A kind of polyvinyl butyral synthesis process based on microdispersion technology

A polyvinyl butyral synthesis process technology, applied in the field of polyvinyl butyral synthesis process, can solve problems such as difficult precise control, affecting product quality, strong randomness of reaction, etc., to achieve enhanced dissolution and reaction, and guaranteed Batch stability, guaranteed high acetalization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

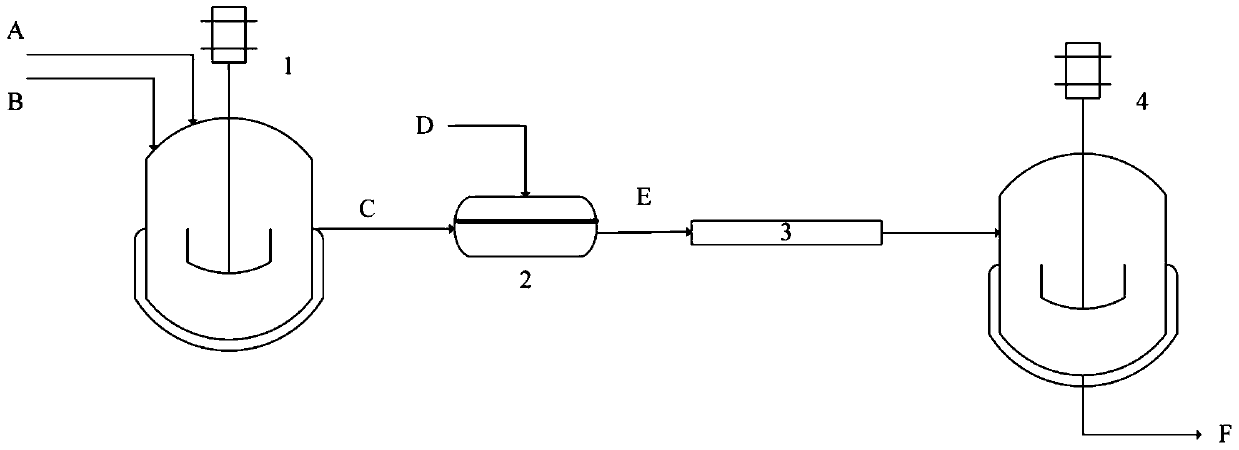

[0036] Process device: use a stirred tank as the mixer 1, use a membrane dispersion device filled with a 5μm metal sintered film as a microdisperser 2, use a single-row tubular tubular reactor 3 with a temperature control jacket, and use a heat exchange clamp The set of stirred tank is used as collection tank 4.

[0037] Reaction conditions: the mass fraction of PVA in the PVA aqueous solution A is 10%; the mass fraction of HCl in the HCl aqueous solution B is 31%, and the mass ratio of HCl to PVA in the mixed material liquid C is 0.08:1; The mass ratio of butyraldehyde D to PVA is 0.70:1. The mixing temperature of the mixer 1 is 25°C; the operating temperature of the microdisperser 2 is 50°C, and the material residence time is 7s; the reaction temperature of the tubular reactor 3 is 50°C, and the reaction time is 2min; the collection temperature of the collector 4 The temperature was 55°C and the collection time was 6.0h.

[0038] Reaction result: The acetal degree of the produc...

Embodiment 2

[0040] Reaction device: use a microchannel mixer as the mixer 1, use a micro-mesh dispersing device with a diameter of 500 μm as a microdisperser 2, use a single-row tubular tubular reactor 3 with a temperature control jacket, and use a heat exchanger The jacketed stirred tank is used as the collecting tank 4.

[0041] Reaction conditions: the mass fraction of PVA in the PVA aqueous solution A is 8%; the mass fraction of HCl in the HCl aqueous solution B is 36%, and the mass ratio of HCl to PVA in the mixed material liquid C is 0.25:1; added to the mixed material liquid C The mass ratio of n-butyraldehyde D to PVA is 0.63:1. The mixing temperature of the mixer 1 is 20°C; the operating temperature of the microdisperser 2 is 30°C, and the material residence time is 20s; the reaction temperature of the tubular reactor 3 is 75°C, and the reaction time is 5 minutes; the collection temperature of the collector 4 The temperature is 75°C and the collection time is 3.5h.

[0042] Reaction...

Embodiment 3

[0044] Reaction device: a static mixer is used as the mixer 1, a membrane dispersion device filled with a 20μm metal sintered film is used as a microdisperser 2, a single-row tubular tubular reactor 3 with a temperature control jacket is used, and a heat exchange is used The jacketed stirred tank is used as the collecting tank 4.

[0045] Reaction conditions: the mass fraction of PVA in the PVA aqueous solution A is 12%; the mass fraction of HCl in the HCl aqueous solution B is 30%, and the mass ratio of HCl to PVA in the mixed material liquid C is 0.10:1; added to the mixed material liquid C The mass ratio of n-butyraldehyde D to PVA is 0.60:1. The mixing temperature of the mixer 1 is 23°C; the operating temperature of the microdisperser is 42°C, and the material residence time is 10s; the reaction temperature of the tubular reactor 3 is 50°C, and the reaction time is 30min; the collection temperature of the collecting tank 4 is The collection time is 9.0h at 50°C.

[0046] Reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com