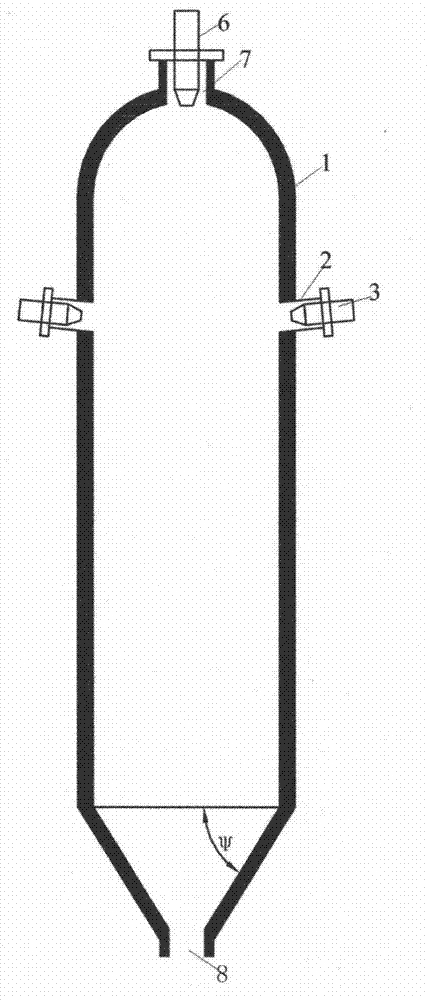

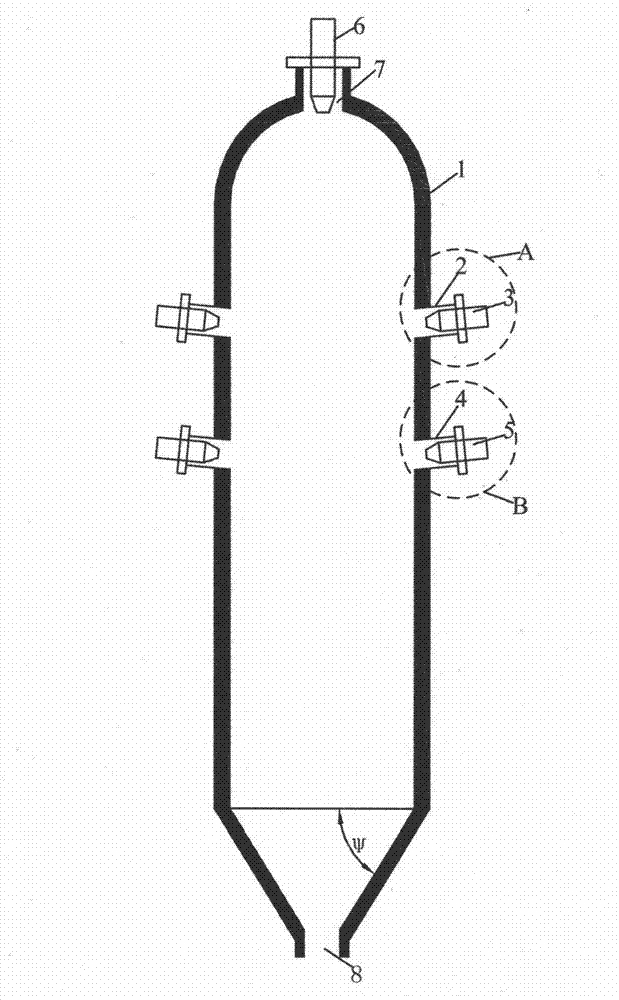

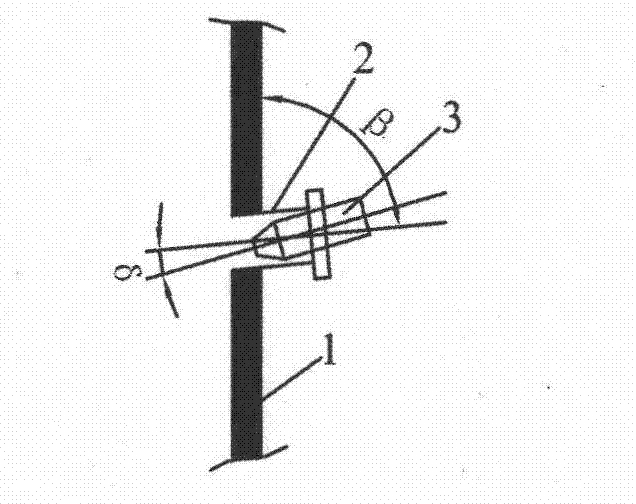

Two-section type multi-nozzle gasifying furnace with hierarchical oxygen supplying function and gasifying method of gasifying furnace

A technology for grading oxygen supply and gasification furnace, which is applied in the direction of granular/powder fuel gasification, etc. It can solve the problems of the service life of local high-temperature wall materials and the short service life of furnace wall lining materials, so as to improve the service life, Easy to adjust and increase the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] This example illustrates the results obtained from the gasification test using the two-stage multi-nozzle gasification furnace with staged oxygen supply of the present invention.

[0054] A graded oxygen supply two-stage multi-nozzle dry coal pulverized coal gasifier with a daily processing capacity of 3,000 tons of coal. The gasification pressure is 4.0 MPa. There are 4 nozzles, 3 side process burners, and 4 secondary oxygen supply lances 5. The main size parameters of the gasifier are shown in Table 1:

[0055]

[0056] Table 1: Main dimension parameters of gasifier

[0057] Pure oxygen gas is used as the gasification agent, and an appropriate amount of water vapor is sprayed into the process burner on the top of the gasifier. 2 The coal powder is transported in pressurized and dense phase with the carrier gas, and the oxygen injected into the secondary oxygen supply lance accounts for 10% of the total amount. The coal quality analysis data of the used coal types...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com