A rapid assembly method for a radiation unit with a special-shaped cavity

A radiation unit and assembly method technology, applied in the field of communication, can solve problems such as low efficiency, repeated disassembly, poor installation accuracy and consistency, and achieve the effects of improving accuracy, avoiding extrusion, and optimizing the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail by the following examples. It is necessary to point out that this example is only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention. Those skilled in the art can according to the above invention Some non-essential improvements and adjustments have been made to the content. In the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

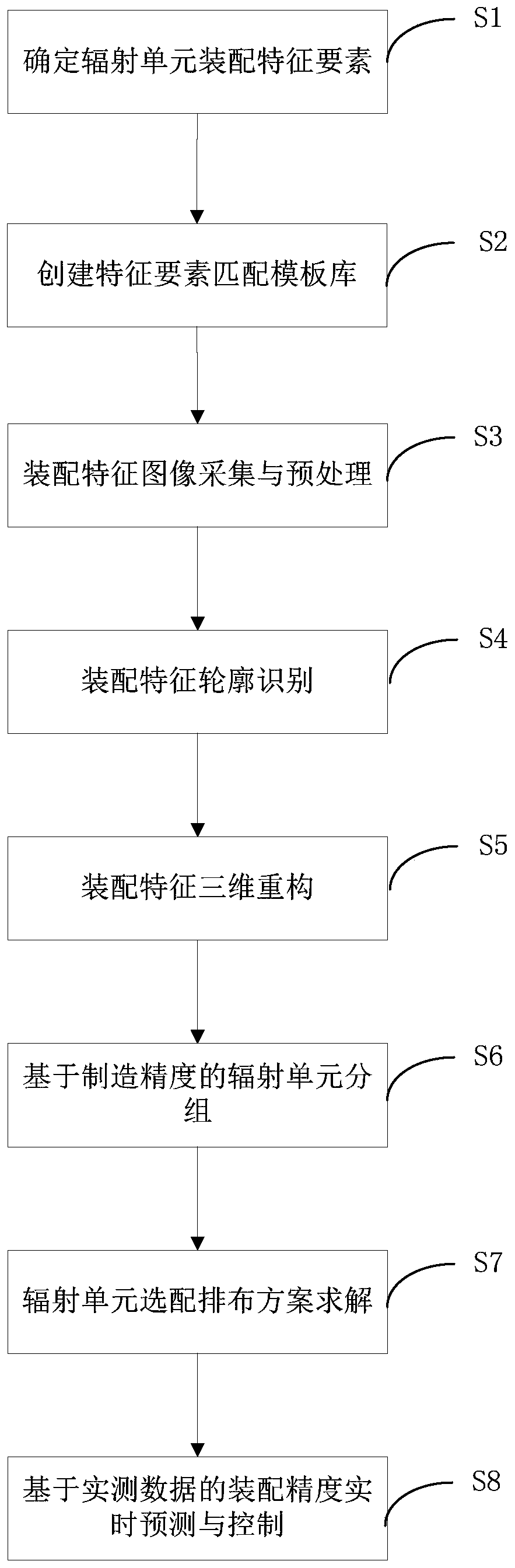

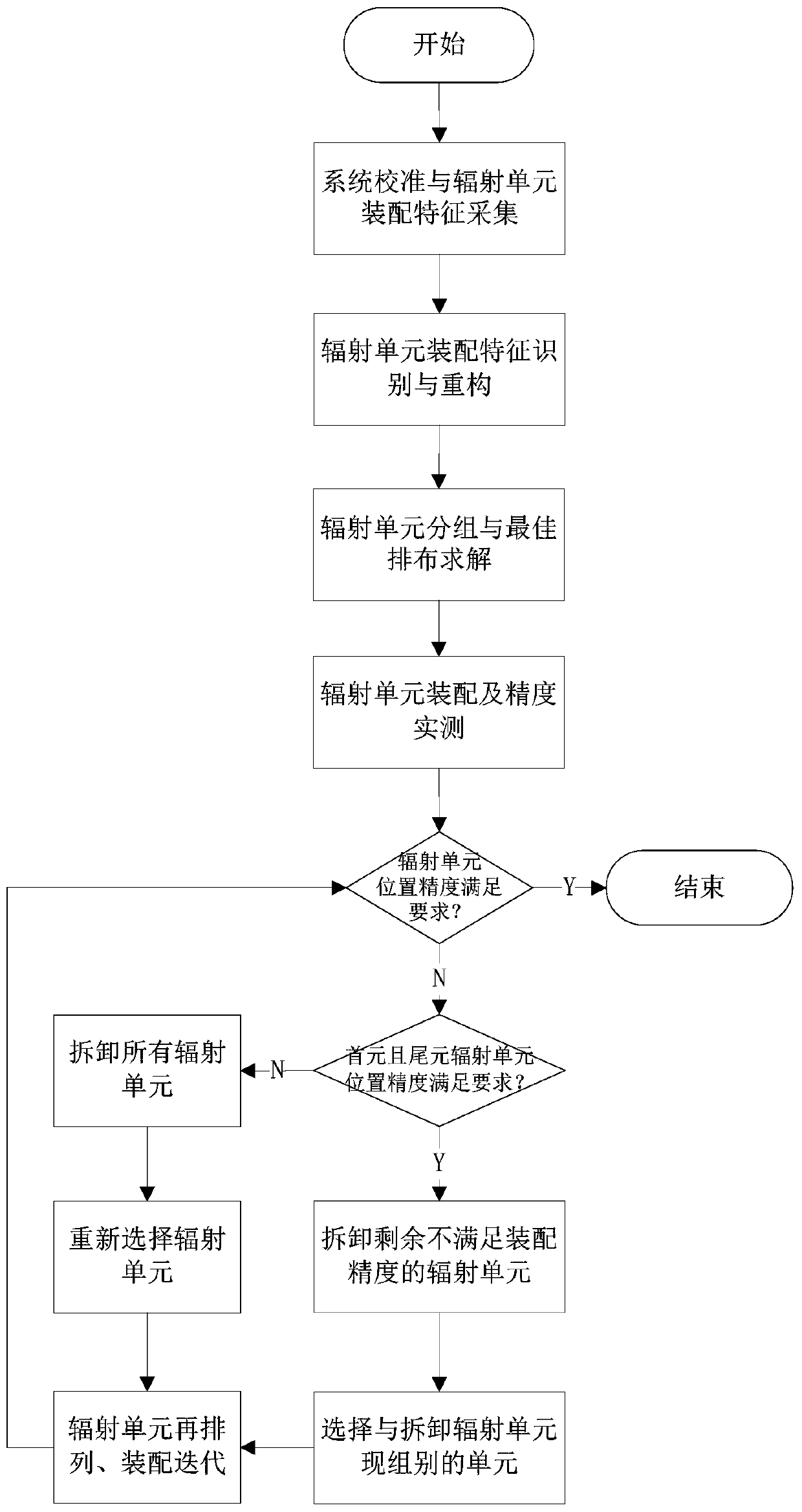

[0034] A rapid assembly method for a radiation unit with a special-shaped cavity, such as figure 1 shown, including the following steps:

[0035] S1: Determine the assembly feature elements of the radiation unit

[0036] The radiation unit assembly feature elements of the present invention refer to the key geometric feature areas (such as installation holes, mouth edges, etc.) related to the physical assembly quality of the radiation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com