Cation dyeable flame-retardant polyester and preparation method thereof

A flame-retardant polyester and cationic technology, applied in the direction of single-component polyester rayon, rayon manufacturing, and fiber chemical characteristics, can solve the problems of poor color tone, poor light resistance, and low polymerization performance of polymers, and achieve Excellent color tone, good spinning performance and low DEG content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] First, the phosphorus compound B shown in the following formula 6 is esterified with ethylene glycol at 230° C. to obtain an ethylene glycol solution with an esterification rate of 90% and a flame retardant A concentration of 60% shown in formula 5.

[0056] Formula 6

[0057] Formula 5

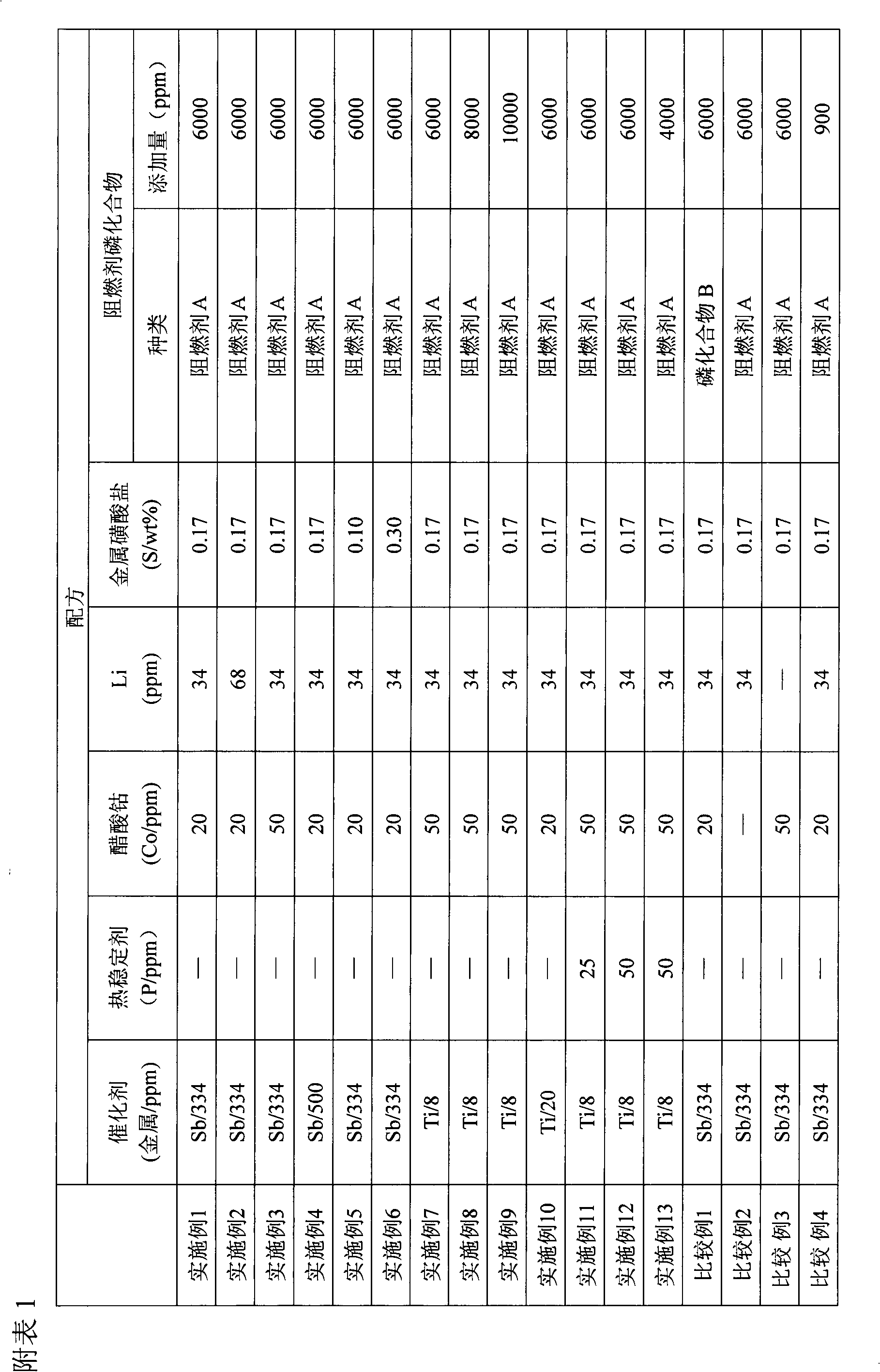

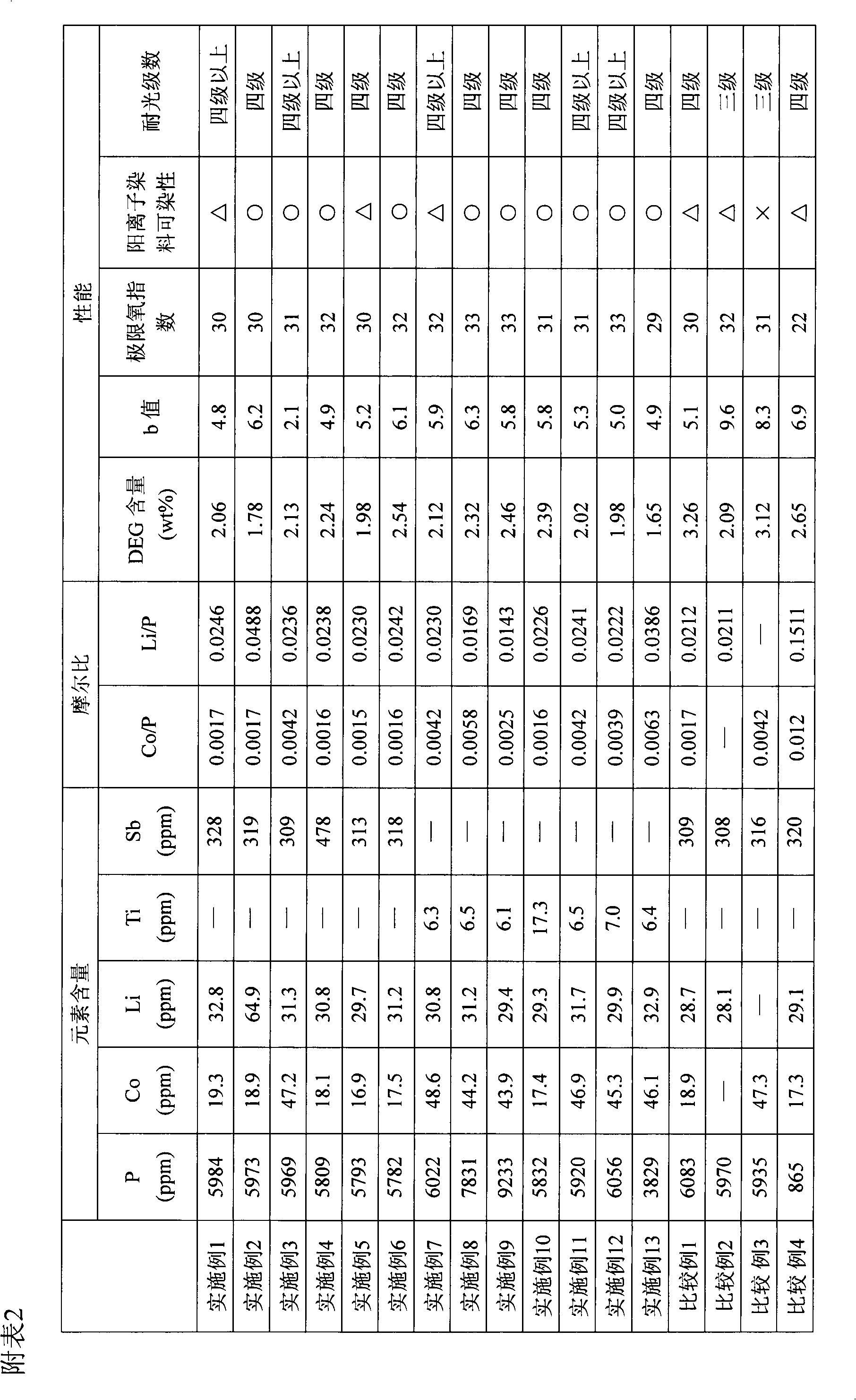

[0058] A certain amount of dimethyl terephthalate and ethylene glycol, dimethyl isophthalate-5-sodium sulfonate, catalyst antimony trioxide, alkali metal compound lithium acetate, and cobalt acetate are added to the first reaction tank, The reaction was carried out for 4 to 6 hours. Wherein the addition of dimethyl isophthalate-5-sodium sulfonate is 0.17wt% of sulfur element relative to the total amount of polyester, and the addition amount of catalyst antimony trioxide is based on antimony element relative to the total amount of polyester 334ppm, the addition amount of alkali metal compound lithium acetate was 34ppm as lithium element relative to the total amount of polyester, a...

Embodiment 2~6

[0061] Change the addition amount of substance, other is with embodiment 1, specifically see attached table 1 and 2.

Embodiment 7~10

[0063] The catalyst used is tetrabutyl titanate, and its addition amount is 8ppm in terms of titanium element relative to the total amount of polyester. Others are the same as in Example 1. See attached tables 1 and 2 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com