Spinning-grade polyamide composite aliphatic amine shaped energy storage material and preparation method thereof

An energy storage material, polyamide technology, applied in rayon manufacturing, heat exchange materials, filament/thread forming, etc., can solve the problem of small addition, difficult control of particle size, poor mechanical properties of energy storage and temperature-regulating fibers, etc. problems, achieve good rheological properties, good spinnability, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

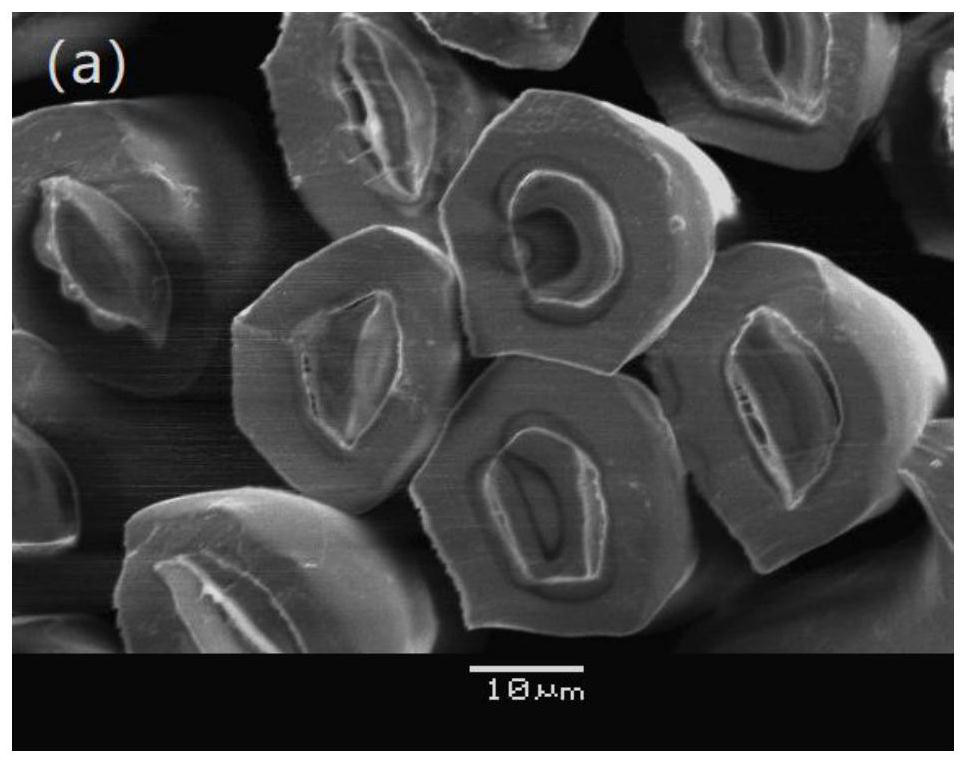

[0024] The preparation method of the spinning grade polyamide composite fatty amine shaped energy storage material involved in the present invention comprises the following steps:

[0025] (1) Dissolve a certain proportion of polyamide and fatty amine in a polar organic solvent, heat and stir until completely dissolved as an oil phase;

[0026] (2) A certain amount of emulsifier is added into water to be activated as the water phase, and the above-mentioned oil phase is added to the water phase and emulsified by high-speed shearing to form a uniform emulsion;

[0027] (3) The above-mentioned emulsion is spray-dried to prepare a composite shaped phase-change material powder.

Embodiment 1

[0035] The invention provides a spinning-grade polyamide composite fatty amine shaped energy storage material and a preparation method thereof, comprising the following steps:

[0036] Add 300 grams of polyamide and dodecylamine with a mass ratio of 1:0.2 to 500 ml of formic acid and chloroform 1:2 mixed solvent, heat and stir at 40°C until completely dissolved, as an oil phase;

[0037] Add 10 grams of sodium lauryl sulfate emulsifier into 1.8 liters of water to activate as the water phase, add the above oil phase to the water phase, and emulsify at 30°C with high speed shear to form a uniform emulsion;

[0038] The above-mentioned emulsion was spray-dried at high temperature, the temperature was set at 180°C, and the outlet pressure of the air compressor was adjusted to 0.25Mpa to obtain a composite shaped energy storage material powder.

Embodiment 2

[0040] The invention provides a spinning-grade polyamide composite fatty amine shaped energy storage material and a preparation method thereof, comprising the following steps:

[0041] Add 200 grams of polyamide and dodecylamine with a mass ratio of 1:0.5 to 200 ml of formic acid and chloroform 1:1 mixed solvent, heat and stir at 80°C until completely dissolved, as an oil phase;

[0042] Add 50 grams of sodium lauryl sulfate emulsifier into 2 liters of water to activate as the water phase, add the above oil phase to the water phase, and emulsify at 30°C with high speed shear to form a uniform emulsion;

[0043] The above-mentioned emulsion was spray-dried at high temperature, the temperature was set at 160°C, and the outlet pressure of the air compressor was adjusted to 0.15Mpa to obtain a composite shaped energy storage material powder.

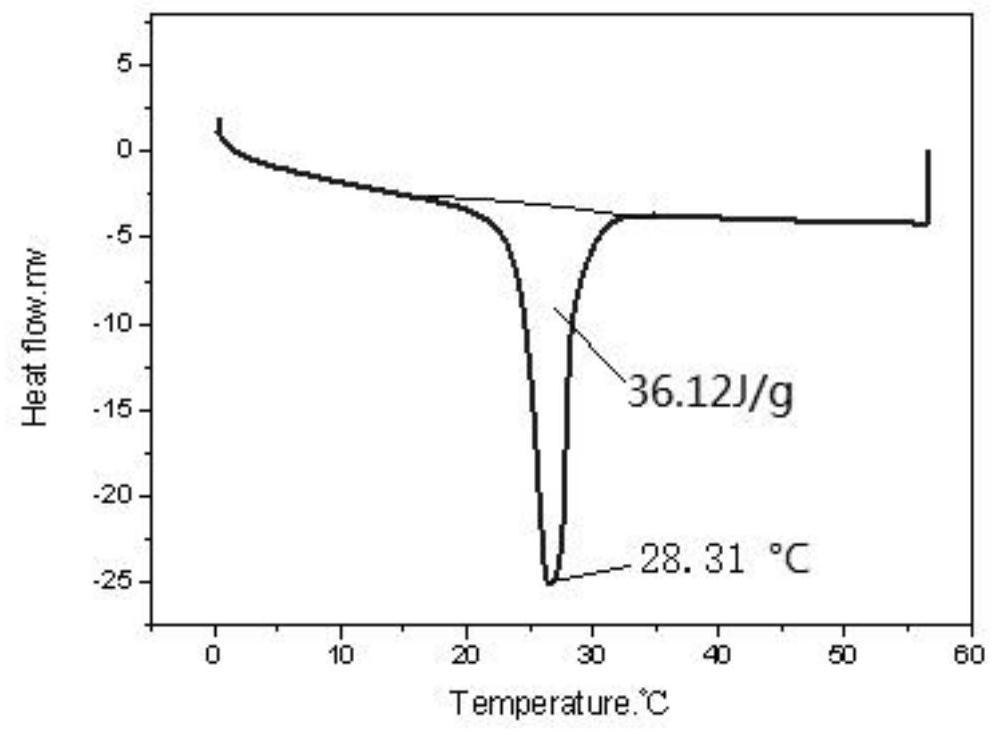

[0044] The peak melting temperature of the composite shaped energy storage material measured by a differential scanning calorimeter is 28°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com