Special-shaped cross section viscose filament yarn and preparation method thereof

A viscose filament and special-shaped cross-section technology, applied in the field of viscose fiber, can solve the problems of no antibacterial and antibacterial performance, increase fiber production cost, increase fiber production cost, etc., achieve smooth hand feeling, good antibacterial property, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

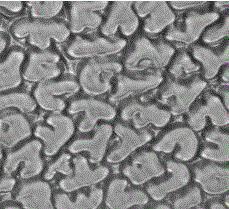

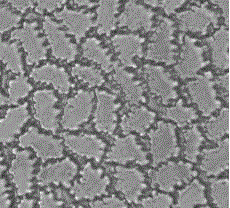

Image

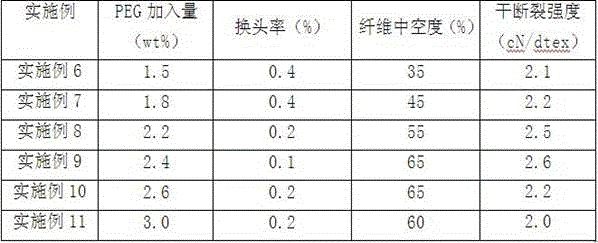

Examples

Embodiment 1

[0040] The preparation of embodiment 1 special-shaped section viscose filament

[0041] (1) Preparation of spinning viscose

[0042] Using cellulose pulp as raw material, through steps including dipping, pressing, pulverizing, aging, yellowing, dissolving, mixing, filtering, defoaming, aging and other steps to obtain Type A with cellulose content of 7.8wt%, viscosity of 35s, and maturity of The spinning viscose of 18ml, described viscosity adopts falling ball method to measure, and described degree of maturity adopts 10%NH 4 Cl solution measurement, add viscose denaturant PEG in the described dissolving step, the addition of PEG is 0.5wt% relative to the first cellulose.

[0043] (2) Spinning

[0044] Use viscose filament with spinneret 30 holes × 0.08mm (aperture diameter), in H 2 SO 4 Concentration 115g / l, Al 2 (SO 4 ) 3 Concentration 2g / l, Na 2 SO 4 Concentration 260g / l, temperature 45 ℃ coagulation bath coagulation molding, and then through nozzle drafting, ...

Embodiment 2

[0052] The preparation of embodiment 2 special-shaped cross-section viscose filaments

[0053] (1) Preparation of spinning viscose

[0054] Using cellulose pulp as raw material, through steps including dipping, pressing, pulverizing, aging, yellowing, dissolving, mixing, filtering, defoaming, aging and other steps to obtain Type A with cellulose content of 8.2wt%, viscosity of 40s, and maturity of 21ml of spinning viscose, the viscosity is measured by the falling ball method, and the degree of maturity is measured by 10%NH 4Cl solution is measured, and described solution step adds denaturing agent AC1815, and the addition amount of first kind of cellulose in AC1815 relative viscose is 1.0wt%.

[0055] (2) Spinning

[0056] Use viscose filament with spinneret 30 holes × 0.08mm (aperture diameter), in H 2 SO 4 Concentration 123g / l, Al 2 (SO 4 ) 3 Concentration 5g / l, Na 2 SO 4 Concentration 280g / l, temperature 47 ℃ coagulation bath coagulation molding, and then thr...

Embodiment 3

[0064] The preparation of embodiment 3 special-shaped cross-section viscose filaments

[0065] (1) Preparation of spinning viscose

[0066] Using cellulose pulp as raw material, through steps including dipping, pressing, pulverizing, aging, yellowing, dissolving, mixing, filtering, defoaming, aging and other steps to obtain Type A with cellulose content of 8.0wt%, viscosity of 43s, and maturity of The spun viscose of 25ml, described viscosity adopts falling ball method to measure, and described maturity adopts 10%NH 4 Cl solution measurement, the dissolving step adds viscose denaturant EB, and the addition amount of EB is 1.2wt% relative to the first cellulose.

[0067] (2) Spinning

[0068] Use viscose filament with spinneret 30 holes × 0.08mm (aperture diameter), in H 2 SO 4 Concentration 127g / l, Al 2 (SO 4 ) 3 Concentration 7g / l, Na 2 SO 4 Concentration 270g / l, temperature 43 ℃ coagulation bath coagulation molding, and then through nozzle drafting, inter-disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com