Tea foam vitreous enamel produced in Yaozhou kiln and manufacturing method thereof

A manufacturing method and technology of glazed porcelain, which is applied in Yaozhou kiln tea foam glazed porcelain and its manufacturing field, can solve the problems of precise glaze matching, narrow firing range, and difficult manufacturing process, and achieve the effect of high brightness and consistent hair color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

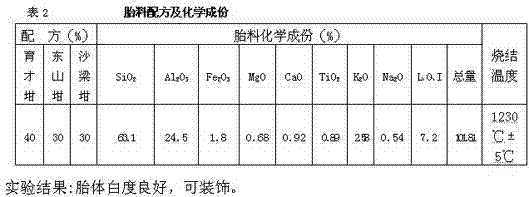

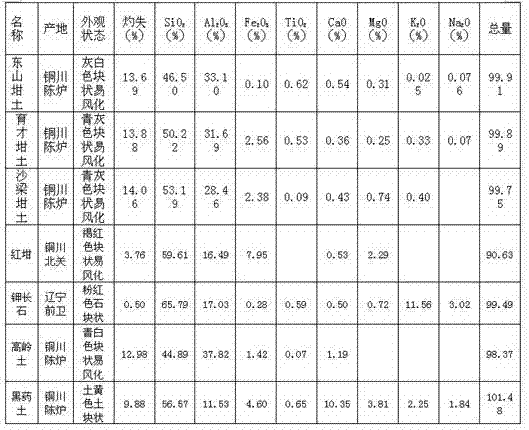

[0028] The tire material of tea foam glaze porcelain according to the present invention is composed of the following raw materials in parts by weight: 40 parts of Yucai crucible, 30 parts of Dongshan crucible, and 30 parts of Shaliang crucible;

[0029] The glaze is composed of the following raw materials in parts by weight: 80 parts of black medicine soil, 5 parts of potassium feldspar and 15 parts of kaolin.

[0030] A manufacturing method of Yaozhou kiln tea foam glazed porcelain is as follows:

[0031] 1) The preparation process of the tire material is: weathering the Yucai crucible, Dongshan crucible, and Shaliang crucible in the open air for more than half a year → put it into the ball mill according to the proportion → add water with 70% weight of the tire material, finely grind for 3-4 hours → Pass through a 180-200 mesh sieve, remove iron in the iron remover, and get the sludge with a residue of <0.3% through a million-hole sieve → refine the mud with a filter press t...

Embodiment 2

[0044] The tire material of tea foam glaze porcelain according to the present invention is composed of the following raw materials in parts by weight: 45 parts of Yucai crucible, 25 parts of Dongshan crucible, and 30 parts of Shaliang crucible;

[0045] The glaze is composed of the following raw materials in parts by weight: 70 parts of black medicine soil, 10 parts of potassium feldspar and 10 parts of kaolin.

[0046] A manufacturing method of Yaozhou kiln tea foam glazed porcelain is as follows:

[0047] 1) The preparation process of the tire material is: weathering the Yucai crucible, Dongshan crucible, and Shaliang crucible in the open air for more than half a year → put it into the ball mill according to the proportion → add water with 70% weight of the tire material, finely grind for 3-4 hours → Pass through a 180-200 mesh sieve, remove iron in the iron remover, and get the sludge with a residue of <0.3% through a million-hole sieve → refine the mud with a filter press ...

Embodiment 3

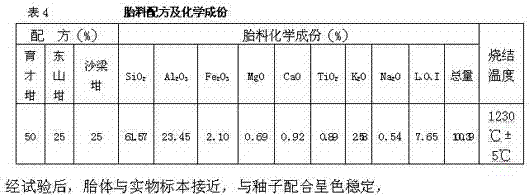

[0060] The tire material of tea foam glaze porcelain according to the present invention is composed of the following raw materials in parts by weight: 50 parts of Yucai crucible, 25 parts of Dongshan crucible, and 25 parts of Shaliang crucible;

[0061] The glaze is composed of the following raw materials in parts by weight: 80 parts of black medicine soil, 5 parts of potassium feldspar and 15 parts of kaolin.

[0062] A manufacturing method of Yaozhou kiln tea foam glazed porcelain is as follows:

[0063] 1) The preparation process of the tire material is: weathering the Yucai crucible, Dongshan crucible, and Shaliang crucible in the open air for more than half a year → put it into the ball mill according to the proportion → add water with 70% weight of the tire material, finely grind for 3-4 hours → Pass through a 180-200 mesh sieve, remove iron in the iron remover, and get the sludge with a residue of <0.3% through a million-hole sieve → refine the mud with a filter press t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com