Coating biological latex, precoating paint and preparation method of precoating paint

A bio-latex and coating technology, which is applied in the field of papermaking coatings, can solve the problems of layered and foamed paper, adverse effects on the operation performance of large-scale high-speed paper machines, and low strength of bio-latex, achieving surface strength improvement, good water retention, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

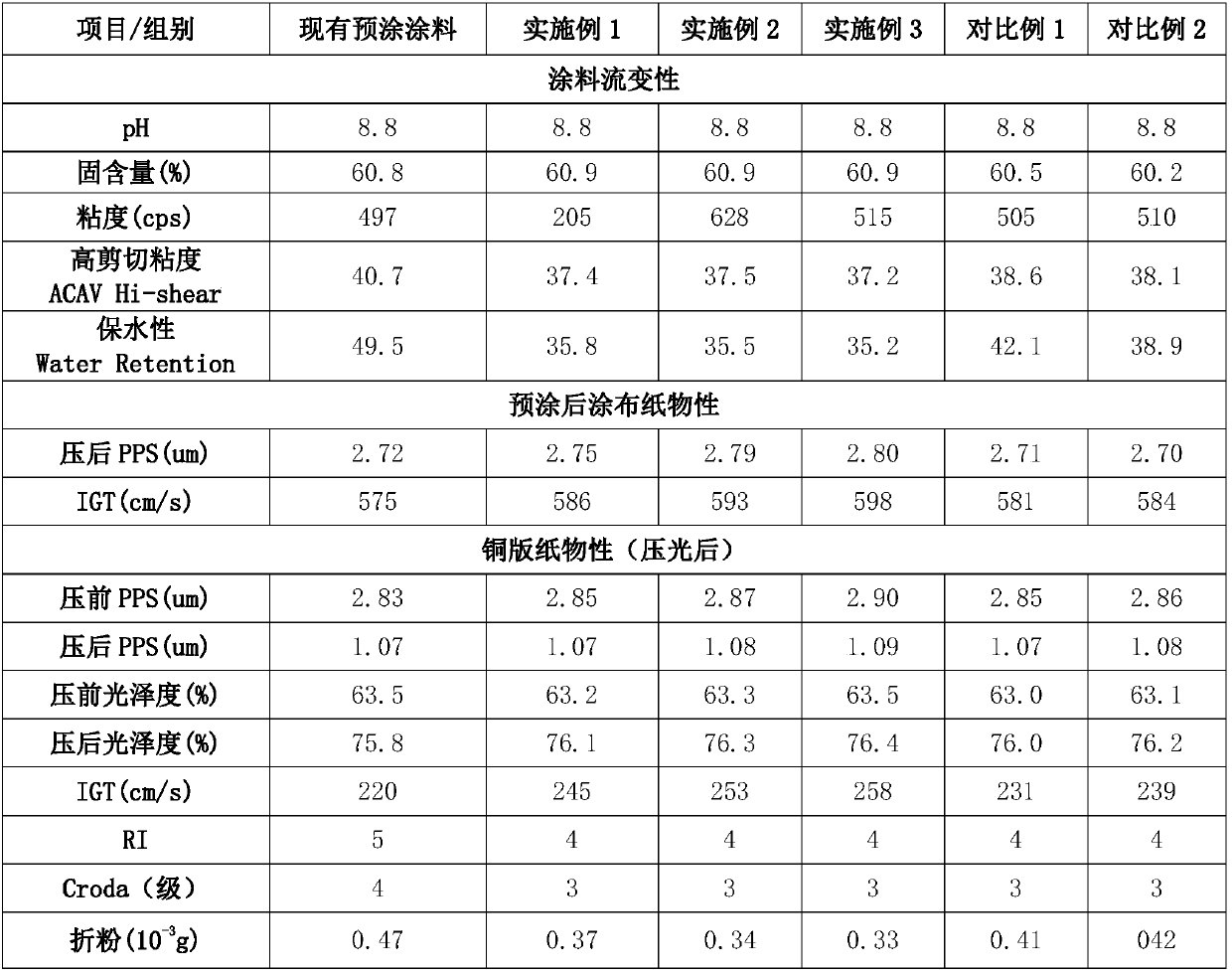

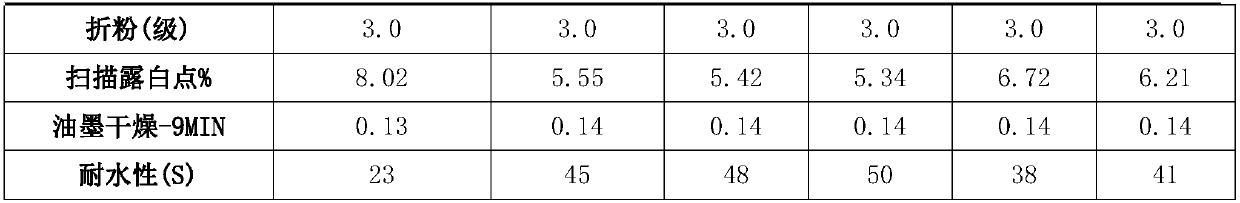

Examples

Embodiment 1

[0023] A biological latex for coating, comprising the following raw materials in parts by weight: 100 parts by weight of starch, 0.005 parts of mesophilic amylase and 0.01 part of biological intermediates; wherein, the biological intermediates include the following raw materials in parts by weight: methylene succinic acid 20 part, 50 parts of polypropylene glycol and 6 parts of hydrogen peroxide; The volume concentration of described hydrogen peroxide is 12%;

[0024] The preparation method of described biological latex comprises the following steps:

[0025] (1) According to the above weight ratio, the starch and water are mixed and stirred evenly to obtain the starch water slurry;

[0026] (2) adding the starch water slurry to a medium-temperature amylase, and pumping it into a constant temperature reaction tank for gelatinization reaction;

[0027] (3) Pump the starch water slurry after the gelatinization reaction to the digester for instant inactivation, and keep warm in ...

Embodiment 2

[0032] A biological latex for coating, comprising the following raw materials in parts by weight: 100 parts of starch, 0.05 parts of medium temperature amylase, 30 parts of glycerol, 10 parts of ethylene glycol and 30 parts of biological intermediates; wherein, the biological intermediates include The following raw materials in parts by weight: 5 parts of methylene succinic acid, 30 parts of polypropylene glycol and 4 parts of hydrogen peroxide, wherein the volume concentration of the hydrogen peroxide is 8%;

[0033] The preparation method of described biological latex comprises the following steps:

[0034] (1) According to the above weight ratio, ethylene glycol and glycerol are mixed with water and stirred, then starch is added, and stirred evenly to obtain starch water slurry;

[0035] (2) adding the starch water slurry to a medium-temperature amylase, and pumping it into a constant temperature reaction tank for gelatinization reaction;

[0036] (3) Pump the starch water...

Embodiment 3

[0041] A biological latex for coating, comprising the following raw materials in parts by weight: 100 parts of starch, 0.01 part of medium temperature amylase, 20 parts of glycerol, 5 parts of ethylene glycol and 20 parts of biological intermediates; wherein, the biological intermediates include The following raw materials in parts by weight: 10 parts of methylene succinic acid, 40 parts of polypropylene glycol and 5 parts of hydrogen peroxide; the volume concentration of the hydrogen peroxide is 10%;

[0042] The preparation method of described biological latex comprises the following steps:

[0043] (1) According to the above weight ratio, ethylene glycol and glycerol are mixed with water and stirred, then starch is added, and stirred evenly to obtain starch water slurry;

[0044] (2) adding the starch water slurry to a medium-temperature amylase, and pumping it into a constant temperature reaction tank for gelatinization reaction;

[0045] (3) Pump the starch water slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com