Scale

A sensor and measuring hopper technology, applied in the field of weighing instruments, can solve the problems of rough weighing accuracy, low work efficiency, and no mutual compensation of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

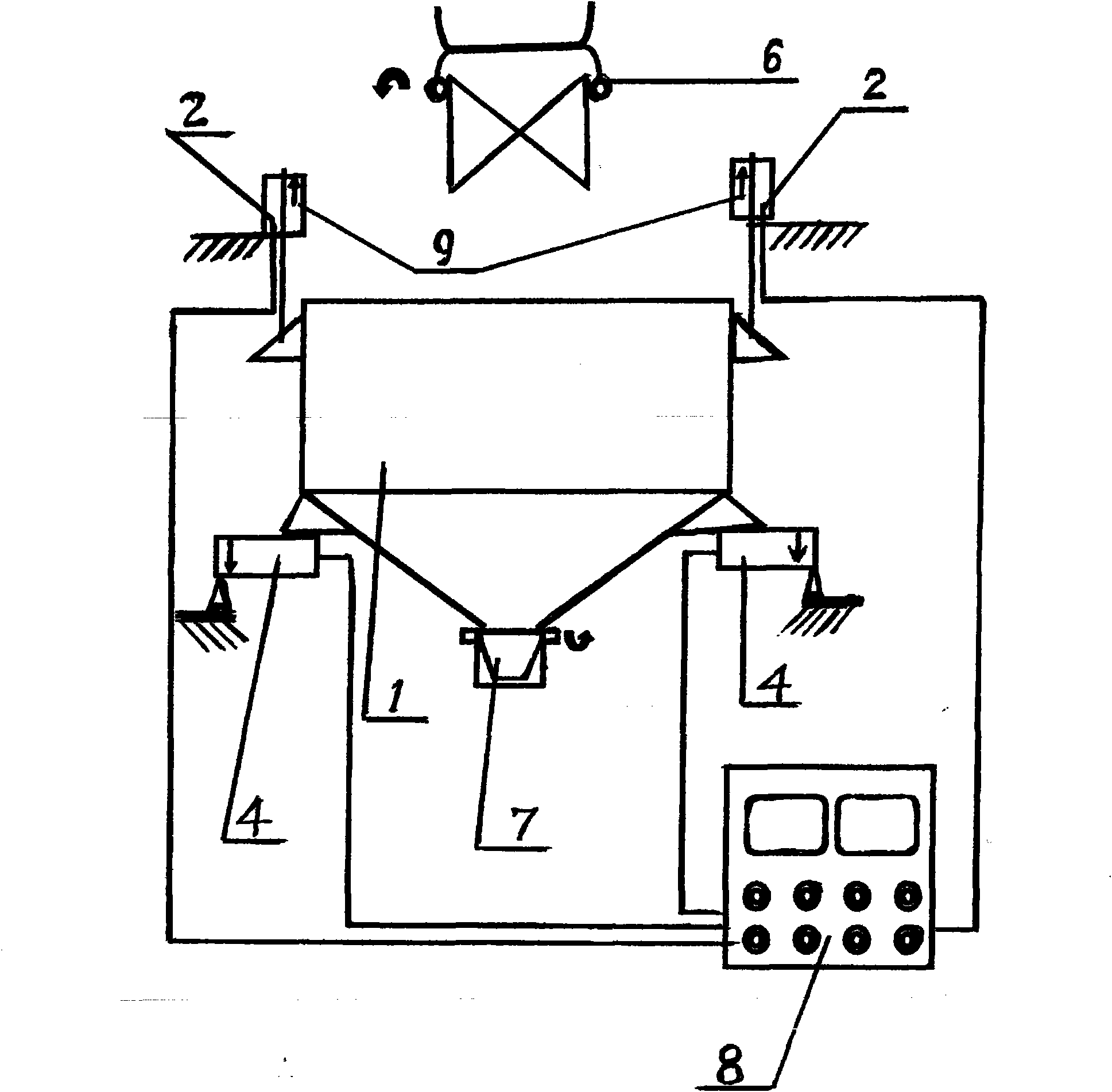

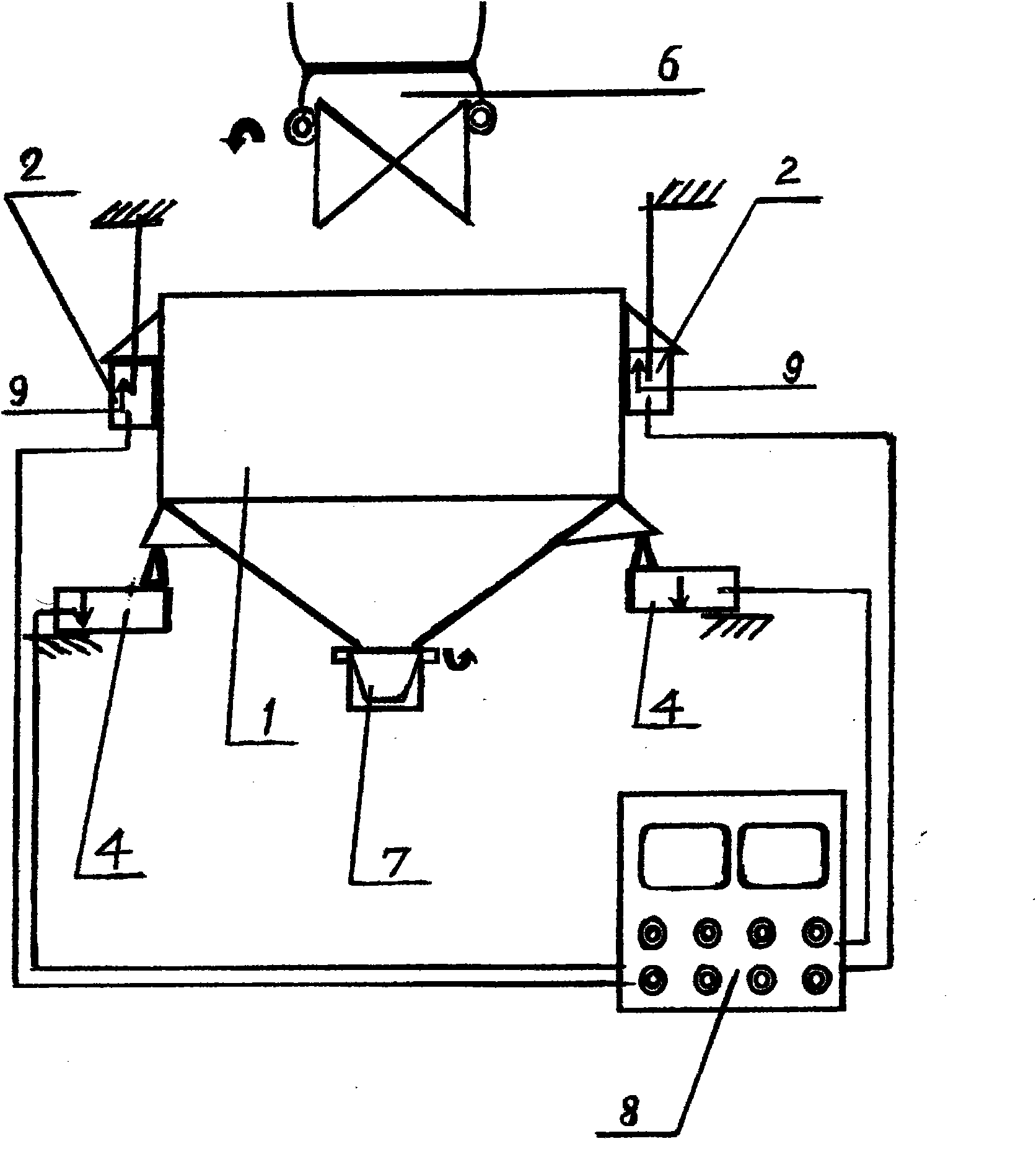

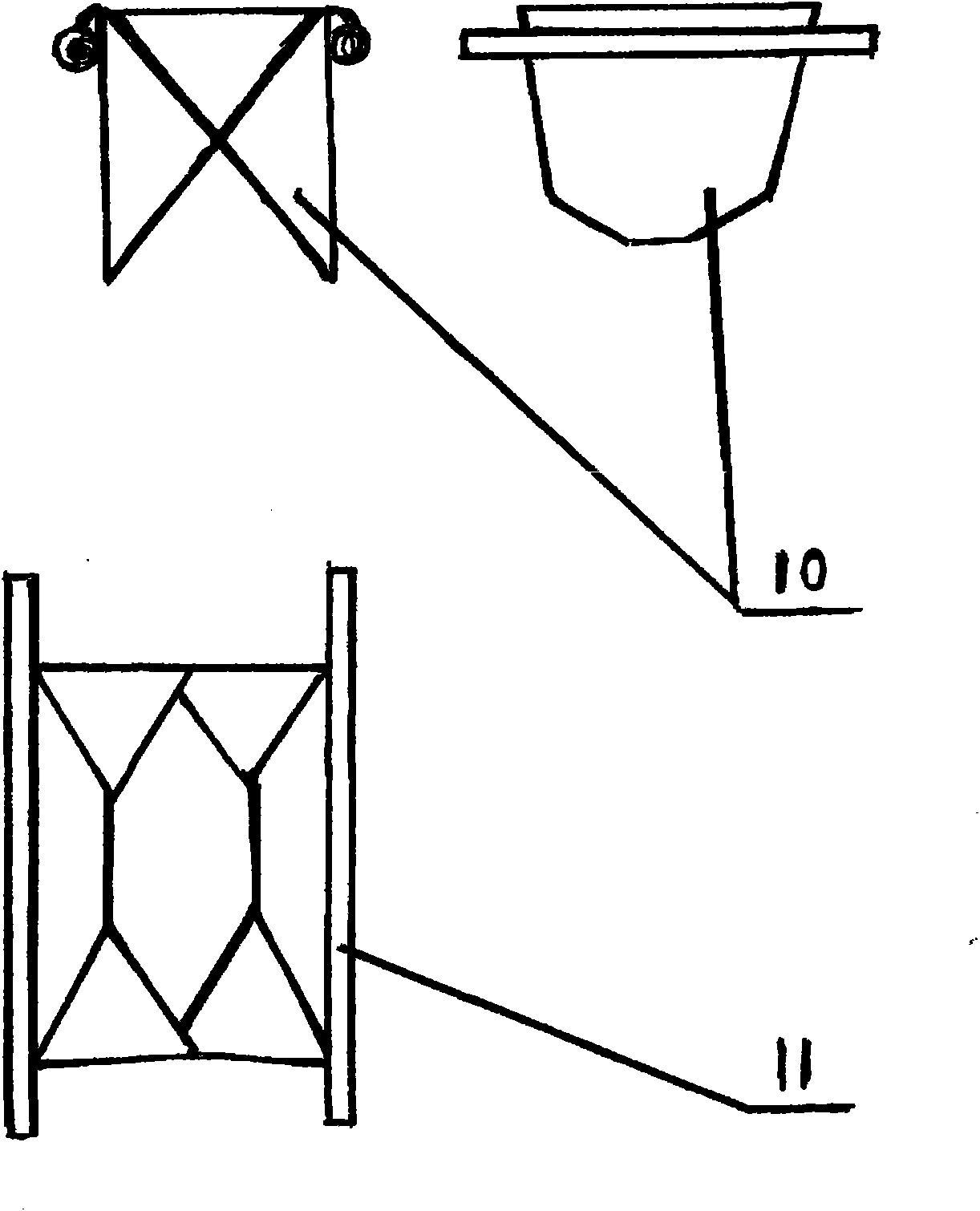

[0018] In order to better understand and implement, below in conjunction with accompanying drawing, provide specific embodiment, describe a kind of balance of the present invention in detail, as figure 1 , 2 , Shown in 3, present embodiment is a multifunctional scale, and it can have multiple schemes to make according to claim.

[0019] Make the measuring bucket 1 at a relatively stable height, install the suspension sensor 2 on its upper end, and install the supporting sensor 4 on its lower end, across the center of gravity of the measuring bucket 1, and form two different horizontal plane devices, the installation direction of the sensor 2 and the sensor 4 with the same range 9 on the contrary, and ensure that the structure of its scale body is stable, the force balance of each sensor, all suspension sensors 2 and all support sensors 4 are connected with the control instrument 8, just made a kind of single unit that accuracy and efficiency are all high scales.

[0020] Bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com