LiFePO4/CG compounded anode material prepared by liquid phase synthesis-microwave solid phase sintering method

A composite positive electrode material and liquid phase synthesis technology, which is applied in the direction of electrode manufacturing, battery electrodes, structural parts, etc., can solve the problem of low electronic conductivity and achieve good cycle performance, uniform heating, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

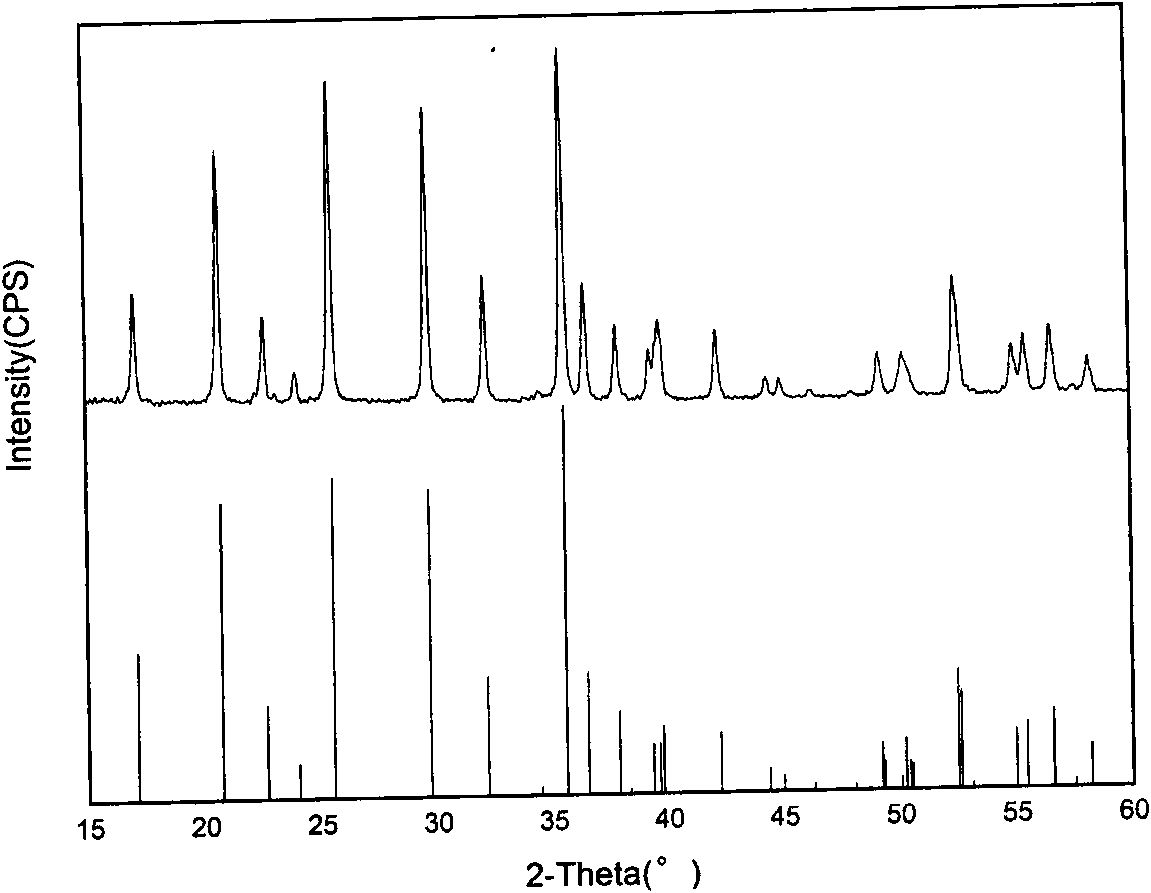

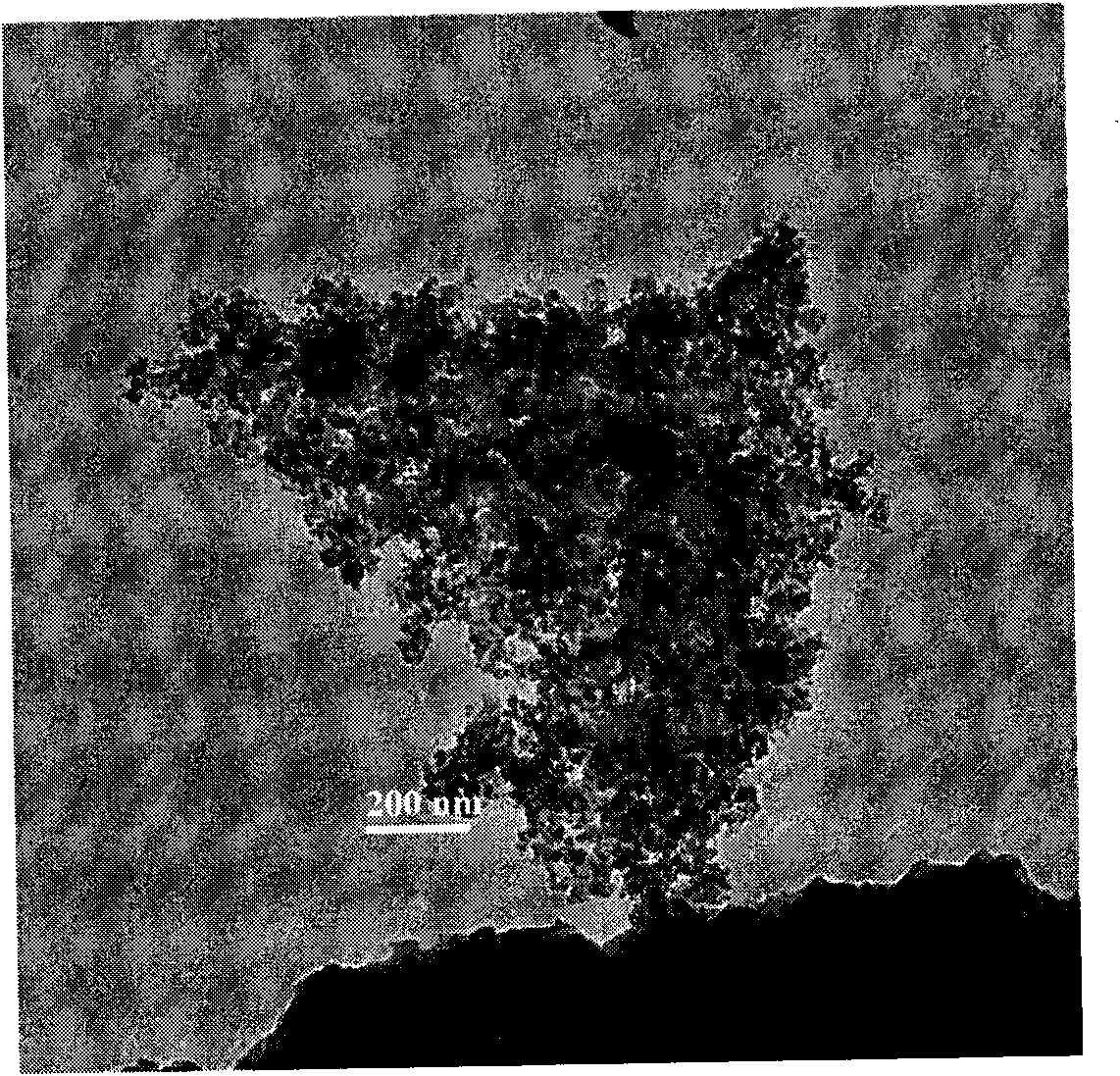

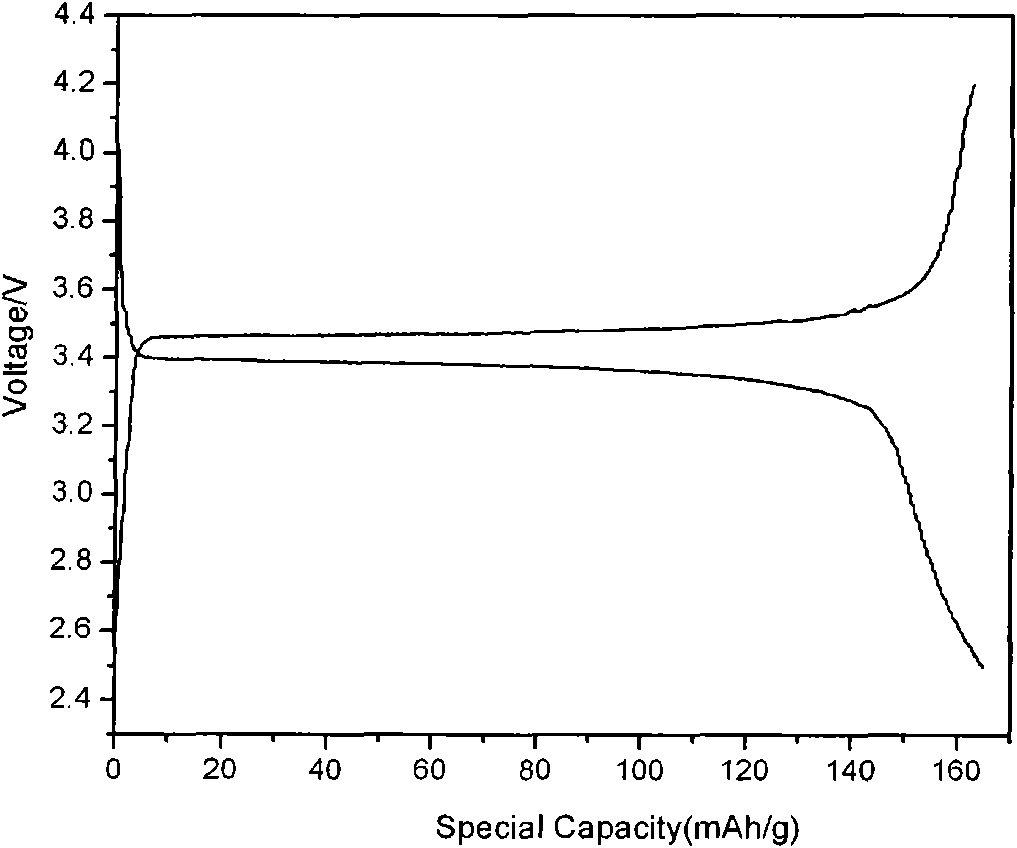

Embodiment 1

[0035] Weigh a certain amount of Fe according to the molar ratio Li:Fe:P=1.0:1.0:1.0 2 (C 2 o 4 ) 3 and LiH 2 PO 4 , dissolved in deionized water to form a solution with a concentration of 0.5mol / L, and adding CRF (carbon aerogel) and PEG400 thereto, the amount added is respectively 5% and 2% of the theoretical amount of lithium iron phosphate, stirring 1h to make CRF and PEG400 uniformly dispersed in the suspension. Then add the suspension to the reaction bottle, dry at 60°C for 1 hour, and evaporate the water to dryness to obtain the precursor powder. Then grind the obtained precursor powder and put it into a microwave oven with a frequency of 2.46GHz. Under microwave sintering, control the microwave power to 500W, and heat for 10min, you can get LiFePO 4 / CRF composite cathode material. The primary particle size of the prepared material is 1-2 μm, the discharge specific capacity reaches 152mAh / g at 0.1C rate, and 100mAh / g at 1C rate.

Embodiment 2

[0037] Weigh a certain amount of FeC according to the molar ratio Li:Fe:P=1.0:1.0:1.0 2 o 4 and LiH 2 PO 4 , dissolved in deionized water to form a solution with a concentration of 0.5mol / L, and adding CRF (carbon aerogel) and PEG400 thereto, the amount added is respectively 5% and 2% of the theoretical amount of lithium iron phosphate, stirring 1h to make CRF and PEG400 uniformly dispersed in the suspension. Then add the suspension to the reaction bottle, dry at 60°C for 1 hour, and evaporate the water to dryness to obtain the precursor powder. Then grind the obtained precursor powder and put it into a microwave oven with a frequency of 2.46GHz. Under microwave sintering, control the microwave power to 500W, and heat for 10min, you can get LiFePO 4 / CRF composite cathode material. The primary particle size of the prepared material is 1-2 μm, the discharge specific capacity reaches 148mAh / g at 0.1C rate, and 96mAh / g at 1C rate.

Embodiment 3

[0039] Weigh a certain amount of Fe according to the molar ratio Li:Fe:P=1.0:1.0:1.0 2 (C 2 o 4 ) 3 and LiH 2 PO 4 , be dissolved in deionized water to form a solution with a concentration of 0.5mol / L, and add CRF (carbon aerogel) and PEG400 thereto, the added amount is respectively 5% and 5% of the theoretical amount of lithium iron phosphate, stirring 1h to make CRF and PEG400 uniformly dispersed in the suspension. Then add the suspension to the reaction bottle, dry at 60°C for 1 hour, and evaporate the water to dryness to obtain the precursor powder. Then grind the obtained precursor powder and put it into a microwave oven with a frequency of 2.46GHz. Under microwave sintering, control the microwave power to 500W, and heat for 10min, you can get LiFePO 4 / CRF composite cathode material. The primary particle size of the prepared material is 0.5-1 μm, the discharge specific capacity reaches 165mAh / g at 0.1C rate, and 112mAh / g at 1C rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com