Microwave exractor

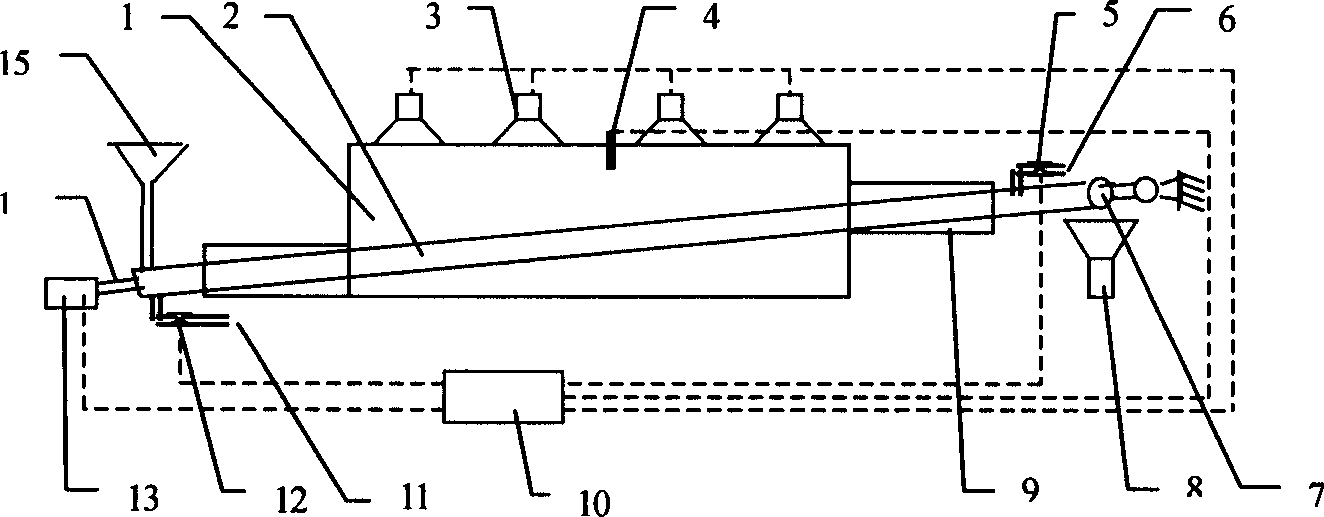

An extraction device and microwave technology, which is applied in the field of microwave extraction devices, can solve the problems of inability to realize continuous large-scale production, high processing temperature, and low processing efficiency, and achieve the effects of continuous operation, high processing efficiency, and increased processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

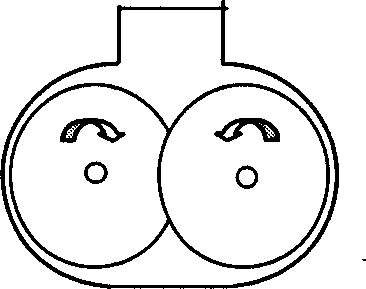

Method used

Image

Examples

Embodiment 1

[0022] The pre-broken sugarcane is sent to the extraction device, the processing capacity is 30kg / hour, the bagasse takes about 15 minutes from entering to discharging, the amount of water added per hour is 150kg, microwave power is added to 10kW, and the temperature is controlled at 90-95°C to obtain 140kg of extracted juice, the recorded refraction hammer (solid matter accounts for the mass percentage of solution) is 2.69 ° Bx, and the sucrose content (light conversion) is 2.62%. After calculation, 3.76kg of dry solids are extracted altogether, and sucrose is 3.67kg. And adopt Soxhlet extraction, same 30 kilograms of bagasse add 300kg water, heat and reflux 180 minutes, finally obtain the extract of 290kg, Brix is 1.28 ° of Bx, and sucrose content (light conversion degree) is 1.23%, calculates and obtains dry solid matter altogether It is 3.71kg, and sucrose is 3.60kg. However, if a closed batch industrial microwave oven is used for extraction, only 5 kg of bagasse and 30 ...

Embodiment 2

[0024] Utilize this system to process Luo Han Guo, extract mogrosides, process 10 kilograms of Luo Han Guo (through crushing) in the same way, add 300 liters of 50% alcohol, the processing time is 26 minutes, control the leaching temperature to be 70 ° C, and obtain 745 g of Luo Han Guo saponins. Using the Soxhlet method for extraction, with the same treatment capacity and solid-liquid ratio, reflux for 120 minutes to finally obtain 725g mogroside. With the same processing capacity and solid-to-liquid ratio, the intermittent microwave industrial extraction system is used for extraction. Each batch can be filled with a capacity of 30 liters, and the processing time of each batch is 10 minutes. It takes a total of 100 minutes to obtain about 739g of mogrosides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com