Polyester staple fiber hydrophilic spinning oil

A technology of polyester staple fiber and spinning oil, which is applied in the directions of fiber treatment, fiber type, textile and paper making, etc., can solve the problems of unsuitable fibers and short fibers water repellency, etc., and achieves good hydrophilicity and good spinnability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The proportions of the following components are percentages by weight:

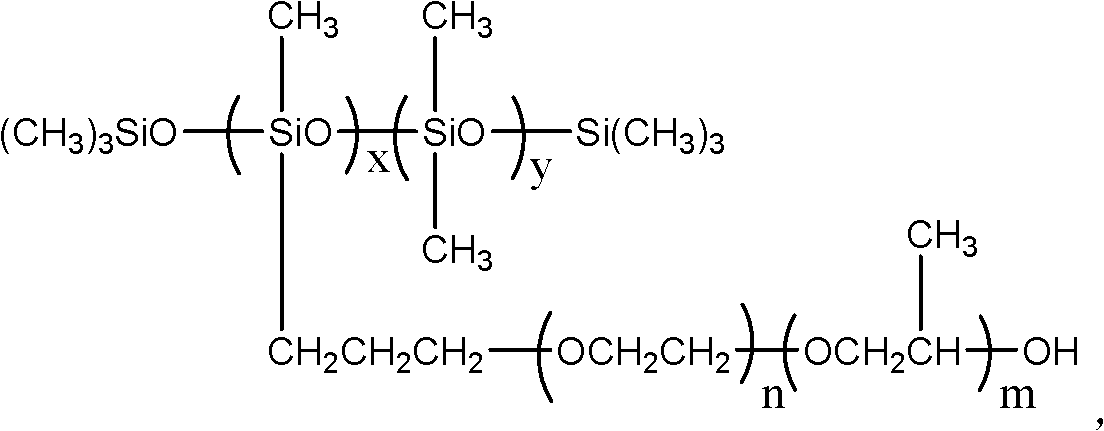

[0034] 1. Polyether modified silicone oil (structure as follows) 70 parts

[0035]

[0036] Where X=15, Y=350, n=20, m=10.

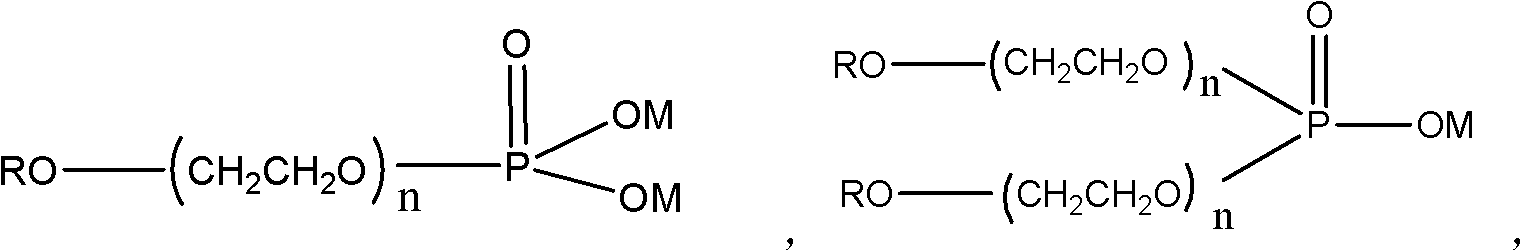

[0037] 2. Isomerized alcohol polyether phosphate (structure as follows) 20 parts

[0038]

[0039] Wherein, R is an isomeric fatty alcohol with 10 carbons; n is 3; M is potassium.

[0040] 3. Octadecylamine polyoxyethylene (10) ether 10 parts

[0041] The above three components are formulated into 0.3% (pre-spinning) and 2.0% (post-spinning) emulsions with pure water, and the pH is adjusted to 8-10.

Embodiment 2

[0043] The proportions of the following components are percentages by weight:

[0044] 1. Polyether modified silicone oil (structure as follows) 75 parts

[0045]

[0046] Where X=8, Y=300, n=15, m=8.

[0047] 2. 16 parts of isomeric alcohol polyether phosphate (structure as follows)

[0048]

[0049] Wherein, R is an isomeric fatty alcohol with 15 carbons; n is 3; M is potassium.

[0050] 3. Hexadecylamine polyoxyethylene (10) ether 9 parts

[0051] The above three components are formulated into 0.3% (pre-spinning) and 2.0% (post-spinning) emulsions with pure water, and the pH is adjusted to 8-10.

Embodiment 3

[0053] The proportions of the following components are percentages by weight:

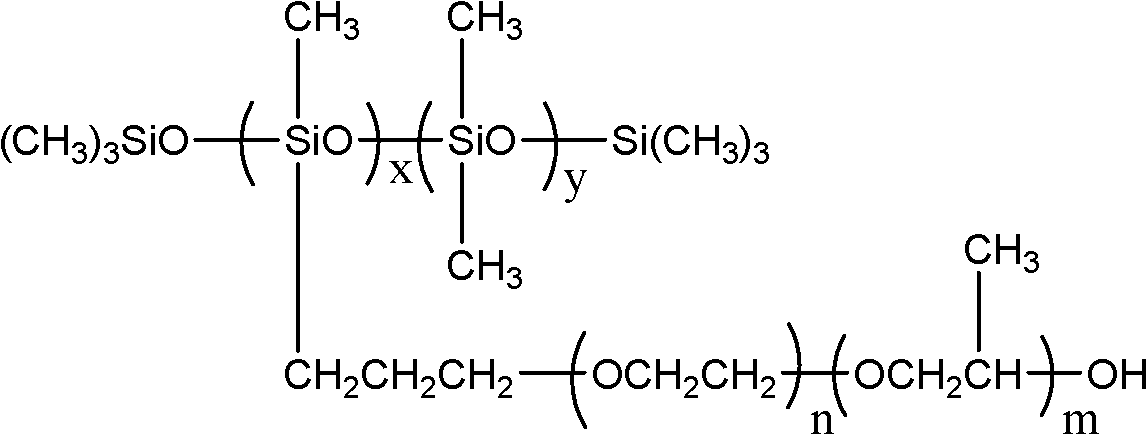

[0054] 1. Polyether modified silicone oil (structure as follows) 80 parts

[0055]

[0056] Where X=5, Y=200, n=25, m=5.

[0057] 2. Isomerized alcohol polyether phosphate (structure as follows) 13 parts

[0058]

[0059] Wherein, R is an isomeric fatty alcohol with 18 carbons; n is 5; M is sodium element.

[0060] 3. Dodecylamine polyoxyethylene (10) ether 7 parts

[0061] The above three components are formulated into 0.3% (pre-spinning) and 2.0% (post-spinning) emulsions with pure water, and the pH is adjusted to 8-10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com