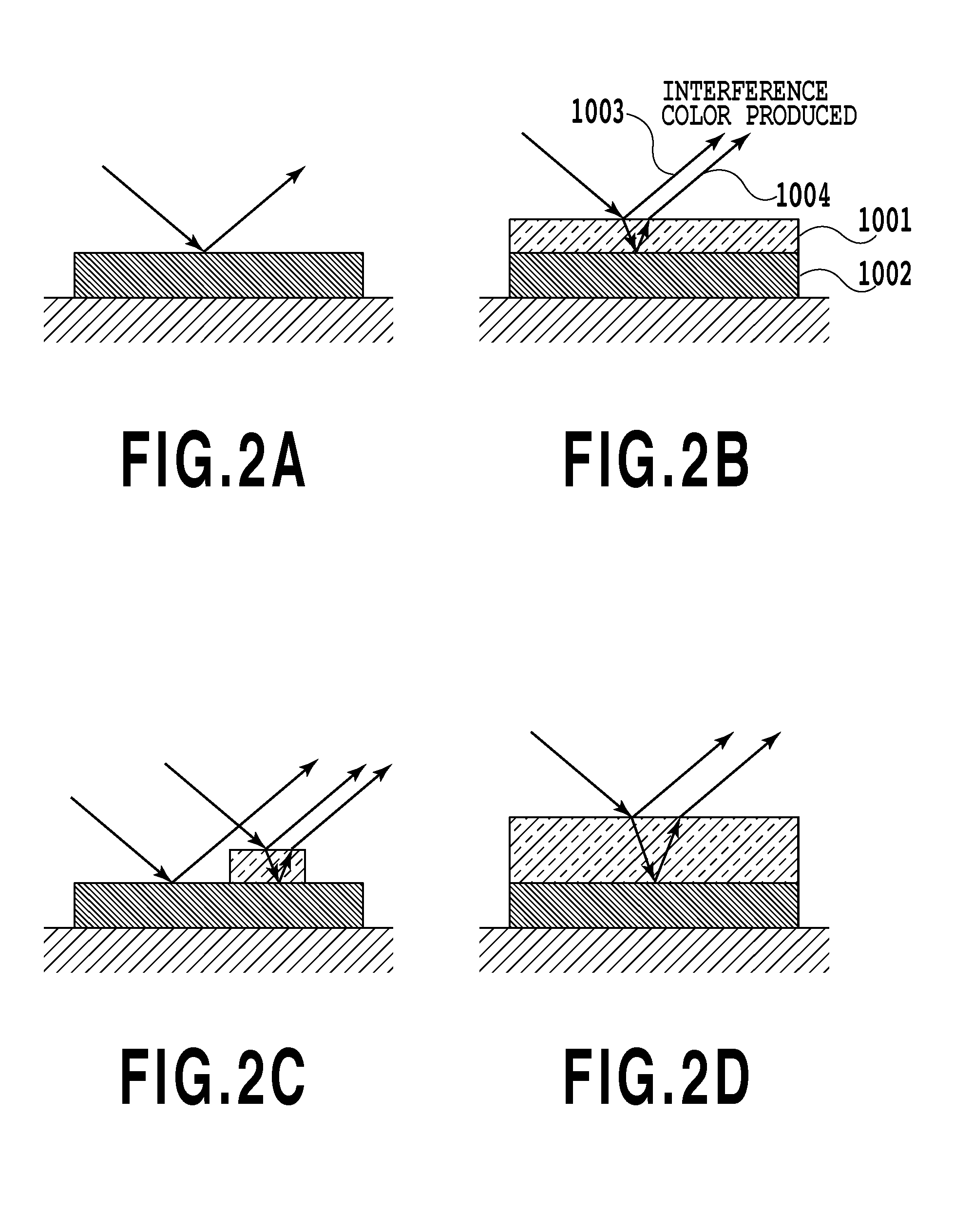

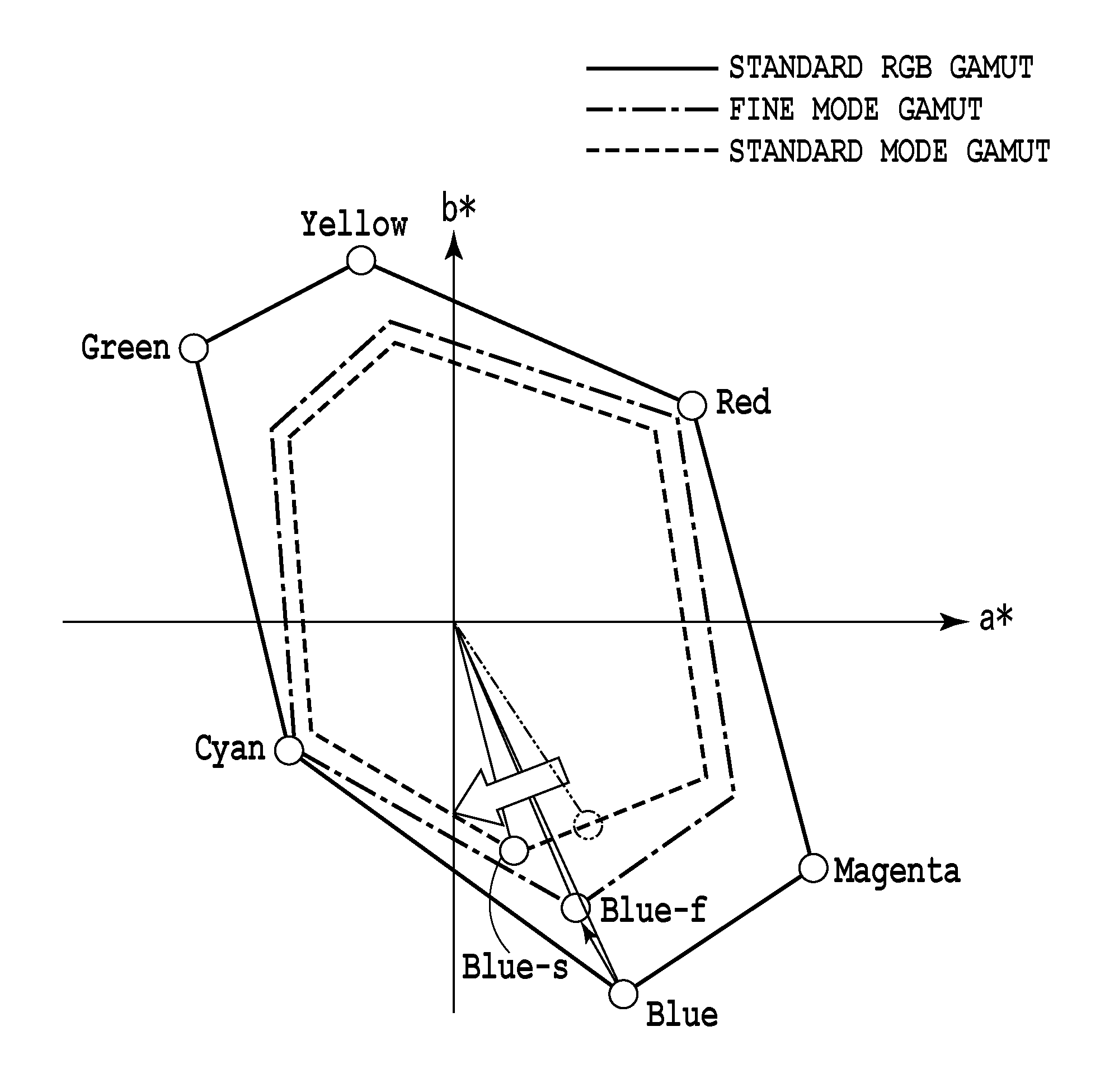

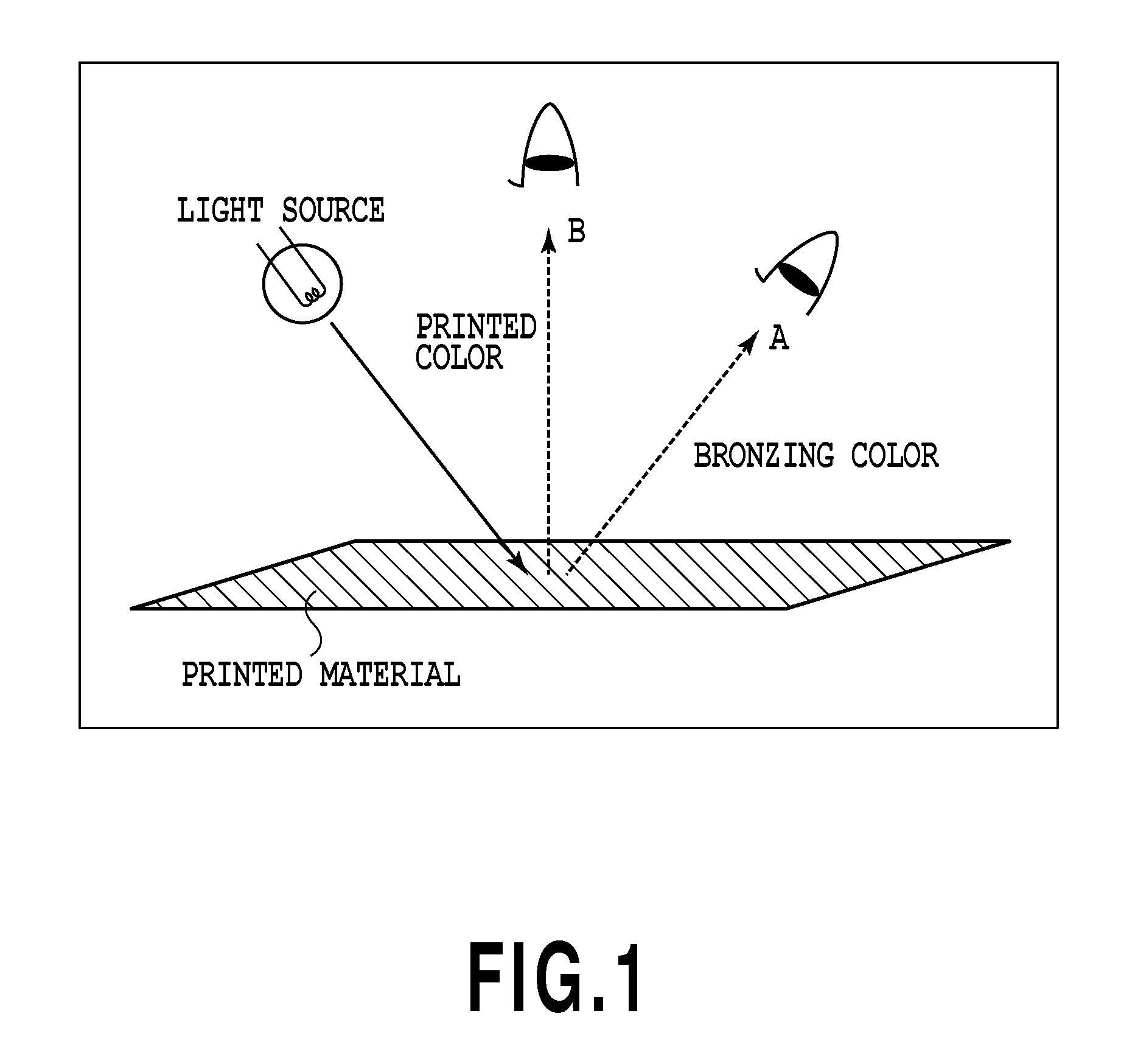

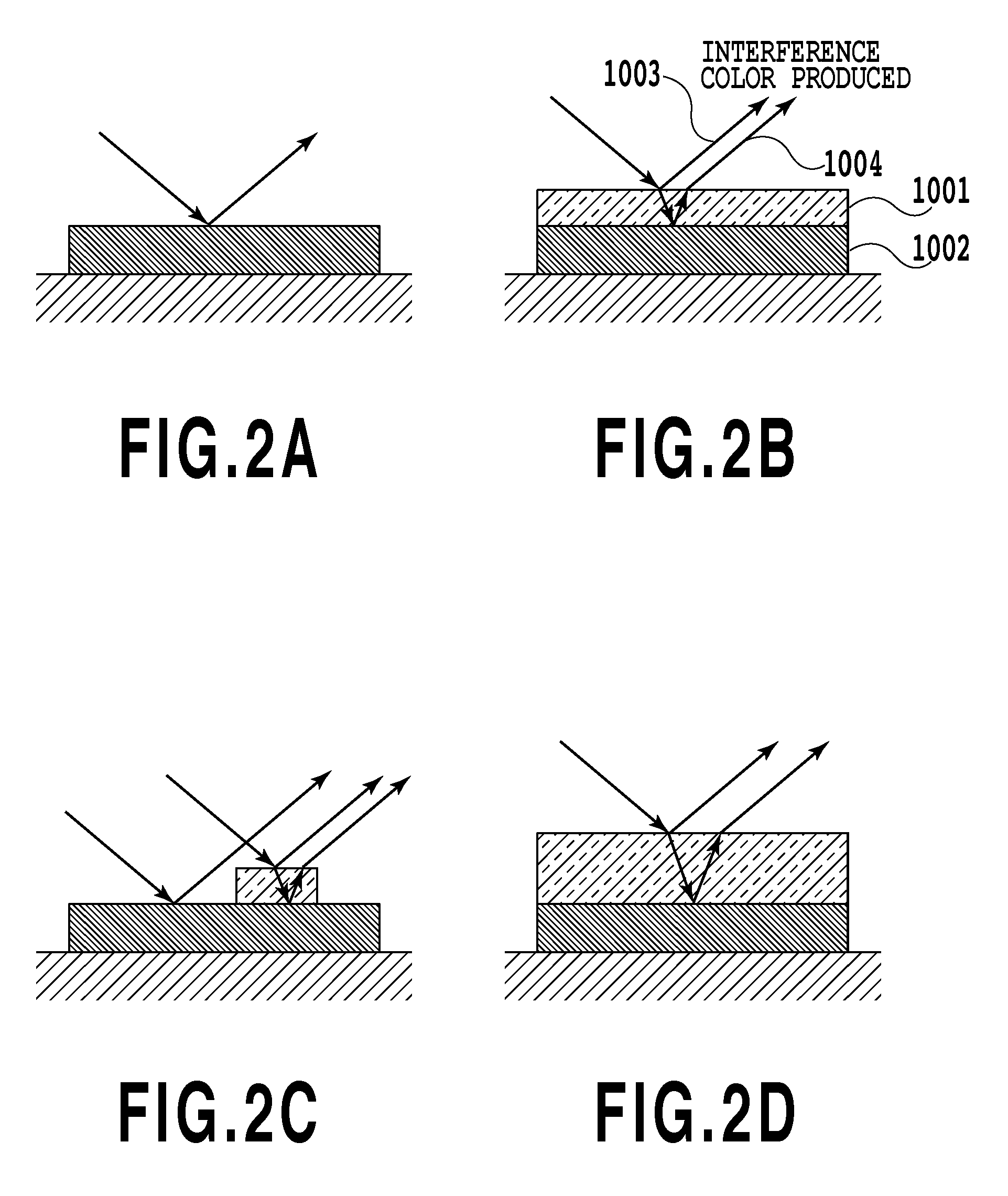

Image processing apparatus, inkjet printing apparatus, and image processing method

ActiveUS20130301065A1Avoid differencesDigitally marking record carriersDigital computer detailsColor shiftImaging processing

Differences in color change due to bronze colors and the optical interference state related to bronzing are suppressed among multiple print modes. The blue primary color “Blue” in the standard RGB gamut is mapped to a point (color) that has moved in the clockwise direction, and that color is taken to be the primary color “Blue-s” in the Standard mode gamut. As a result, when an observer observes this color, the color shifted in the counter-clockwise direction is perceived as a color of the same hue as the primary color “Blue-f” in the Fine mode gamut, suppressing the difference in perceived color between the Fine mode and the Standard mode.

Owner:CANON KK

Technological process for dying light antique bronze color on surface of brass products

InactiveCN101311312ASimple processEasy to masterNatural patternsArtistic surface treatmentSurface finishStaining

The invention relates to a technique of painting light bronze on the surface of a brass (copper-zinc) device, which belongs to the technique field of processing technology of metal surface finish and plating. The invention is characterized in that a copper device with light bronze surface can be got by first washing the brass device with hot lye and then dyeing the device by socking the device into a light bronze staining solution and then by buffing and waxing. The light bronze staining solution is a mixed solution which is made by mixing any one or two solutions of the three solutions: KMnO4 solution or K2S2O8 solution or NH4S2O8 solution with certain concentration with any one solution of the two solutions: CuSO4.5H2O solution or CuC12 solution. The method of the invention is a brass device staining method which is simple in technique, easy in operation and low in cost. The method has the advantages that the dyeing quality is uniform and good and the color is steady. More particularly, the method is suitable for making antique reproduction brass artwork and has good exterior effect.

Owner:SHANGHAI UNIV +1

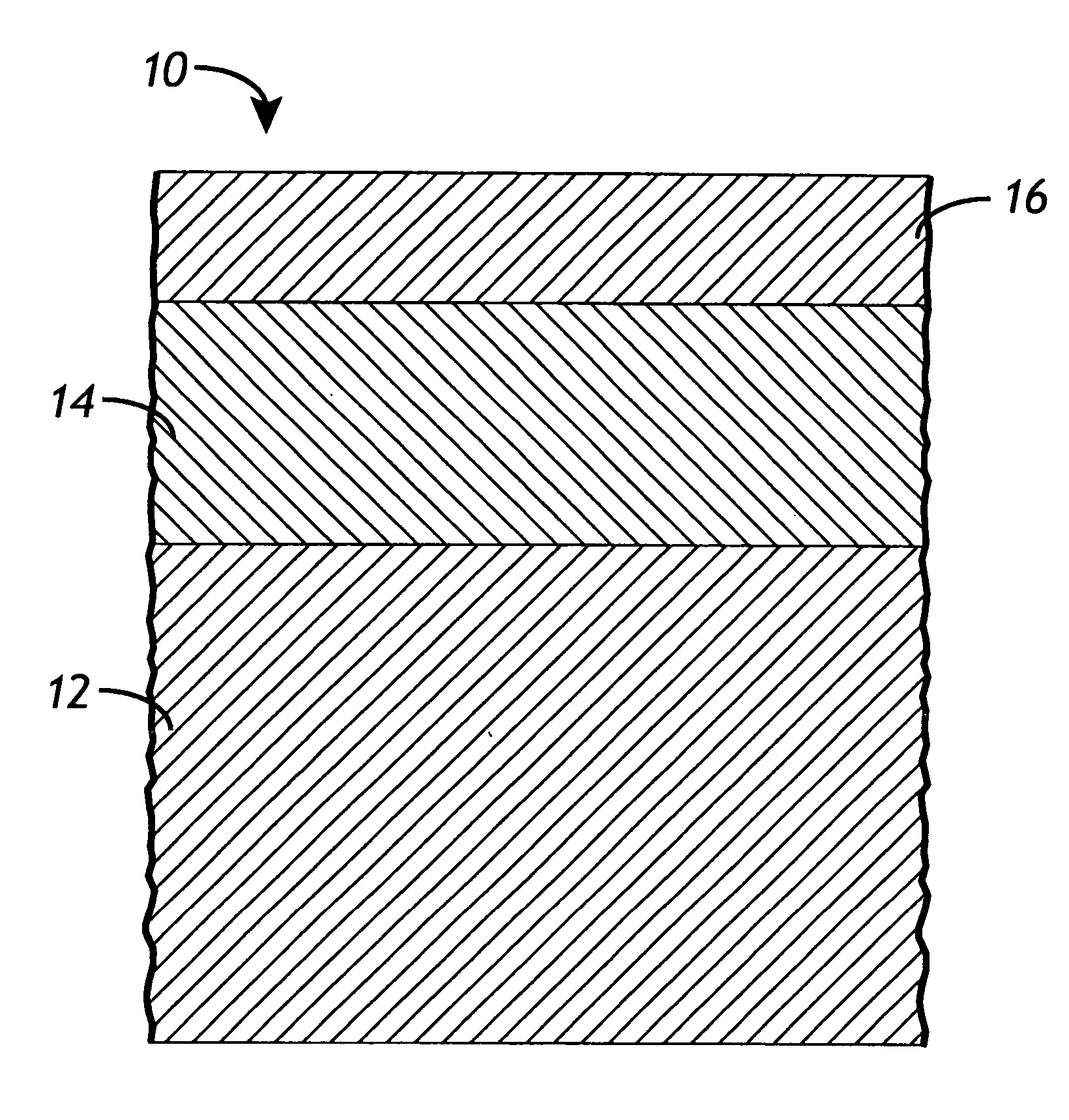

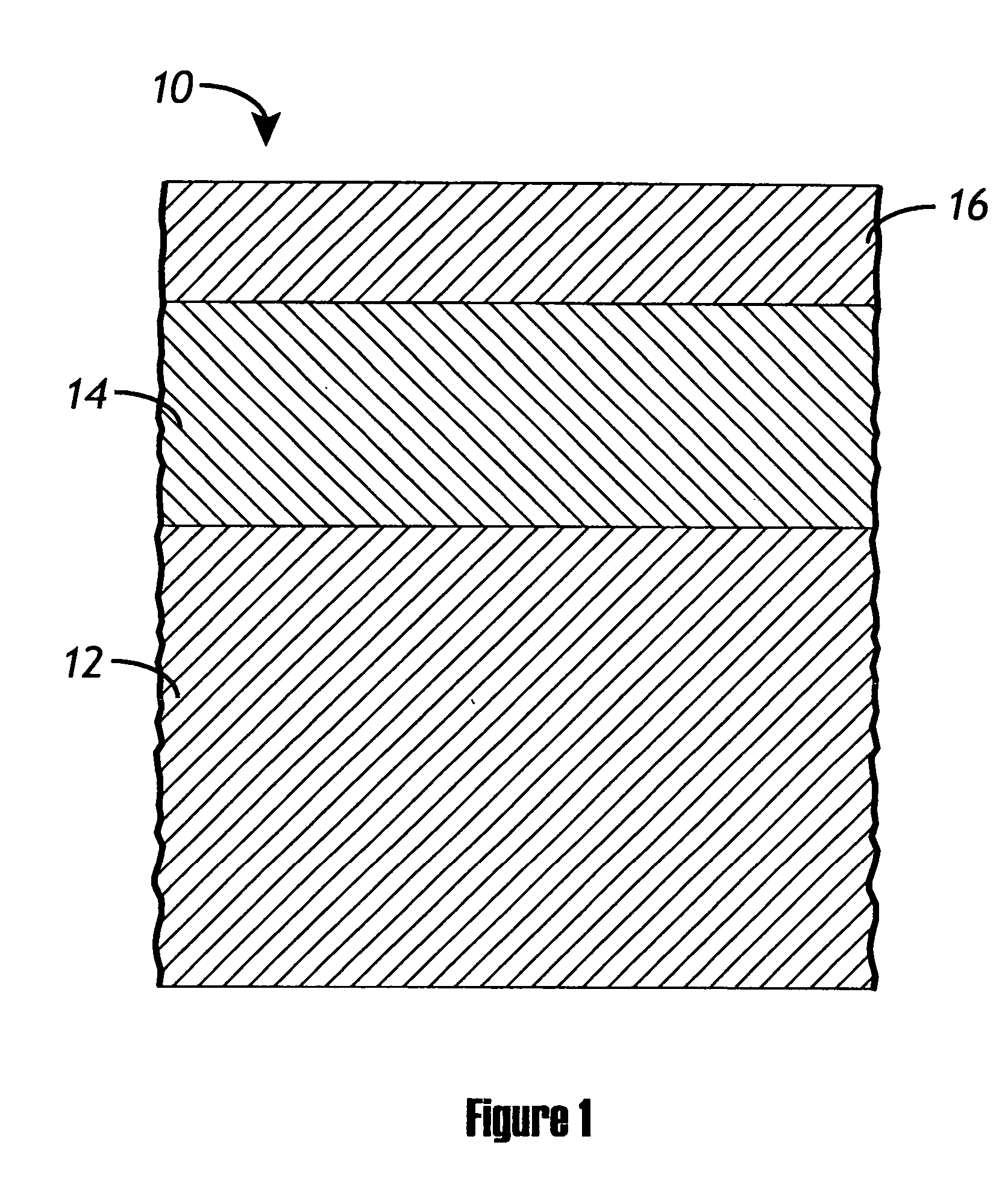

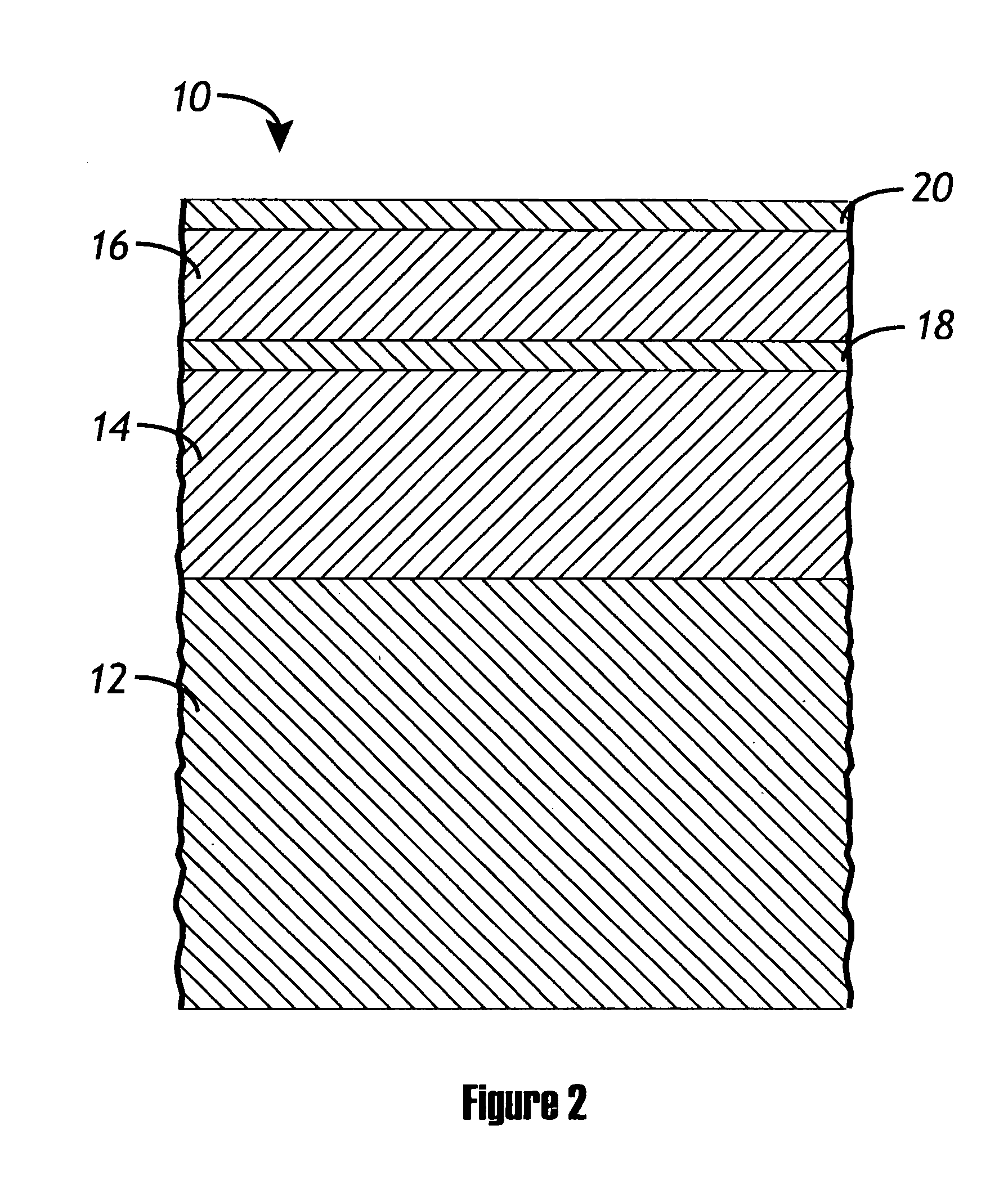

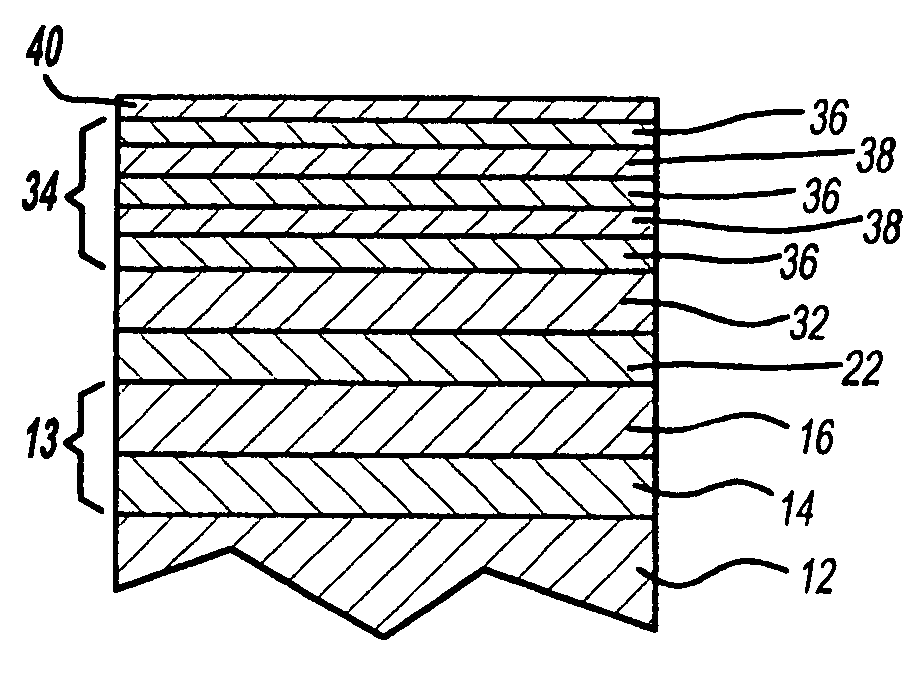

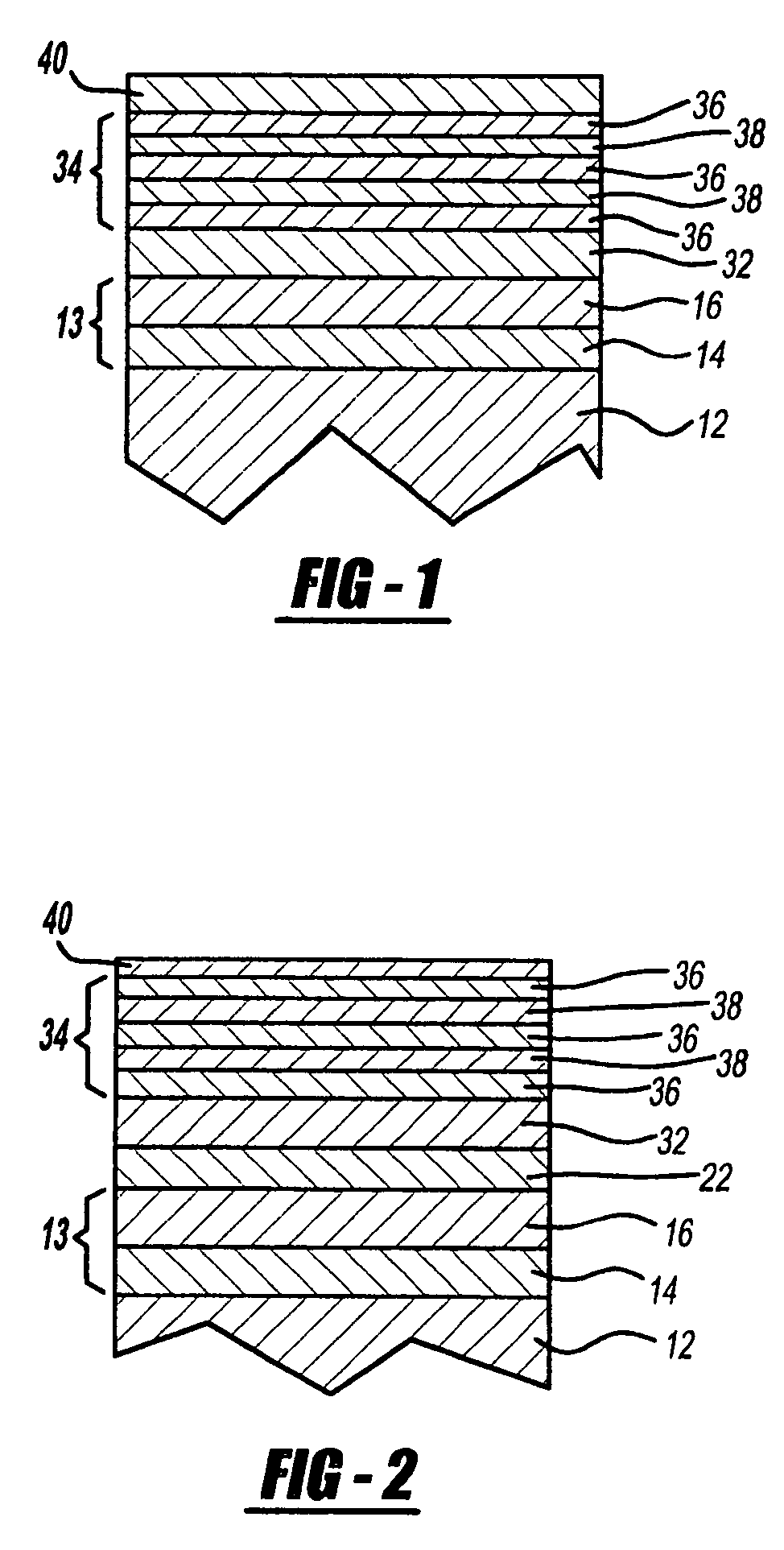

Coated article with dark color

ActiveUS20060222892A1Natural mineral layered productsSuperimposed coating processDark colorBronze color

An article is coated with a coating having a dark gray or bronze color. In a preferred embodiment, the coating comprises a nickel or polymer basecoat layer, and a color and protective stack layer comprised of layers of oxygen-rich refractory metal oxycarbides. The preferred dark grey, oxygen rich color layer is zirconium oxycarbide. A refractory metal adhesion layer and a refractory metal oxide top coat layer also may be used.

Owner:VAPOR TECH

Bronzer composition

Bronzer compositions are provided. They comprise (a) water, (b) at least one water-soluble dye; and (c) at least one water-dispersible or water-soluble film-forming polymer. Optionally, a self-tanning agent such as 1,3-dihydroxyacetone may be present.

Owner:MARRS CHRISTOPHER

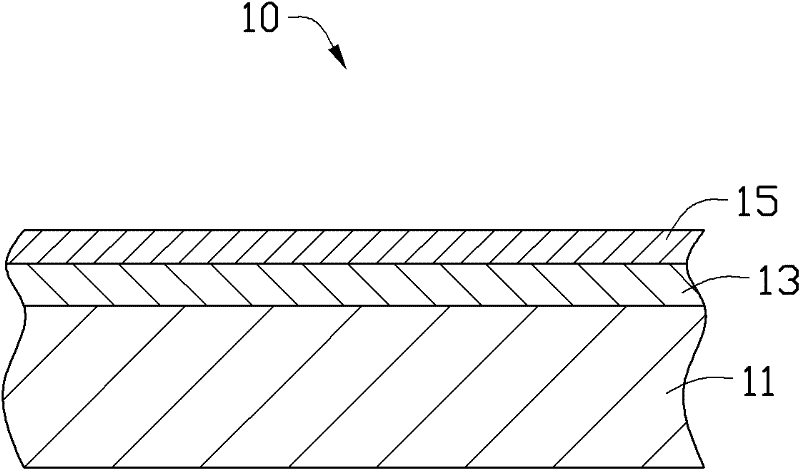

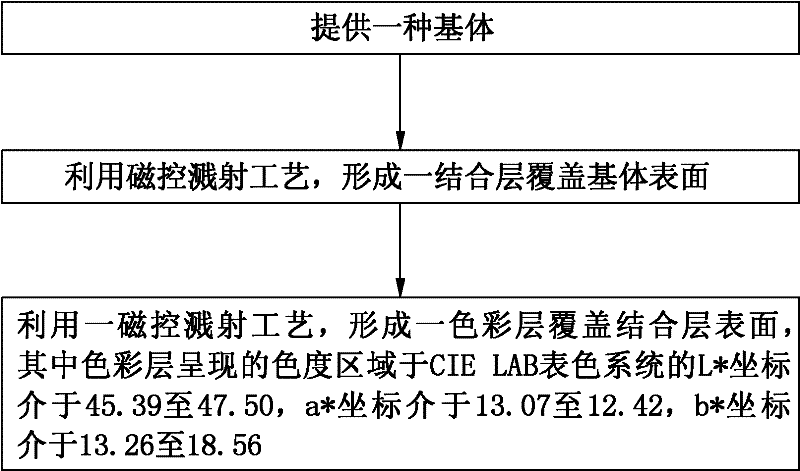

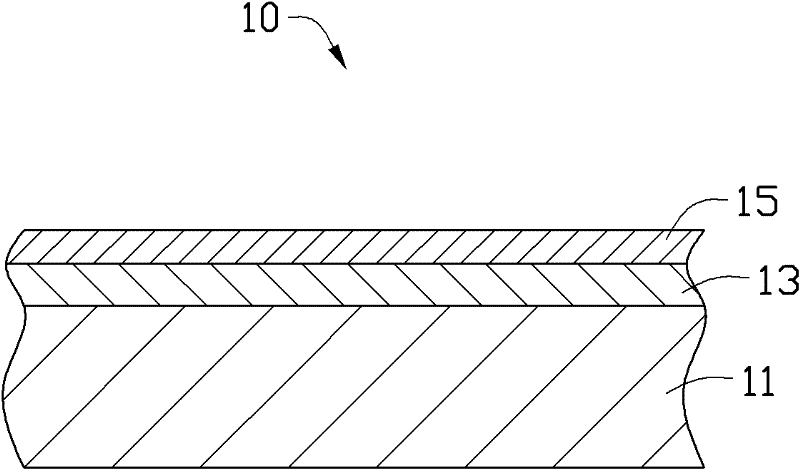

Shell and manufacturing method thereof

InactiveCN102333422ARich in colorImprove appearance competitivenessNatural patternsVacuum evaporation coatingOptoelectronicsTitanium

The invention relates to a shell and a manufacturing method thereof. The shell comprises a substrate, a bonding layer and a color layer, wherein the surface of the substrate is provided with the bonding layer, and the color layer is covered on the bonding layer of the substrate. The bonding layer is a titanium metal layer, and the color layer is a Ti-N-C membrane, wherein a chromaticity area presented on the color layer is between 45.39 and 47.50 at the L* coordinate of a CIE LAB color system, between 13.07 and 12.42 at the a* coordinate of the CIE LAB color system, and between 13.26 and 18.56 at the b* coordinate of the CIE LAB color system. The invention also provides a magnetron sputtering manufacturing method of the shell. The shell and the manufacturing method can achieve the effect that the color layer presents a bronze color, so the color of a vacuum plating layer is enriched.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Processing method for imitation copper electrophoresis decorative profile

InactiveCN107345310AReduce consumptionFill the gap in the marketAnodisationElectrophoretic coatingsElectrophoresisWater soluble

The invention discloses a processing method for an imitation copper electrophoresis decorative profile. An aluminum profile is subjected to electrolytic coloring in a copper salt electrolyte after anodic oxidation, and a layer of red bronze color is painted on the surface of the profile; then the outside of an oxidation film is coated with a layer of water soluble varnish by means of electrophoretic coating, a layer of bright coating film is formed after curing so that the properties of corrosion resistance, ageing resistance and the like of a coloring layer can be improved, the appearance gets close to the red bronze in color, and the uniformity consistency is good; and due to covering by the coating film, the surface is bright and the corrosion resistance and weather fastness of the material are better improved. The imitation copper electrophoresis decorative profile prepared through the method highly approaches the red bronze in color and luster. Serving as a substitute material of a bronze door after application, the imitation copper electrophoresis decorative profile has great advantages, the market blank is filled, and consumption of a large quantity of copper resources is reduced; and moreover, the market requirements are met, and the imitation copper electrophoresis decorative profile can be afforded by common people.

Owner:浙江新祥铝业股份有限公司

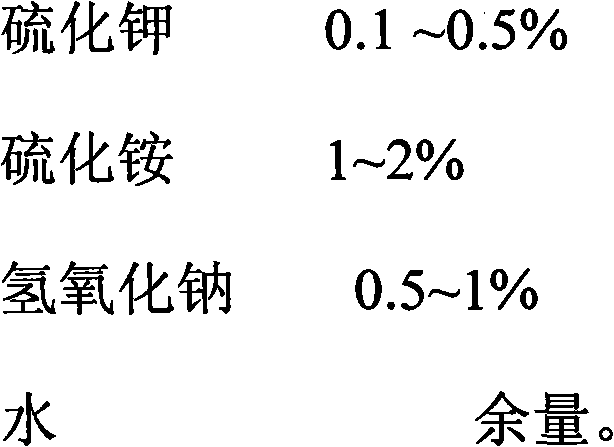

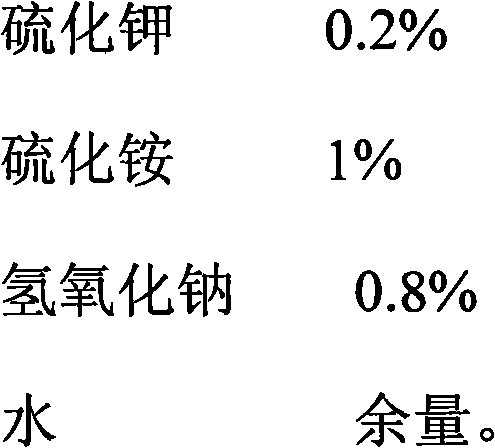

Metal antique bronze color colorant

InactiveCN102041498AReasonable formulaEasy to useMetallic material coating processesPotassium sulfideAmmonium sulfide

Owner:石晓春

Technological process for dying red antique bronze color on surface of brass products

InactiveCN101311311ASimple processEasy to operateNatural patternsArtistic surface treatmentSurface finishStaining

The invention relates to a technique of painting red bronze on the surface of a brass (copper-zinc alloy) device, which belongs to the technique field of processing technology of metal surface finish and plating. The method of the invention is characterized in that a copper device with red bronze surface can be got by treating the brass device with dezincification solution, etching solution and staining solution and then by buffing and waxing. The red bronze staining solution is KMnO4 solution or K2S2SO8 solution or NH4S2O8 solution with certain concentration. The method of the invention is a brass device staining method which is simple in technique, easy in operation and low in cost. The method has the advantages that the dyeing quality is uniform and good and the color layer is steady and not easy to fall off. More particularly, the method is suitable for making old processing and antique reproduction of brass artwork and has good appearance effect.

Owner:JIANGSU JINLEIKAI PHOTOELECTRIC TECH

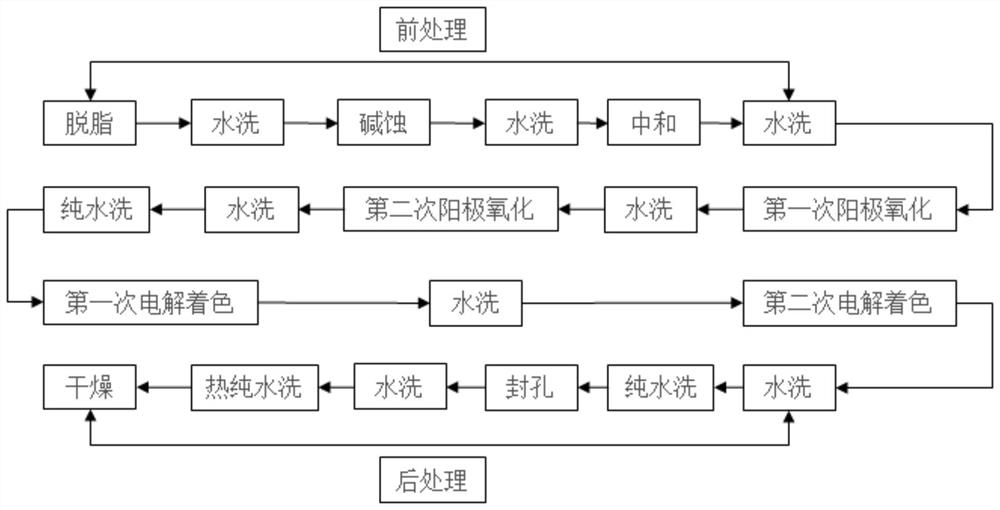

Electrolytic coloring process for aluminum material

The invention relates to an electrolytic coloring process for an aluminum material, and belongs to the field of aluminum material surface treatment. The electrolytic coloring process comprises the following steps of: carrying out first-time anodic oxidation treatment on the pretreated aluminum material, and forming an anodic oxidation film with the thickness of 4-8 microns on the surface of the aluminum material; carrying out second-time anodic oxidation treatment on the aluminum material, and enabling the thickness of the film to be greater than 10 microns; carrying out first-time electrolytic coloring treatment on the aluminum material in a silver salt electrolytic coloring solution, wherein the silver salt electrolytic coloring solution comprises AgNO3 with the concentration of 1g / L andH2SO4 with the concentration of 20g / L; and carrying out second-time electrolytic coloring treatment on the aluminum material in a nickel-tin mixed salt electrolytic coloring solution, wherein the nickel-tin mixed salt electrolytic coloring solution comprises NiSO4 with the concentration of 8-12g / L, SnSO4 with the concentration of 10-15g / L and H2SO4 with the concentration of 15-20g / L. Through twotimes of anodic oxidation treatment, the requirements of a subsequent electrolytic coloring process on the thickness of the film are met; and through two times of electrolytic coloring treatment, thecolor of the film is transited from a brass color as a bronze color system to a bronze color with uniform and stable color, so that the bronze color system is expanded.

Owner:盘锦忠旺铝业有限公司

Method of coloring surface of bronze with stable black, brown and chestnut color at constant temperature

InactiveCN107858678AReasonable designColor stableDecorative surface effectsMetallic material coating processesThermostatMaroon

The invention discloses a method for coloring stable black, brown and chestnut colors on the surface of a bronze artwork at constant temperature. The bronze material of the bronze artwork specifically refers to the 313 copper alloy formula and the C90300 copper alloy formula. By dipping three different reagents, Achieve constant temperature stable coloring. The color attached by this coloring process is uniform and stable, especially achieving the effect that the surface color of the bronze artwork is very stable for several years.

Owner:SHANXI YUDA GRP

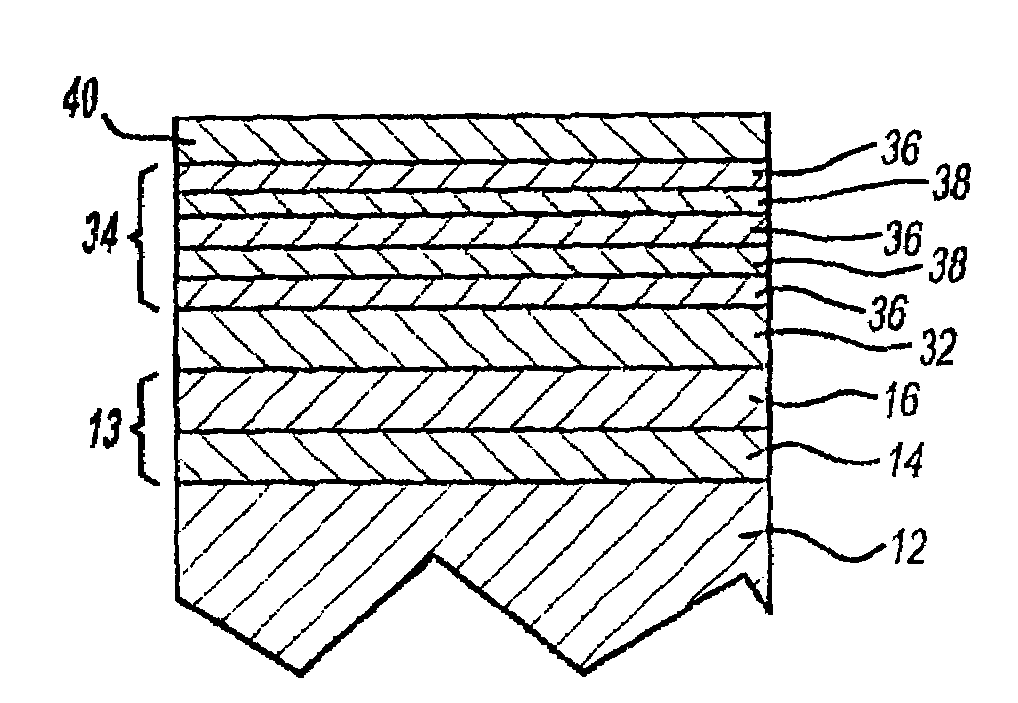

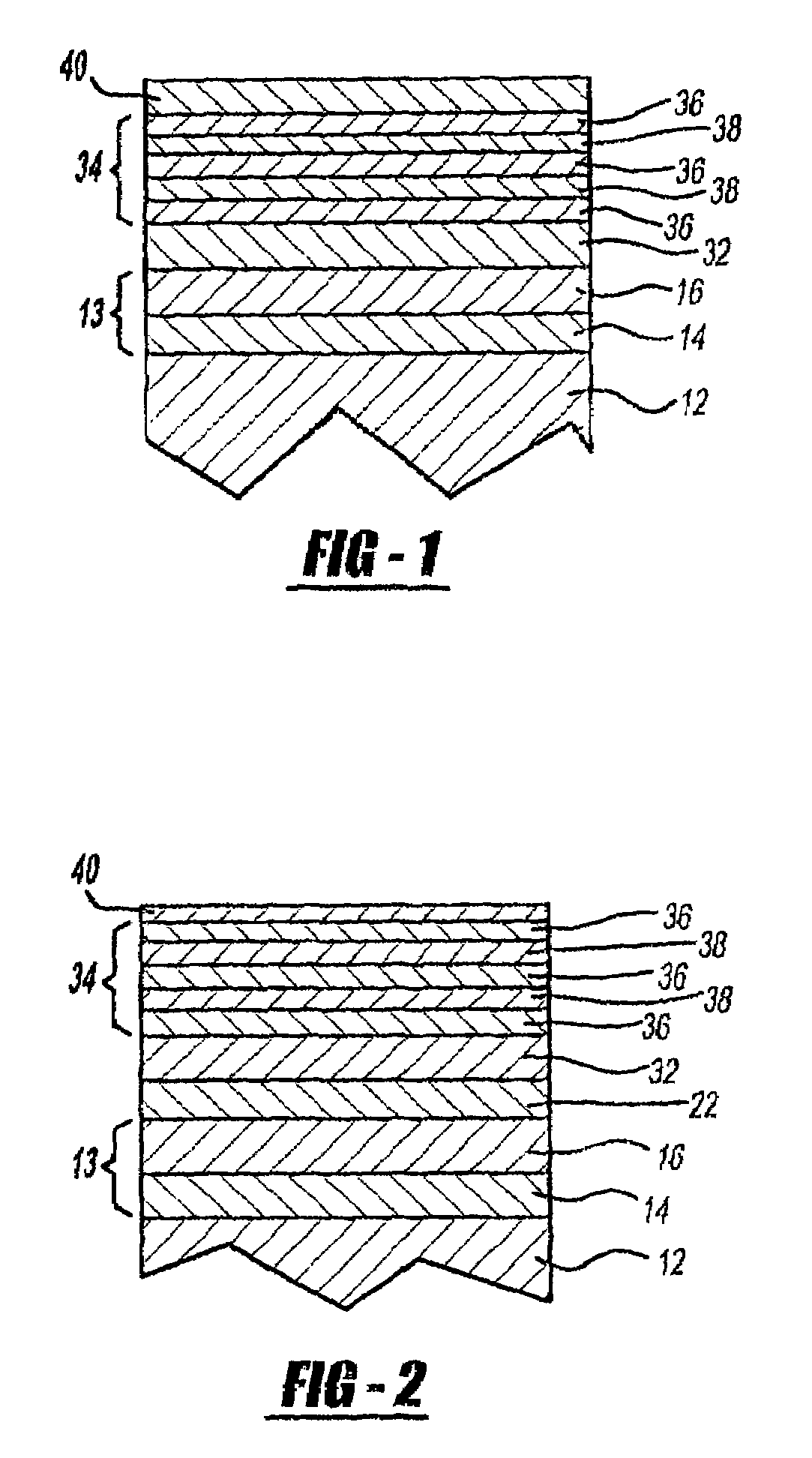

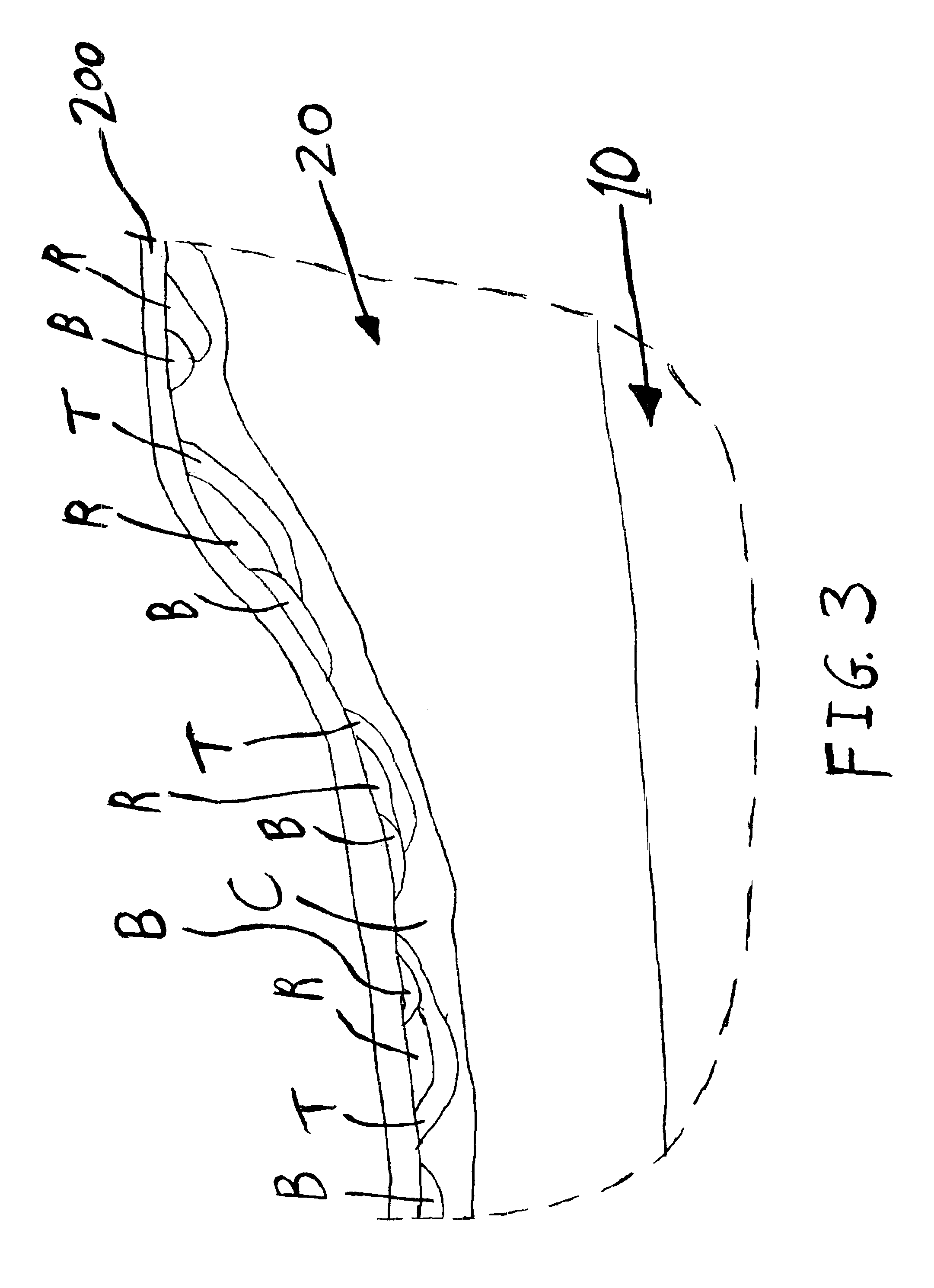

Coated article

InactiveUS7135220B1Increase dark appearanceGood chemical resistanceVacuum evaporation coatingSputtering coatingCarbideAlloy

An article is coated with a multi-layer coating having a bronze color. In a preferred embodiment, the coating comprises a nickel or polymer basecoat layer, and a color and protective stack layer comprised of layers of carbon-rich refractory metal or refractory metal alloy carbonitride alternating with layers of nitrogen-rich refractory metal or refractory metal alloy carbonitride. In another embodiment, the alternating layers of the color stack layer may comprise layers of carbon-rich refractory metal carbides or carbon-rich refractory metal alloy carbides alternating with layers of nitrogen-rich refractory metal nitrides or nitrogen-rich refractory metal alloy nitrides.

Owner:VAPOR TECH

Bronze dye for weaved and knitted product

The invention discloses bronze dye for a weaved and knitted product. The bronze dye is prepared from the following raw materials: pine barks, chestnut shells, rapeseed dregs, dry paulownia leaves, salak shells, tea tailings, poplar flower, ixora chinensis lam, yellow lily flower, yellow flos sophorae immaturus, flower of japanese kerria, mango and ginkgo nuts. According to the bronze dye of the weaved and knitted product, provided by the invention, the preparation is simple, the bronze dye is prepared by extracting raw materials of pure natural plants, the cost is low, and the cost is reduced by 16.3 percent; according to the characteristics of brown and yellow plants, brown and yellow are respectively extracted, color matching is carried out according to the principle of three-primary color matching, high efficiency and quickness are realized, and a natural bronze color is obtained; only ultrasonic short-time soaking needs to be carried out in a water solution of the bronze dye during dyeing, so that the working efficiency is increased, dyeing is uniform, the color is pure, the bronze dye is fadeless, mould-proof and moth-proof, the storage is convenient, the use period is prolonged, no any toxic reagents exist, safety and environment protection are realized, a healthcare function and the fragrance of plants are obtained, and the health of a human body is protected.

Owner:阜南县大喜柳编工艺品有限公司

Processing and printing apparatus, and processing method for suppressing bronzing in a printed image

ActiveUS9262705B2Avoid differencesDigitally marking record carriersVisual representation by matrix printersGamutColor shift

Differences in color change due to bronze colors and the optical interference state related to bronzing are suppressed among multiple print modes. The blue primary color “Blue” in the standard RGB gamut is mapped to a point (color) that has moved in the clockwise direction, and that color is taken to be the primary color “Blue-s” in the Standard mode gamut. As a result, when an observer observes this color, the color shifted in the counter-clockwise direction is perceived as a color of the same hue as the primary color “Blue-f” in the Fine mode gamut, suppressing the difference in perceived color between the Fine mode and the Standard mode.

Owner:CANON KK

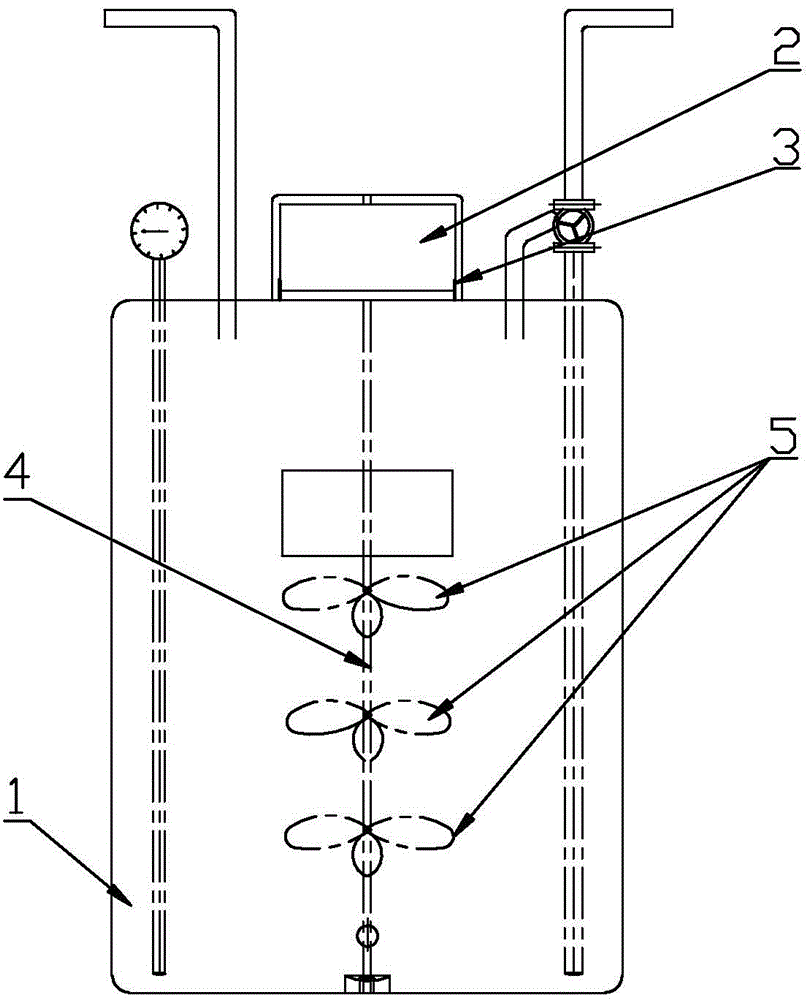

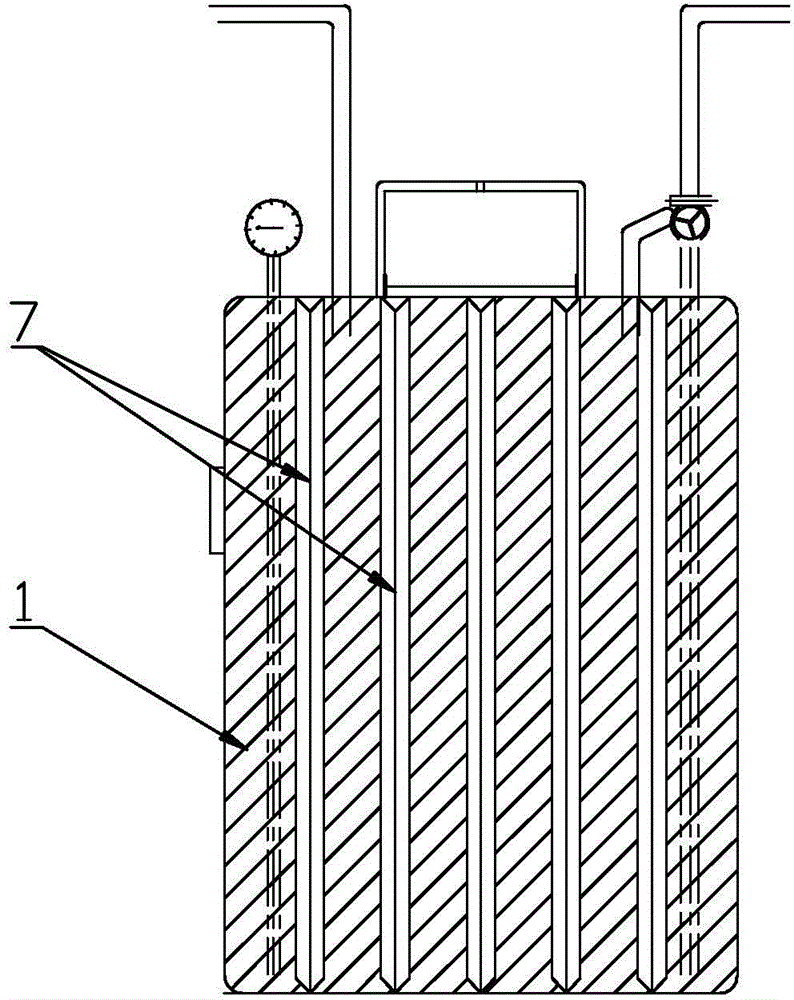

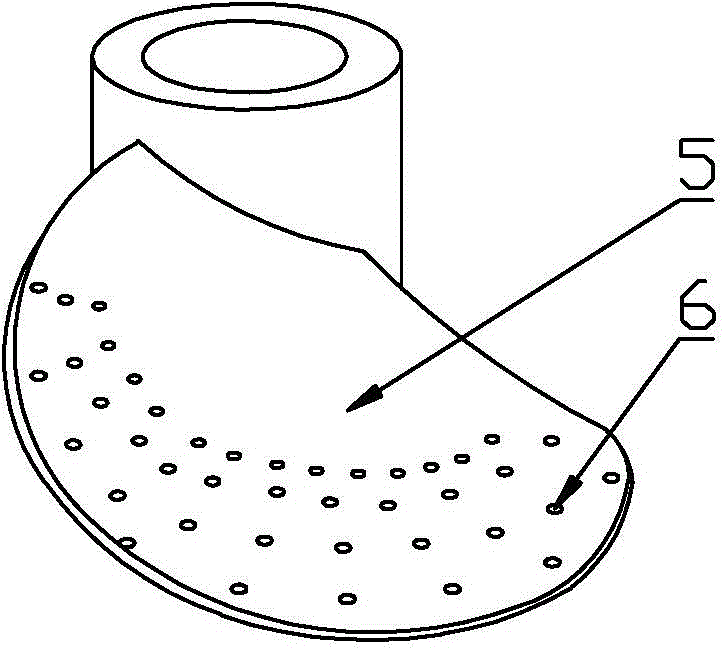

Copper alloy slide fastener heat tinting solution stirrer apparatus

InactiveCN105755460ASolve efficiency problemsSolve the problem of obvious copper color difference on the surface of the zipperMetallic material coating processesEngineeringBronze color

The invention discloses a copper alloy slide fastener heat tinting solution stirrer apparatus. The apparatus comprises a hollow liquid medicine storage tank, a motor and a stirring device, the stirring device is fixedly arranged in the liquid medicine storage tank through a main shaft, one end of the main shaft is fixedly connected with the motor, the other end of the main shaft is fixedly connected with the stirring device, the stirring device comprises three-grade stirring blades, the three-grade stirring blades are fixedly jointed at the lower portion of the main shaft side by side up and down, the edge of the outer side of every grade stirring blade is provided with flow guiding holes, and the inner wall of the liquid medicine storage tank is vertically fixedly connected with at least ten flow guiding baffle blocks. Fragmented vortex required by confluence interpenetration of a liquid in the clockwise and counter-clockwise rotation process of the main shaft is obtained through adopting three-layer spiral directions in the liquid medicine storage tank, and liquid medicine bumping is rapidly neutralized through using rotation of the flow guiding baffle blocks and the stirring blades and the effect of the flow guiding holes, so the problems of low solution neutralization efficiency of a tinting solution stirrer apparatus and obvious bronze color difference of the surface of a slide fastener are solved.

Owner:CMZ ZIPPER ANHUI

GRC copper-plated-surface decorative hanging panel curtain wall

A GRC copper-plated-surface decorative hanging panel curtain wall comprises a GRC self-supporting steel keel layer, a GRC outer wall panel layer, GRC reinforcing ribs, a GRC insulating layer and a GRC copper-plated light hanging panel layer. The GRC self-supporting steel keel layer is located below the GRC outer wall panel layer, the GRC reinforcing ribs are evenly distributed on the GRC outer wall panel layer, insulating material is laid on the rear side of the GRC outer wall panel layer to form the GRC insulating layer, and copper plating is performed on the front side of the GRC outer wall panel layer to form the GRC copper-plated light hanging panel layer, so that the GRC outer wall panel layer has good metallic luster and a beautiful color. Surface processing such as hollowing and lettering printing are more easily and beautifully performed on the GRC outer wall panel layer, properties of abrasion resistance, corrosion resistance, scrubbing resistance and the like are enhanced, various bronze colors can be presented without coatings, and the GRC copper-plated-surface decorative hanging panel curtain wall is free of poison, harmless, healthy and environmentally friendly.

Owner:JIANGSU HEFA GROUP

Coated article

InactiveUS7635528B1Good lookingIncrease resistanceVacuum evaporation coatingSputtering coatingCarbideNitrogen

An article is coated with a multi-layer coating having a bronze color. In a preferred embodiment, the coating comprises a nickel or polymer basecoat layer, and a color and protective stack layer comprised of layers of carbon-rich refractory metal or refractory metal alloy carbonitride alternating with layers of nitrogen-rich refractory metal or refractory metal alloy carbonitride. In another embodiment, the alternating layers of the color stack layer may comprise layers of carbon-rich refractory metal carbides or carbon-rich refractory metal alloy carbides alternating with layers of nitrogen-rich refractory metal nitrides or nitrogen-rich refractory metal alloy nitrides.

Owner:VAPOR TECH INC

Bronze-gold-tooth colored zipper and manufacturing method thereof

ActiveCN108707882AMeet diverse needsUpgrade the zipperLiquid/solution decomposition chemical coatingSuperimposed coating processThioureaCopper nitrate

The invention provides a bronze-gold-tooth colored zipper and a manufacturing method thereof. The manufacturing method comprises the following steps of: soaking a to-be-colored zipper in a bronze aqueous solution for 1-3 minutes, soaking the to-be-colored zipper in a white copper aqueous solution for 3-60 seconds after cleaning the to-be-colored zipper, and performing passivating treatment after cleaning the to-be-colored zipper again, thereby obtaining the bronze-gold-tooth colored zipper. The bronze aqueous solution consists of the following components in mass fraction: 0.8-1% of selenium dioxide, 4-5% of sodium persulfate, 3-4% of copper nitrate, 2-3% of sulfuric acid, 2-3% of nitric acid, 6-7.5% of phosphoric acid, 0.6-0.8% of sodium carbonate and the balance of water; and the white copper aqueous solution consists of the following components in mass fraction: 2-4% of stannous chloride, 5-12% of thiourea, 1-2% of hydrochloric acid, 0.4-1% of a fatty alcohol-polyoxyethylene ether emulsifier, 0.5-14% of auxiliaries and the balance of water. The method provides unique perception for the bronze-gold-tooth colored zipper, improves the zipper level, compensates the defect part between light gold color and bronze color, and meets various needs of a client.

Owner:ZHEJIANG WEIXING IND DEV

Bird cage, raw material for producing same and production method of raw material

InactiveCN106945143AHigh strengthEfficient killingWood treatment detailsReed/straw treatmentAqueous solutionBronze color

The invention discloses a bird cage, a raw material for producing the same and a production method of the raw material and relates to the technical field of bird cage processing. The production method of the raw material for producing the bird cage comprises the step of steaming bamboos by using an alkali water solution. The production method is scientific, reasonable and capable of realizing large-scale industrial production. The raw material for producing the bird cage is produced by using the production method. The raw material has the characteristics of insect prevention, moth prevention and no resilience. The bird cage is produced by using the raw material. The bird cage has the characteristics of insect prevention, moth prevention, low damage possibility and bronze color.

Owner:凯里经济开发区大溪鸟笼工艺品农民专业合作社

Spraying process for antique brass brushed aluminum veneer

InactiveCN112156957AAntique copper color is beautifulBrushed surface naturalPretreated surfacesCoatingsColored whiteMetallurgy

Owner:江苏苏缘幕墙材料有限公司

Copper sculpture powder

The invention discloses copper sculpture powder. The copper sculpture powder is prepared from, by weight, 20-45 parts of bronze powder, 1-5 parts of bronze colored pearl powder, 15-25 parts of white cement, 10-18 parts of calcium carbonate, 6-15 parts of diatomite, 4-9 parts of attapulgite, 5-12 parts of quartz sand, 18-28 parts of Chinese cabbage roots, 8-16 parts of titanium dioxide, 6-14 partsof perlite, 12-20 parts of sepiolite granules, 5-11 parts of nano-porous bamboo charcoal, 1-3 parts of sodium metasilicate, 3-6 parts of rock wool, 1-5 parts of glitter powder, 4-8 parts of oily fluorocarbon resin and 7-13 parts of anti-blushing agent. The copper sculpture powder has the advantages of good finish degree, high strength, small shrinking percentage, strong corrosion resistance and the like and can be put in an outdoor environment for a long time.

Owner:安徽省隆徽雕塑工艺有限公司

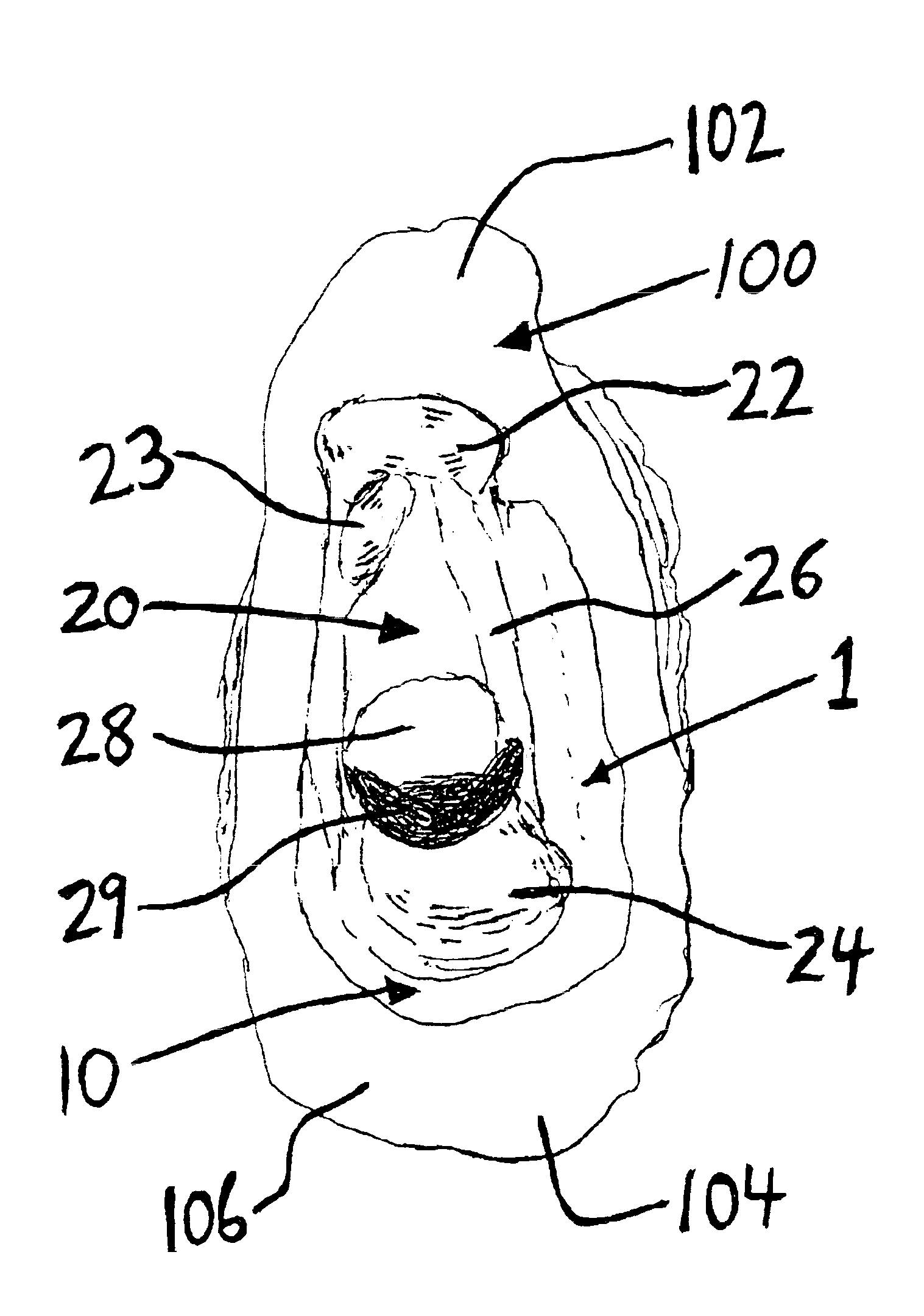

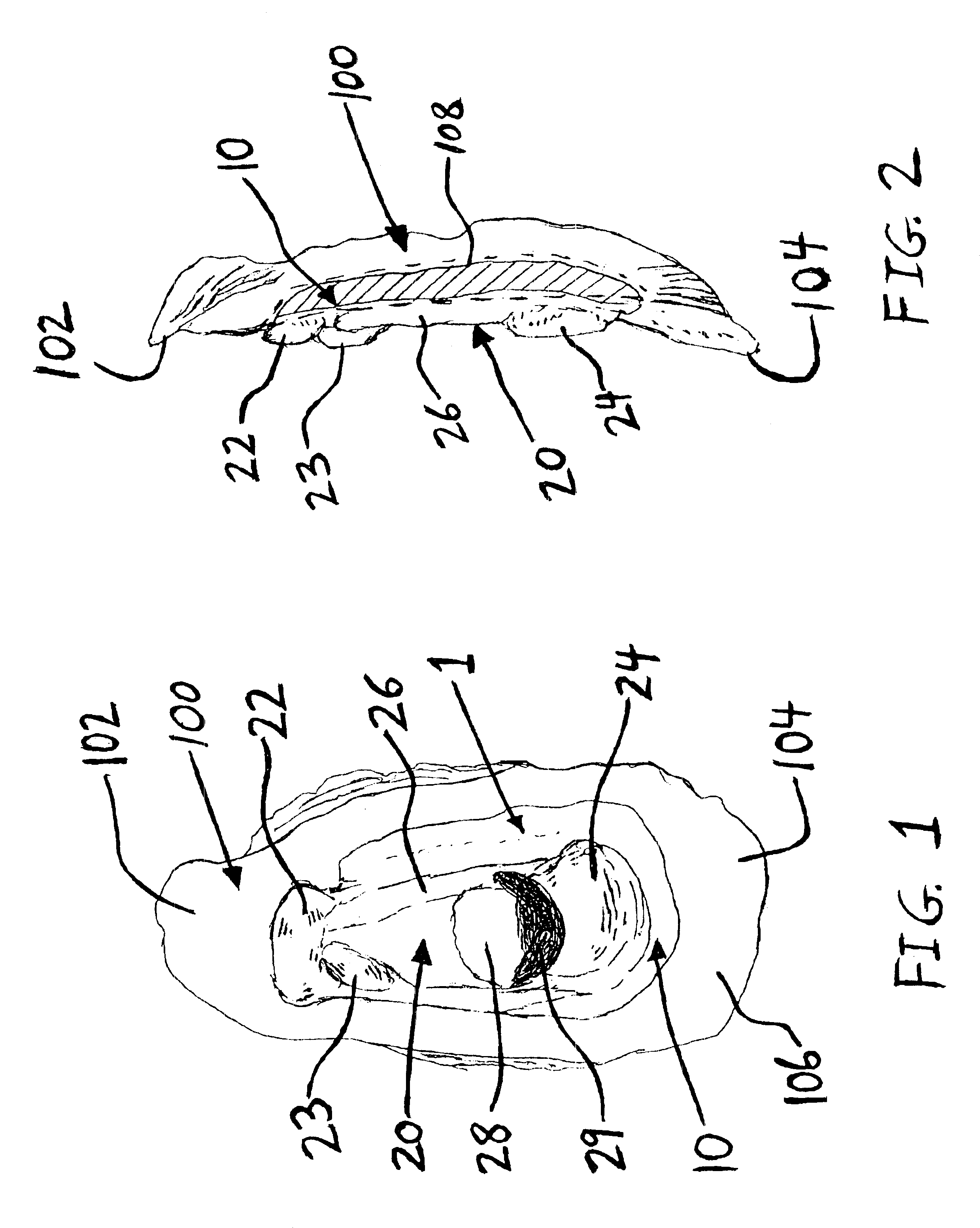

Methods of making realistic artificial oysters on the half-shell

A manufacture resembling a natural oyster on the half-shell comprising an oyster half-shell having a painted artificial oyster fixed therein. The oyster is painted with a certain set of colors in a particular order to thereby create the coloring and appearance of a natural oyster. The shell is preferably a natural oyster shell having an oyster cavity on an interior surface thereof. The artificial is preferably formed from hot glue. A coating of cream, tan, dark brown, and metallic bronze colored paints cover an outer surface of the artificial oyster, such that portions of the various paints are exposed. Splotches of white and black paint are preferably applied in order to mimic the eye region of a natural oyster. A coating of clear coat covers the painted artificial oyster to thereby give the artificial oyster a wet, translucent appearance.

Owner:KENNAIR III PATRICK J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com