Method for recycling post-industrial recycling waste plastic

A recycling method and waste plastic technology, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of inappropriateness and low utilization value, achieve high performance retention rate, compact and complete process method, and avoid performance degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

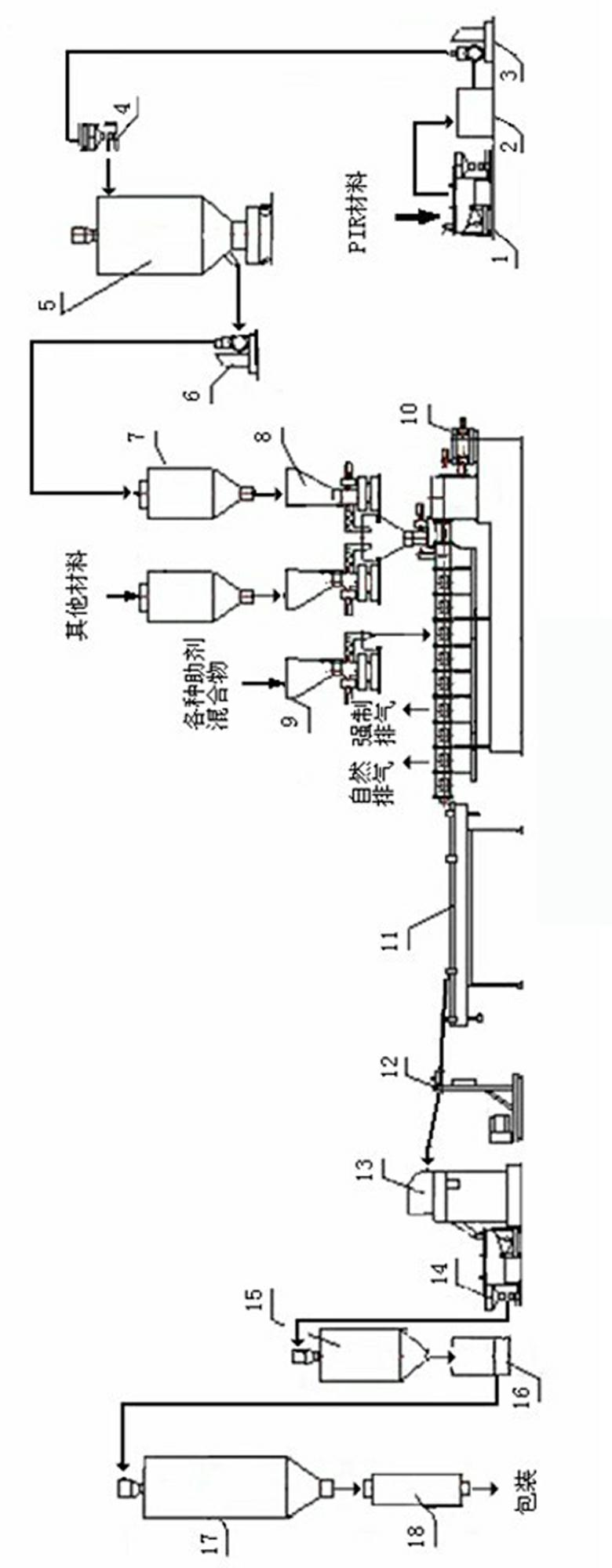

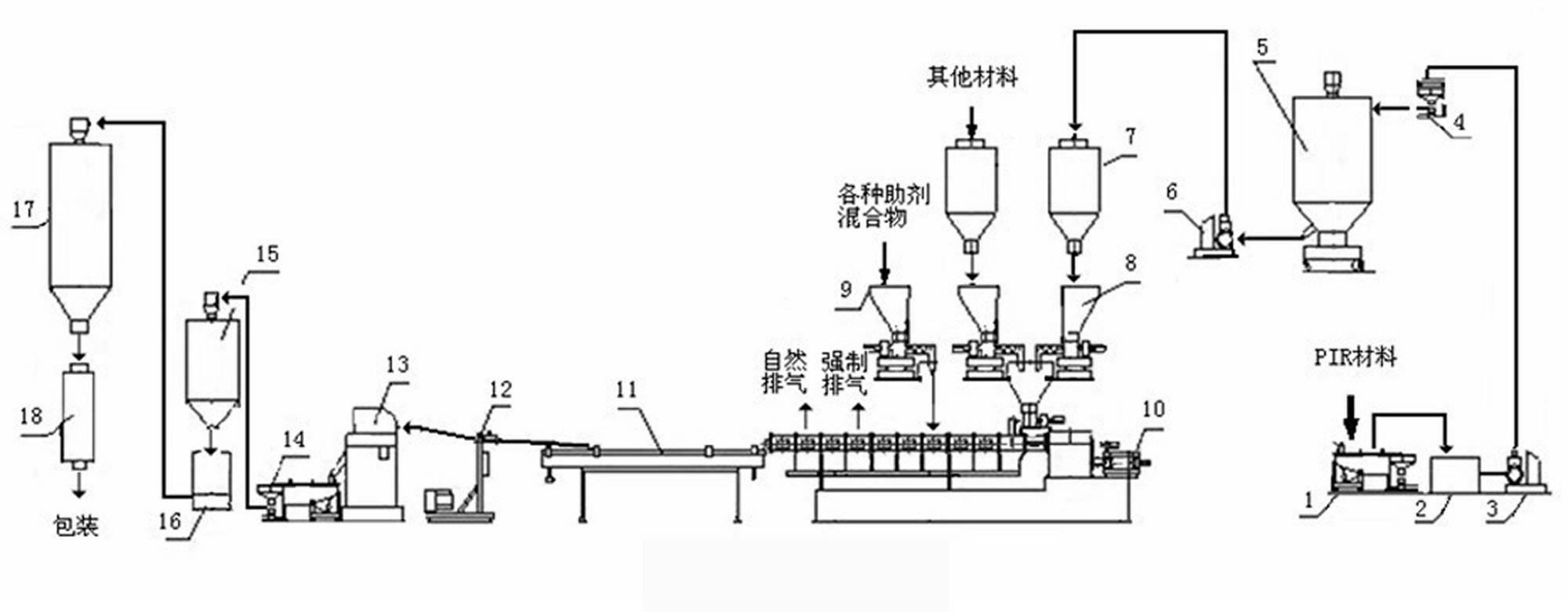

Method used

Image

Examples

Embodiment 1

[0047] The PIR polycarbonate material of embodiment 1 is selected from the mixture of modified materials such as polycarbonate containing flame retardant, polycarbonate / acrylonitrile-butadiene-styrene copolymer (mainly derived from components such as electrical housings) Manufacturer company).

Embodiment 2

[0048] The PIR polycarbonate material of embodiment 2 is selected from the mixture ( Mainly from manufacturers of laptop casings and other components).

Embodiment 3

[0049] The PIR polycarbonate material of Example 3 is selected from a mixture of polycarbonate modified materials containing mineral fillers, glass fibers, metal coatings, etc. (mainly sourced from manufacturers of automotive parts).

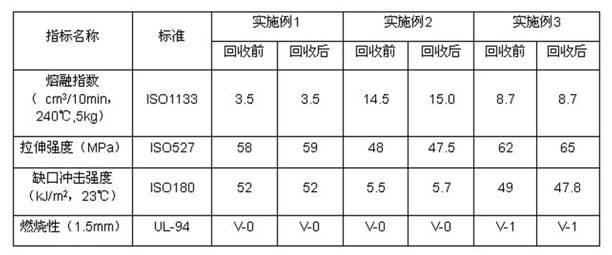

[0050] The physical and chemical properties of table 1 PIR polycarbonate material before and after granulation through the recovery method of the present invention are contrasted

[0051]

[0052] As can be seen from the above table, the performance of the material does not change substantially, which shows that the recovery method of the present invention can make the material have a very high performance retention rate when recycling the PIR polycarbonate material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com