Flame retardant cationic dyeable polyesters and preparation method

A copolymer and cationic technology, which is applied in the field of functional polyester and its preparation, can solve the problems of limited application of antimony-based catalysts, poor spinnability and poor durability of raw yarn, and achieve excellent cationic dyeability, excellent flame retardancy, Good spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

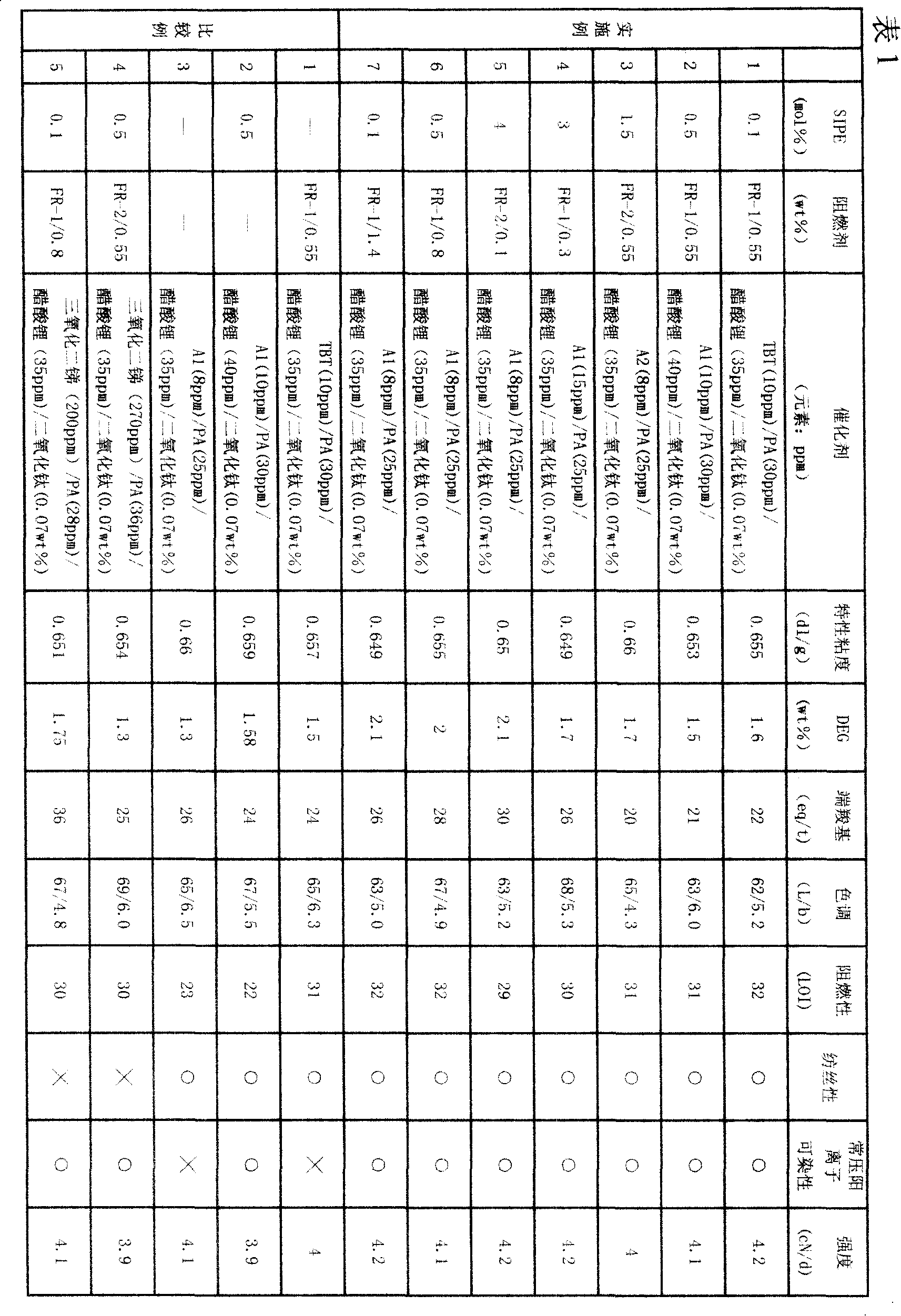

Examples

Embodiment 1

[0046] 100 grams of terephthalic acid and 45 grams of ethylene glycol were put into the beating tank, and the lithium metal element in the lithium acetate was 35 ppm relative to the polyester. Then the slurry is supplied to an esterification tank with partially melted polyester material to carry out an esterification reaction at 250°C. After the esterification reaction finishes, in this oligomer, add the SIPE (Jiangsu Qunfa Company product) that accounts for polyester total amount 3.0wt%, the FR-1 of 0.55wt%, tetrabutyl titanate (TBT, Jiangsu Yonghua fine Chemicals Co., Ltd.) the addition of titanium metal elements is 10ppm relative to the polyester, the addition of phosphorous element phosphorus is 30ppm relative to the polyester, wherein tetrabutyl titanate (TBT) and phosphoric acid are ethylene glycol solutions. Then pressurize to below 200 Pa within 1 hour, and carry out polymerization reaction at 280° C. to obtain polyester copolymer.

[0047] The preparation process of ...

Embodiment 8

[0067] A method for preparing a flame-retardant cationic dyeable polyester copolymer, including esterification and polycondensation reactions, using terephthalic acid and ethylene glycol as the first monomer and the second monomer in the reaction; reactive phosphorus-based flame retardant, The isophthalic acid ester containing sulfonate group is the third monomer and the fourth monomer respectively, the titanate is used as the catalyst, the phosphorus compound is used as the stabilizer, and the alkali metal compound is used as the concomitant additive.

[0068] The general chemical formula of the reactive phosphorus flame retardant is as formula 1 or formula 2

[0069] Formula 1

[0070] R in formula 1 1 , R 2 Representative (CH 2 ) m, m is CH 2 The number of groups, the value of m is 1 to 10 (example 1, 2, 5, 10);

[0071] Formula 2

[0072] R in formula 2 3 Is C1-C6 alkyl (or C6-C9 aryl); R 4 Is C1-C6 alkyl; R 5 and R 6 It is a hydrogen group (or hydroxyalkylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com