Strong-plugging hydrophobic ultra-deep well high-performance water-based drilling fluid and preparation method thereof

A water-based drilling fluid and hydrophobic technology, applied in chemical instruments and methods, drilling compositions, transportation and packaging, etc., can solve the problems of inhibiting anti-slump performance and poor anti-pollution performance, and achieve improved mixing effect , Improve the stirring efficiency and expand the stirring area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A high-performance water-based drilling fluid for strong plugging and hydrophobic ultra-deep wells, including main raw materials and auxiliary raw materials, wherein the main raw materials include 2-5% bentonite, 0.5-1% alkaline regulator, and 2 high-temperature fluid loss reducers ~6%, anti-high temperature and anti-salt fluid loss reducer 2~6%, high temperature resistant polymer fluid loss reducer 1~2%, plugging and anti-slump agent 2~5%, CMC1~2%, K-PAM0.1 ~0.3%, PHP0.1~0.2%, mud shale inhibitor 0.5~1%, potassium chloride 5~15%, calcium chloride 0.3~1%, well wall strengthening agent 2~5%, polymer coating The inhibitor is 0.1-0.5%, and the rest is weighting agent; the auxiliary raw material is water.

[0051] Wherein, the density of the drilling fluid is 1.15-1.80g / cm 3 .

[0052] The bentonite is a first-grade banton, the alkaline regulator is sodium hydroxide, the plugging and anti-collapse agent is sulfonated asphalt, cationic emulsified asphalt, and the mud shale...

Embodiment 2

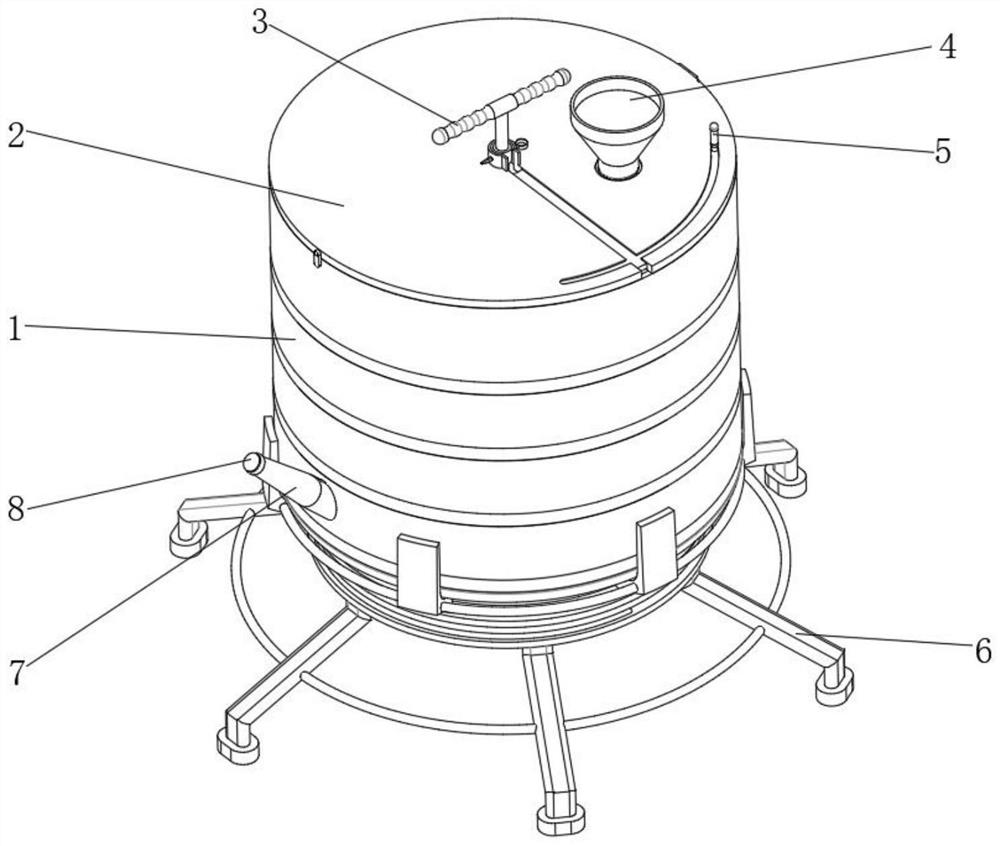

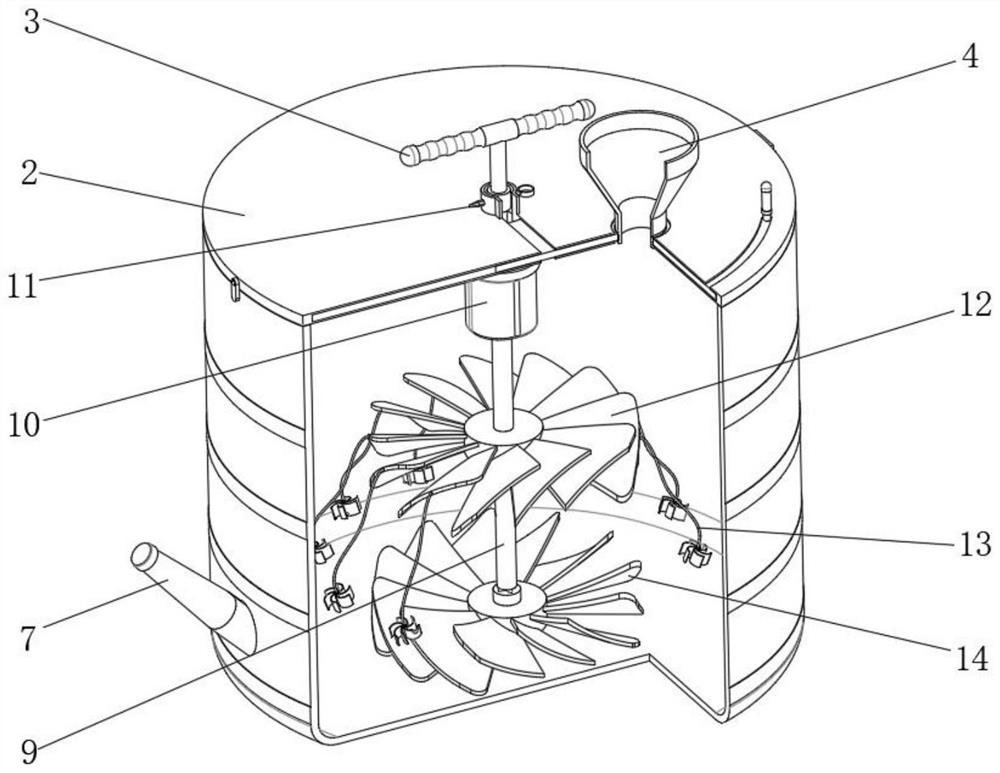

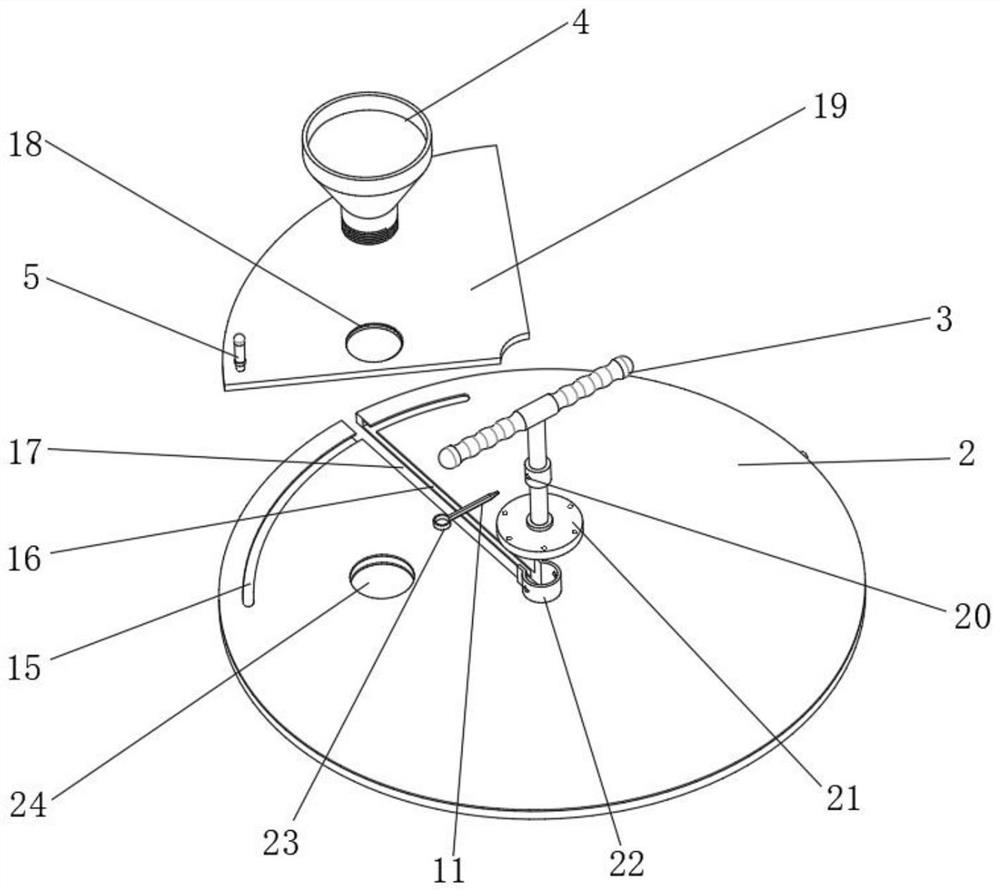

[0056] A method for preparing a high-performance water-based drilling fluid for strong plugging and hydrophobic ultra-deep wells, such as Figure 1-6 shown, including the following steps:

[0057] S1: At room temperature, take a certain amount of tap water and add it to the stirring device;

[0058] S2: Control the operation of the mixing equipment, add 0.5-1% alkaline conditioner and 2-5% bentonite in proportion and stir evenly;

[0059] S3: After fully hydrating for 12 hours, add 2-6% anti-high temperature fluid loss reducer and stir for 5 minutes;

[0060] S4: Add 2-6% anti-high temperature and anti-salt fluid loss reducer and stir for 5 minutes;

[0061] S5: Add 1-2% high temperature resistant polymer fluid loss reducer and stir for 10 minutes;

[0062] S6: Add 2-5% blocking and anti-slumping agent and stir for 5 minutes;

[0063] S7: Add 0.5-1% mud shale inhibitor and stir for 5 minutes;

[0064] S8: Add 5-15% potassium chloride and stir for 5 minutes;

[0065] S9: ...

Embodiment 3

[0075] A method for preparing a high-performance water-based drilling fluid for strong plugging and hydrophobic ultra-deep wells, such as figure 1 , Figure 6 As shown, in order to facilitate shock absorption during stirring; this embodiment makes the following improvements on the basis of embodiment 2: a shock-absorbing base 6 is detachably installed on the bottom of the mixing tank 1, and the shock-absorbing base 6 includes a first seat body 29 and the second seat body 31, the first seat body 29 is installed above the second seat body 31 through a shock absorbing spring 33, the outer wall of the top circumference of the first seat body 29 is welded with a shape adapted to the shape of the bottom side wall of the mixing tank 1 The limit bracket 30, the outer wall of the bottom of the second seat body 31 is welded with a uniform part of the support leg 32; by setting the first seat body 29, the second seat body 31 and the shock absorbing spring 33 and other structures, it can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com