Preparation method of flexible super capacitor based on paper and application thereof

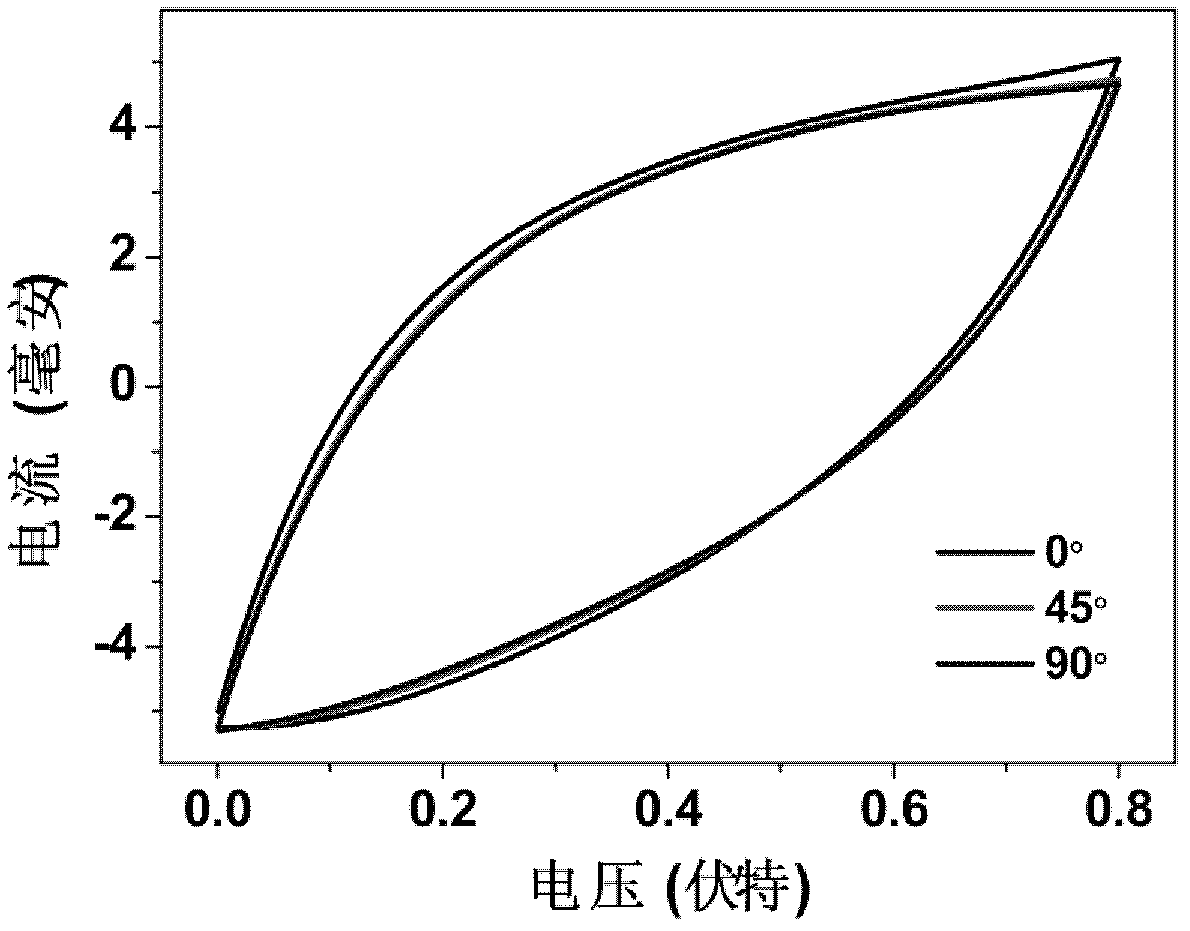

A supercapacitor and paper technology, applied in the field of preparation of supercapacitors, can solve the problems of increased volume and weight of capacitors, unsuitable for portable electronic devices, etc., and achieve the effects of easy production control, suitable for large-scale production, and good electrochemical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

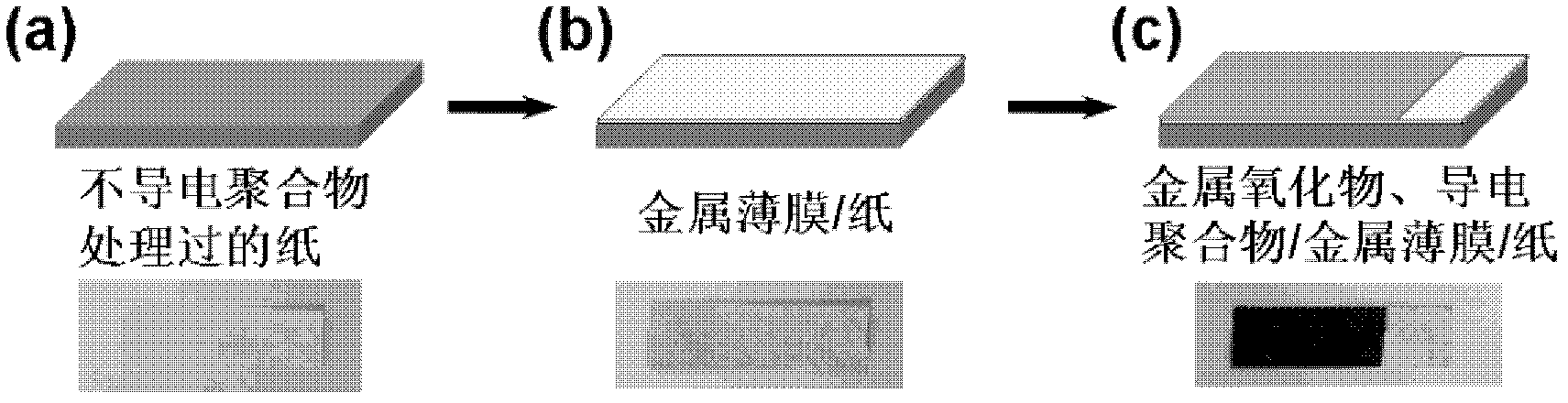

[0024] 1. Cut the printing paper into a suitable size, immerse it in a certain concentration of polyvinyl alcohol aqueous solution, take out and dry the excess water after the paper is soaked.

[0025] 2. Use the paper treated by the above method as a substrate, and use electron beams to evaporate a copper film with a certain thickness. It is enough that the copper film does not fall off under the folding condition.

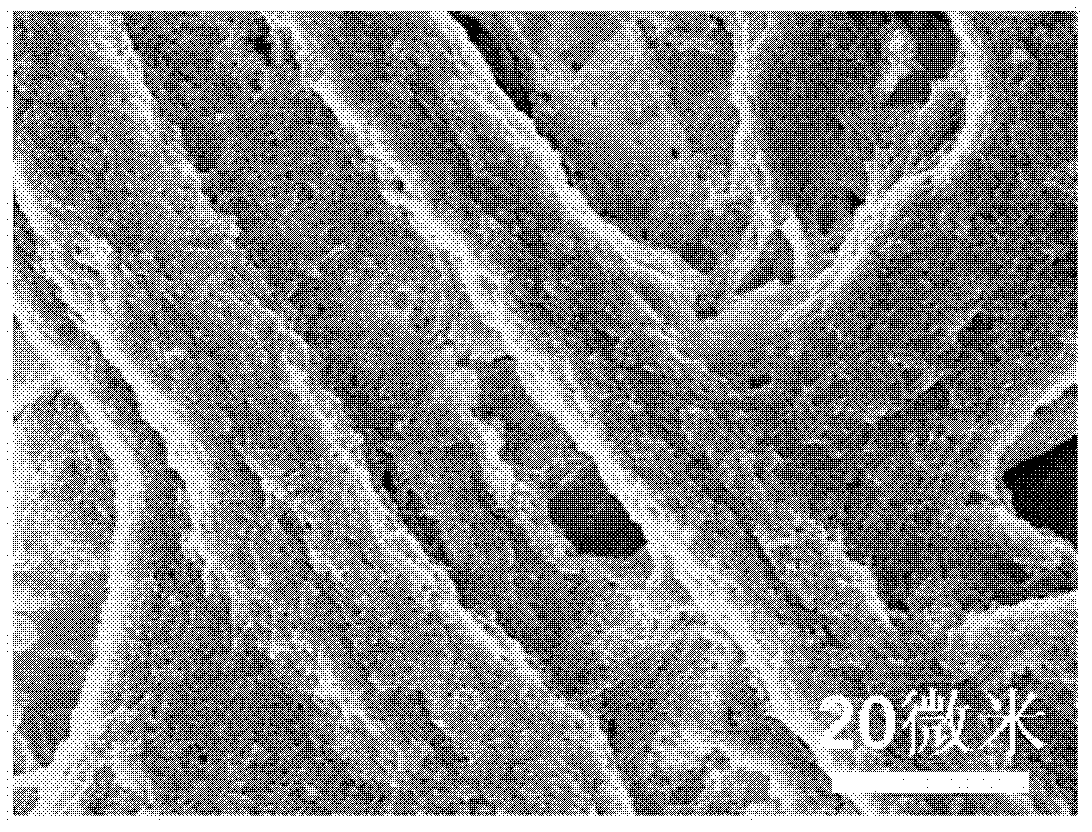

[0026] 3. A polyaniline film with a suitable thickness is grown on the above-mentioned paper deposited with the copper film by solution polymerization. The thickness of the film can be selected and determined according to the actual situation, as long as the thickness of the polyaniline does not fall off, for example, it can be 10-100 microns.

[0027] 4. Take two pieces of paper with polyaniline film grown above and soak them in a mixed solution of polyvinyl alcohol and phosphoric acid at a certain concentration, take them out after a period of time and stick t...

Embodiment 2

[0030] 1. Dissolve a certain quality of polyvinylidene fluoride in methylpyrrolidone, soak a suitable size of newsprint, take it out after the paper is completely soaked, and wait for the solvent to evaporate completely.

[0031] 2. Utilize the magnetron sputtering method to prepare a gold film with a suitable thickness on the above-mentioned treated paper. The thickness of the film can be selected and determined according to the actual situation, as long as the conductivity of the gold film is good and it does not fall off.

[0032] 3. Immerse the paper deposited with the gold film in a mixed solution of a certain concentration of manganese acetate and ammonium acetate, and deposit a certain amount of manganese oxide on the gold film by electrodeposition.

[0033] 4. Take two sheets of paper deposited with manganese oxide and soak them in a mixed solution of polyvinyl alcohol and sulfuric acid at a certain concentration for a certain period of time, then take them out and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com