Loader and bucket loading operation control method thereof

A control method and loader technology, applied to mechanically driven excavators/dredgers, etc., can solve problems such as low efficiency, and achieve the effects of reducing energy consumption, continuous operation, and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

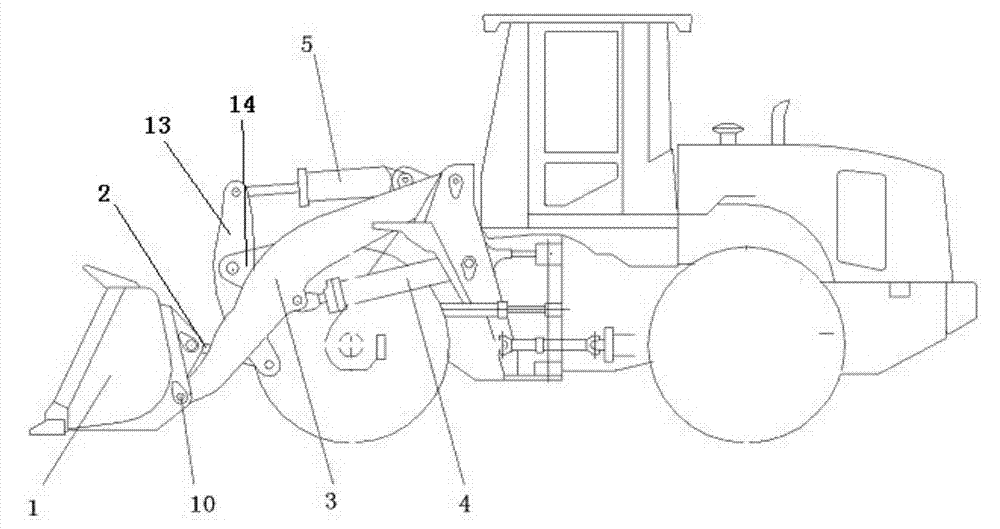

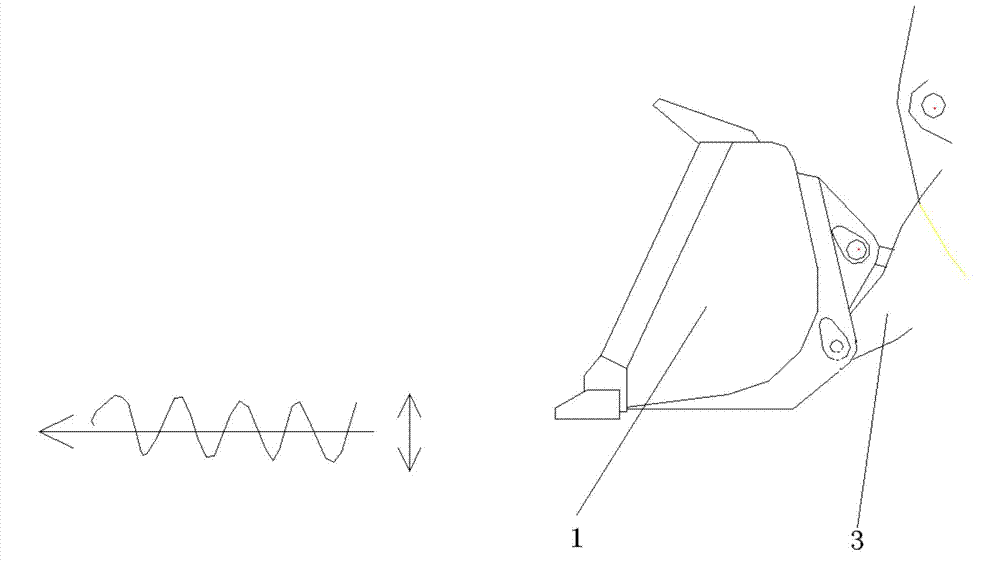

[0022] Such as figure 1 As shown, the loader includes a bucket 1, a bucket connecting rod 2, a bucket rocker arm 13, a boom 3, a boom cylinder 4, and a bucket cylinder 5, and the front of the two booms passes through a box-shaped connecting part 14 Fixed connection, the front end of the boom 3 is hinged with the bucket through the bucket rotation pin 10, the rear end of the boom 3 is hinged with the frame through the boom rotation pin, one end of the boom cylinder 4 is hinged with the boom, and the other end Hinged with the vehicle frame; one end of the bucket cylinder 5 is hinged with the vehicle frame, the other end is connected through the bucket rocker arm 13, the middle part of the bucket rocker arm 13 is hinged with the box-shaped connecting part 14, and the other end of the bucket rocker arm 13 is passed through The bucket connecting rod 2 drives the bucket 1 to rotate around the hinge pin of the bucket and the boom. The expansion and contraction of the boom oil cylind...

Embodiment 2

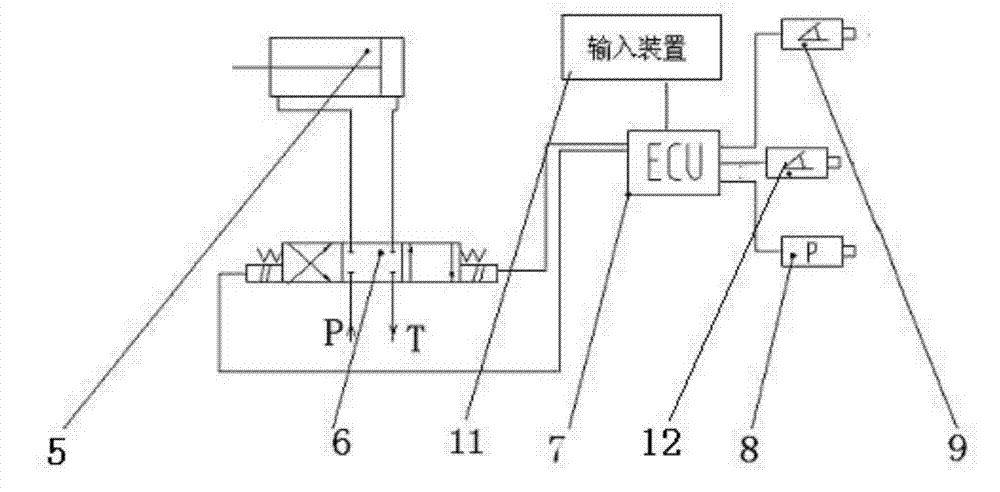

[0028] Compared with the technical solution in embodiment 1, the difference of the technical solution in this embodiment lies in the electronic control device for controlling the solenoid valve and the control of the solenoid valve. Such as Figure 4 As shown, the electronic control device is composed of a controller 7 and an input device 11. The controller 7 is used to send a control signal to the solenoid valve 6 to make the solenoid valve 6 act according to the set frequency and amplitude. The input device 11 is connected to the controller 7. It is used to input signals to the controller to make the controller select the corresponding control signal and send it to the solenoid valve. The input device can be a plurality of associated button switches or knob switches. The position and control of the knob of each button switch or each knob switch A signal sent by the controller to the solenoid valve corresponds to a frequency and amplitude of bucket swing. The manual control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com