COF preparation method

A technology of temporary substrates and flexible films, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems that the precision cannot meet the development needs of the display device field, and the precision is poor, so as to improve the effective utilization rate and reliability. Good bending ability and high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

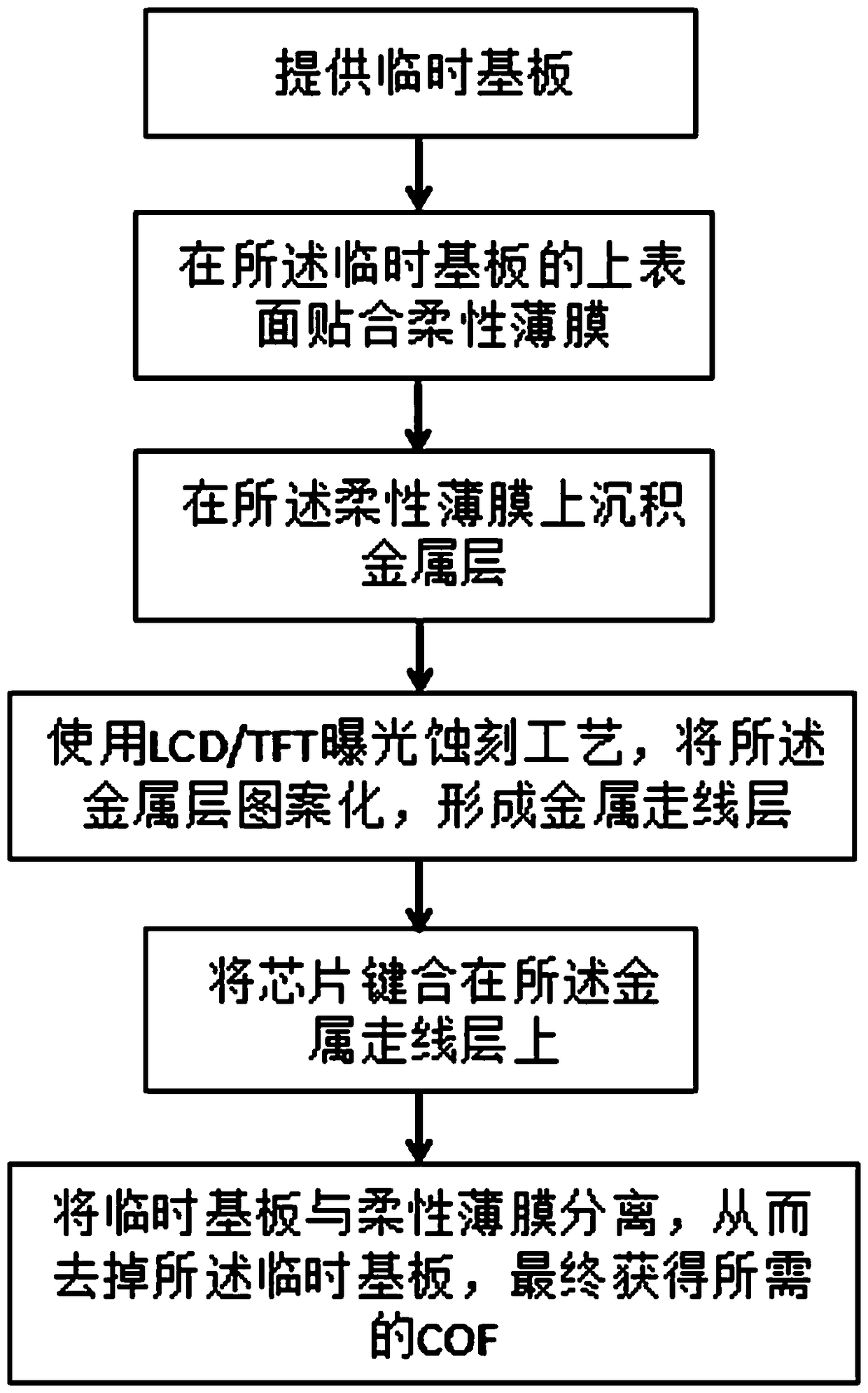

[0028] figure 1 A flow chart of a COF preparation method provided by the present invention is shown. This embodiment is a COF preparation method for single-layer wiring. Specifically, the COF preparation method includes the following steps:

[0029] (a) provision of temporary substrates;

[0030] (b) pasting a flexible film on the upper surface of the temporary substrate;

[0031] (c) depositing a metal layer on said flexible film;

[0032] (d) using an LCD / TFT exposure etching process to pattern the metal layer to form a metal wiring layer;

[0033] (e) Bonding the chip on the metal wiring layer;

[0034] (f) Separating the temporary substrate from the flexible film, thereby removing the temporary substrate and finally obtaining the desired COF.

[0035] It is worth noting that the present invention uses the LCD / TFT exposure etching process to replace the traditional TAPE process, so that the final circuit has higher precision and better flexibility, and improves the ef...

Embodiment 2

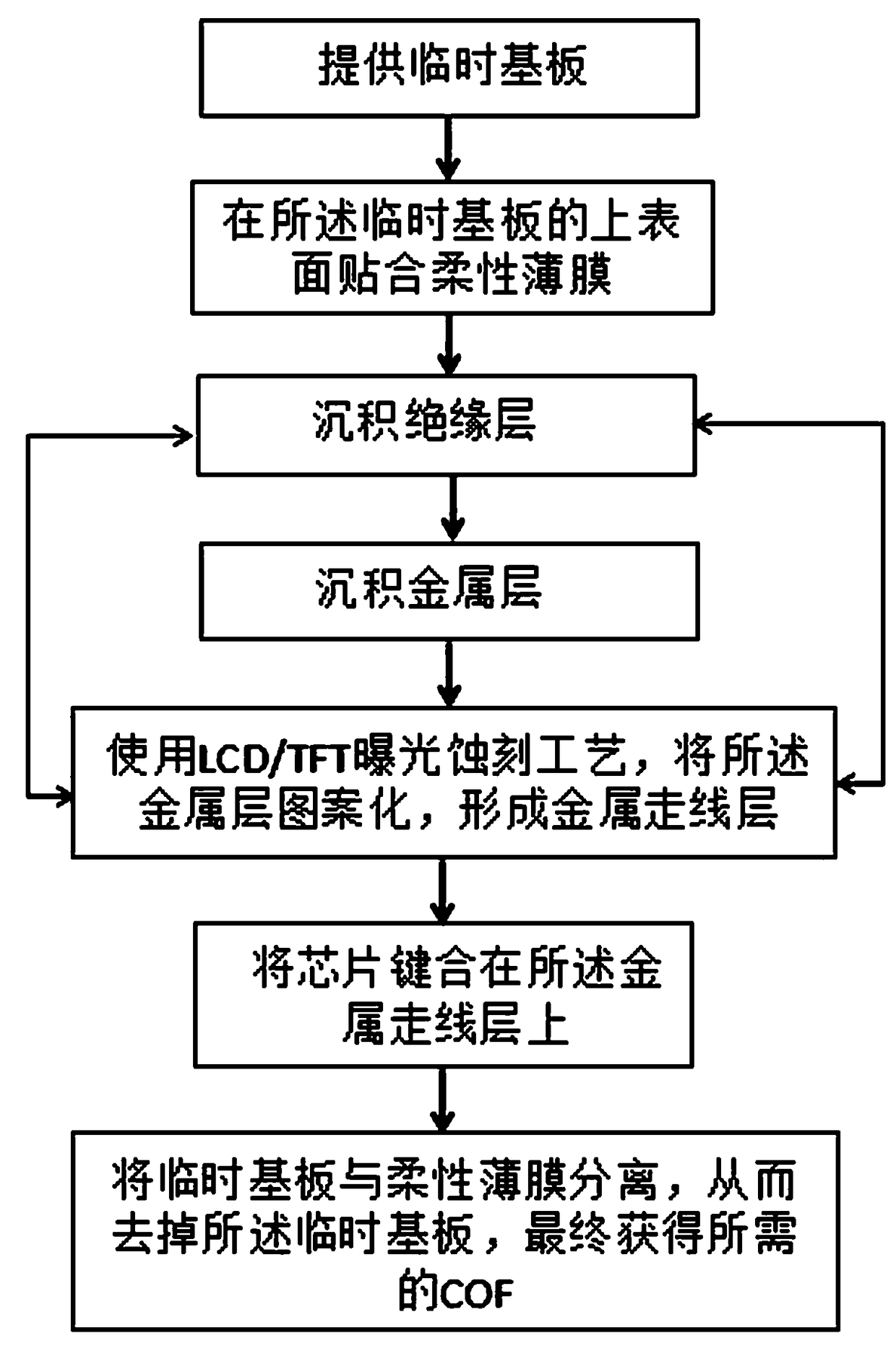

[0041] figure 2 A flow chart of a COF preparation method provided by another embodiment of the present invention is shown. This embodiment is a COF preparation method for multi-layer routing. Specifically, the COF preparation method includes the following steps:

[0042] (a) provision of temporary substrates;

[0043] (b) pasting a flexible film on the upper surface of the temporary substrate;

[0044] (c1) Deposit the insulating layer first;

[0045] (c2) depositing a metal layer on the insulating layer;

[0046] (d) using an LCD / TFT exposure etching process to pattern the metal layer to form a metal wiring layer;

[0047] Repeat the above steps (c1), (c2) and (d) according to the predetermined number of times;

[0048] (e) Bond the chip on the metal wiring layer;

[0049] (f) Separating the temporary substrate from the flexible film, thereby removing the temporary substrate and finally obtaining the desired COF.

[0050] It should be noted that the LCD / TFT exposure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com