Thermal insulation mesh cloth based on graphene and preparation method thereof

A technology of mesh cloth and graphene, which is applied in the field of mesh cloth, can solve the problems affecting the heat preservation effect of mesh cloth, achieve strong coloring ability, improve thermal stability, and improve high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

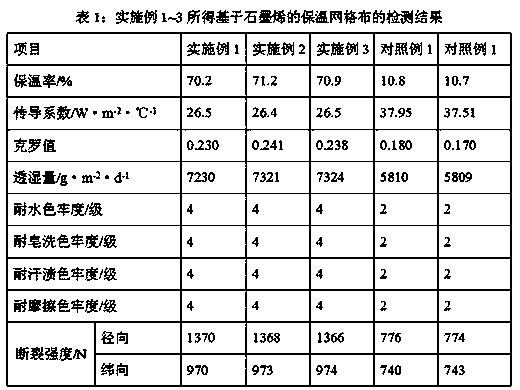

Examples

Embodiment 1

[0037] The preparation method of graphene-based thermal insulation grid cloth comprises the steps:

[0038] Step 1, the preparation of the first treatment agent:

[0039] S1.1. One-time material preparation:

[0040] The first treatment agent includes the following components in parts by mass: 9 parts of methyl cellulose ether, 7 parts of terpene resin, 6 parts of cardanol, 10 parts of graphene powder, and weigh and prepare materials according to the stated proportion.

[0041] S1.2, primary mixing:

[0042] Mix the materials prepared in step S1.1 evenly to obtain the first treatment agent, and the temperature of the primary mixing materials is 80°C.

[0043] Step 2, preparation of the second treatment agent:

[0044] S2.1. Secondary material preparation:

[0045] The second treatment agent includes the following components in parts by mass: 8 parts of hydroxy silicone oil, 6 parts of dodecyltrimethylammonium bromide, and 2 parts of urea, which are prepared by weighing acc...

Embodiment 2

[0058] The preparation method of graphene-based thermal insulation grid cloth comprises the steps:

[0059] Step 1, the preparation of the first treatment agent:

[0060] S1.1. One-time material preparation:

[0061] The first treatment agent includes the following components in parts by mass: 11 parts of methyl cellulose ether, 8 parts of terpene resin, 7 parts of cardanol, and 11 parts of graphene powder, and the materials are prepared according to the stated proportion.

[0062] S1.2, primary mixing:

[0063]Mix the materials prepared in step S1.1 evenly to obtain the first treatment agent, and the temperature of the primary mixing materials is 90°C.

[0064] Step 2, preparation of the second treatment agent:

[0065] S2.1. Secondary material preparation:

[0066] The second treatment agent includes the following components in parts by mass: 9 parts of hydroxy silicone oil, 7 parts of dodecyltrimethylammonium bromide, and 2 parts of urea, which are prepared by weighing ...

Embodiment 3

[0079] The preparation method of graphene-based thermal insulation grid cloth comprises the steps:

[0080] Step 1, the preparation of the first treatment agent:

[0081] S1.1. One-time material preparation:

[0082] The first treatment agent includes the following components in parts by mass: 10 parts of methyl cellulose ether, 10 parts of terpene resin, 9 parts of cardanol, and 15 parts of graphene powder, and the materials are prepared according to the stated proportion.

[0083] S1.2, primary mixing:

[0084] Mix the materials prepared in step S1.1 evenly to obtain the first treatment agent, and the temperature of the primary mixing materials is 100°C.

[0085] Step 2, preparation of the second treatment agent:

[0086] S2.1. Secondary material preparation:

[0087] The second treatment agent includes the following components in parts by mass: 11 parts of hydroxy silicone oil, 8 parts of dodecyltrimethylammonium bromide, and 3 parts of urea, which are prepared by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

| Weft breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com