A cementing latex cement slurry system and preparation method thereof

A technology of cement slurry and cementing glue, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of high brittleness, poor flexibility, poor impermeability, etc., achieve strong impermeability, avoid channeling , the effect of good rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] A method for preparing the cementing latex cement slurry system as described above includes the following steps:

[0021] Step (1): Wet-mix water, fluid loss agent, latex, retarder, defoamer, and dispersant at a stirring rate of 2000-2500r / min and stir evenly;

[0022] Step (2): dry-mix expansion agent, plasticizer and cement uniformly;

[0023] Step (3): Add the dry mixture to the wet mixture at a stirring rate of 4000 to 4500 r / min, and then stir and mix uniformly at a rate of 10000 to 12000 r / min.

Example Embodiment

[0024] Example 1

[0025] A cementing latex cement slurry system, in parts by weight, including the following components: 2 parts of expansion agent, 1 part of plasticizer, 1.5 parts of fluid loss agent, 15 parts of latex, 0.8 parts of defoamer, and retarder 1.5 parts, 0.8 parts of dispersant, 34 parts of water, 100 parts of cement (Jiahua G-grade cement). Among them, the defoaming agent is an organosilicon compound, the plasticizer is an aliphatic dibasic acid ester compound, and the latex and retarder are all based on (2-acrylamido-2-methylpropanesulfonic acid) as a functional monomer Copolymer, dispersant is sulfonated melamine formaldehyde resin.

[0026] Preparation method: (1) Wet-mix water, fluid loss agent, latex, retarder, defoamer, and dispersant at a stirring rate of 2000r / min and stir uniformly; (2) Dry the expansion agent, plasticizer and cement Mix uniformly; (3) Add the dry mixture to the wet mixture in batches at a stirring rate of 4000r / min, and then stir and mix...

Example Embodiment

[0031] Example 2

[0032] A cementing latex cement slurry system, in parts by weight, includes the following components: 1.5 parts of expansion agent, 1.3 parts of plasticizer (production model: AK600), 1.5 parts of fluid loss agent, and 20 parts of latex (production model: AK-J2), 1.2 parts of defoamer (production model: BP-1B), 1.5 parts of retarder (production model: AK200R), 1 part of dispersant (production model: AK300-1), 34 parts of water, 100 cement Copies (Ka Wah Grade G Cement).

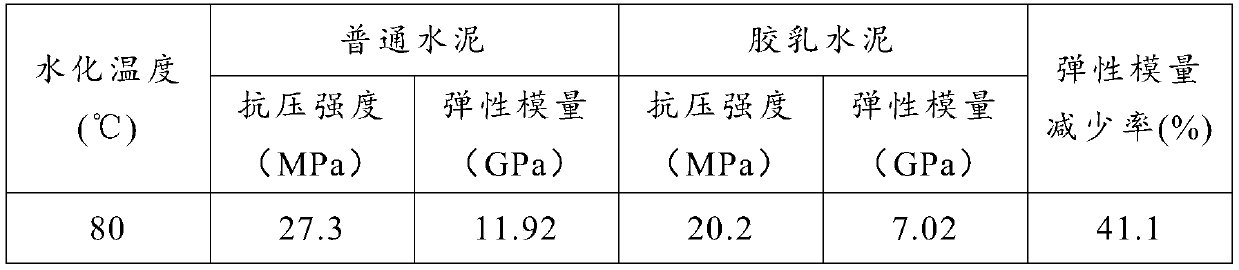

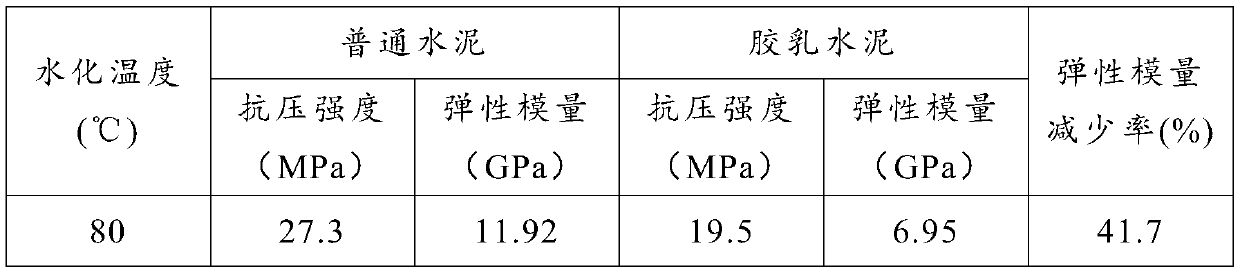

[0033] Preparation method: (1) Wet-mix water, fluid loss agent, latex, retarder, defoamer, and dispersant at a stirring rate of 2000r / min and stir uniformly; (2) Dry the expansion agent, plasticizer and cement Mix uniformly; (3) Add the dry mixture to the wet mixture in batches at a stirring rate of 4500r / min, and then stir and mix evenly at a rate of 10000r / min to obtain a cementing latex cement slurry system. The elastic modulus and compressive strength obtained through the test are shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com