Flexible light bar

A technology of flexible light strips and flexible circuit boards, which is applied in the direction of damage prevention measures for lighting devices, lighting devices, light sources, etc., and can solve problems such as difficult shaping, easy damage to flexible circuit boards, and good bendability of flexible light strips. Achieve good bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

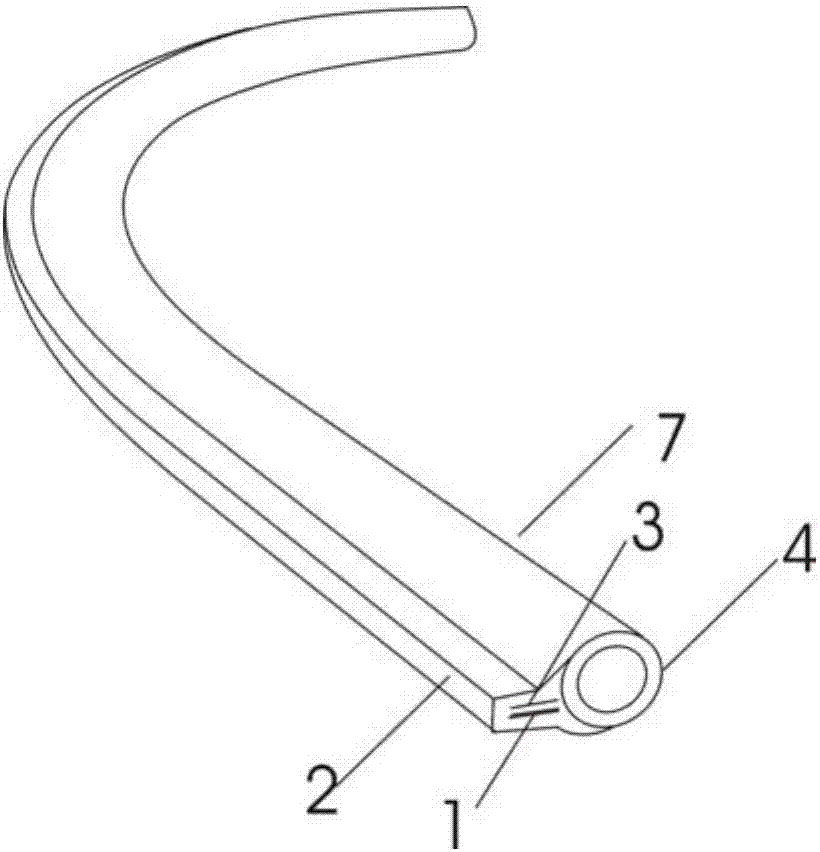

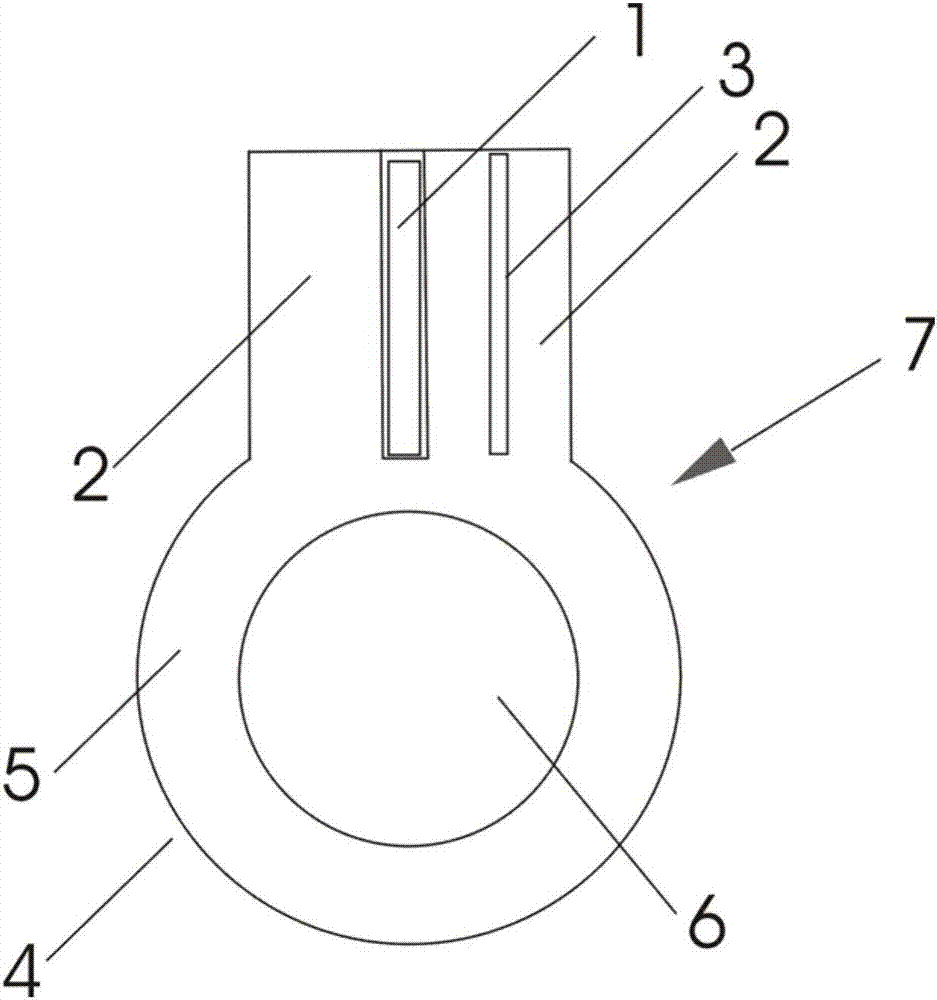

[0046] See figure 1 , 2 , the covering body 7 includes a circuit board covering part 2 and an annular part 4 , the circuit board covering part 2 is connected to the upper end of the annular part 4 , and the annular part 4 has a side part 5 and a first through hole 6 . A flexible circuit board 1 is longitudinally arranged in the middle of the circuit board covering part 2 , and a metal sheet 3 is arranged inside the circuit board covering part 2 on the right side of the flexible circuit board 1 , parallel to the flexible circuit board 1 . The main function of the annular part 4 is to make the light become an annular aperture. The LED lights in the flexible circuit board 1 can be set to emit light from the front or side.

Embodiment 2

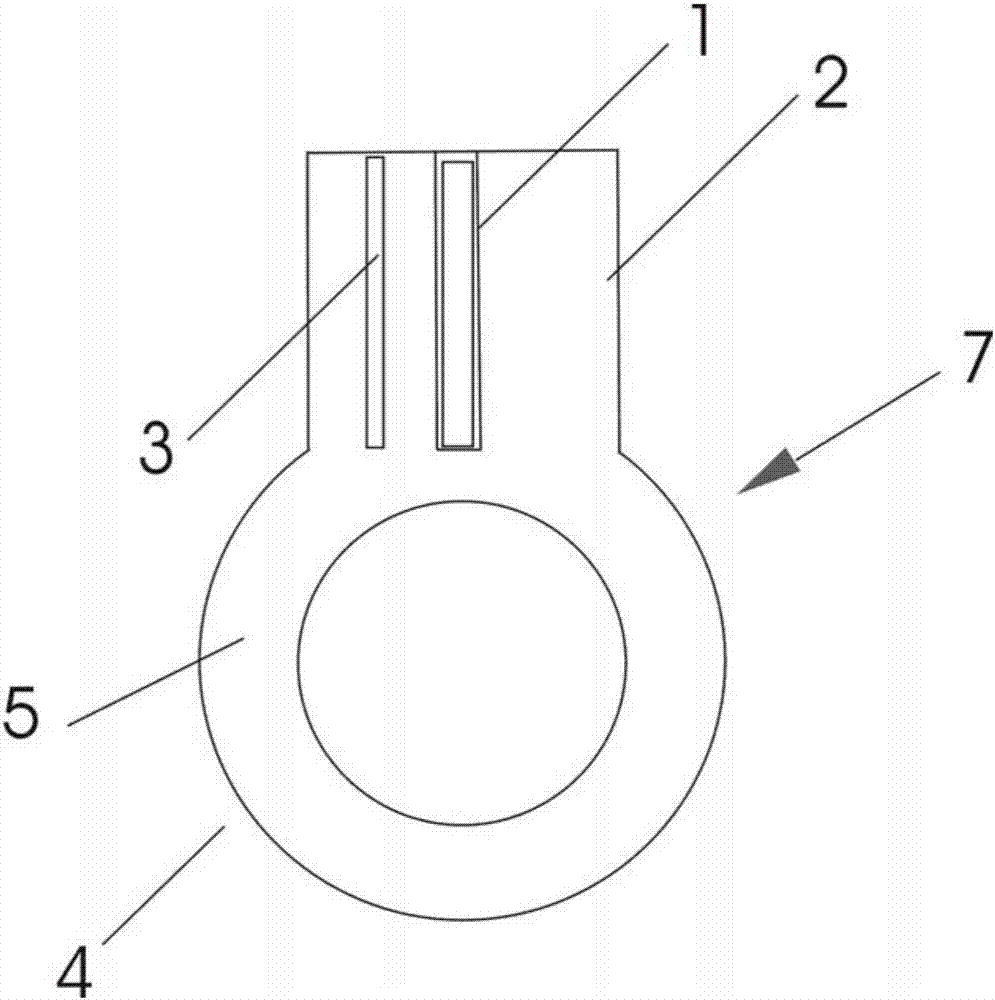

[0048] See image 3 The difference between this embodiment and Embodiment 1 is that the metal sheets 3 are respectively arranged inside the left side of the circuit board covering part 2 .

Embodiment 3

[0050] See Figure 4 The difference between this embodiment and Embodiment 1 is that two pieces of metal sheets 3 are respectively arranged inside the two sides of the circuit board covering part 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com