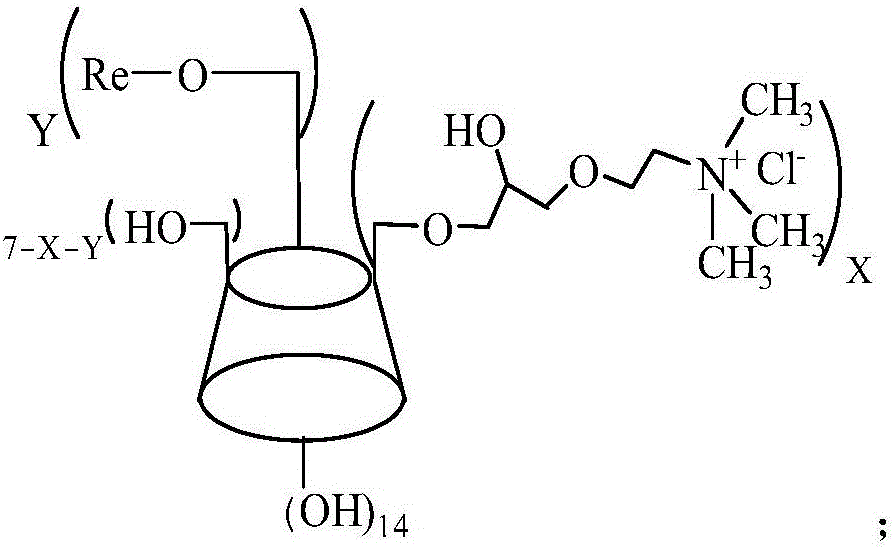

Reactive beta-cyclodextrin quaternary ammonium salt as well as preparation method and application thereof

A technology of cyclodextrin and quaternary ammonium salt, which is applied in dyeing, textile and papermaking, etc., can solve the problems of irritating effect and affecting natural environmental protection, and achieve the effect of reducing pollution, easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

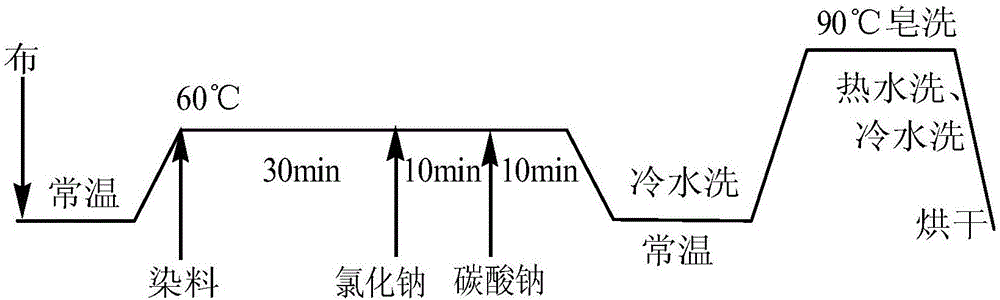

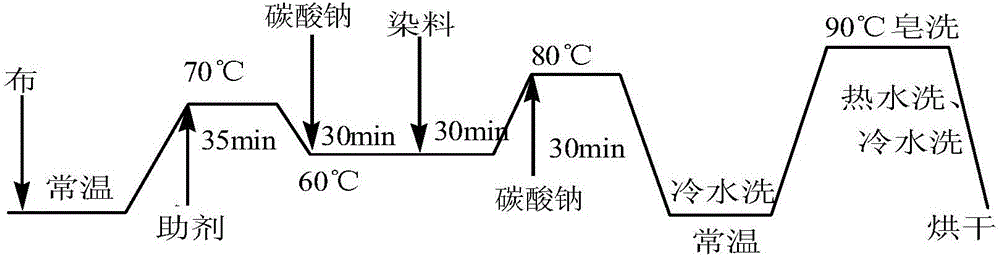

Method used

Image

Examples

Embodiment 1

[0043]A kind of preparation method of reactive β-cyclodextrin quaternary ammonium salt, the steps are as follows:

[0044] 1) To prepare β-cyclodextrin quaternary ammonium salt, first add β-cyclodextrin to a NaOH solution with a concentration of 1.25mol / L and stir at room temperature to fully dissolve it. The mass ratio of β-cyclodextrin to NaOH is 5: 1; then add choline chloride; finally, heat the mixed solution to 20°C, slowly add epichlorohydrin dropwise, react for 24 hours after the dropwise addition, and neutralize the reaction with HCl solution with a concentration of 1mol / L to stop the reaction. The reaction product can be evaporated and dried by rotary evaporation; the ratio of the amount of β-cyclodextrin, choline chloride and epichlorohydrin in the reaction system is 1:0.1:0.1;

[0045] 2) To prepare the reactive β-cyclodextrin quaternary ammonium salt, first place the NaOH solution with a concentration of 3mol / L in a low temperature and constant temperature stirring...

Embodiment 2

[0049] A kind of preparation method of reactive β-cyclodextrin quaternary ammonium salt, the steps are as follows:

[0050] 1) To prepare β-cyclodextrin quaternary ammonium salt, first add β-cyclodextrin to a NaOH solution with a concentration of 1.25mol / L and stir at room temperature to fully dissolve it. The mass ratio of β-cyclodextrin to NaOH is 5: 1; then add choline chloride; finally, heat the mixed solution to 40°C, slowly add epichlorohydrin dropwise, react for 20 hours after the dropwise addition, and neutralize the reaction with HCl solution with a concentration of 1mol / L to stop the reaction. The reaction product can be evaporated and dried by rotary evaporation; the ratio of the amount of β-cyclodextrin, choline chloride and epichlorohydrin in the reaction system is 1:2:2;

[0051] 2) To prepare the reactive-cyclodextrin quaternary ammonium salt, first place the NaOH solution with a concentration of 3mol / L in a low temperature and constant temperature stirring reac...

Embodiment 3

[0055] A kind of preparation method of reactive β-cyclodextrin quaternary ammonium salt, the steps are as follows:

[0056] 1) To prepare β-cyclodextrin quaternary ammonium salt, first add β-cyclodextrin to a NaOH solution with a concentration of 1.25mol / L and stir at room temperature to fully dissolve it. The mass ratio of β-cyclodextrin to NaOH is 5: 1; then add choline chloride; finally, heat the mixed solution to 60°C, slowly add epichlorohydrin dropwise, react for 16 hours after the dropwise addition, and neutralize the reaction with HCl solution with a concentration of 1mol / L to stop the reaction. The reaction product can be evaporated and dried by rotary evaporation; the ratio of the amount of β-cyclodextrin, choline chloride and epichlorohydrin in the reaction system is 1:4:4;

[0057] 2) To prepare the reactive β-cyclodextrin quaternary ammonium salt, first place the NaOH solution with a concentration of 3mol / L in a low temperature and constant temperature stirring re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com