Method for preparing spinnable asphalt from coal tar

A technology for coal tar and pitch, applied in the field of preparing spinnable pitch, can solve the problems of low content and large molecular weight, and achieve the effects of simple preparation process, high utilization rate of raw materials, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

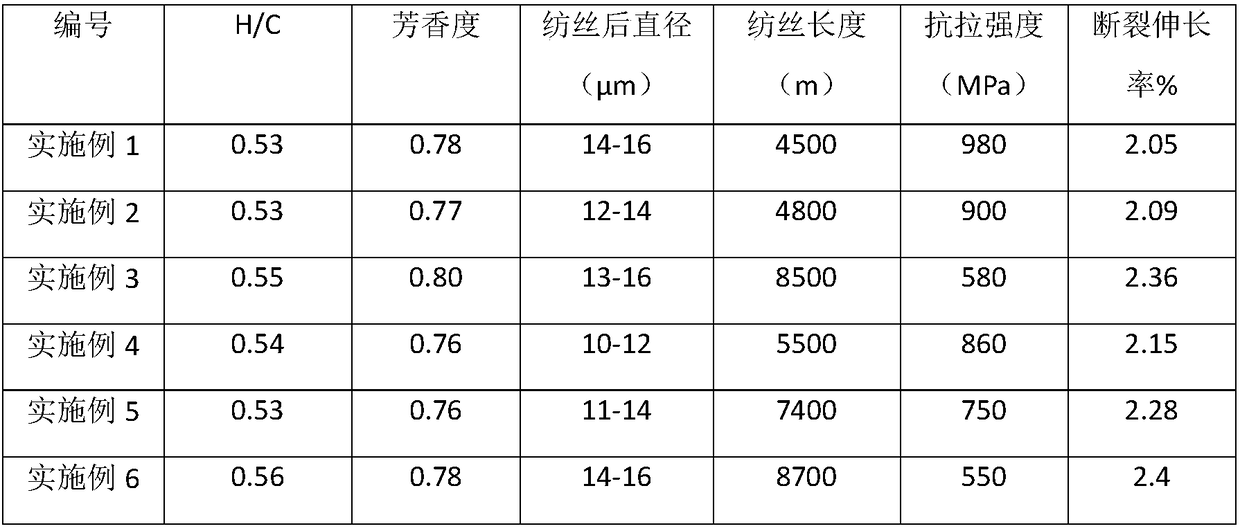

Examples

Embodiment 1

[0032] Step 1. Put coal tar in a reaction kettle with a mass of 1500 grams, heat it to 250° C. and distill it under reduced pressure for 2 hours (vacuum degree is 0.08 MPa), and take out the remaining material from the autoclave, which is the heavy component of coal tar. It is 825g.

[0033] Step 2. Add 50g of coal tar heavy fraction and 100g of n-heptane into the Soxhlet extractor, heat to 80°C, extract for 15 hours to obtain extract S1 and raffinate D1, and then use a rotary evaporator to extract S1 Recovery, the residue after solvent recovery is n-heptane soluble matter, and the residue after solvent recovery is placed in a fume hood for ventilation for 3 hours to obtain heavy oil, which is 5g by weighing. The raffinate D1 is baked in an oven to constant weight, put it and 90g toluene into the Soxhlet extractor, heat to 125°C, extract S2 and raffinate D2 after extraction for 12 hours, and then extract the obtained extract S2 Recover with a rotary evaporator, and the residu...

Embodiment 2

[0036] Step 1. Put coal tar in a reaction kettle with a mass of 1500 grams, heat it to 300° C. and distill it under reduced pressure for 2 hours (vacuum degree is 0.08 MPa), and take out the remaining material from the autoclave, which is the heavy component of coal tar. It is 750g.

[0037]Step 2. Put 50g of coal tar heavy fraction and 150g of n-pentane into a Soxhlet extractor, heat to 80°C, extract for 12 hours to obtain extract S1 and raffinate D1, and then use a rotary evaporator for the obtained extract S1 Recovery, the residue after solvent recovery is n-pentane soluble matter, and the residue after solvent recovery is placed in a fume hood for ventilation for 4 hours to obtain heavy oil, which is 5.01g by weighing. The raffinate D1 is baked in an oven to constant weight, put it and 135g xylene into a Soxhlet extractor, heat to 120°C, extract S2 and raffinate D2 after extraction for 14 hours, and then extract the obtained extract S2 is recovered by a rotary evaporator,...

Embodiment 3

[0040] Step 1. Put coal tar in a reaction kettle with a mass of 1500 grams, heat it to 280° C. and distill it under reduced pressure for 2 hours (vacuum degree is 0.08 MPa), and take out the remaining material from the autoclave, which is the heavy component of coal tar. It is 775g.

[0041] Step 2. Add 50g of coal tar heavy fraction and 200g of n-hexane into the Soxhlet extractor, heat to 90°C, extract for 12 hours to obtain extract S1 and raffinate D1, and then recover the obtained extract S1 with a rotary evaporator , the residue after solvent recovery is n-hexane soluble matter, and the residue after solvent recovery is placed in a fume hood to ventilate for 3 hours to obtain heavy oil, which is 5.12g by weighing. The raffinate D1 is baked in an oven to constant weight, put it and 180g of benzene into the Soxhlet extractor, heat to 120°C, extract S2 and raffinate D2 after extraction for 15 hours, and then extract the obtained extract S2 Recover with a rotary evaporator, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com